Labeling device for corrugated carton production and label detection mechanism thereof

A corrugated box and detection mechanism technology, applied in the field of corrugated box production, can solve the problems of manual manual operation, poor labeling quality, time-consuming and labor-intensive, etc., and achieve the effect of ensuring the quality of pasting and improving the efficiency of labeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

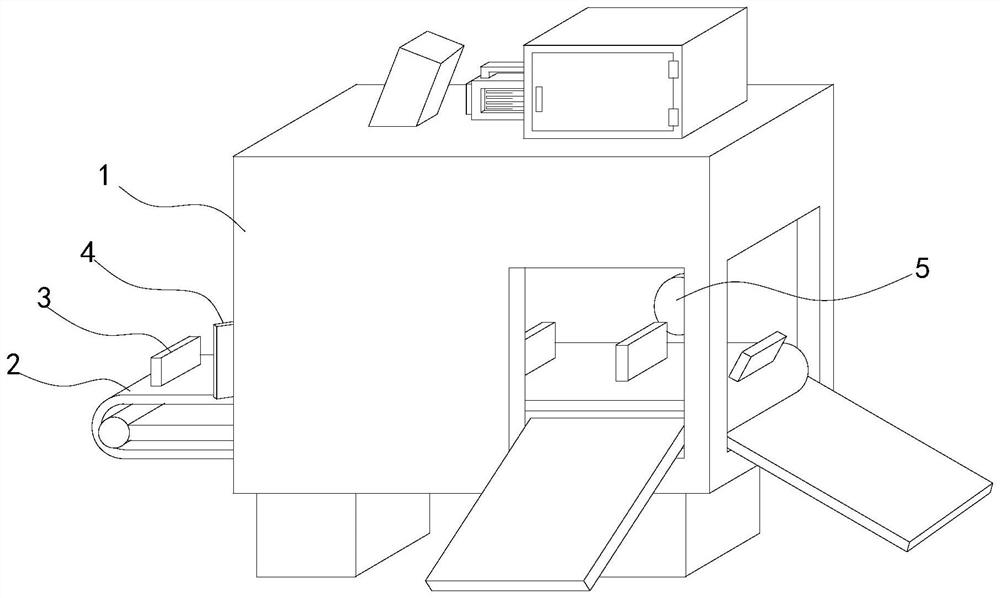

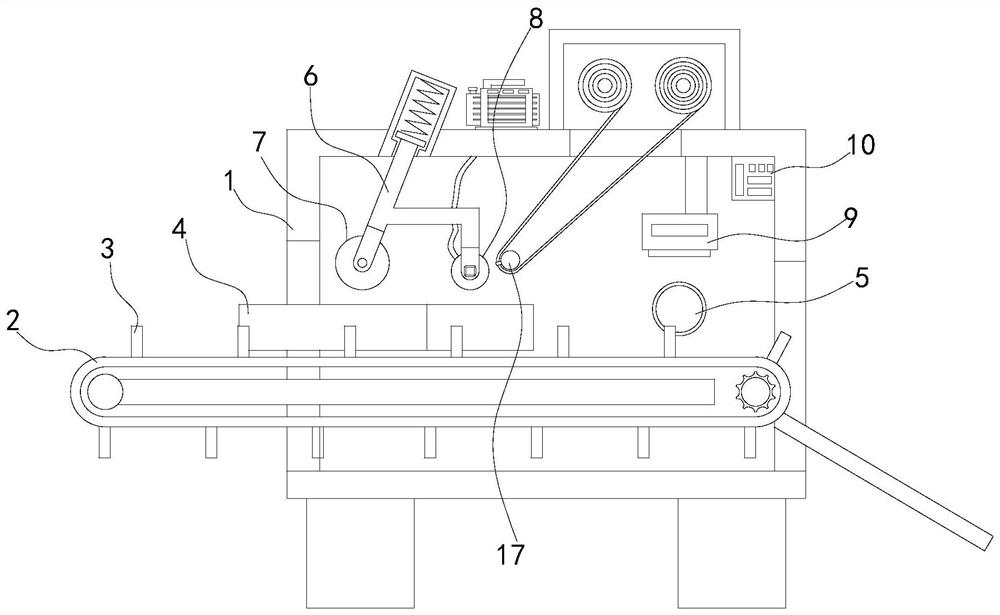

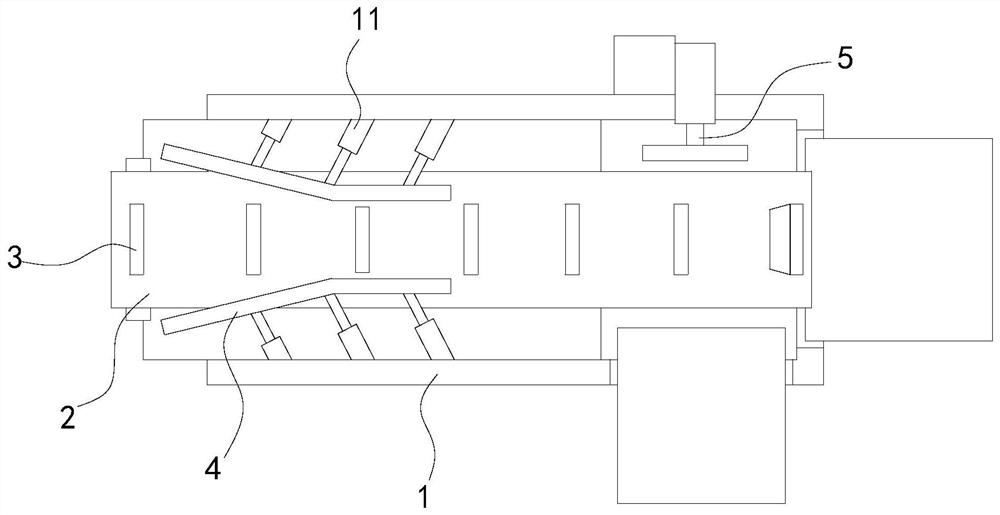

[0028] see Figures 1 to 7 , a schematic diagram of a planar structure and a schematic diagram of a three-dimensional structure of a labeling device for corrugated box production and its label detection mechanism.

[0029] A labeling device for corrugated box production, comprising a device main body 1, a limiting device 4 is movably installed on the left side inside the device main body 1, a conveyor belt 2 is movably installed on the lower end inside the device main body 1, and a moving Frame 6, a guide device 7 is movably installed at the lower end of the moving frame 6, and a labeling device 8 is movably installed on the right side of the moving frame 6.

[0030] In specific implementation, a guide roller 17 is fixedly installed at the middle end of the device main body 1, and a scraper 18 is fixedly installed on the outside of the guide roller 17. An air suction chamber 19 is provided inside the labeling device 8, and a suction chamber 19 is provided inside the labeling d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com