Quick-drying type adhesive for ceramic tiles

A tile adhesive and quick-drying technology, which is applied in the field of construction adhesives, can solve the problems of affecting the efficiency of tile paste, affecting the quality of tile paste, and shifting of tiles, so as to improve paste efficiency, ensure paste quality, and avoid displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

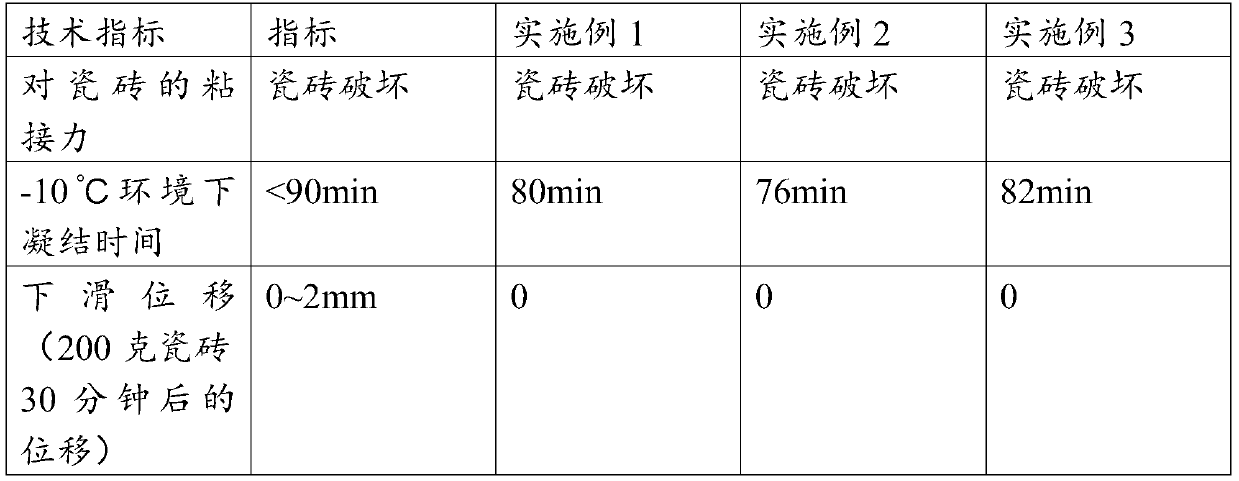

Examples

Embodiment 1

[0018] A quick-drying tile adhesive comprises the following components in parts by weight:

[0019] 62.5 parts of river sand, wherein the river sand is dried river sand, the moisture content is less than 0.8%, and the particle size of the river sand is 100-150 mesh;

[0020] 35 parts of cement, the cement is 42.5 parts of cement, so that the strength of cement meets the requirements of use;

[0021] 0.5 parts of polymer rubber powder;

[0022] 1 part of silica fume;

[0023] 0.7 parts of calcium formate;

[0024] 0.3 parts of cellulose ether.

[0025] Among them, the polymer rubber powder is 5010 type rubber powder of Wacker Chemie, which makes the polymer rubber powder have a good bonding effect.

[0026] The cellulose ether is methyl cellulose. Thus, the cellulose ether has good water retention performance.

[0027] The quick-drying type tile adhesive of the present invention adds silica fume and calcium formate, so that the tile adhesive has the characteristics of rap...

Embodiment 2

[0029] The composition of a quick-drying tile adhesive of this embodiment is basically the same as that of Embodiment 1, the difference between the two is that the weight ratio of each component is different. In the present embodiment, its raw material composition comprises following components:

[0030] 60 parts of river sand;

[0031] 32 parts of cement;

[0032] 0.5 parts of polymer rubber powder;

[0033] 0.8 parts of silica fume;

[0034] 0.5 parts of calcium formate;

[0035] 0.2 parts of cellulose ether. The quick-drying tile adhesive that obtains in this embodiment, its performance is identical with embodiment 1.

Embodiment 3

[0037] The composition of a quick-drying tile adhesive of this embodiment is basically the same as that of Embodiment 1, the difference between the two is that the weight ratio of each component is different. In the present embodiment, its raw material composition comprises following components:

[0038] 65 parts of river sand;

[0039] 38 parts of cement;

[0040] 0.8 parts of polymer rubber powder;

[0041] 1.2 parts of silica fume;

[0042] 0.8 parts of calcium formate;

[0043] 0.3 parts of cellulose ether. The quick-drying tile adhesive that obtains in this embodiment, its performance is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com