Patents

Literature

36results about How to "Positioning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

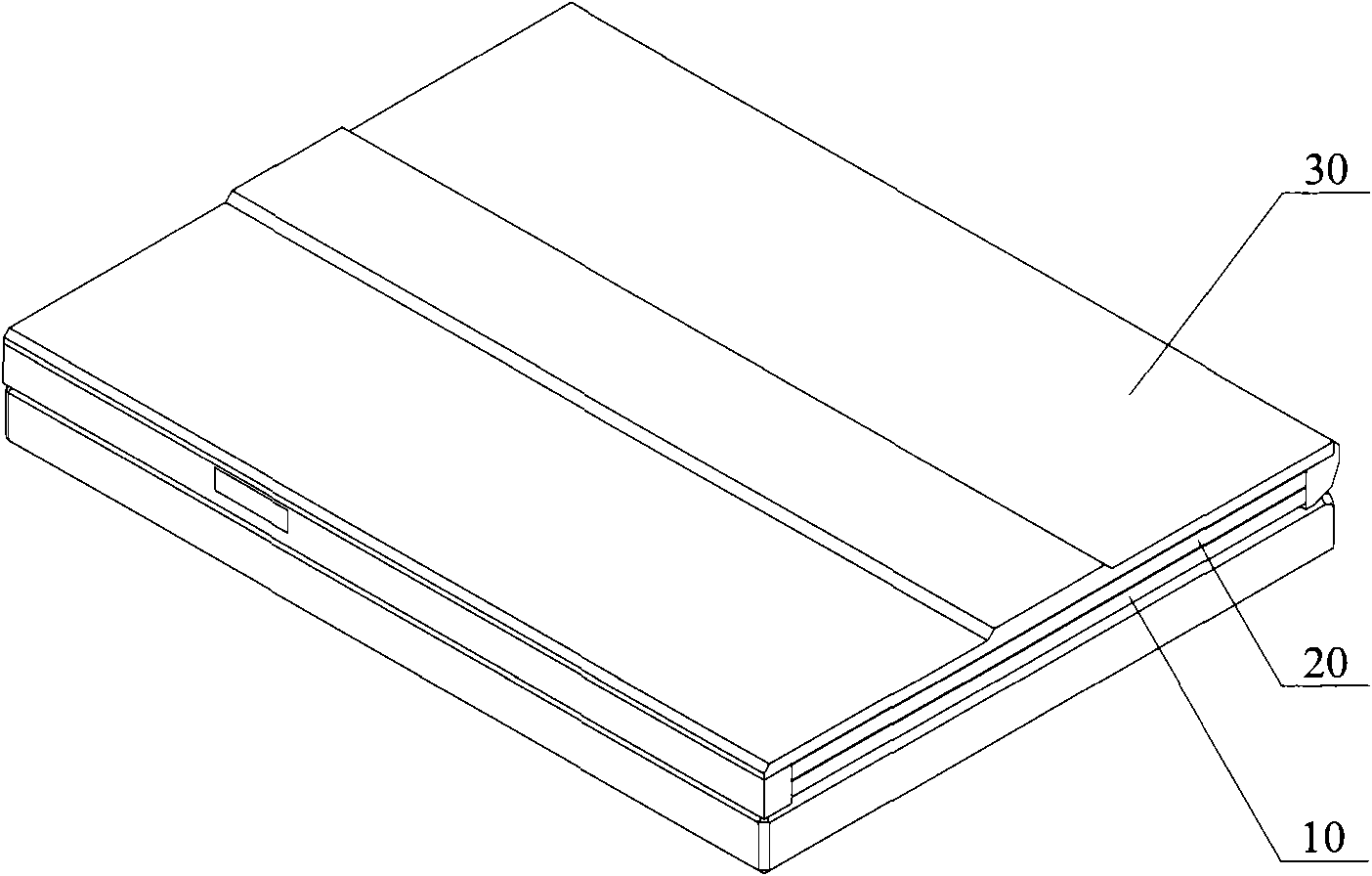

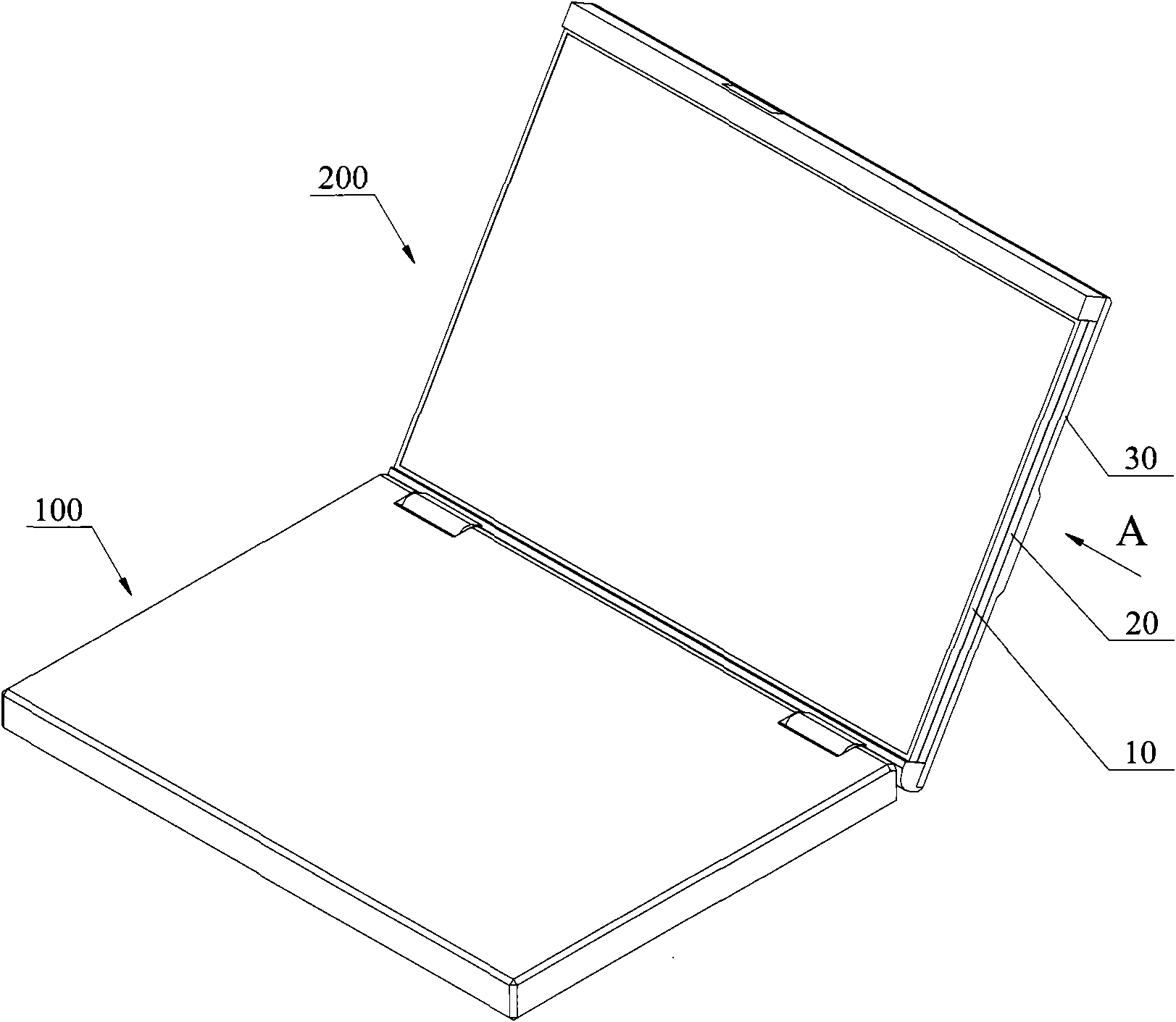

Double screen display and notebook computer

ActiveCN101561698AReasonable structural designPositioning accuracyDigital data processing detailsTelephone set constructionsEngineeringDisplay device

Owner:LENOVO (BEIJING) CO LTD

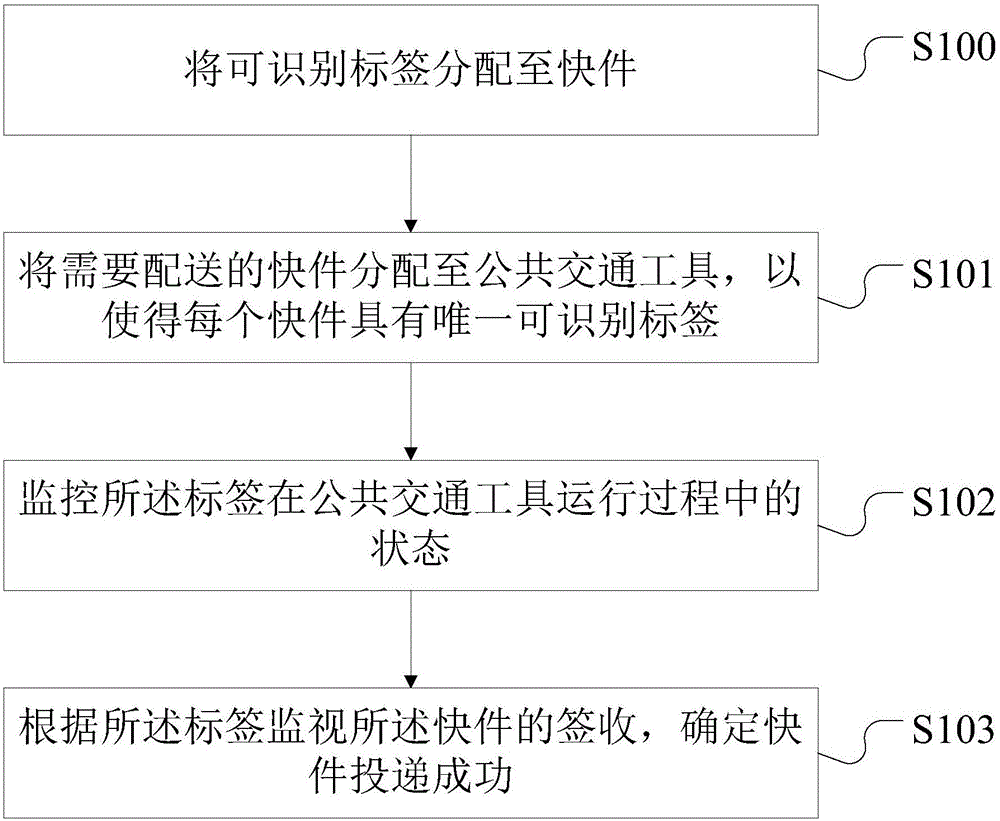

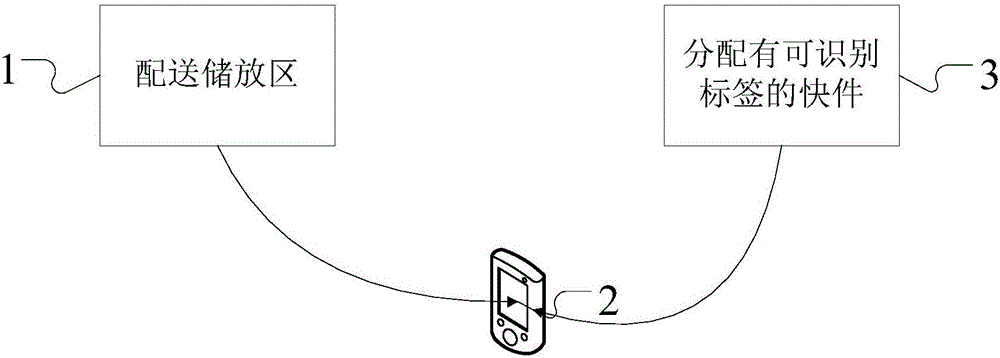

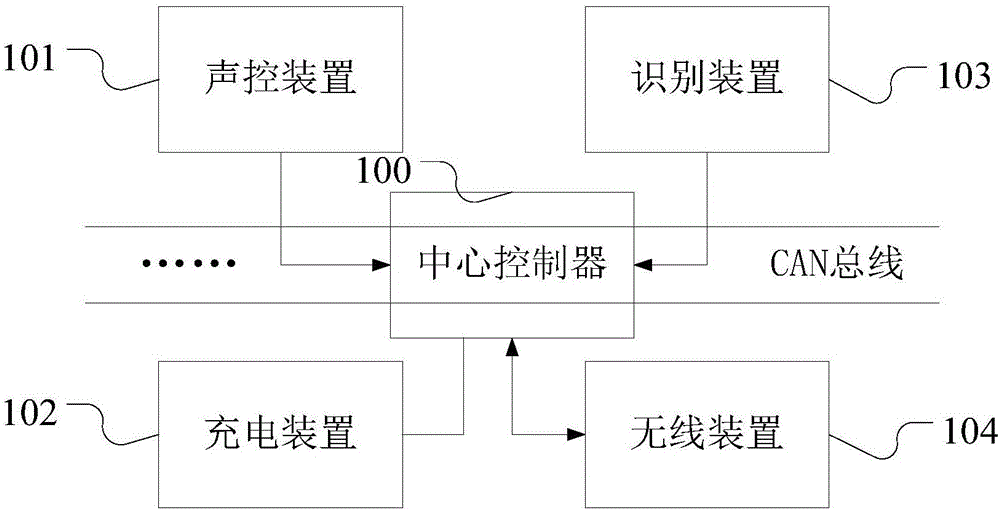

Express intelligent distribution method and system based on urban public transportation system

The present invention discloses an express intelligent distribution method and system based on an urban public transportation system. The method comprises: distributing identification labels to express items; distributing the express items requiring distribution to public transport means or stop stations to allow each express item to have the uniform identification label; monitoring the state of the label in the operation process of the public transport means; and monitoring the signing of the express item according to the label to determine that the express is successfully delivered. The system comprises a distribution storage area connected with the public transport means and configured to distribute the express items with identification labels and an intelligent mobile terminal. The distribution storage area includes a master controller, a recognition device, a wireless device, a charging device and a voice operated device. The express intelligent distribution method and system based on the urban public transportation system can reduce the operation cost of the distribution company to a certain extent. The point-to-point distribution and signing monitoring of the last one kilometer is realized through monitoring the label according to the signing of the express items, so that the problem is solved that the express items cannot be directly distributed to clients' hands.

