Enveloping strip sticking device of wine box automatic assembly machine

An automatic assembly machine and fence technology, which is applied in packaging, transportation and packaging, container manufacturing machinery, etc., can solve the problems of low efficiency, high labor cost, and uneven fence placement, so as to improve efficiency, reduce labor costs, and ensure Effect of Paste Mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

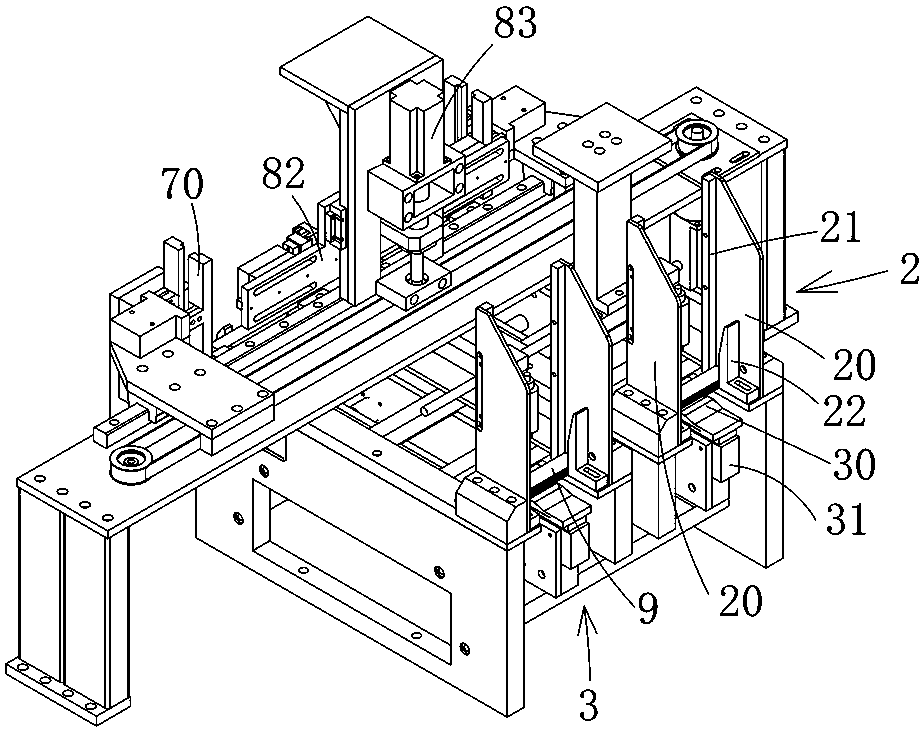

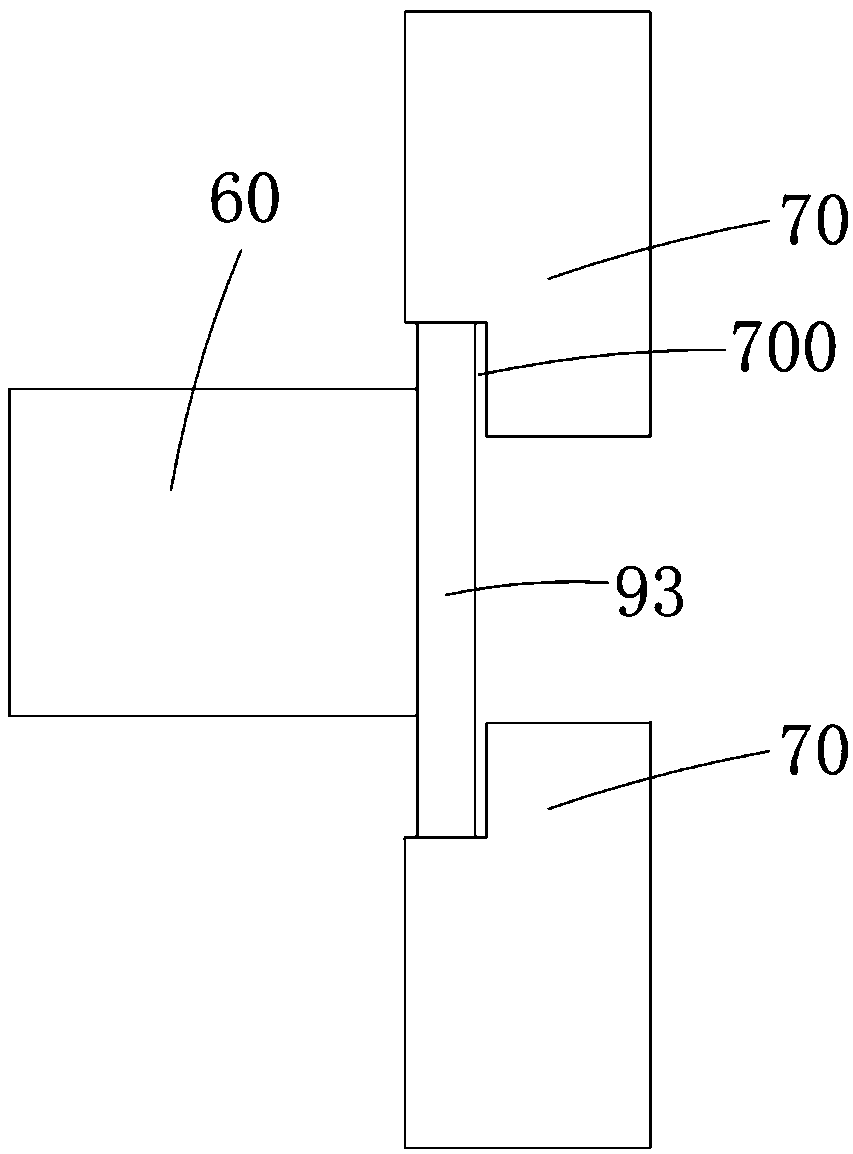

[0016] The wrapping strip device of the wine box automatic assembly machine is a device on the wine box automatic assembly machine (the whole machine of the wine box automatic assembly machine is not shown), the wine box automatic assembly machine includes a rotatable seat, the