Concrete joint glue pouring and adhesive tape sticking device and using method thereof

A technology for sticking adhesive tape and adhesive tape, which is applied in the field of sticking adhesive tape after glue filling in concrete joints, and in the field of adhesive tape sticking device for concrete joint filling. The effect of the construction period and the firmness of the paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

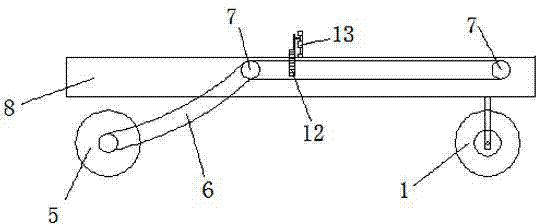

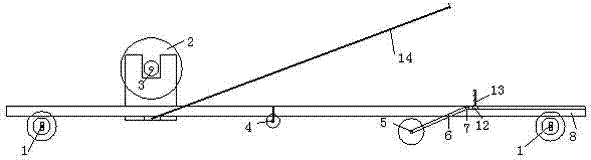

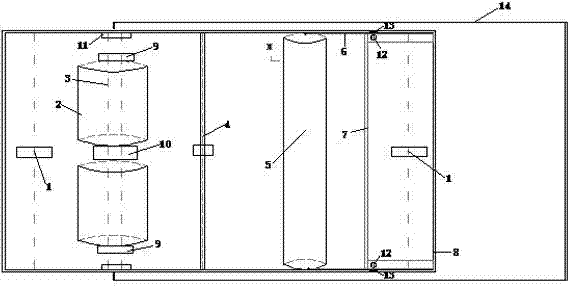

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail, not limiting protection scope of the present invention, see figure 1 and figure 2 . The concrete seam glue sticking tape device includes a chassis 8, a guide wheel 1 and an adhesive tape 2. The guide wheel 1, the tape installation shaft 3, the tape separation shaft 4 and the rolling cylinder 5 are installed on the chassis 8. The tape installation shaft 3 is installed on the bottom of the chassis 8. At the front, there are two rolls of adhesive tape 2 installed on it, and the rolling cylinder 5 is fixed on the lifting frame of the rolling cylinder through the connecting rod 6, the tape separation shaft 4 is installed between the tape installation shaft 3 and the rolling cylinder 5, and the guide wheel 1 is installed At the front and rear ends of the chassis 8 , armrests 14 are fixed on both sides of the chassis 8 . see image 3 , the adhesive tape installation shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com