Owner:刘新建

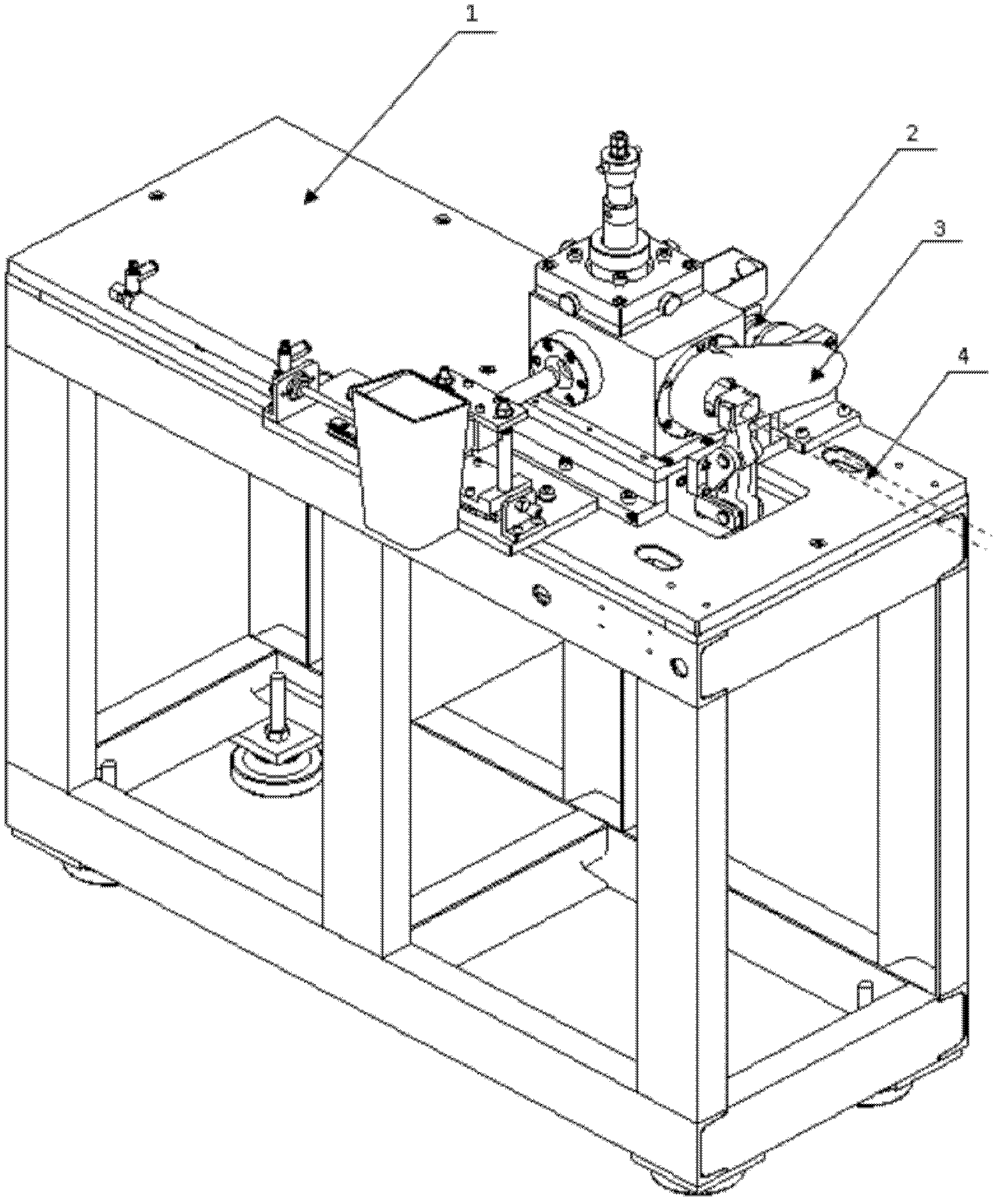

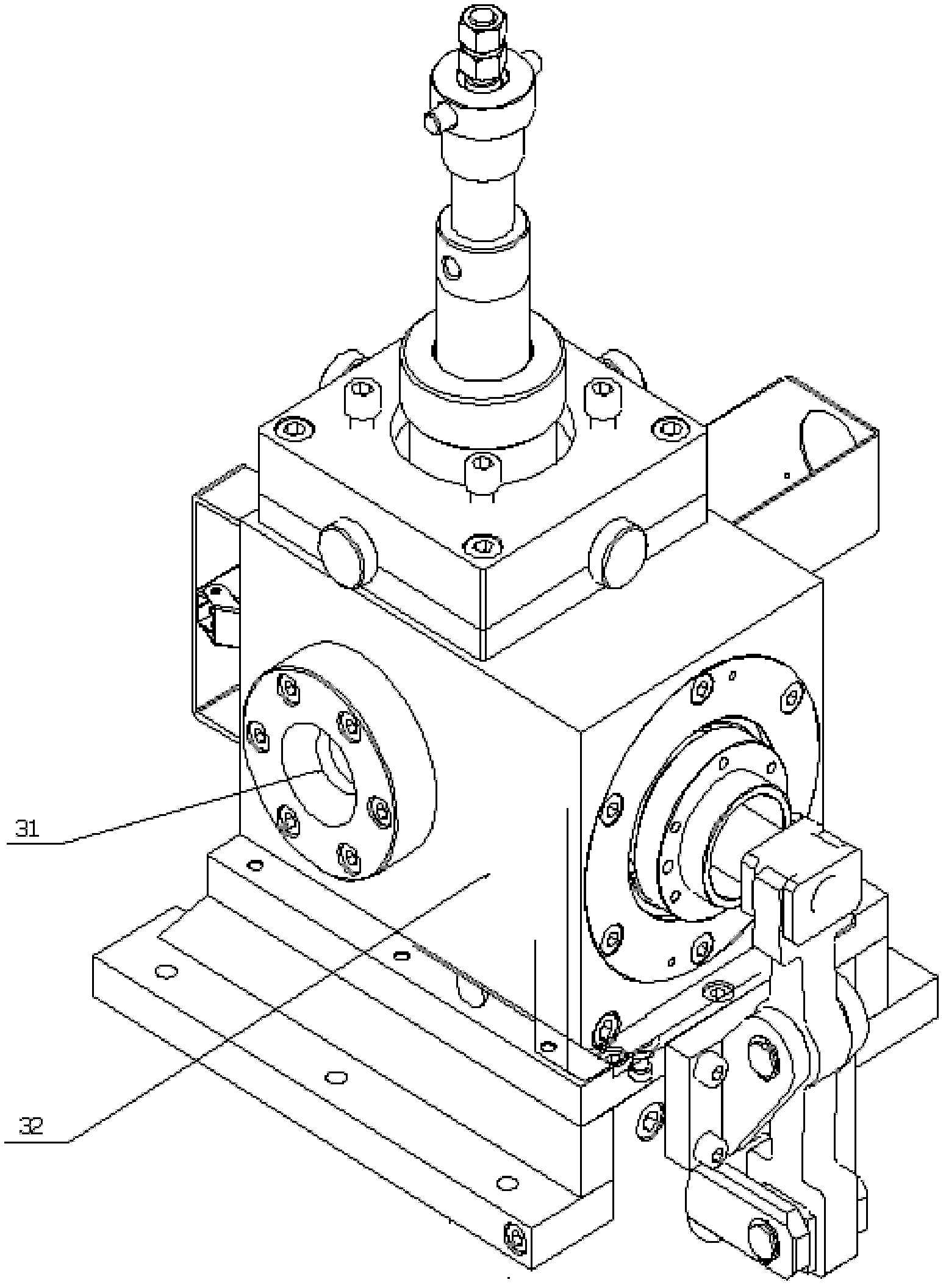

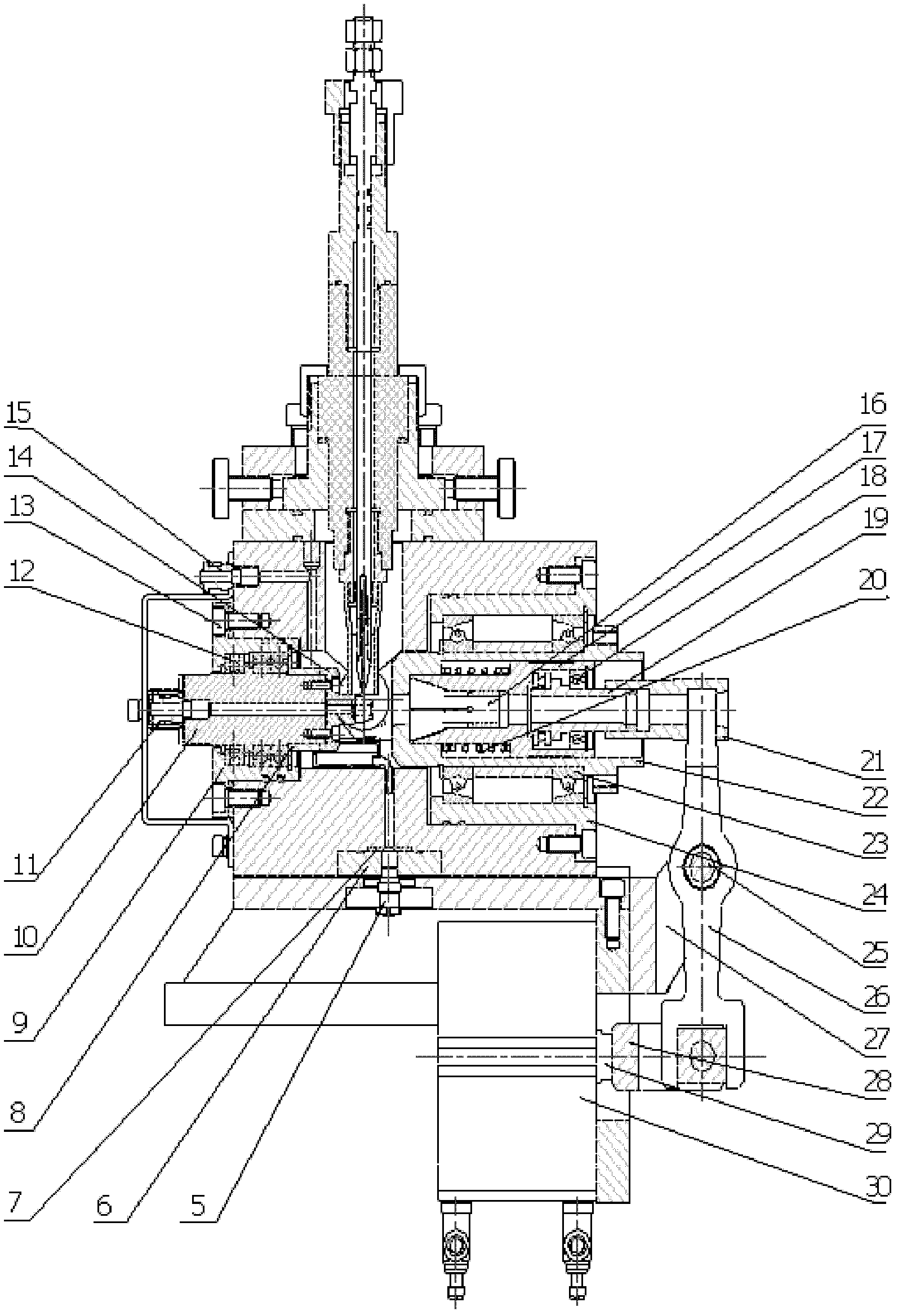

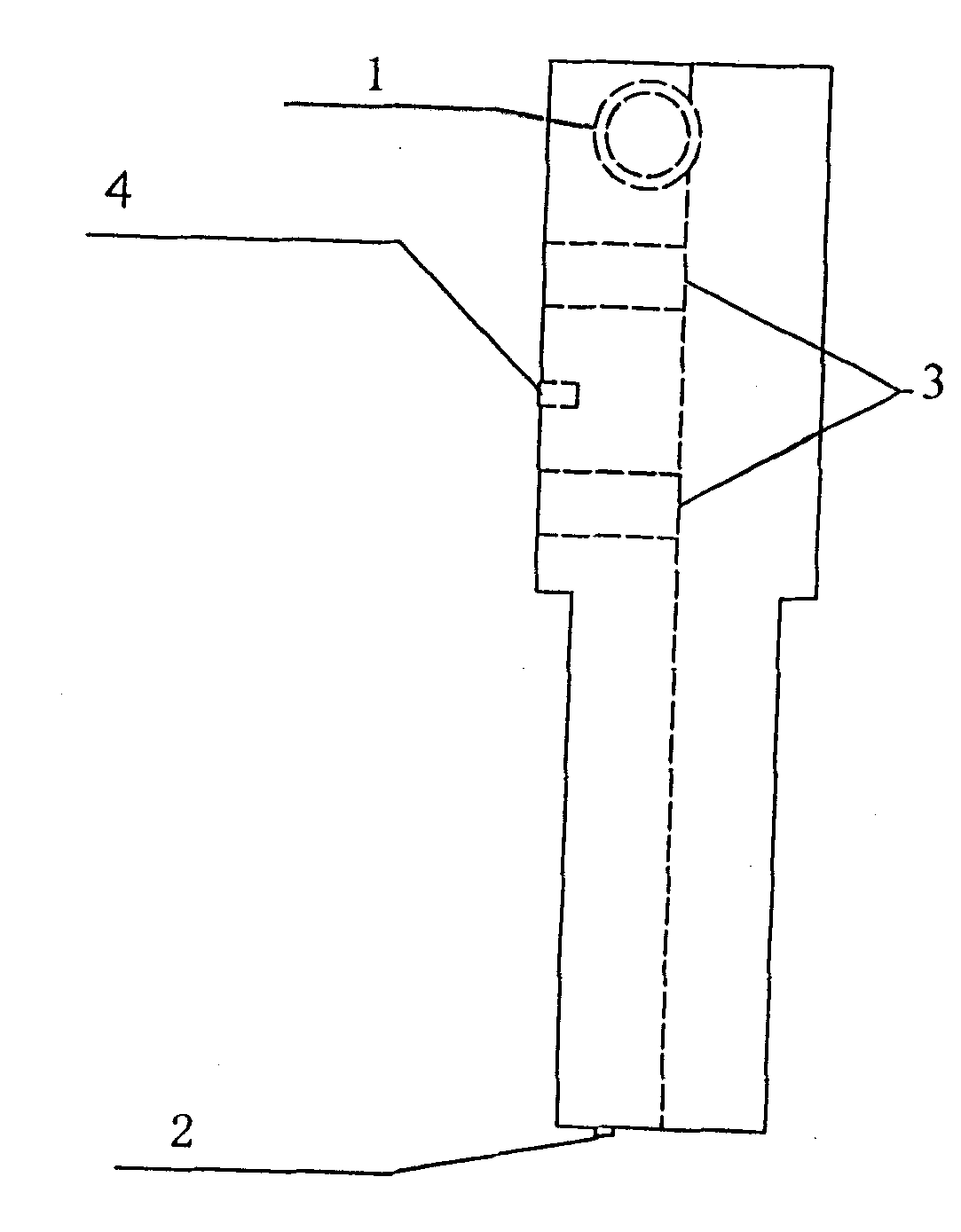

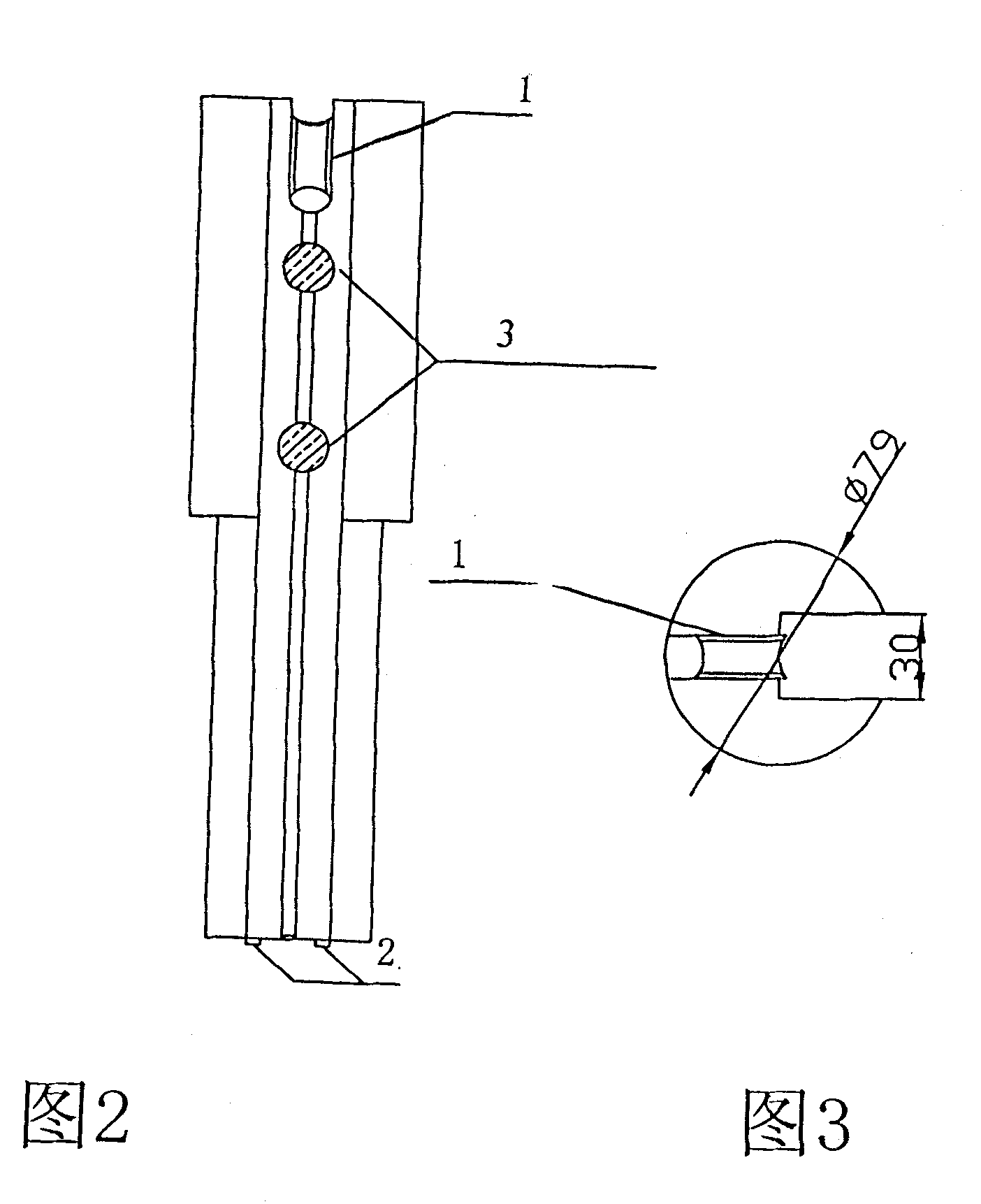

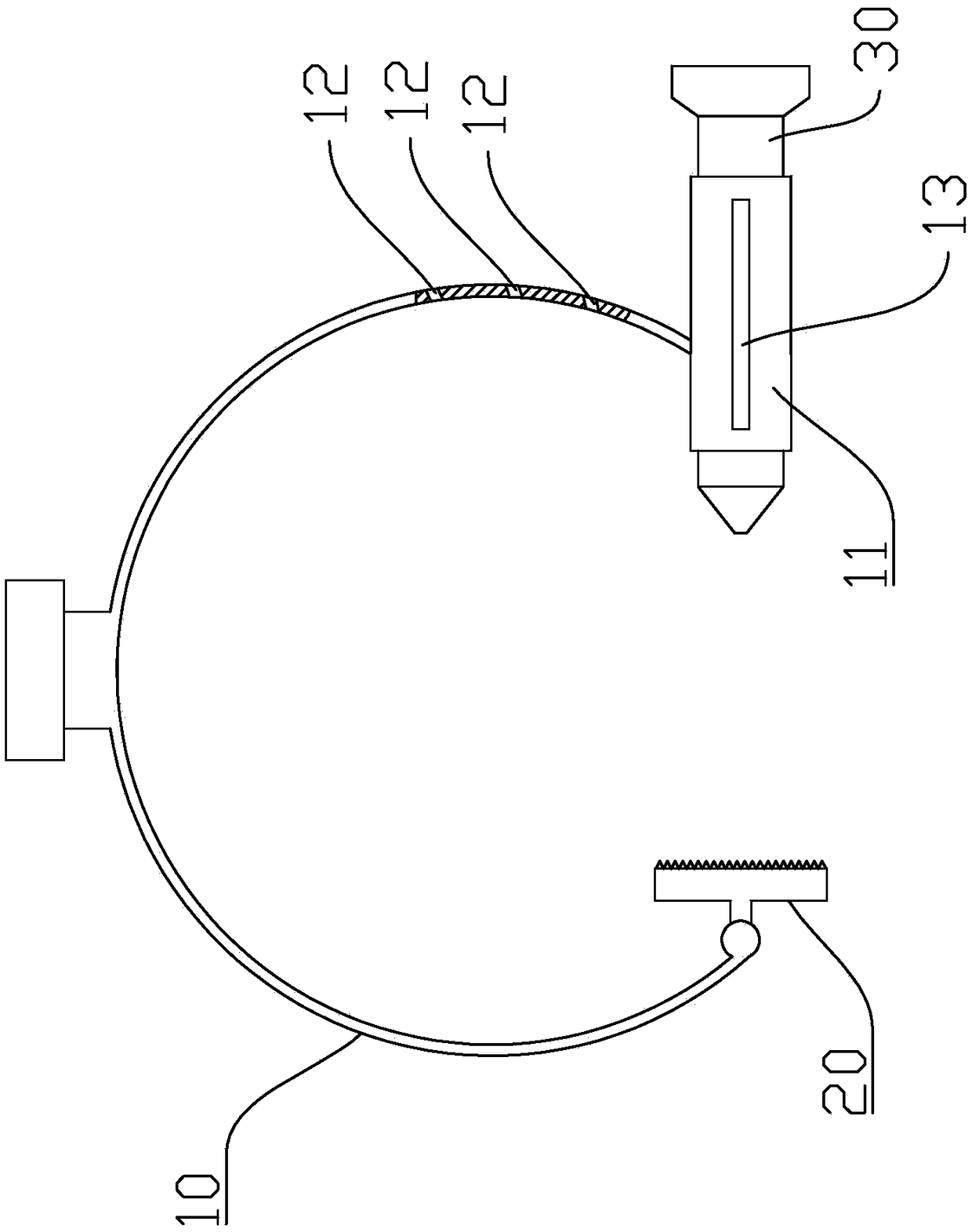

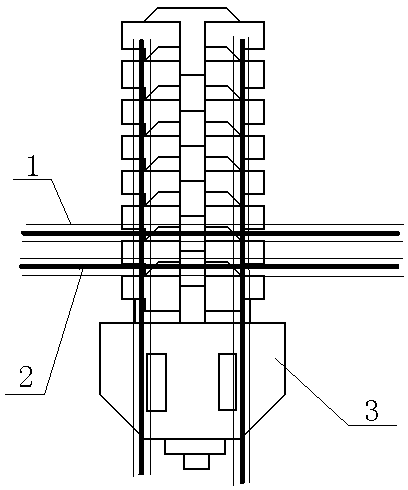

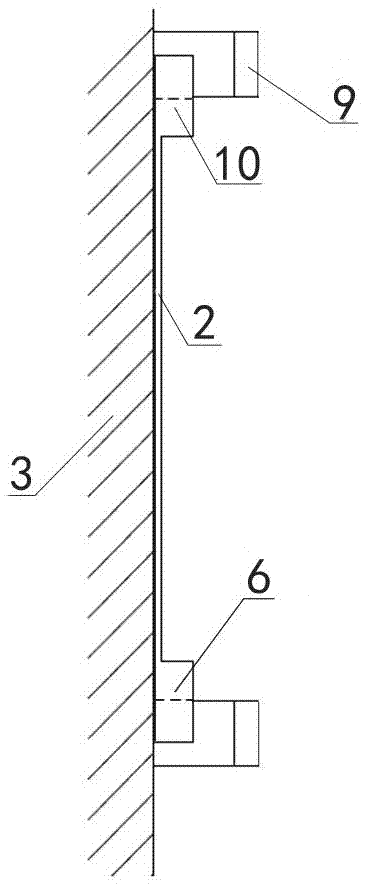

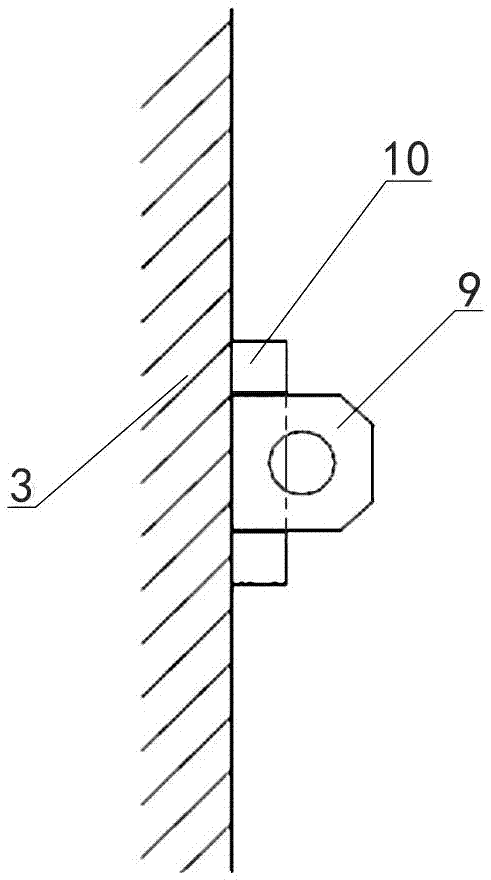

Welding device for lower end plug of guide pipe of pressurized water reactor nuclear power fuel assembly

ActiveCN103182593AEasy to observePositioning accuracyElectrode supporting devicesWeld seamPressurized water reactor

The invention relates to the manufacturing technical field of pressurized water reactor nuclear power fuel assemblies, and particularly discloses a welding device for a lower end plug of a guide pipe of a pressurized water reactor nuclear power fuel assembly. According to the device, a welding gun regulating mechanism is arranged in a cavity at the upper end of a welding chamber, and can regulate an electrode of a welding gun; the side wall of the welding chamber is provided with an optical projection imaging system, and the inside of the welding chamber can be observed through a sight glass; an end plug driven mechanism and a clamping mechanism are respectively arranged in two opposite side wall cavities of the welding chamber; a head end plug of a guide pipe weldment is pressed against the driven mechanism and is tightly clamped by the clamping mechanism; and the clamping mechanism, the driven mechanism and the guide pipe weldment are driven to rotate together by a rotating mechanism, and a weld seam of the end plug of the guide pipe weldment is welded. According to the device, the welding gun is designed in a split way, and a tungsten electrode is quickly replaced; the optical projection imaging system is additionally arranged on the welding chamber, and the tungsten electrode is quickly and accurately positioned; and the guide pipe weldment can be automatically controlled to be clamped, rotated and welded, the requirement of a welding process is met, and the production efficiency is improved.