wine box The box body 90 is first put on the seat body, and the box body 90 first completes the sticking with the lid 91 on the seat body, but then forwards to the next station, and the wrapping strip 93 is pasted into the box body 90 by the wrapping strip device. on the side wall. What the present invention claims to protect is exactly the sticking bar device. The structure and working principle of the sticking strip device will be introduced in detail below.

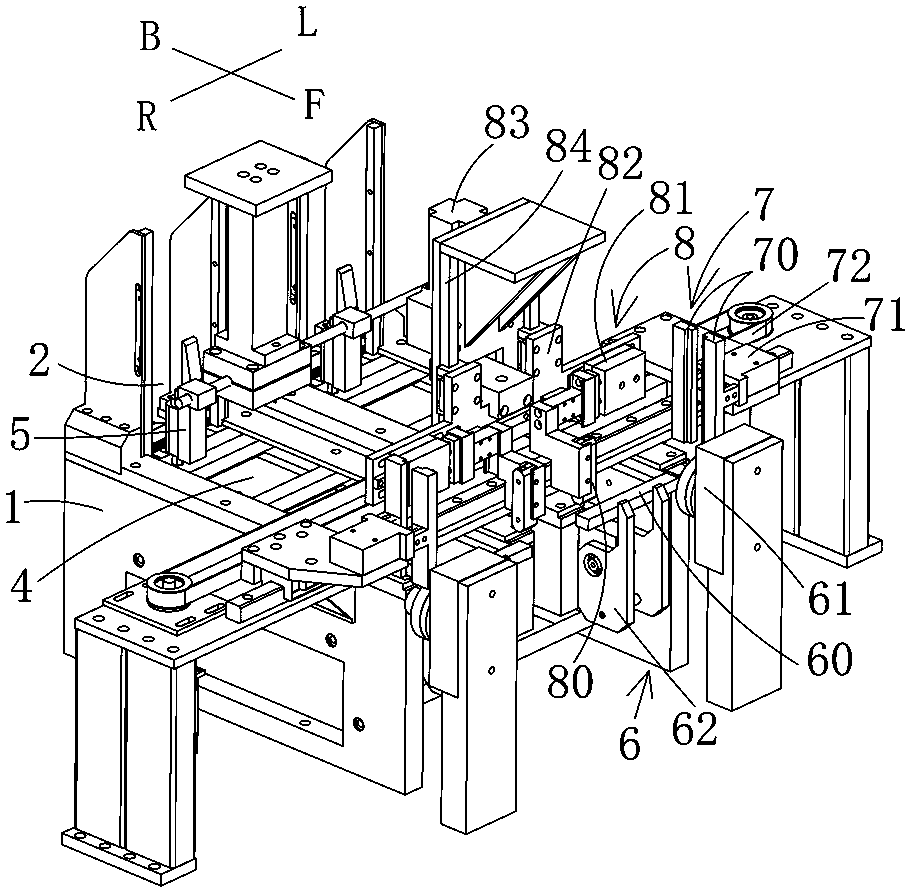

[0017] Such as figure 1 As shown, the device for attaching the fence includes a frame 1 on which a fence silo 2 , a fence table 4 and a fence pushing mechanism 3 are installed. The fence silo 2 is used for stacking the fence 93; the fence ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com