Owner:CHINA NORTH NUCLEAR FUEL

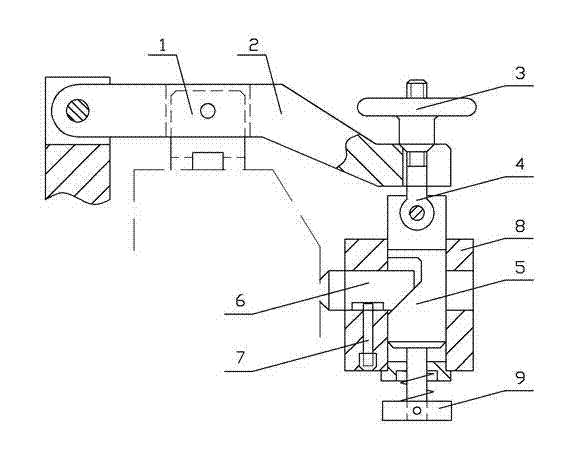

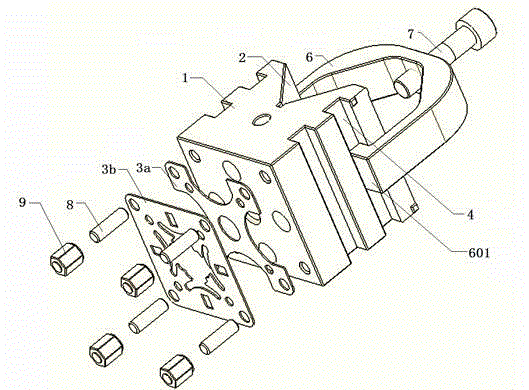

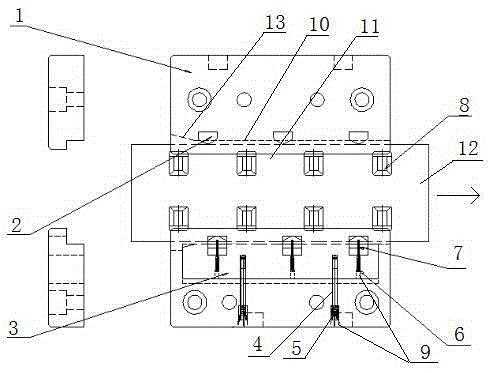

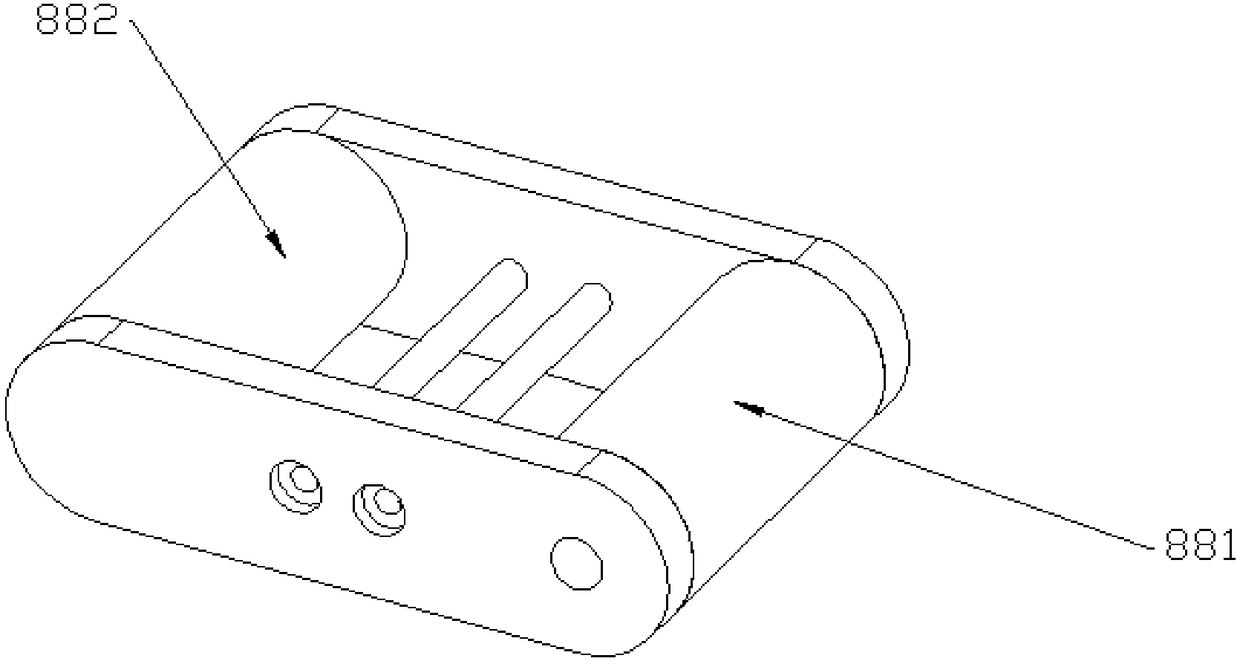

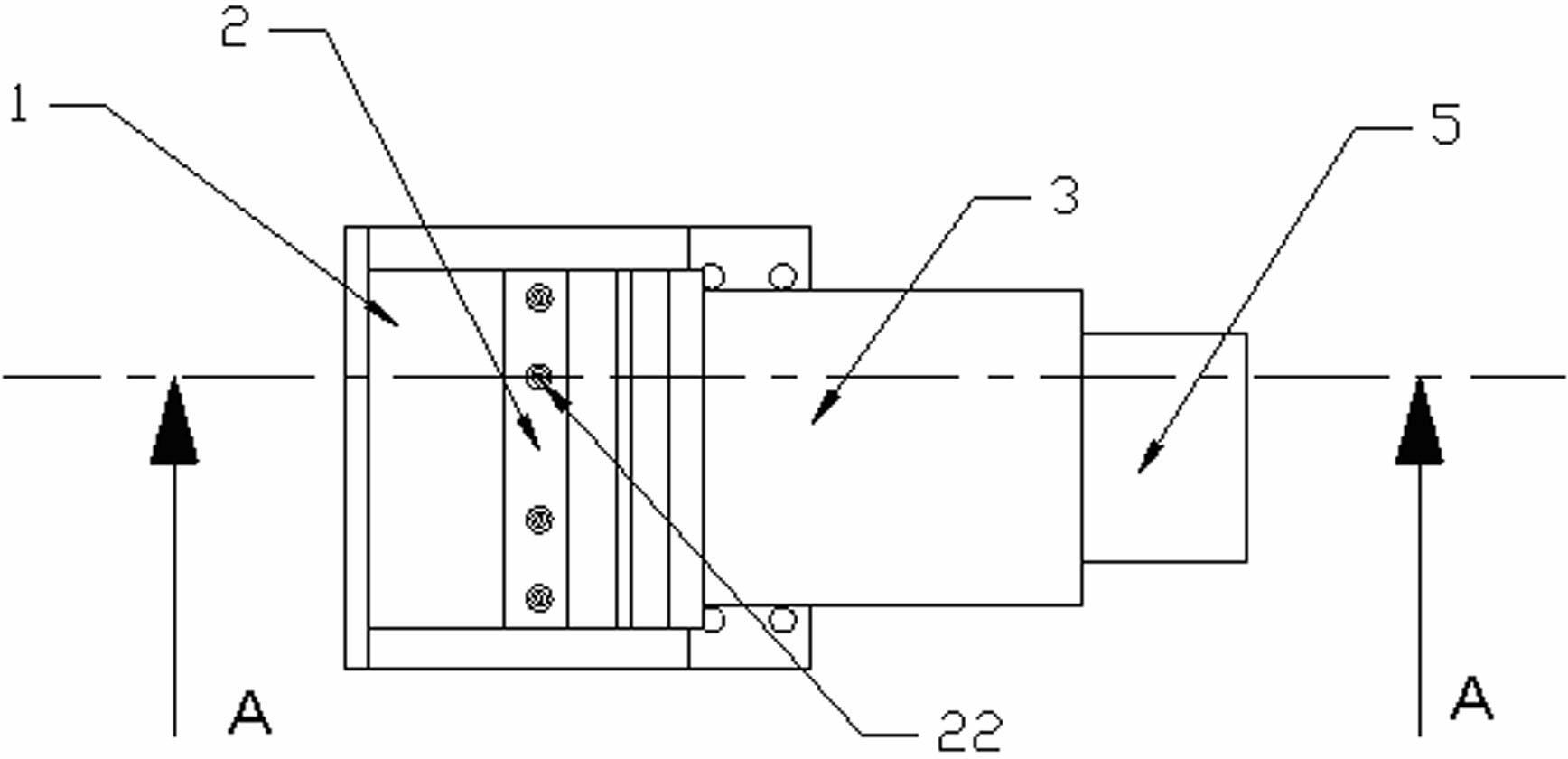

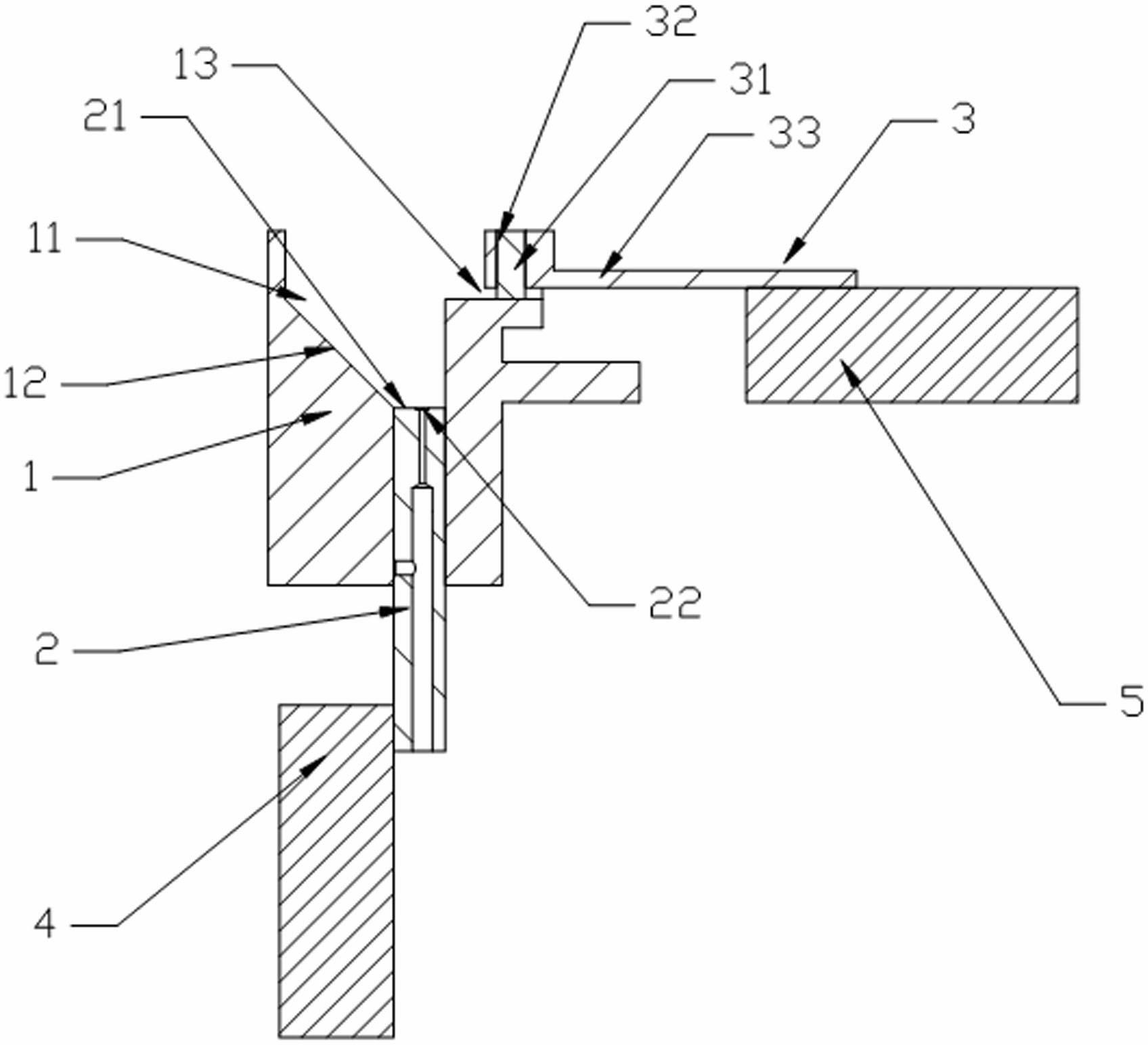

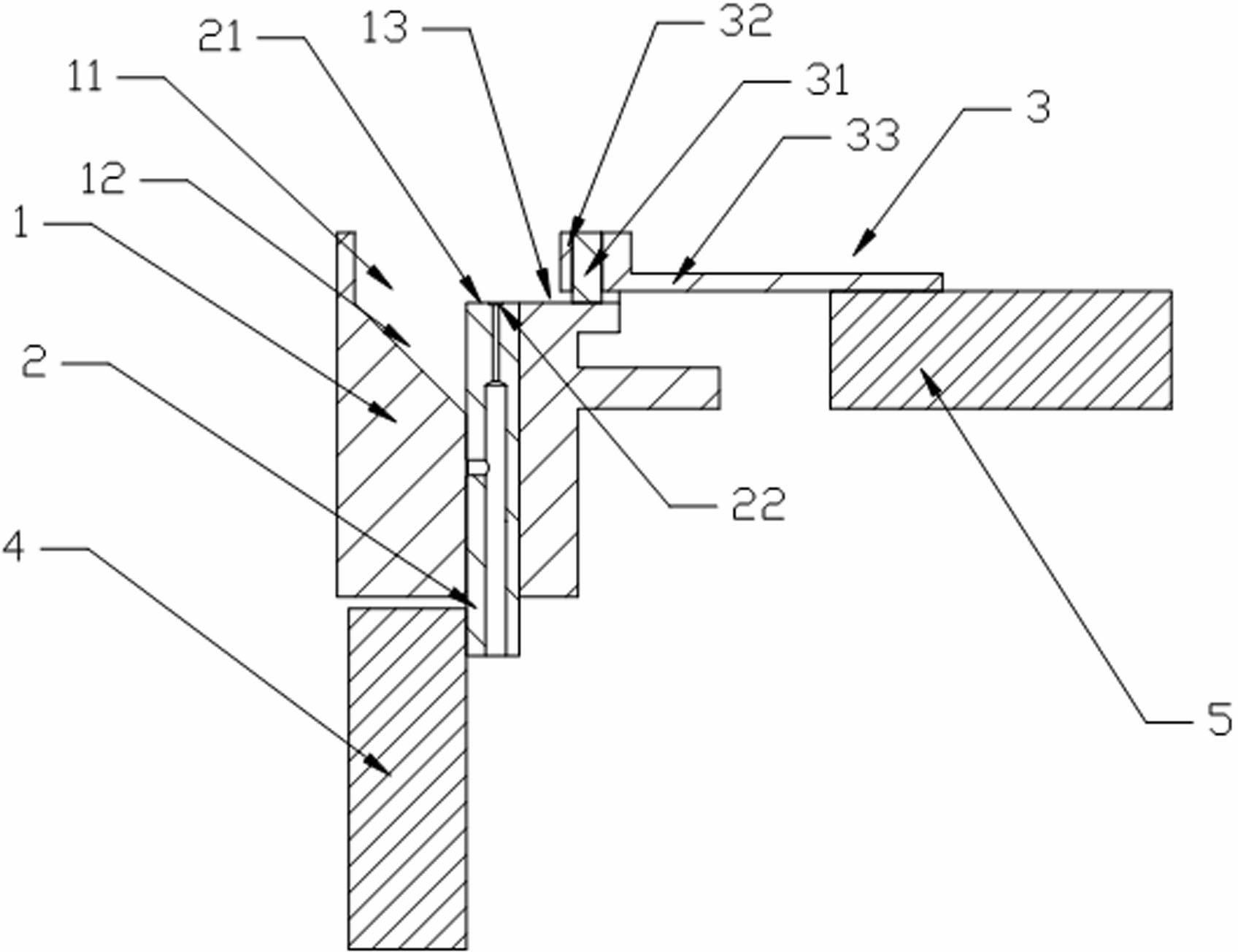

Bidirectional clamping device

InactiveCN103028969APositioning accuracySimple structurePositioning apparatusMetal-working holdersPhysicsEngineering

The invention relates to a clamping device, in particular to a bidirectional clamping device, which comprises a clamp body, a sleeve, an extrusion knob, an upper clamping block, a right clamping block, a swinging arm and a sliding shaft, wherein the sleeve is fixedly arranged on the clamp body; the extrusion knob serves as a force application device; the upper clamping block and the right clamping block are used for pressing the surfaces of a workpiece; the tail end of the right clamping block is a wedge surface; the upper clamping block is driven by the swinging arm to clamp the workpiece; the tail part of the swinging arm is hinged to the clamp body; the upper clamping block is clamped with the middle part of the swinging arm; the end of the swinging arm is a U-shaped end; the right clamping block is driven by the sliding shaft to clamp the workpiece; a wedge hole is formed in the middle part of the sliding shaft, and is in sliding fit with the wedge surface of the right clamping block in the sleeve; a shaft shoulder capable of preventing the sliding shaft from being separated from the sleeve is arranged at the tail end of the sliding shaft; the upper end of the sliding shaft is hinged with one end of a rotating rod; and the other end of the rotating rod is connected with the end of the swinging arm by the extrusion knob in an extrusion way. According to the technical scheme, the bidirectional clamping device has a bidirectional clamping function, and is simple in structure.

Owner:CHONGQING ZHIRUIDE TECH

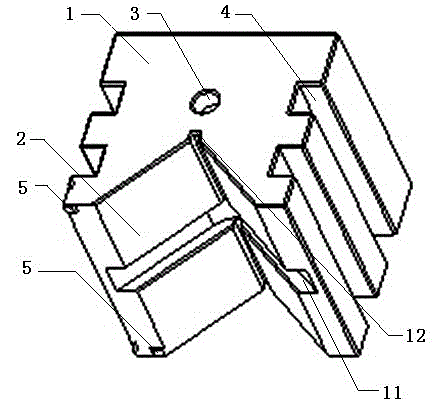

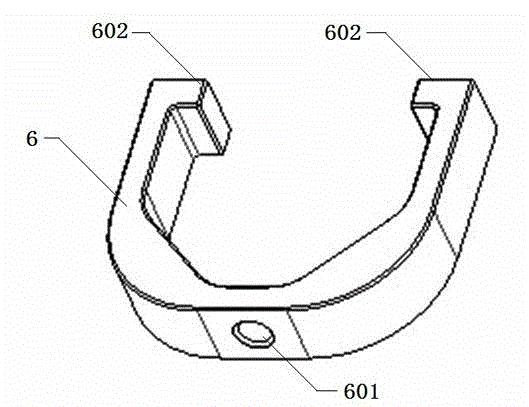

Clamp for quickly clamping and positioning cylindrical components

InactiveCN102744622APositioning accuracyReliable clampingPositioning apparatusMetal-working holdersEngineeringSetting time

The invention discloses a clamp for quickly clamping and positioning cylindrical components. The clamp comprises a main body, wherein a V-shaped positioning groove is formed in the front of the main body; a positioning hole is formed on the upper part of the main body; a cantilever is movably connected with the main body; and a group of positioning sheets are positioned at the back of the main body. The clamp has the characteristics of high repeated positioning accuracy and repeated utilization ratio; and moreover, each machining procedure can be joined in a seamless mode, and each procedure form a flexible manufacturing unit, so that the working time of a machine which generates direct value is prolonged, the set time of the machine which does not generate the value is shortened, the machining cost is reduced, and the accurate machining requirement of a large quantity of cylindrical components can be met.

Owner:OECHSLER PLASTIC PROD TAICANG

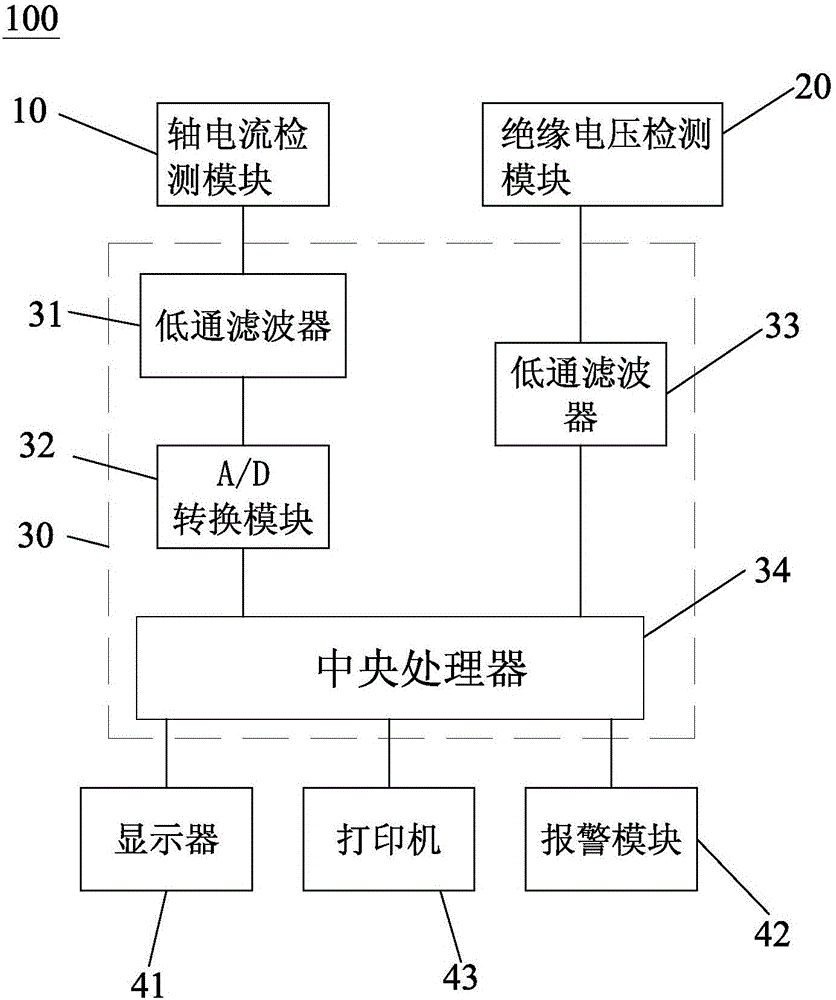

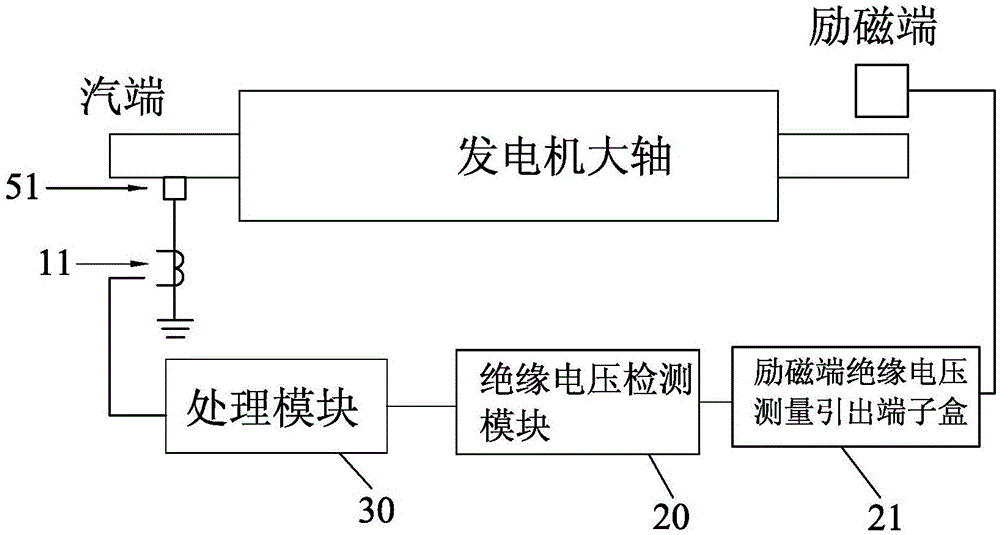

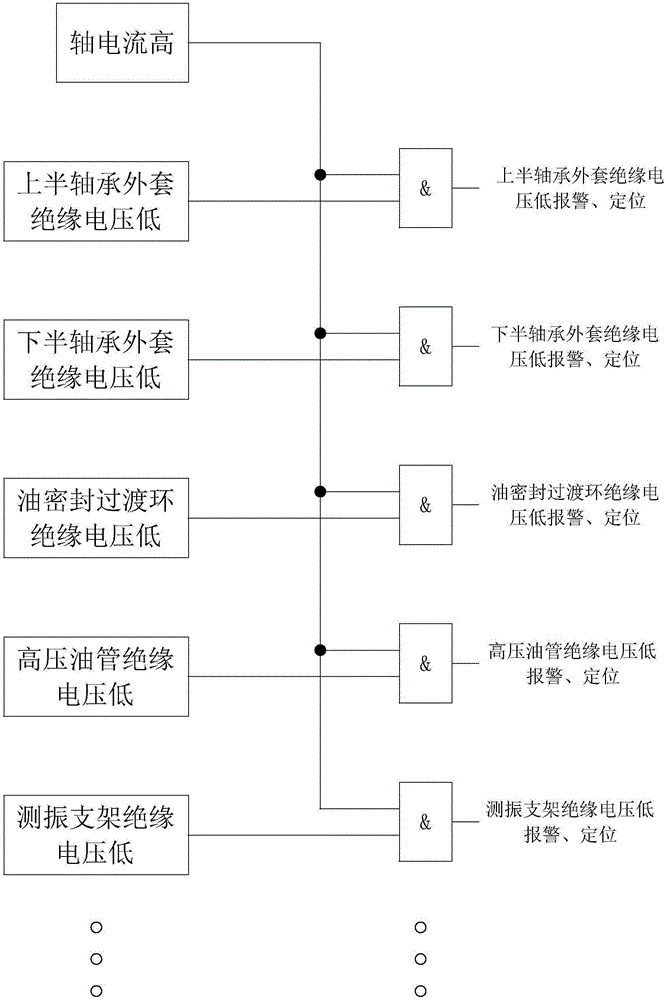

Insulation monitoring and positioning device and method for main shaft of generator

PendingCN106772049AAccurate measurementPositioning accuracyDynamo-electric machine testingElectric generatorVoltage

The invention discloses an insulation monitoring and positioning device for a main shaft of a generator. The insulation monitoring and positioning device comprises a shaft current detection module, an insulation voltage detection module and a processing module, wherein the shaft current detection module detects shaft current of a turbine end of the main shaft of the generator; the insulation voltage detection module detects insulation voltage of a plurality of excitation-end ground insulation parts of the main shaft of the generator; the processing module processes the shaft current and the insulation voltage and outputs a main shaft low-insulation alarm signal when the shaft current is higher than a first default value and any insulation voltage is lower than a second default value, and the ground insulation part corresponding to the insulation voltage is positioned and displayed. Low-insulation monitoring of the main shaft of the generator is realized by measuring the shaft current of the main shaft of the generator and the insulation voltage of the excitation-end ground insulation parts, and an insulation-reduced part is positioned by measuring the shaft current and the insulation voltage, so that the measurement is accurate and the insulation-reduced part can be positioned timely and accurately.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

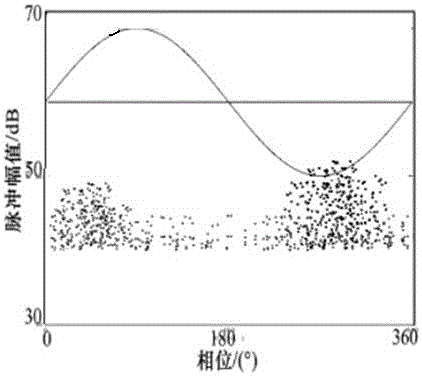

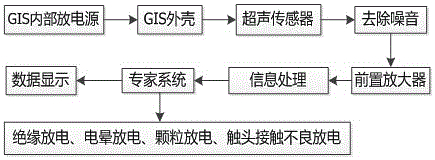

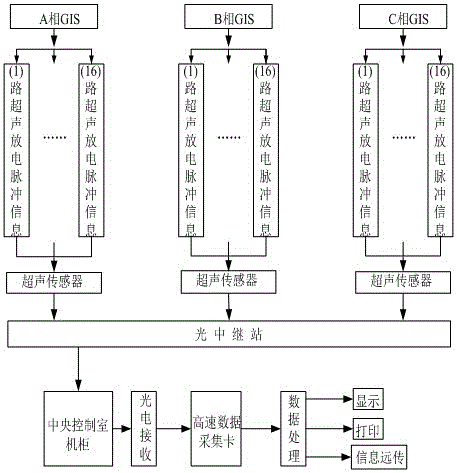

Supersonic online detection system of 1000kV GIS

InactiveCN105717425AReduce energy consumptionPositioning accuracyTesting dielectric strengthEngineeringPartial discharge

The invention discloses a supersonic online detection system of a 1000kV GIS, and relates to the field of electronic technology. Supersonic probes are mounted on a casing or basin-type insulator of the 1000kV GIS, and collect internal discharge signals of the GIS in real time, the signals are transmitted to an optical relay station via fibers and converted into electric signals, the electric signals are amplified, processed and stored, and then analyzed by a host computer, and display, printing and teletransmission functions are provided. The supersonic online detection system of the 1000kV GIS can be applied to the field in detecting partial discharge defect of the common 1000kV GIS, the problems as inaccurate positioning and slow response of a traditional detection method are effectively solved, and the system of the invention is worthy of popularization and use widely.

Owner:STATE GRID CORP OF CHINA +1

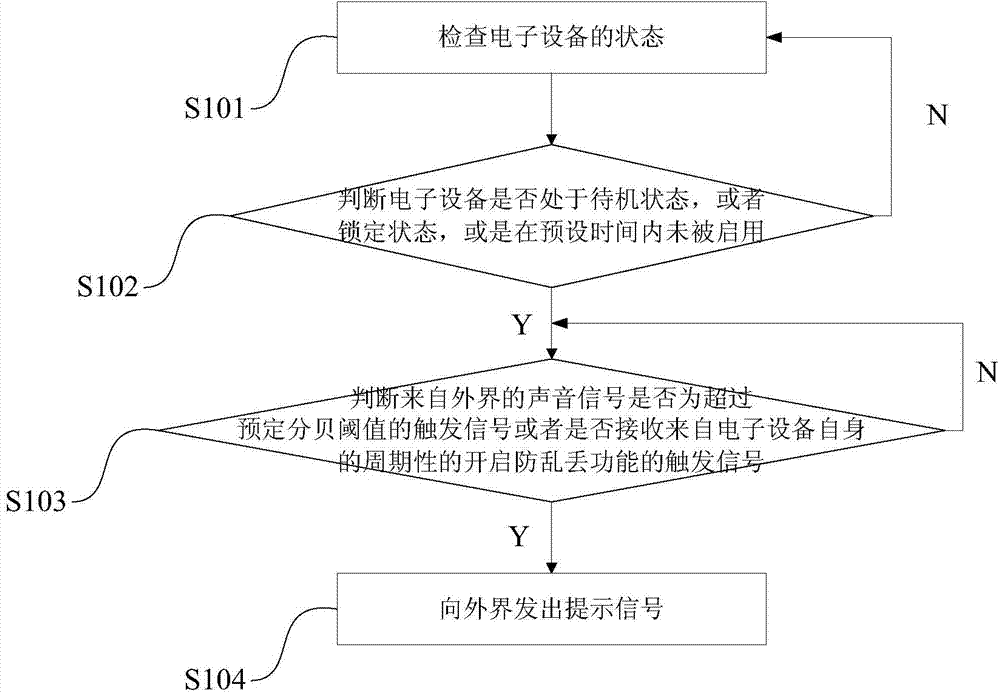

Lost electronic equipment locating method and system

InactiveCN103617405APositioning accuracyPrecise positioningInternal/peripheral component protectionElectrical and Electronics engineeringDecibel

The invention discloses a lost electronic equipment locating method and system. The method comprises the following steps that the operation state of electronic equipment is checked; whether the operation state of the electronic equipment is a standby state, a locking state or is not started in a preset time is judged; when the operation state of the electronic equipment is the standby state, the locking state or is not started in the preset time, whether external voice signals are triggering signals exceeding a preset decibel threshold value or whether periodic triggering signals from the electronic equipment are received is judged; and when the external voice signals are the triggering signals exceeding the preset decibel threshold value or the periodic triggering signals from the electronic equipment are received, hint signals are sent to the outside. According to the lost electronic equipment locating method, under the situation that other auxiliary equipment is of no need, a quick accurate locating function can be achieved.

Owner:HEFEI LCFC INFORMATION TECH

Method and device for positioning terminal

ActiveCN106535132APositioning accuracyPrecise positioningLocation information based serviceWireless signalComputer science

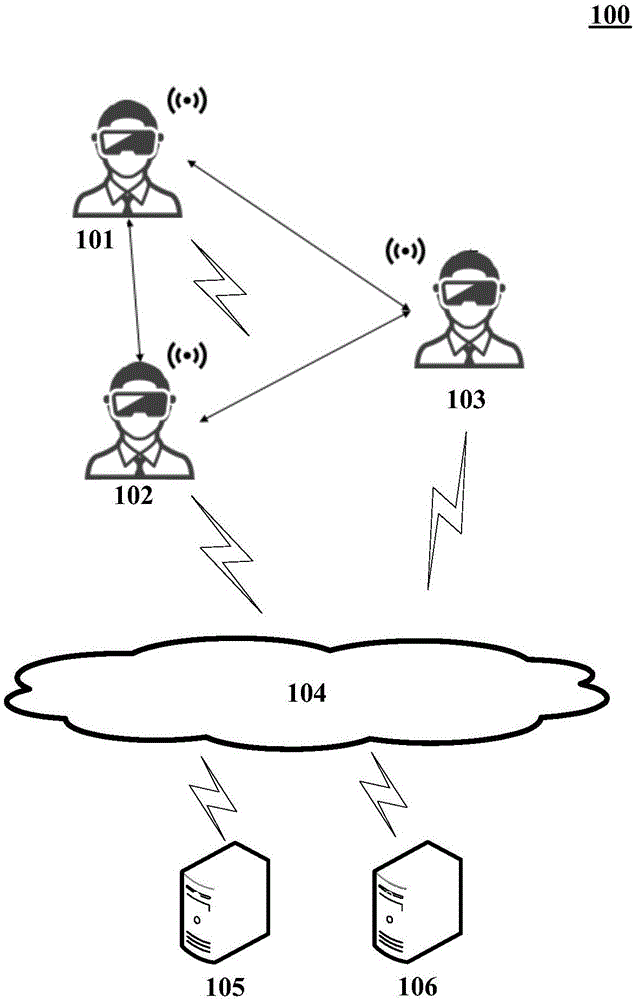

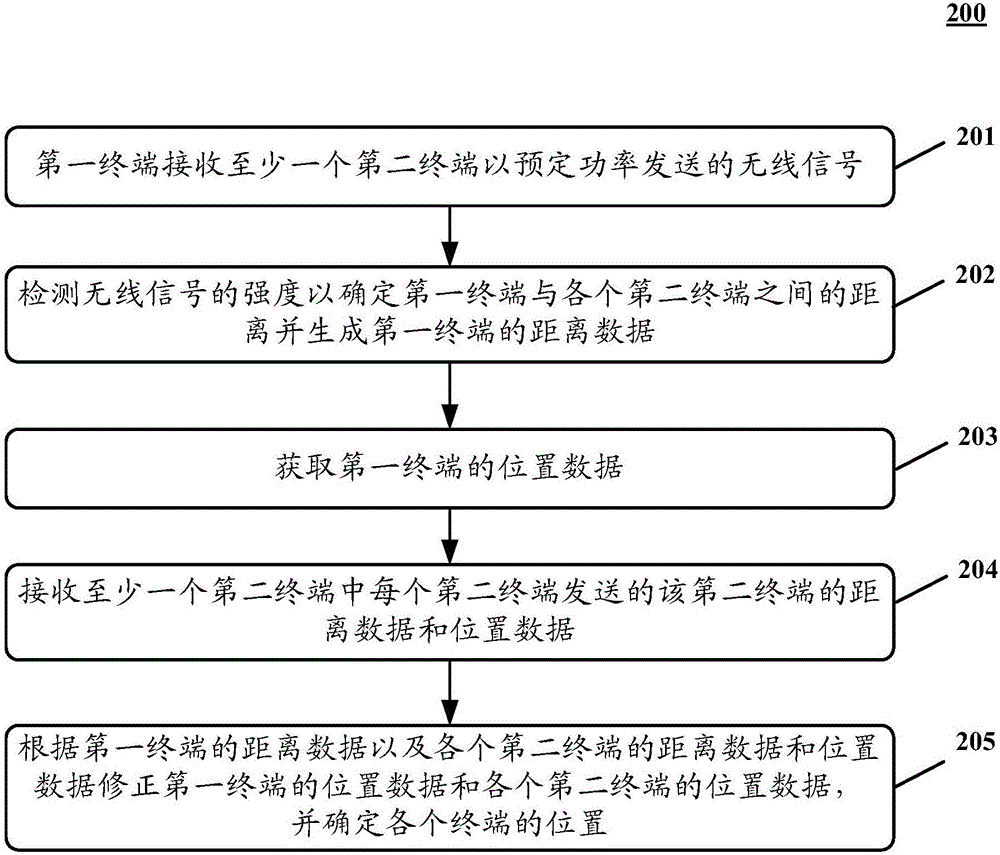

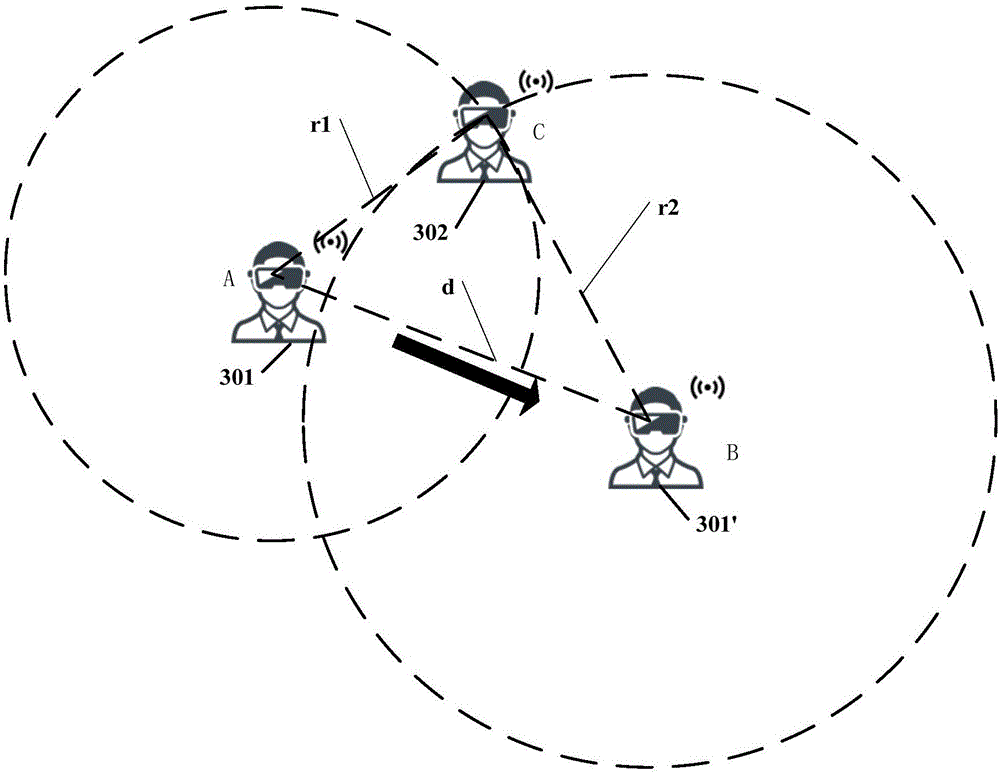

The invention discloses a method and device for positioning a terminal. One embodiment of the method comprises the steps of allowing a first terminal receives a wireless signal sent by at least one second terminal with a preset power, detecting the intensity of the wireless signal so as to determine the distance between the first terminal and each second terminal and generates the distance data of the first terminal, obtaining the position data of the first terminal, receiving the distance data and position data of the second terminal sent by each second terminal in the at least one second terminal, and correcting the position data of the first terminal and the position data of each second terminal according to the distance data of the first terminal and the distance data of each second terminal and determining the position of each terminal. According to the embodiment, the terminal can rapidly and accurately determine the positions of multiple terminals without the aid of an external positioning device.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

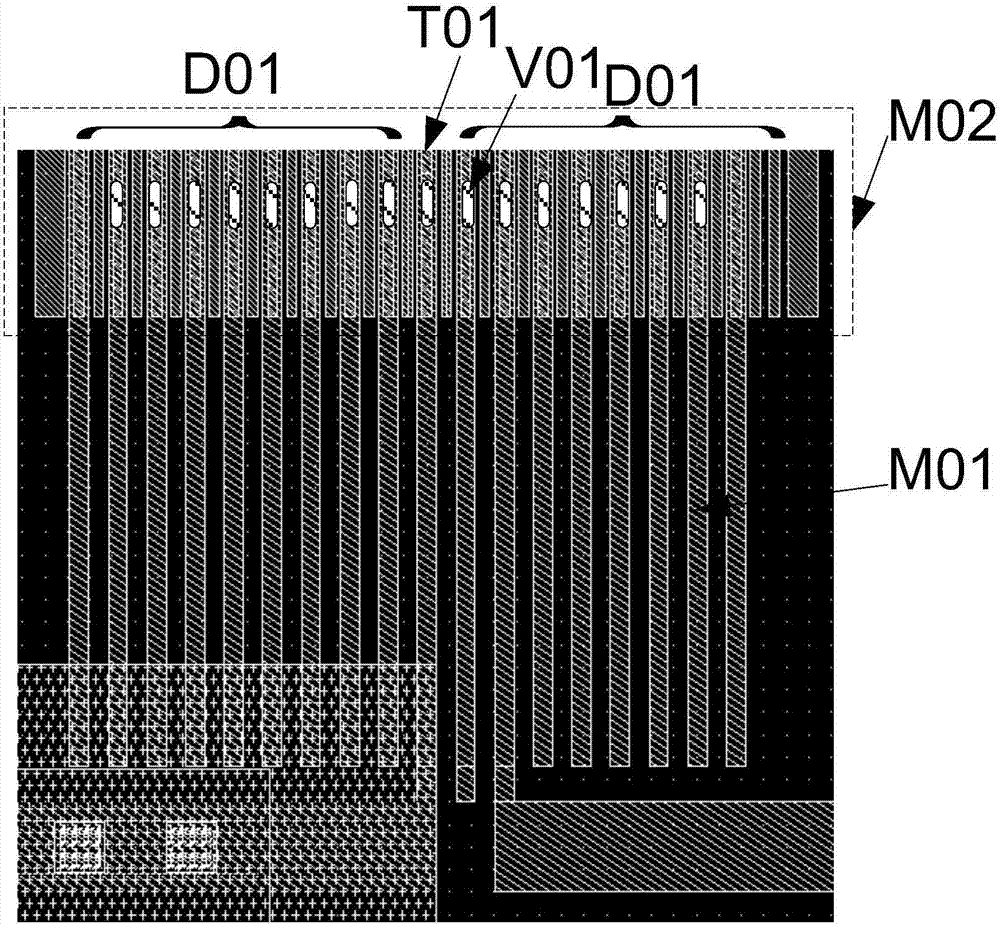

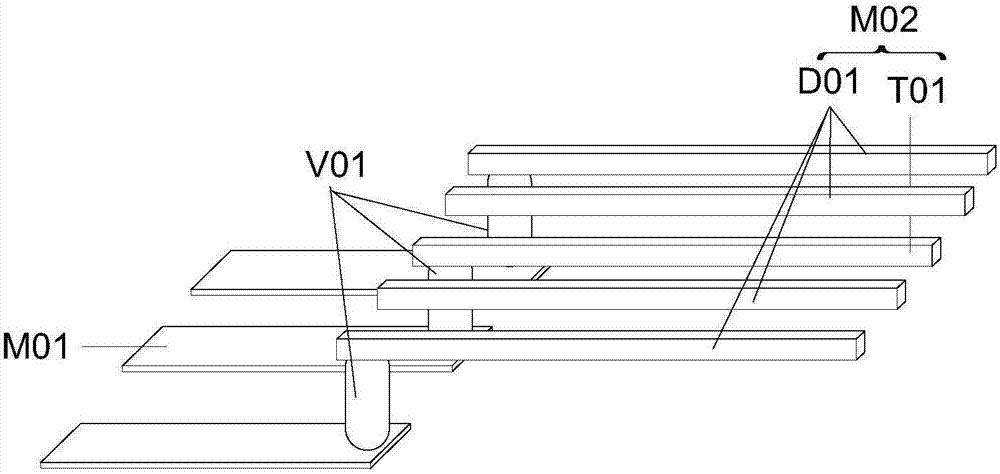

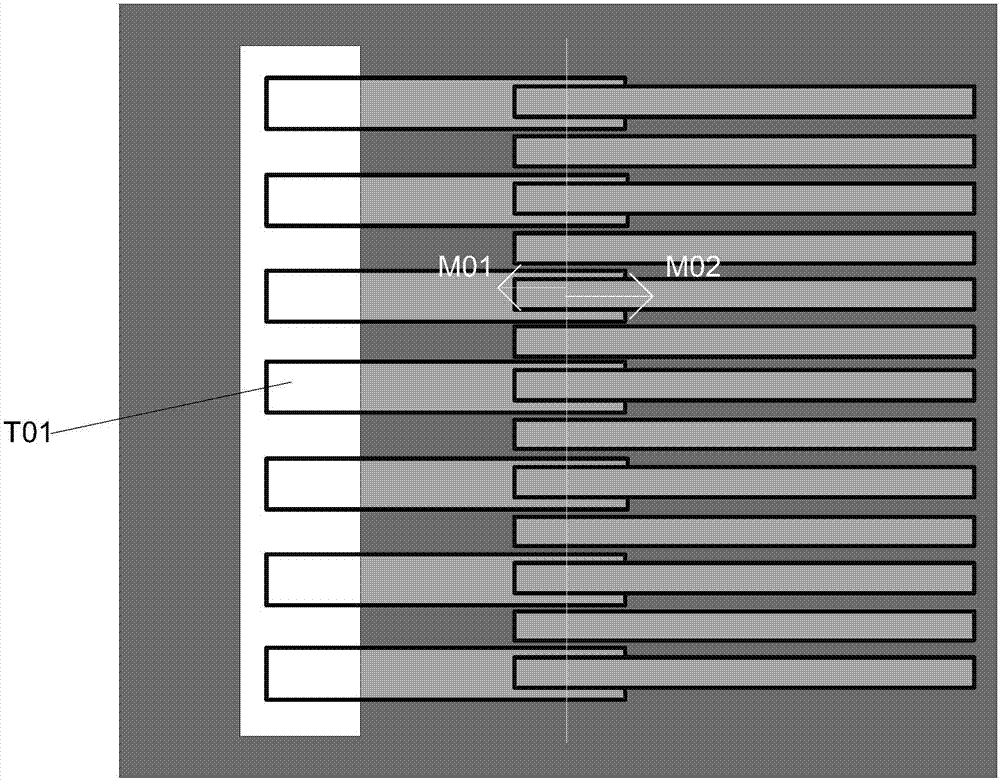

Three-dimensional memory electromigration test structure and manufacturing method thereof

ActiveCN107369670APositioning accuracyAchieve precise positioningSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectromigrationTest structure

The invention provides a three-dimensional memory electromigration test structure and the manufacturing method thereof. In an electromigration test structure manufacturing process, Markers are made on oxide layers of a first virtual line and a second virtual line adjacent to a test line to position the test line. Since markers are made on the oxide layers of the first virtual line and the second virtual line on the two sides of the test line, the metallic line in the middle of markers can be directly positioned as the test line during making an electromigration test structure sample, and rapid and accurate position of the test line can be realized. An electromigration test structure sample can be obtained by cutting the two sides of the test line. Since the markers are on the oxide layers of the first virtual line and the second virtual line, the test line may not be affected, and accurate position of the test line can be realized without damaging the test line and a first metallic line connected with the test line. Sample making success rate is greatly improved, and the positioning time of test line can be shortened.

Owner:YANGTZE MEMORY TECH CO LTD

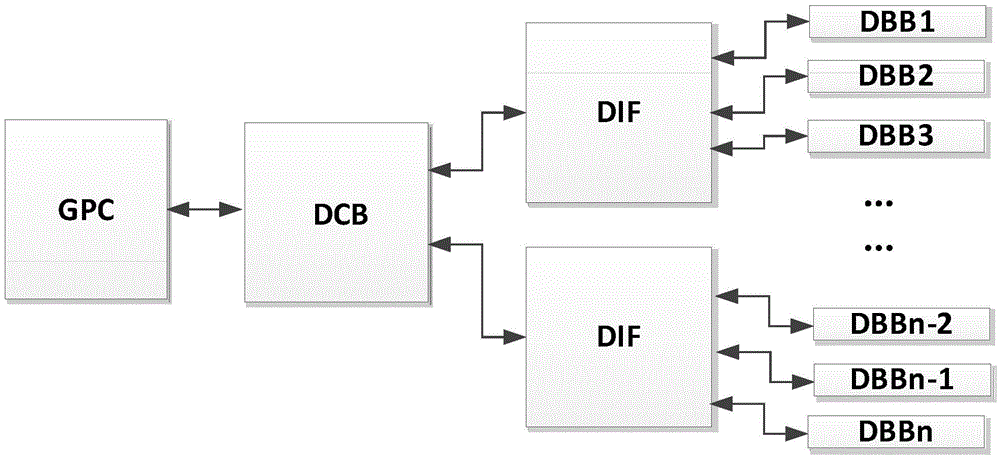

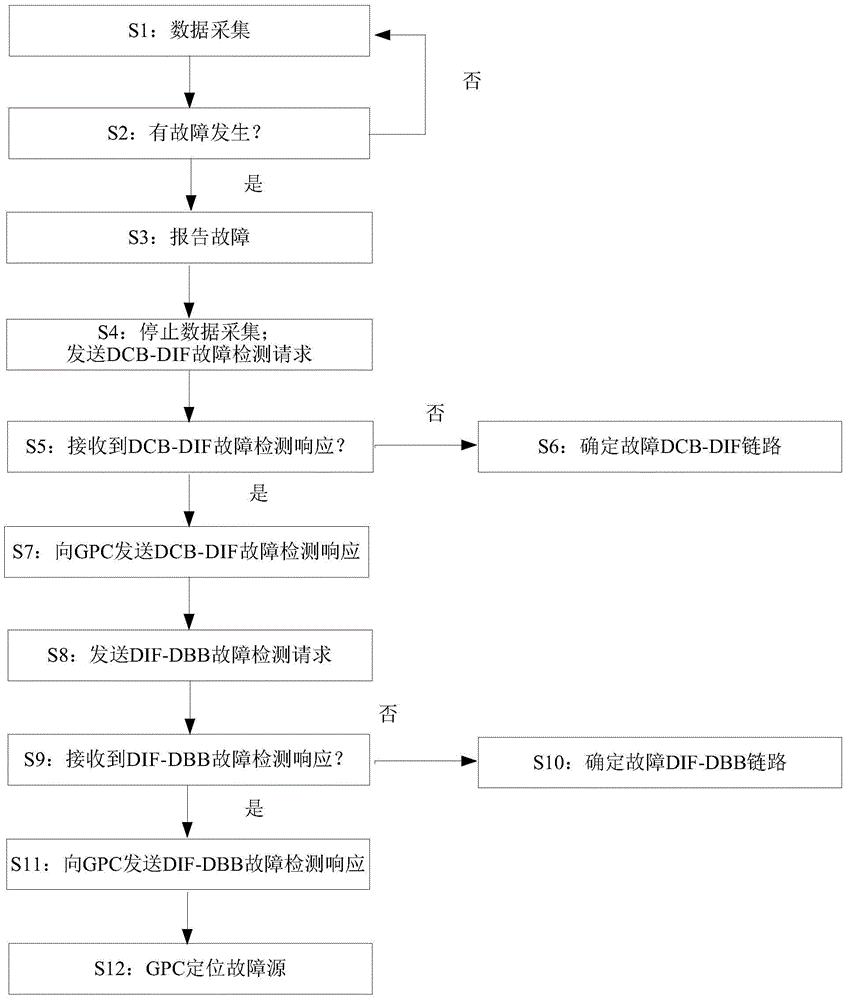

Detector fault diagnosis method and device

ActiveCN105629293AReduce the burden onPositioning accuracyRadiation measurementDiagnosis methodsCollections data

The present invention provides a method and device for carrying out rapid fault diagnosis of a detector. The method comprises the steps that: a data control board sends a data collection command to an associated data interface and the detector in real time when a system is running; the data from the data interface and the detector are processed to determine the existence of a fault; if the fault is determined, the data control board carries out response information collection; and response information is sent to a master control unit, and the master control unit carries out fault positioning.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

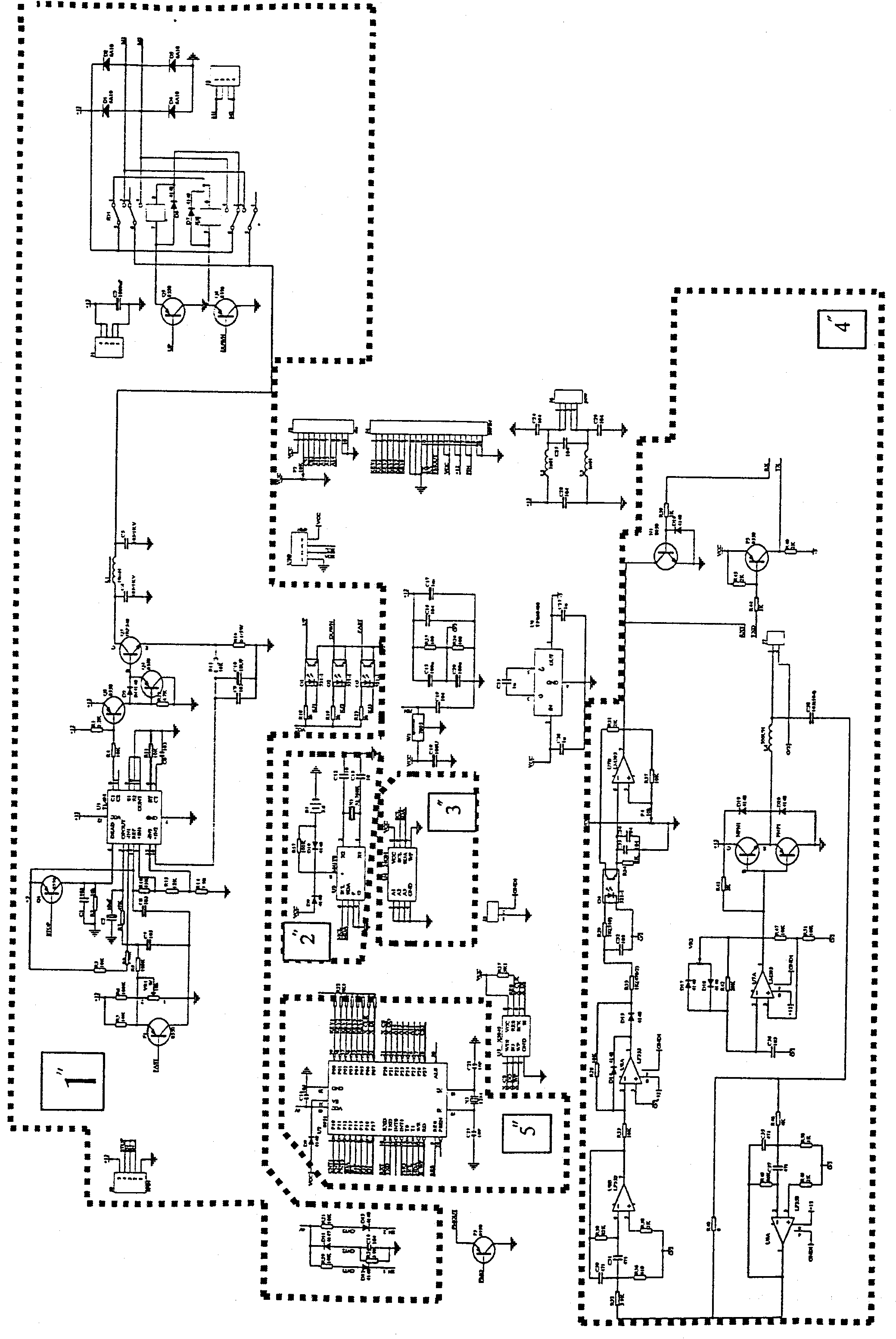

Sliding type locator for intelligent inclinometer cable guide probe

The invention discloses a sliding type locator for an intelligent inclinometer cable guide probe, which is characterized by consisting of a device body and a motor control circuit of an integrative induction type winding machine control circuit, wherein the motor control circuit is independently arranged outside the device body. The device body is connected with the motor control circuit via leads; the device body is a hollow cylinder; a cable guide fixed pulley is embedded in the top of the device body; two vertical NPN proximity switch sensors are embedded in the side wall of the device body; two point-contact switches are embedded in the bottom end of the device body; a five-chip cable interface is arranged on the outer side wall of the device body; and the lower part of the device body is embedded in an inclinometer pipe opening. The invention has the advantages that the device can ensure that the cable passes through the centre of the inclinometer pipe opening; the host of the inclinometer can be placed at any position around the measuring point instead of being placed rightly above the measuring point; the wear of the cable is reduced, the length mark of the cable is automatically identified, and the accurate and fast location of the probe and the security of the shut-down control during the measurement are ensured.

Owner:HOHAI UNIV

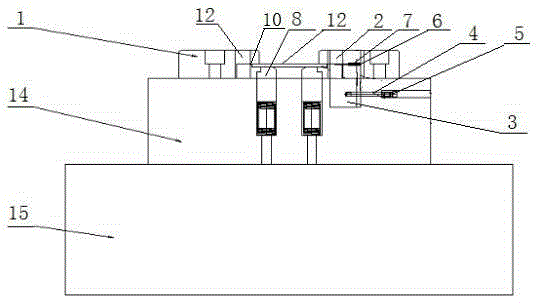

Self-adaption material width determination device for progressive die

ActiveCN105382108AEven by forcePositioning accuracyShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention discloses a self-adaption material width determination device for a progressive die. The device comprises material guide plates which are arranged on a female die plate to form a material guide channel and a side blade stop block arranged on one side of the material guide channel, the material inlet end of the material guide channel is provided with a horn mouth, and the side blade stop block is connected with the female die plate through elastic parts; the two sides of the material guide channel are provided with side blades, the side blades on one side of the material guide channel are fixed on the material guide plates, and the side blades on the other side of the material guide channel are arranged on the side blade stop block in a front-back moving mode and connected with the side blade stop block through elastic parts. According to the device, it can be guaranteed that a die stably and continuously works and is evenly stressed; when a material belt enters the material guide plates, coarse positioning can be firstly performed on the material belt through the horn mouth material inlet end of the material guide channel, and then the side blade stop block on one side of the material guide channel and the side blades on the side blade stop block can make close contact with the material belt, so that the material belt is quickly and accurately positioned and the material belt width is determined.

Owner:HUNAN UNIV +2

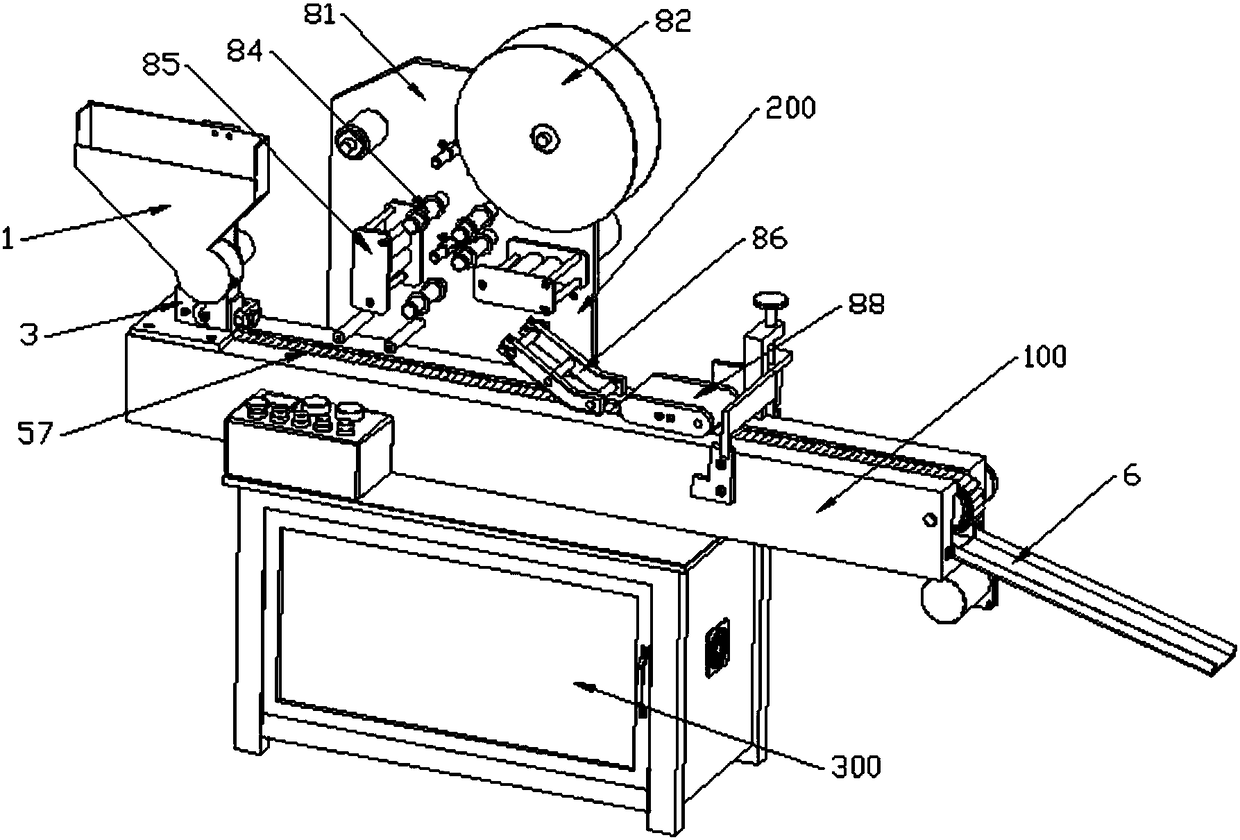

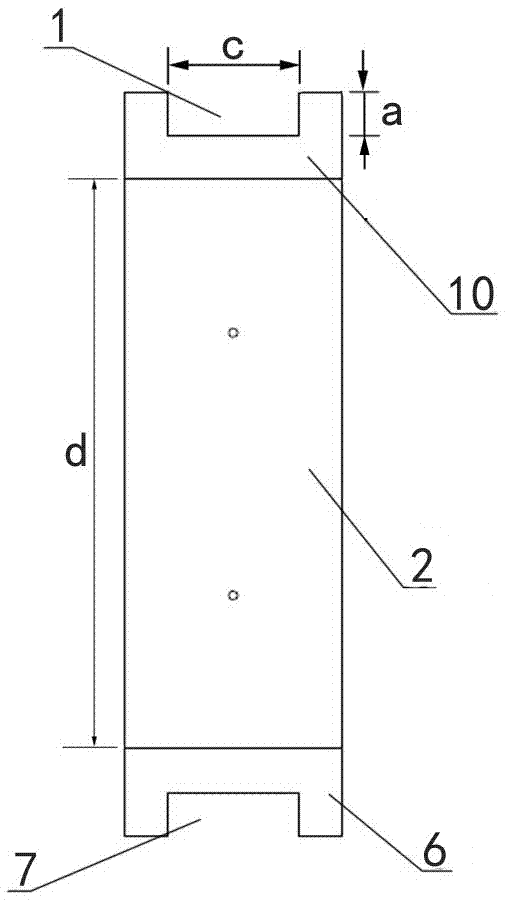

Rod part labeling device

InactiveCN108146758APrevent movementPositioning accuracyLabelling machinesEngineeringSpeed reduction

The invention provides a rod part labeling device and belongs to the field of labeling equipment. The rod part labeling device comprises a feeding assembly, a press-covering assembly and a working table. The feeding assembly is arranged above the working table. The press-covering assembly is arranged on one side of the working table. The feeding assembly comprises a discharge chute, a discharge wheel, a guide block and a conveying assembly. The width of the discharge chute is greater than the length of one battery and less than the length of the two batteries. The discharge chute comprises a feed area located at the upper end and a transition area located at the lower end. The transition area is circular. The discharge wheel is arranged in the transition area and is rotatably connected tothe transition area. A plurality of locating grooves are uniformly formed in the discharge wheel. The axes of the locating grooves are perpendicular to the width direction of the discharge chute. Theguide block is arranged at the lower end of the transition area. A speed reduction groove communicating with the transition area is formed in the guide block. A transmission assembly arranged horizontally is arranged at the lower end of the speed reduction groove. The longitudinal center line of the transmission assembly is parallel to the center lines of the locating grooves. The rod part labeling device is accurate in feeding, capable of achieving rapid labeling of a label on the outer surface of a rod part and high in efficiency.

Owner:新昌县小毅家电子商务有限公司

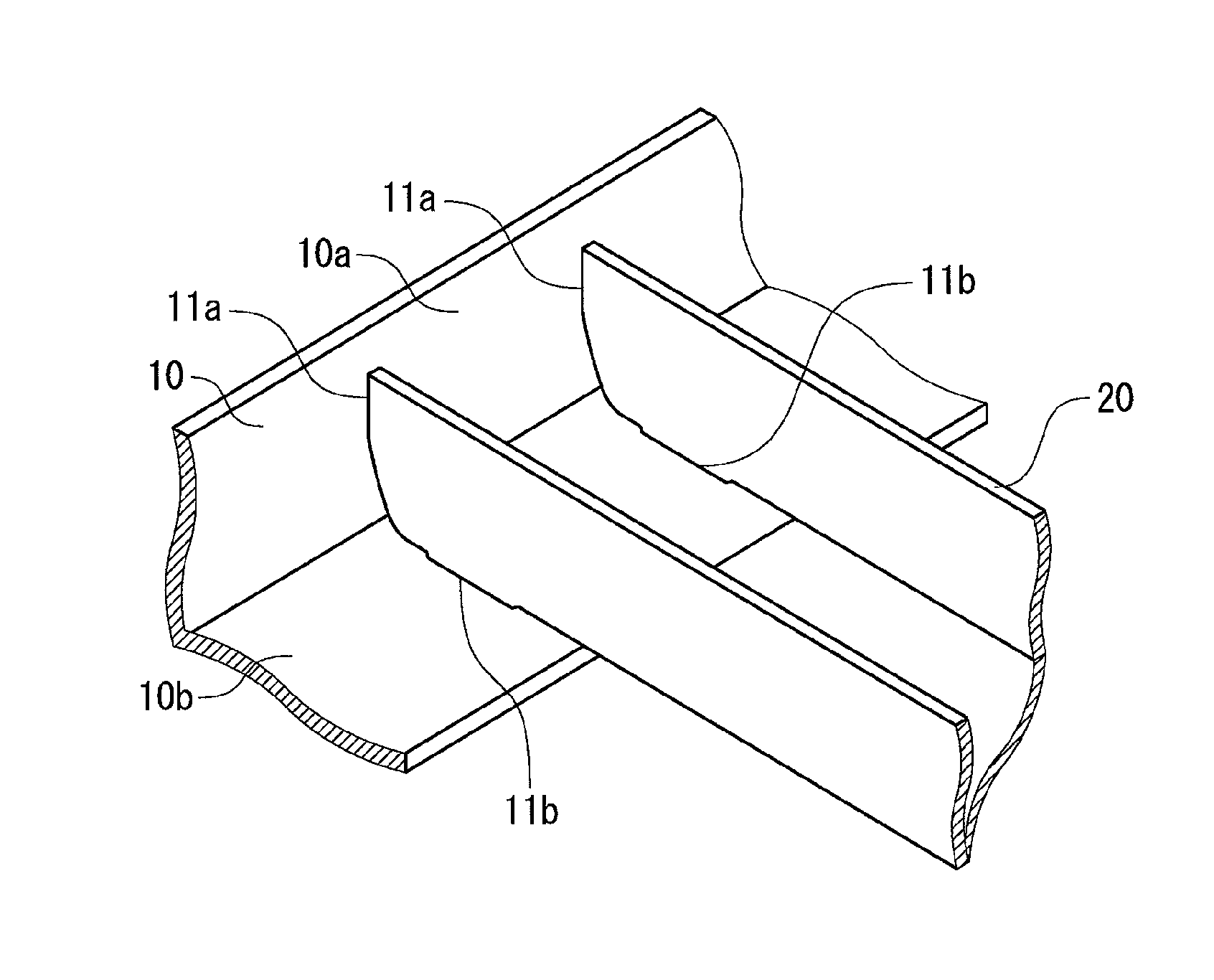

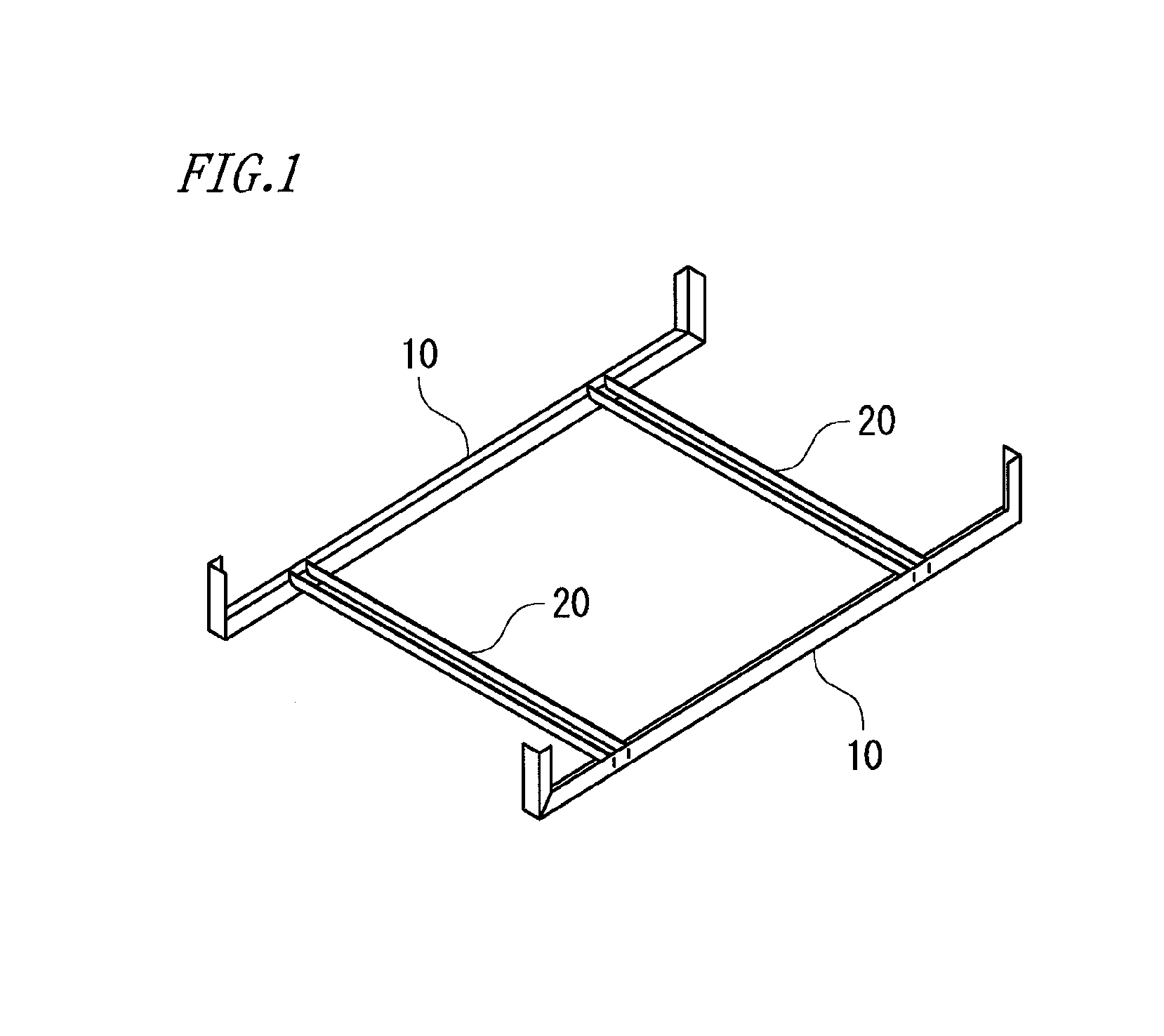

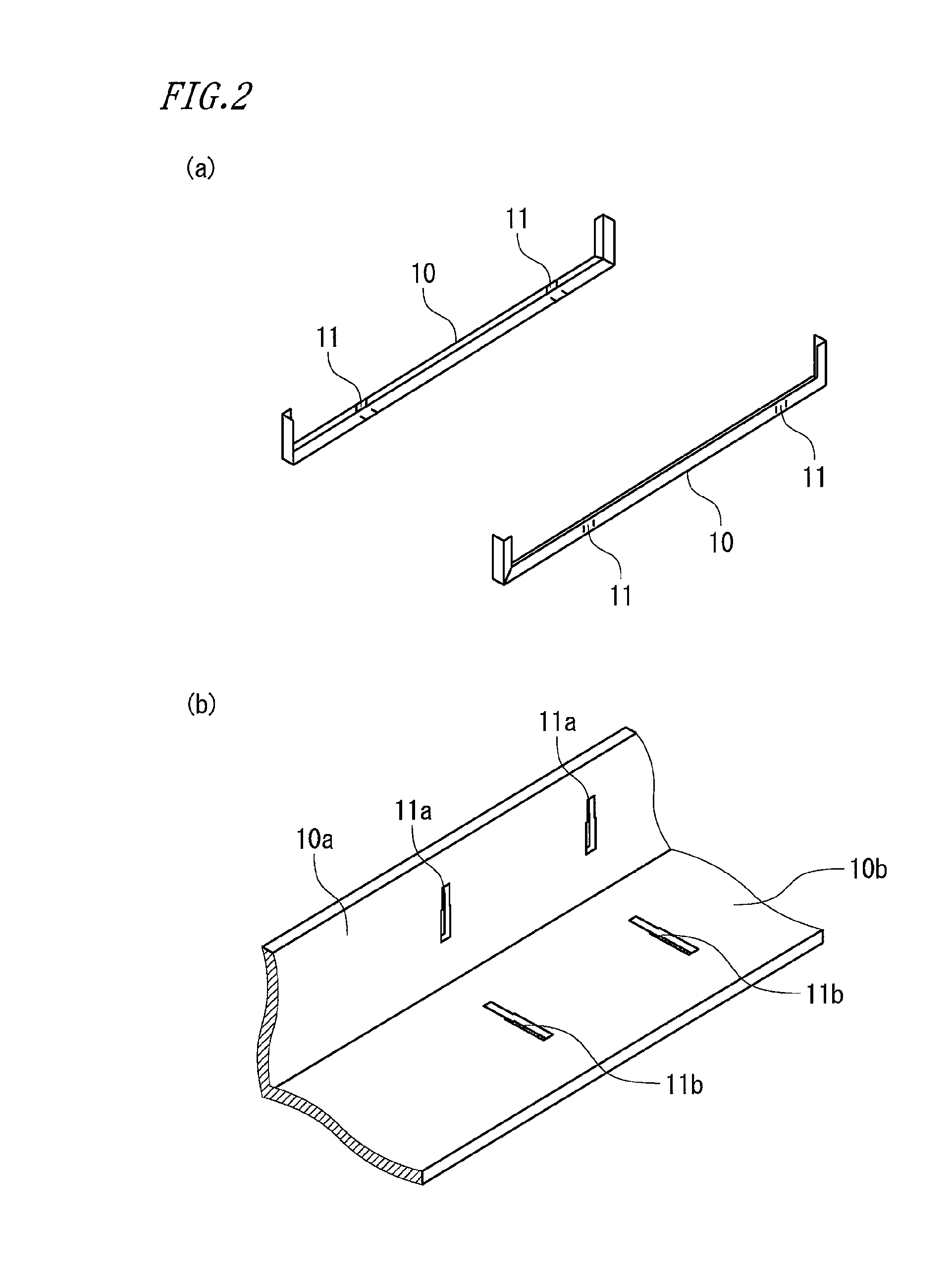

Insertion frame structure and housing using same

To enhance the positioning accuracy between primary members and auxiliary members without need of latch parts such as rivets, an insertion frame structure includes: a pair of primary members having L-shaped cross-sections and placed with the L shapes facing to each other symmetrically; and several auxiliary members having angular U-shaped cross-sections between the primary members. The primary members and the auxiliary members are joined at latch portions. The latch portions of the primary members have clearance-shaped latch holes. The latch portions of the auxiliary members have convex portions to be inserted into the latch holes. Each latch hole has a clearance with a larger dimension than a plate thickness t of the auxiliary members, and continuously from the clearance, a clearance with a dimension smaller than the plate thickness t of the auxiliary members.

Owner:MITSUBISHI ELECTRIC CORP

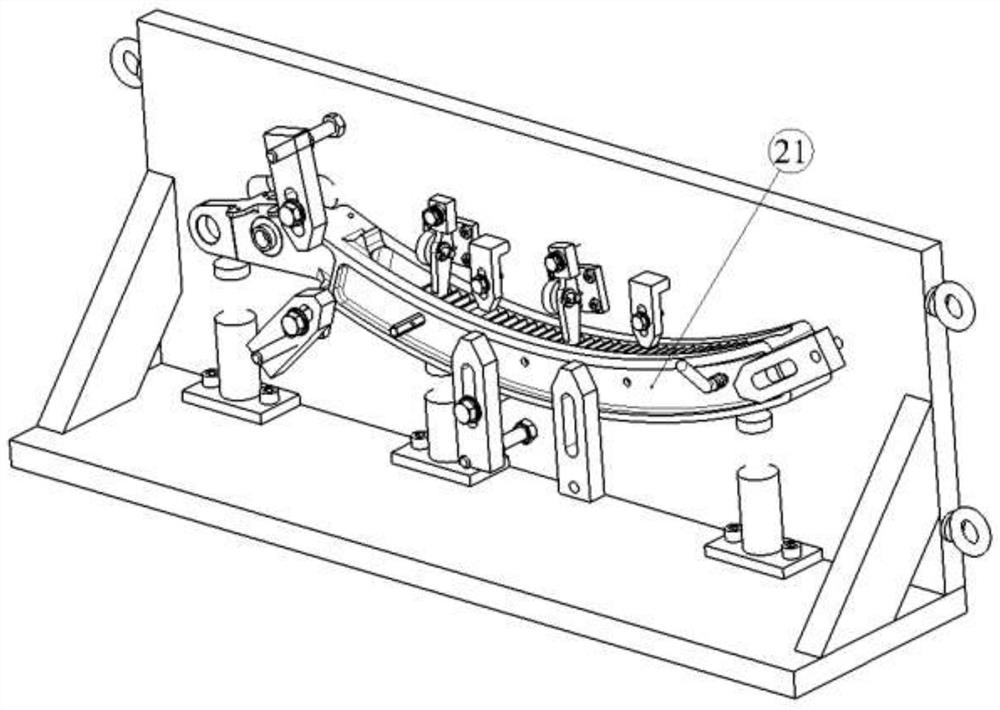

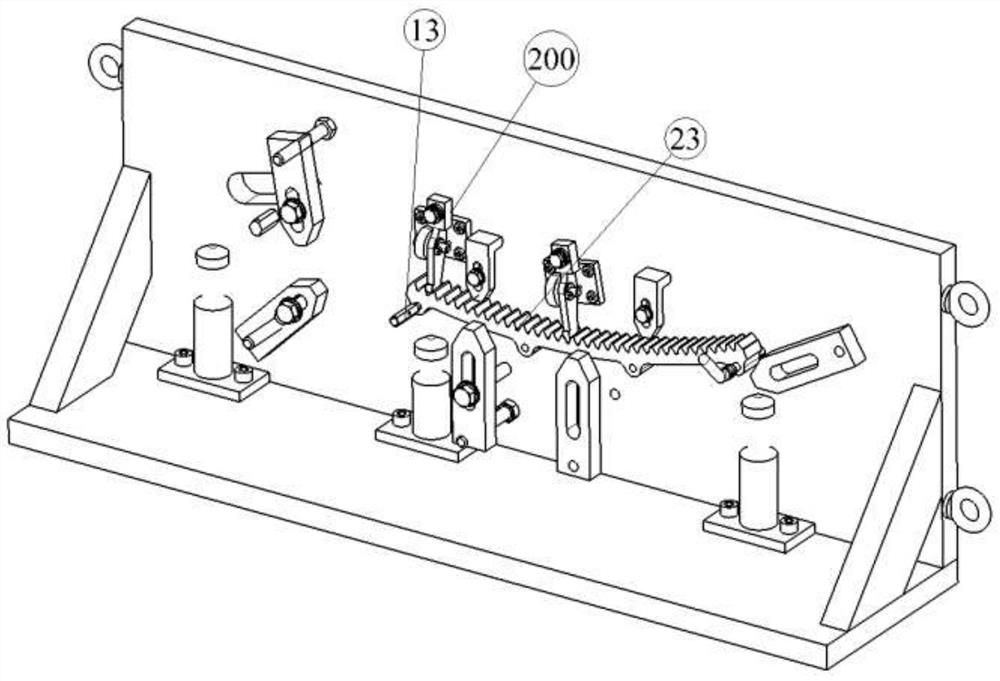

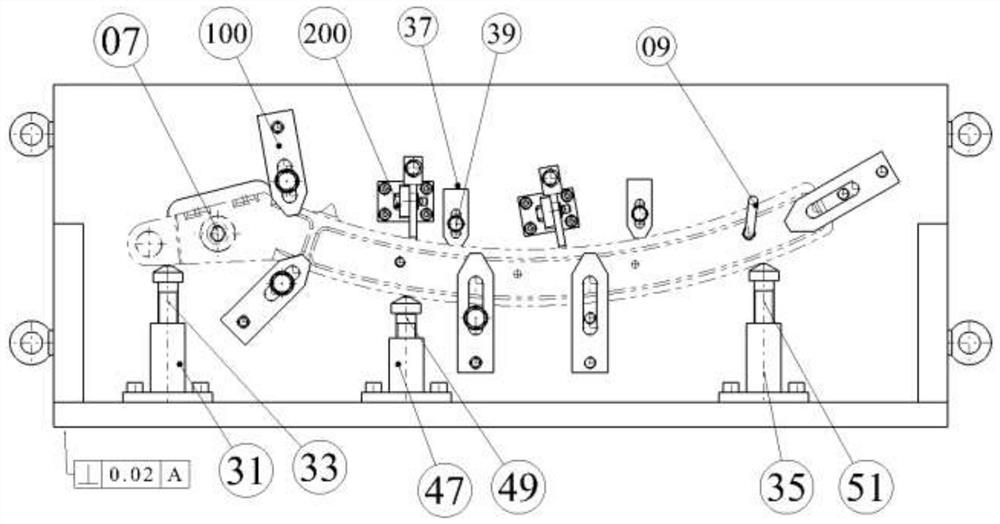

Special boring clamp

InactiveCN112296399APositioning accuracyImprove clamping efficiencyPositioning apparatusDrill jigsLocknutRhomboid

The invention relates to a special boring clamp which is composed of a main positioning plate, a bottom plate, a reinforcing plate, a positioning origin bushing, a rhombic positioning pin, drill jig assemblies, a first pressing plate assembly, a second pressing plate assembly, a first jacking supporting assembly, a second jacking supporting assembly, a third jacking supporting assembly and an inner rack pressing assembly. An origin bushing hole, a rhombus pin hole and three drill jig sleeve holes are machined in the main positioning plate, the special boring clamp is provided with three same drill jig plate assemblies according to the characteristics of machined products, and each drill jig assembly is composed of a first drill sleeve, a second hinge sleeve, a third hinge sleeve and a fastening locking screw. The first pressing plate assembly is composed of a flat pressing plate, a first pressing plate locking bolt, a first spring pad, a first supporting bolt and a first locking nut, and the inner rack pressing assembly is composed of a T-shaped support, a hook-shaped top pressing plate, a rotating shaft pin, a cotter pin, a third locking bolt, a spherical elastic pad and a conicalelastic pad. By means of the scheme design of the special boring clamp, the machining problems that when a specific outer arc-shaped cavity piece and an inner rack assembly are machined, positioningand clamping are difficult, dislocation is likely to happen, and scrapping is likely to happen are solved.

Owner:蒋元明

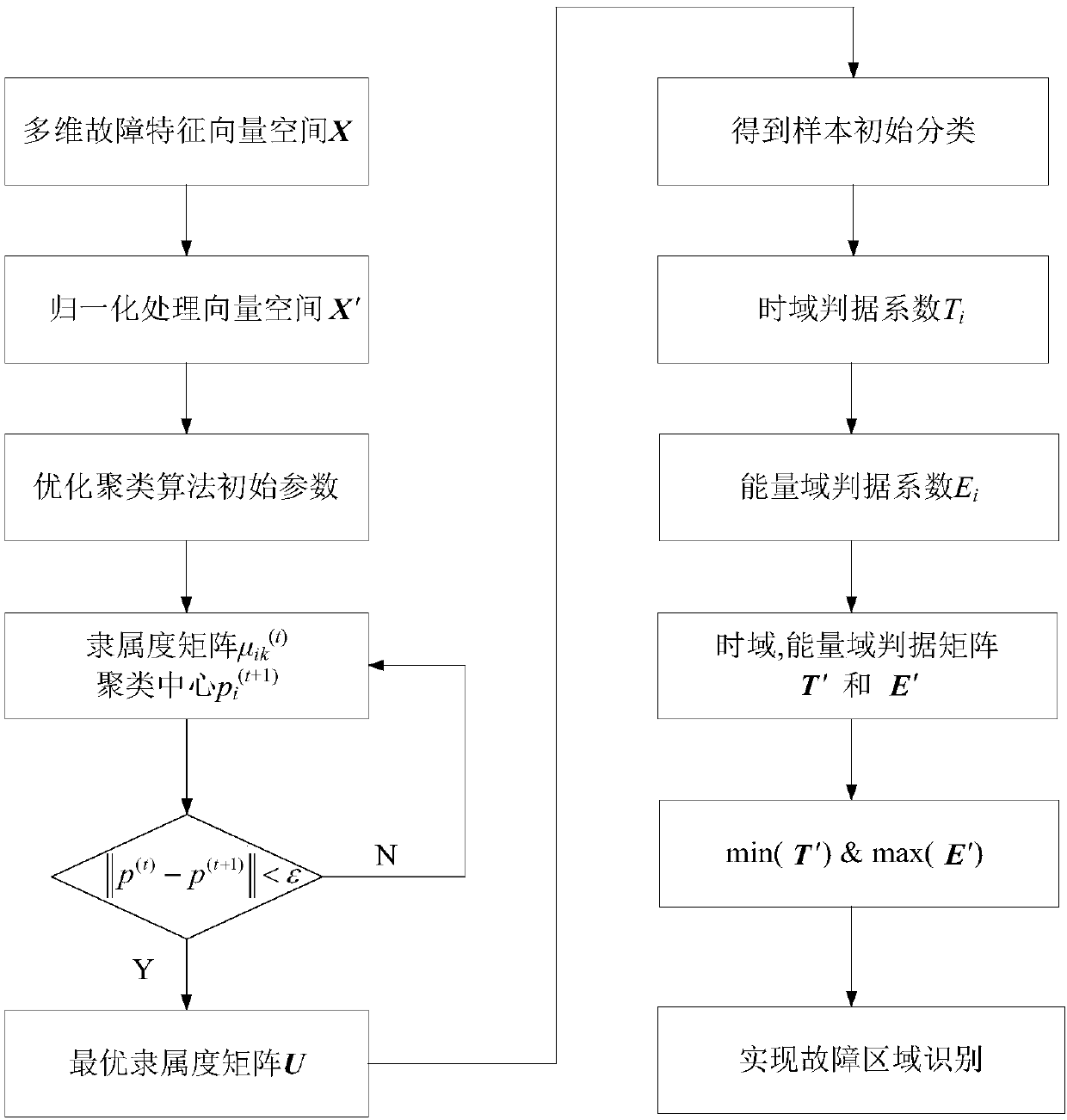

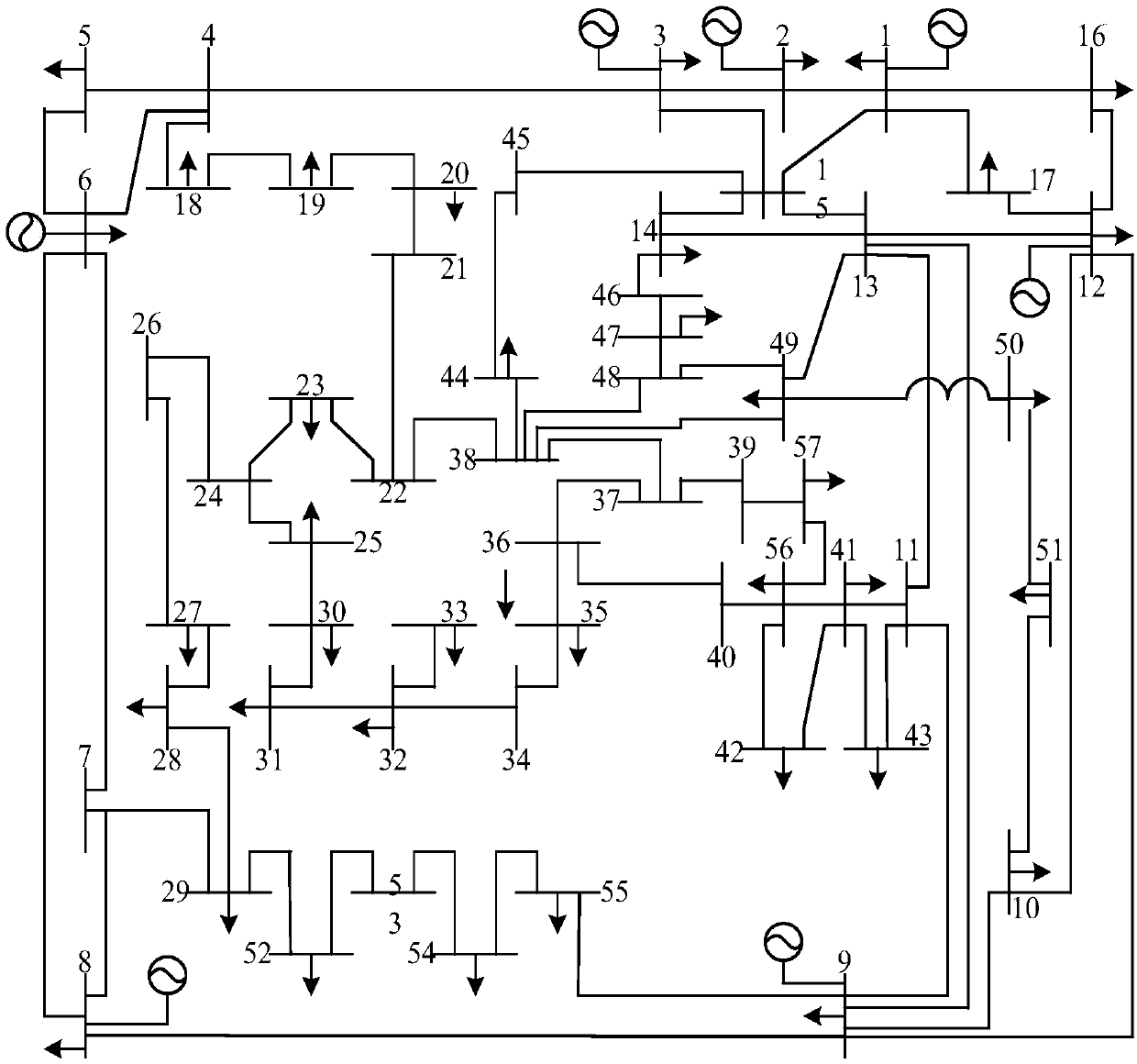

Method for locating fault area of power grid based on multi-dimensional information

ActiveCN107607836APositioning accuracyRequirement to reduce sampling frequencyFault locationPower gridFrequency domain

The invention discloses a method for locating a fault area of a power grid based on multi-dimensional information. First, multi-dimensional eigenvectors X of the time domain, the frequency domain, theenergy domain and the like, are constructed and then normalized to obtain vector space X'. Then, the optimal clustering analysis algorithm is used to obtain the optimal membership matrix U, and samples are classified based on U. Finally, based on a classification criterion value matrix of the inherent characteristics of multi-dimensional fault vectors of the time domain, the frequency domain, theenergy domain and the like, classification measurement points are concretely attributed, and the power grid area is divided into four categories: a fault area, a fault boundary area, a fault transition area and a non-fault area. The method integrates multi-dimensional information such as the time domain and the frequency domain in a complex power grid, identifies and corrects error data by usingmulti-dimensional information correlation characteristics, and quickly and accurately locates the fault area. At the same time, the requirement for the sampling frequency of field devices is reduced,and the method provided by the invention is more robust and universally applicable than the existing whole-network one-dimensional fault location method.

Owner:CHINA UNIV OF MINING & TECH

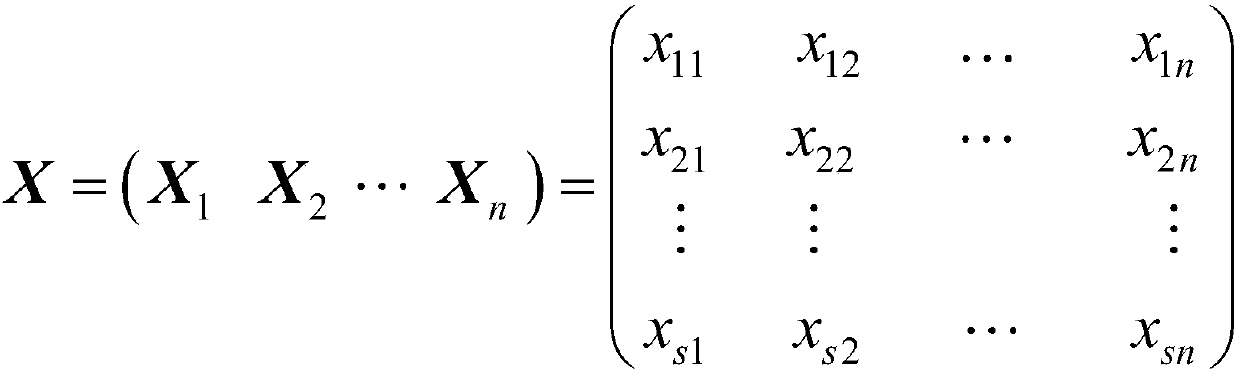

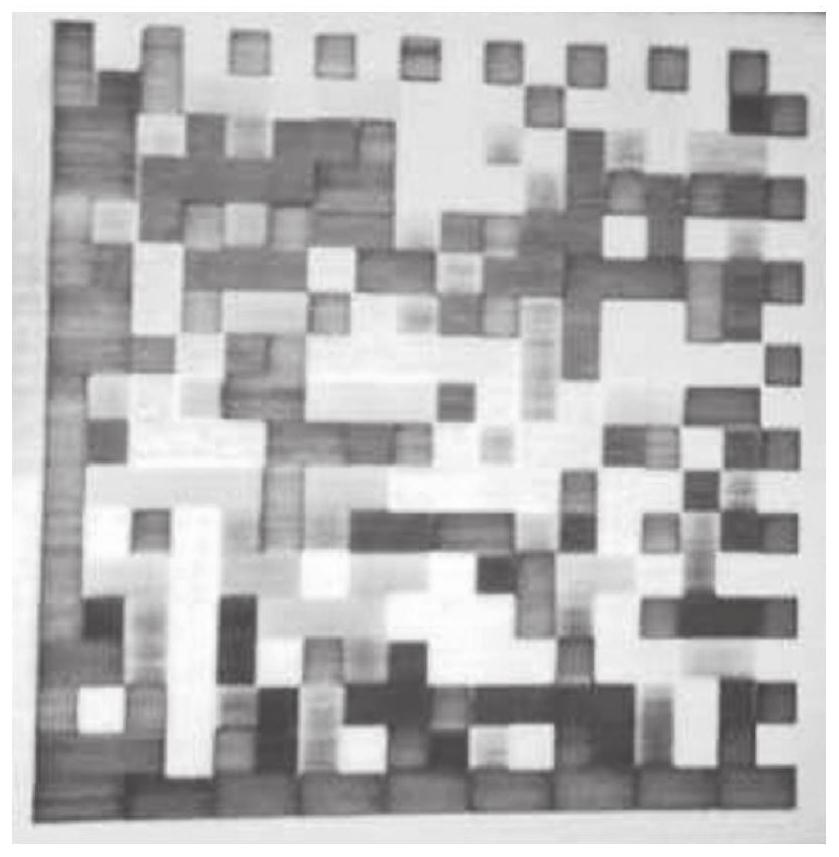

Image reconstruction method and system for distorted color direct component marking

ActiveCN112434543APositioning accuracyImprove module color changeImage analysisGeometric image transformationDistortion correctionEngineering

The invention provides an image reconstruction method for distorted color direct component marking, and the method comprises the steps: loading a collected color bar code image, and carrying out the preprocessing of the image; determining four vertexes of the laser marked color bar code based on the structural features of the bar code, and extracting the color bar code after distortion correction;clustering the two channels of the color bar code image according to colors, and calculating the mean value of the last channel value of each clustering area to serve as the last channel value of each clustering center, thereby recognizing the processing color of the bar code; reconstructing the color bar code; performing error correction on the edge finding area of the reconstructed bar code according to the structural features of the bar code, and completing color bar code reconstruction after error correction. According to the invention, the problems of bar code deformity caused by an image acquisition system and module color change and different sizes caused by laser marking are solved, and the readability of color direct component marking is greatly improved.

Owner:SHANDONG UNIV

Fracture compression restoration internal fixation guiding device

InactiveCN109223148APositioning accuracyPrecise positioningInternal osteosythesisFractures compressionEngineering

The invention discloses a fracture compression restoration internal fixation guiding device, comprising a positioning frame, a movable baffle plate and a guide part, wherein the movable baffle plate is hinged on one end of the positioning frame, the guide part is installed on the other end of the positioning frame through threads, the screw-in direction of the guide part points to one end of the movable baffle plate on the positioning frame, and a plurality of limit holes for insertion of Kirschner pins are formed on the positioning frame. By designing a hinged movable baffle plate on the positioning frame, the positioning frame can be installed at a plurality of positions when in use, and both ends of the positioning frame can be guaranteed to have supporting points. It can be used not only for calcaneal fracture reduction and fixation, but also for limb fracture reduction and fixation.

Owner:NANFANG HOSPITAL OF SOUTHERN MEDICAL UNIV

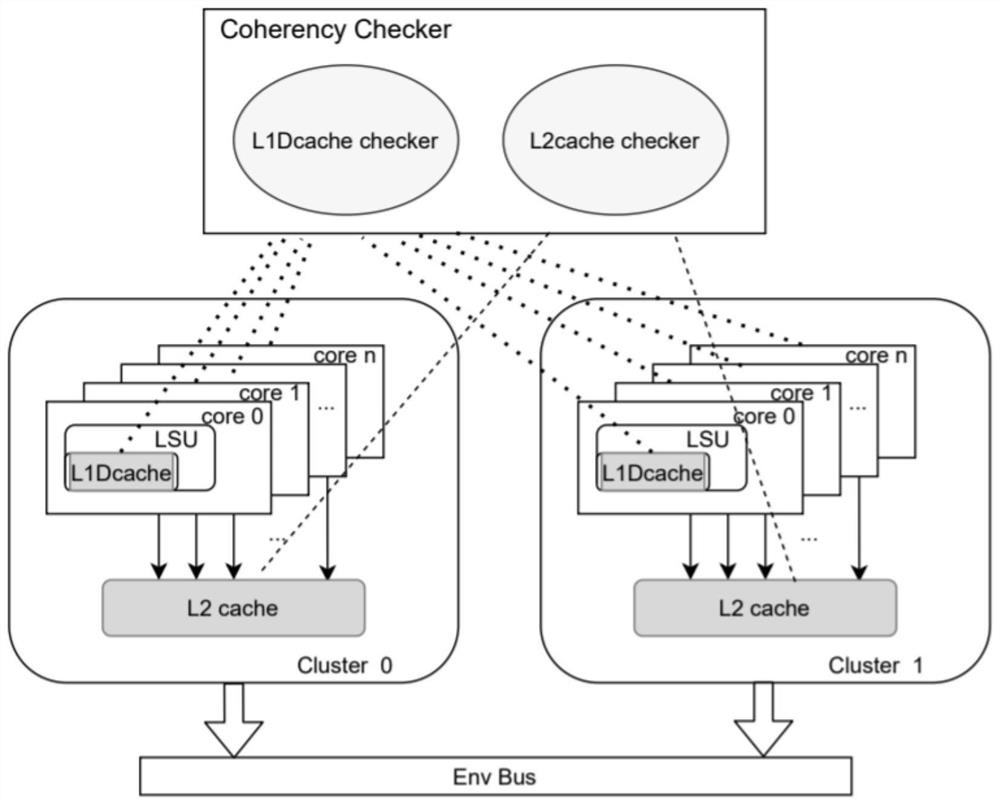

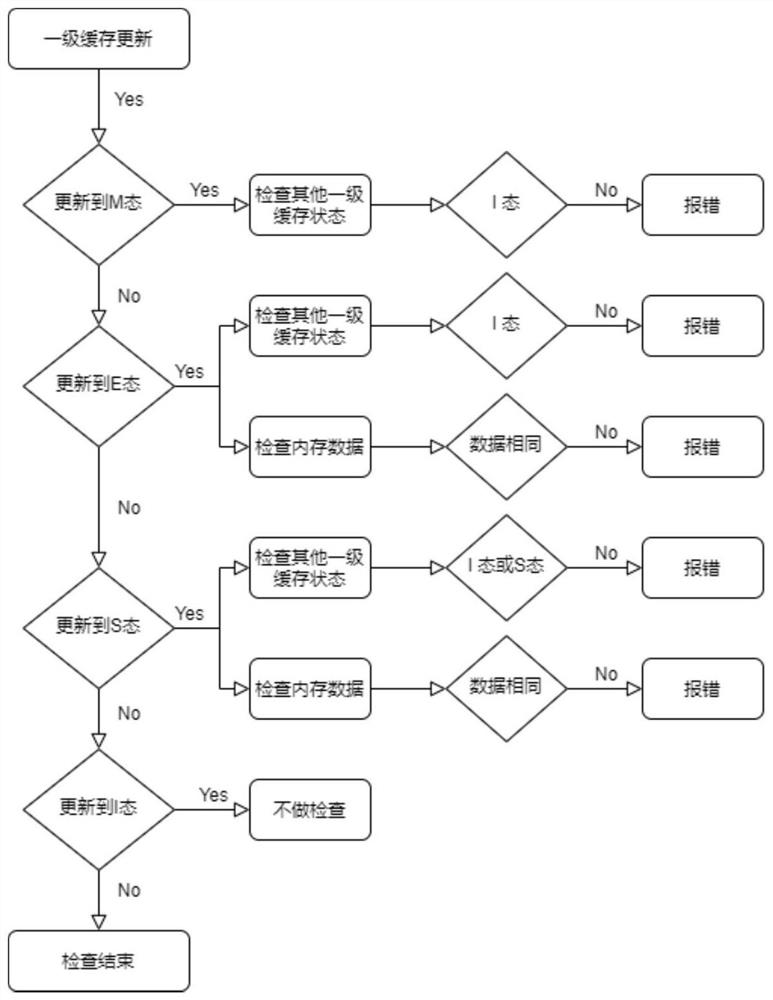

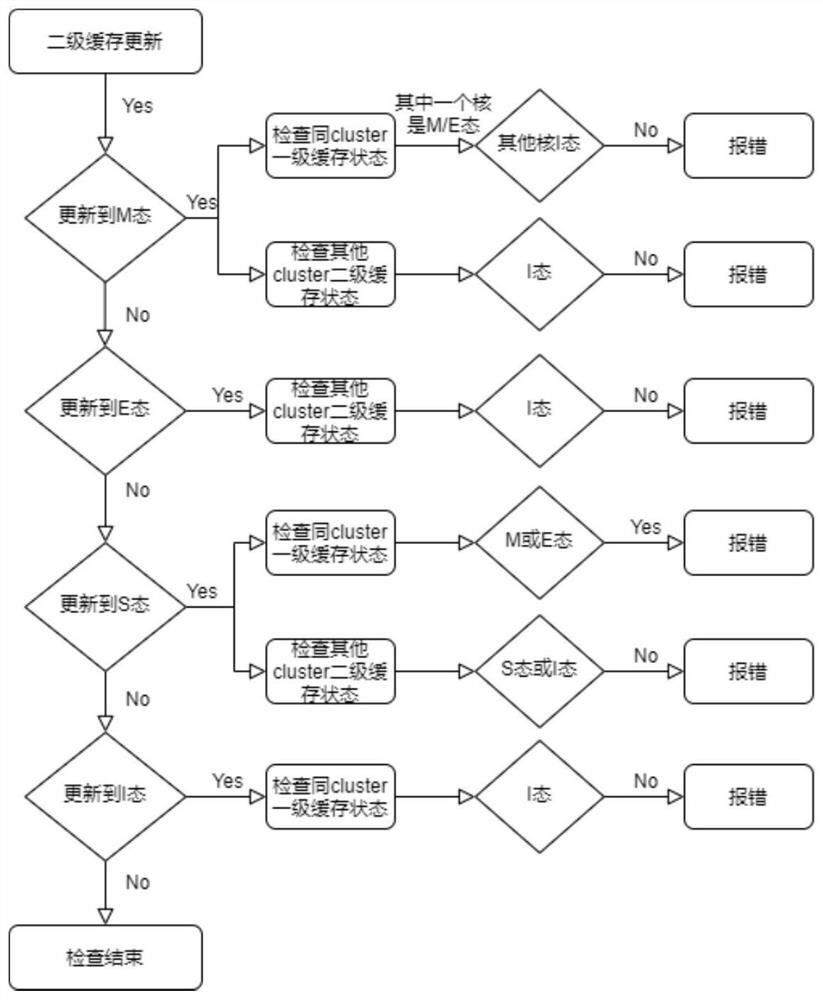

Method for realizing multi-core cache consistency verification

PendingCN114416440APositioning accuracyScalableDetecting faulty computer hardwareMultiple digital computer combinationsOperating systemCache consistency

The invention discloses a method for realizing multi-core cache consistency verification, which comprises the following steps of: S1, when a core updates a cache line to an M state, checking whether the cache line exists in caches of other cores; s2, when each core updates a cache line to an E state, checking whether the cache line exists in caches of other cores or not; s3, when one core updates the cache line to the S state, checking whether the cache line exists in the caches of other cores, if the state of other cores is S, checking whether the cache line data of the two cores are consistent, and meanwhile, checking whether the cache line data is consistent with the data in the memory; and S4, when one core updates the cache line to the I state, other cores are possible to be in any state, and check is not needed. According to the method and the device, by monitoring the update information of the first-level cache and the second-level cache and checking the data in the memory, the cache can be ensured to comply with an MESI consistency protocol, and meanwhile, the correctness of the data can be ensured.

Owner:GUANGDONG STARFIVE TECH LTD

Cross positioning method before spine surgery

InactiveCN103432658APositioning accuracyAvoid redundant operationsIntravenous devicesSpine surgeryEngineering

The invention provides a cross positioning method before a spine surgery. Thin metal pins through which a ray cannot pass are adopted; a rubber layer is coated outside each thin metal pin; two thin meta pins are intersected and penetrated with each other to form a #-shaped locating rack of which opposite sides are respectively parallel; the locating rack is put on the position to be located on the back of a sufferer; a local part of the sufferer is observed through the ray in a perspective manner; the locating rack is adjusted according to the position to be injected until an intersection point of the locating rack overlaps with an injection point; the injection point to be searched can be accurately obtained one time by marking on the intersection point. The cross positioning method is fast and accurate to locate; redundant operations for locating a plurality of times and the pain of the sufferer caused by the redundant operations are avoided; the rubber layers coated outside the thin metal pins are large in friction force, so that the locating rack can be prevented from sliding on the body of the sufferer in the locating process. Thus, locating is more accurate; the material for fabricating the locating rack is low in cost; the cross positioning method is convenient to popularize and use.

Owner:WUHAN UNIV

Circular cross section surface vibrating wire type strain sensor positioning clamp and precise installation tool

PendingCN107449352APositioning accuracyReduce construction costsElectrical/magnetic solid deformation measurementVibrating wireStrain sensor

The invention provides a circular cross section surface vibrating wire type strain sensor positioning clamp and a precise installation tool. The precise installation tool includes a rhombic stretchable net and a plurality of installation clamps, the installation clamps include vertical supports made of magnetic materials and suitable for the length of strain sensors, the upper ends of the vertical supports are provided with upper supporting blocks, the upper supporting blocks are provided with upper cushion block clamping and fixing grooves for clamping and fixing cushion blocks, the lower ends of the vertical supports are provided with lower supporting blocks, and the lower supporting blocks are provided with lower cushion block clamping and fixing grooves for clamping and fixing cushion blocks. The installation clamps are transversely connected to the stretchable net at equal intervals, and each installation clamp is connected to a hinge point on the rhombic stretchable net. The circular cross section surface vibrating wire type strain sensor positioning clamp provided by the invention is rapid and accurate in positioning, and a single person can install vibrating wire type strain sensors, thereby greatly reducing construction cost, reducing risks of high-altitude complex operation, and improving installation efficiency.

Owner:BEIJING URBAN CONSTR GROUP

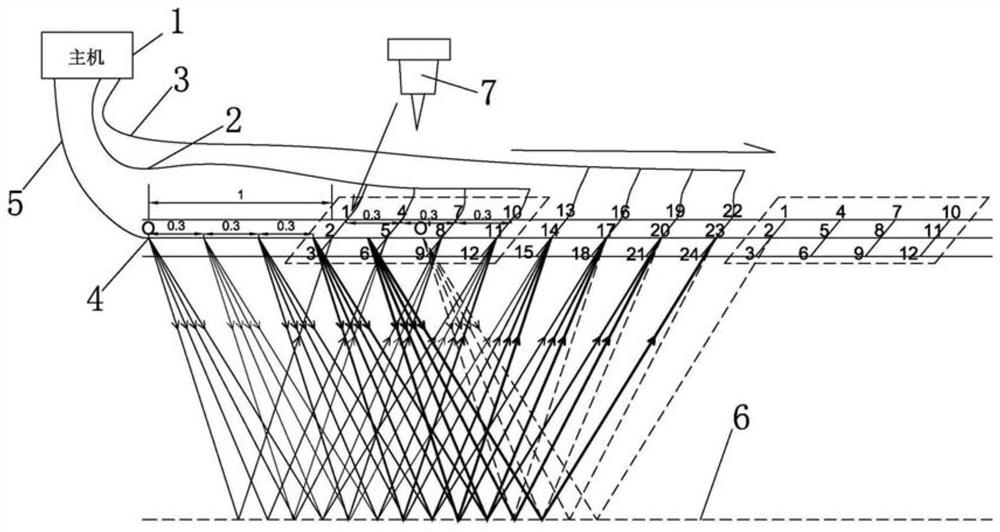

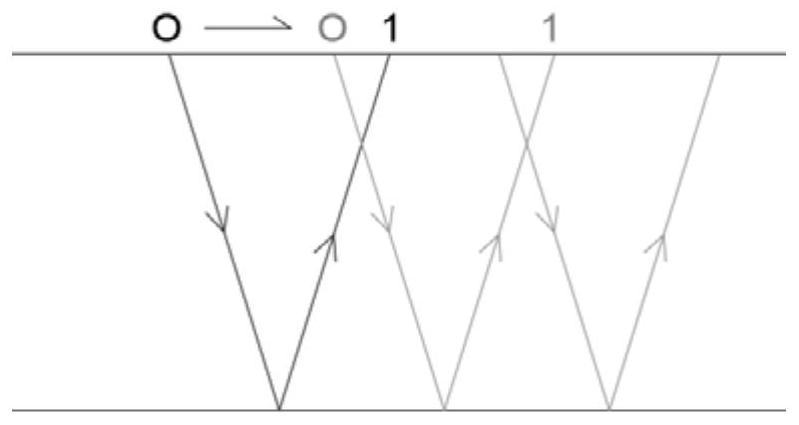

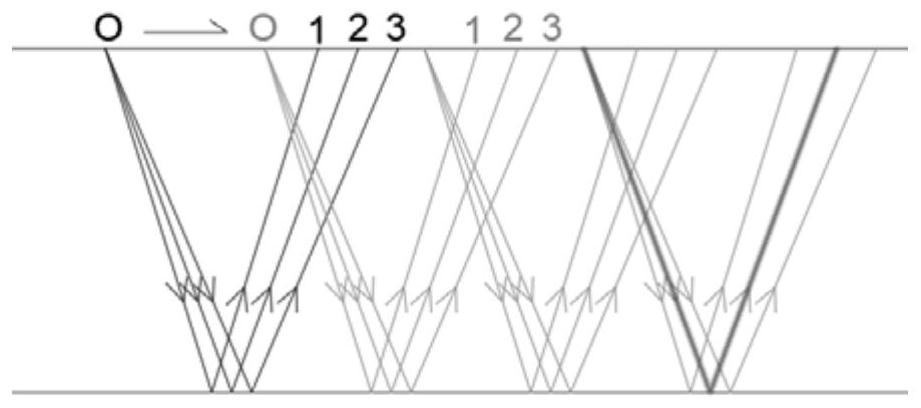

Full-arrangement seismic image observation system for positioning large drainage pipe culvert

PendingCN114152975AImprove detection efficiencyPositioning accuracySeismic signal receiversSeismic signal processingPhysicsField tests

The invention discloses a full-array seismic image observation system for positioning a large drainage pipe culvert. The full-array seismic image observation system comprises a seismic image detection measuring line arranged on the ground surface above the drainage pipe culvert; the vibration source is arranged at the vibration excitation point; a plurality of detectors arranged at detection points; wherein all the detectors are equally divided into at least two groups along the direction of the measuring line, the positions of the detectors are alternately switched towards the extension direction of the measuring line in the detection process, and a detector rectangular array is formed on a seismic mapping plane; a plurality of shock excitation points arranged at intervals in the measuring line direction are preset on the earth surface above the drainage pipe culvert, and the seismic sources are sequentially located at the preset shock excitation points and gradually approach the detector distribution area. On the basis of a conventional measuring line arrangement structure, an observation system is improved, the collected data volume is increased, proper parameters can be selected without field testing, and the working efficiency is improved.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

Distributing and positioning device for wear-resistant sheets of small fans

ActiveCN102431792APositioning accuracyReduce labor loadConveyor partsEngineeringElectrical and Electronics engineering

The invention discloses a distributing and positioning device for wear-resistant sheets of small fans. The distributing and positioning device comprises a distributing hopper, a distributing block and a scraper, wherein the distributing hopper is provided with a distributing groove; the bottom of the distributing groove is provided with a through hole extending along the longitudinal direction; the distributing block is inserted into the through hole, and is arranged on the distributing groove in a relative sliding way; the upper end face of the distributing block is provided with a pluralityof positioning holes; a laser monitoring probe is arranged in each positioning hole; the distributing block is provided with two working positions; at a first working position, the upper end face of the distributing block is not higher than the bottom surface of the distributing groove; and at a second working position, the distributing block is ejected along the longitudinal direction, and the scraper can move on the upper end face of the distributing block. Due to the adoption of the structure and full-automatic equipment, positioning is accurate and rapid, and the work load of operating personnel is greatly lowered.

Owner:南通市通州区三槐机械制造有限公司

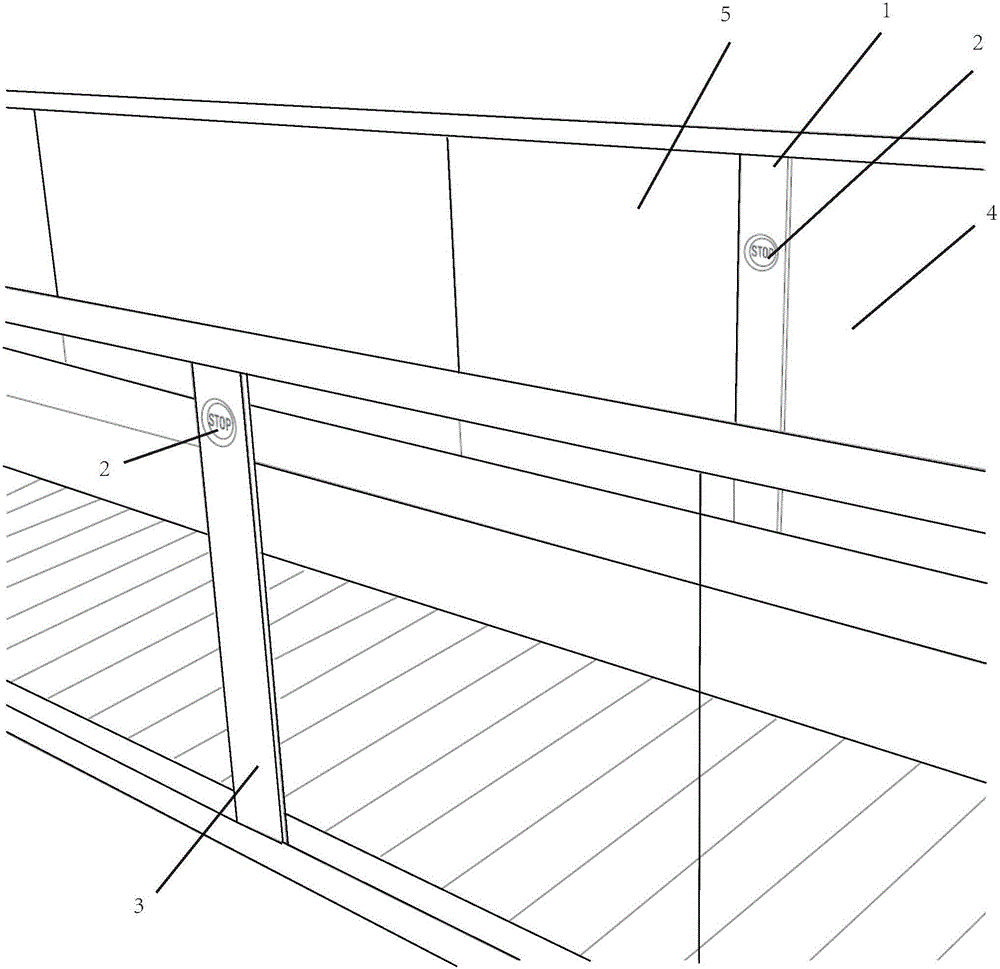

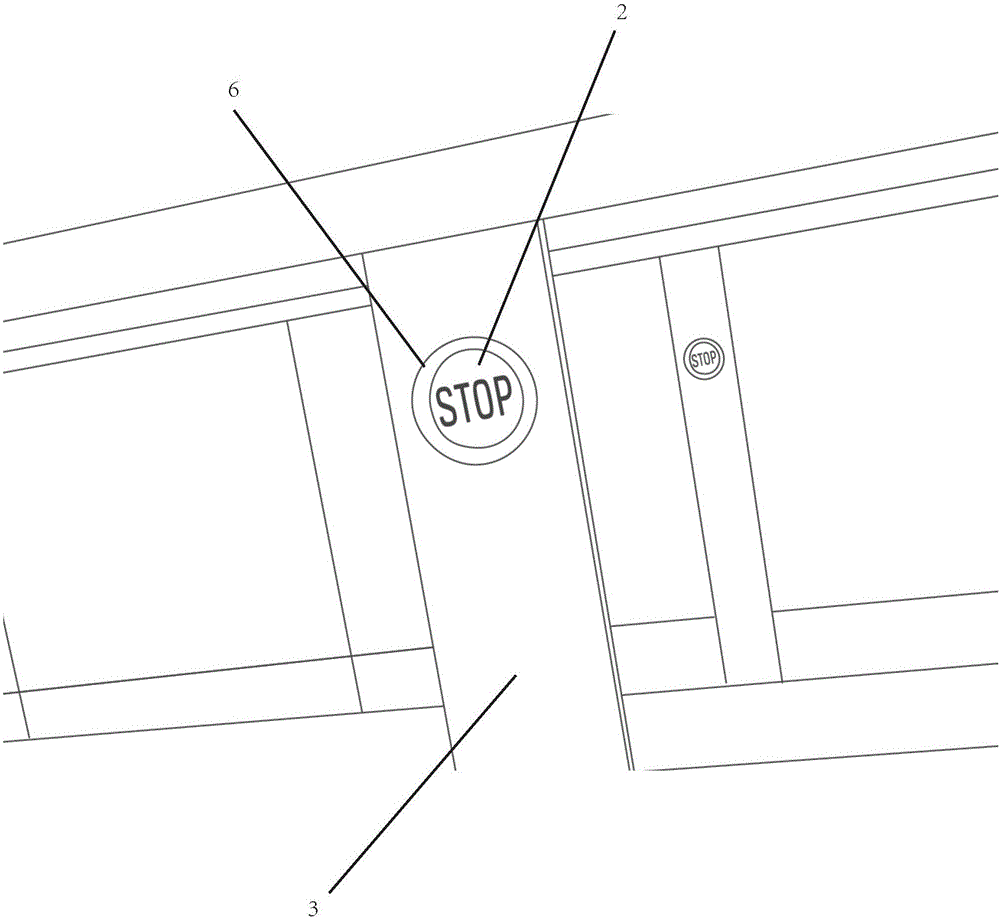

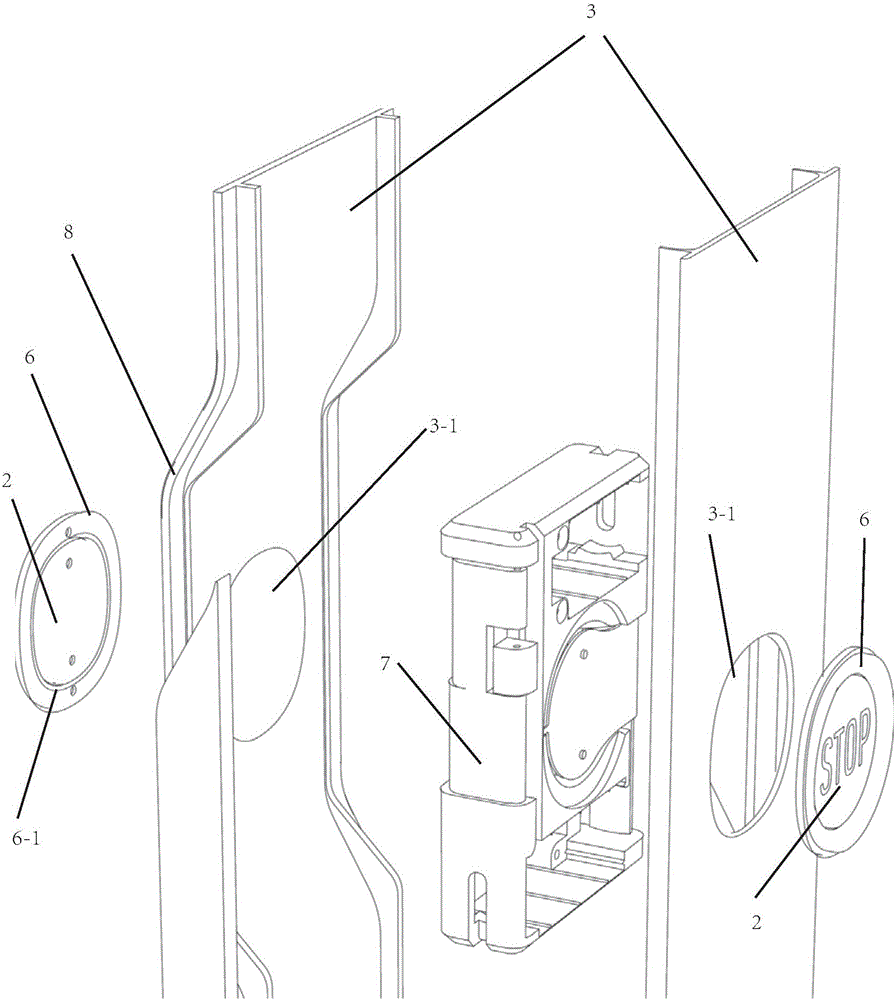

Emergent button

ActiveCN107434205APositioning accuracyAccurate discoveryControlling membersEscalatorsEngineeringMechanical engineering

Owner:KONE CORP

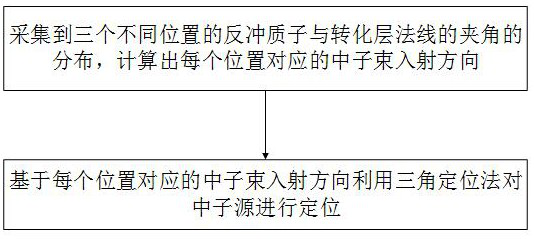

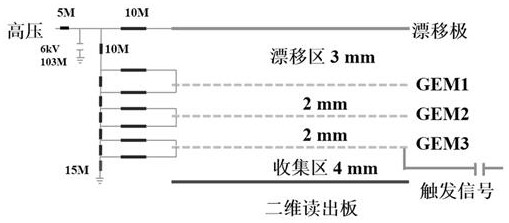

Neutron source three-dimensional positioning method and system

PendingCN112363202APositioning accuracyAvoid radiationNeutron radiation measurementNuclear engineeringGas electron multiplier

The invention discloses a neutron source three-dimensional positioning method and system. The method comprises the steps: employing three gas electron multipliers, placing the three gas electron multipliers at different positions, obtaining the distribution of included angles between recoil protons collected by each gas electron multiplier and the normal line of a conversion layer during the three-dimensional positioning of a neutron source, amplifying the signals acquired by the three gas electron multipliers by using an integrated pre-amplifier, and calculating the incident direction of a neutron beam corresponding to each gas electron multiplier by using a processor; and positioning the neutron source by using a triangulation method based on the incident directions of the neutron beamscorresponding to the three gas electron multipliers. According to the invention, rapid and accurate positioning of the neutron source is realized, so that a worker can rapidly find the neutron source,and the worker can be effectively prevented from being subjected to excessive radiation in the neutron source finding process.

Owner:CHONGQING JIANAN INSTR

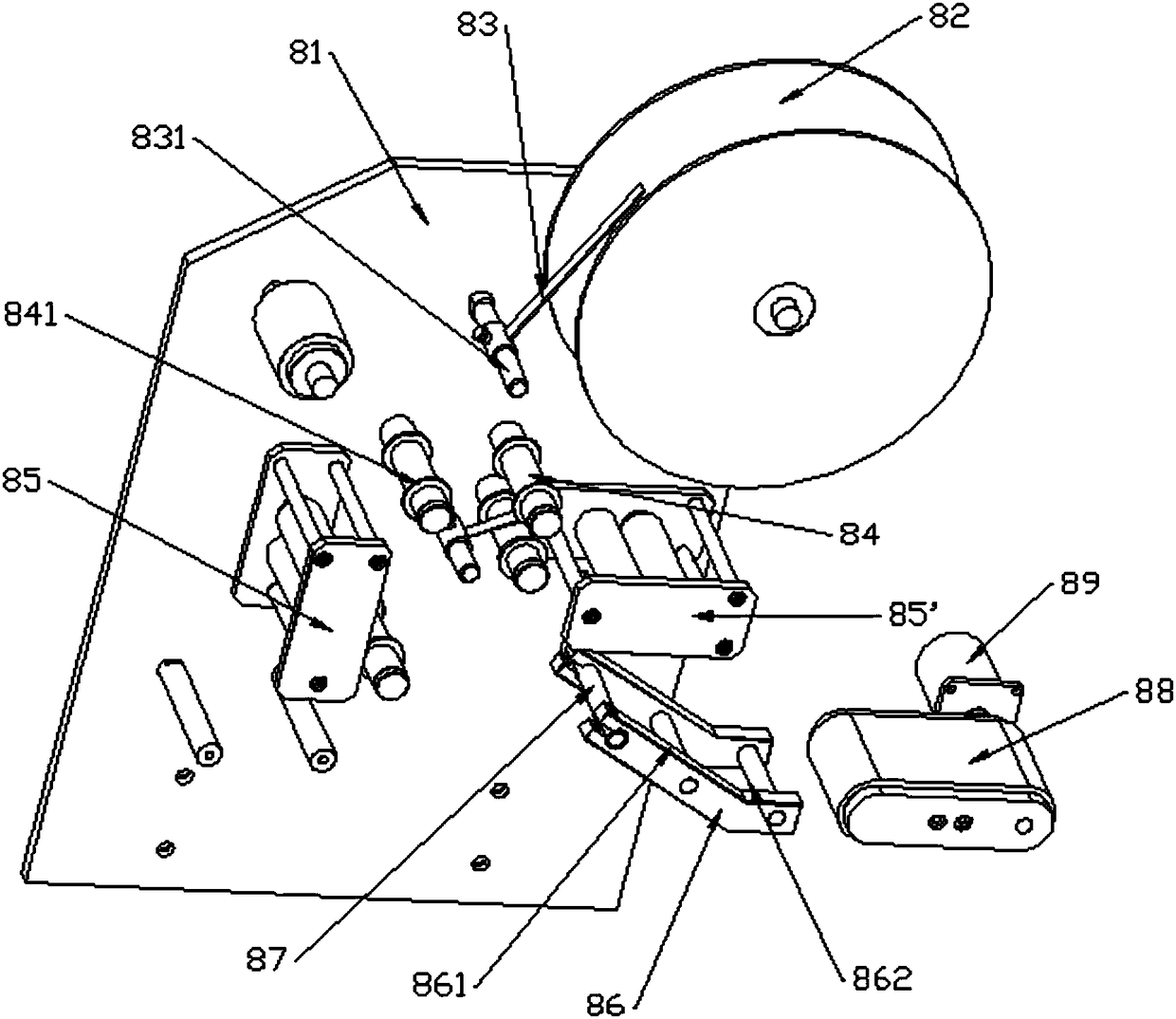

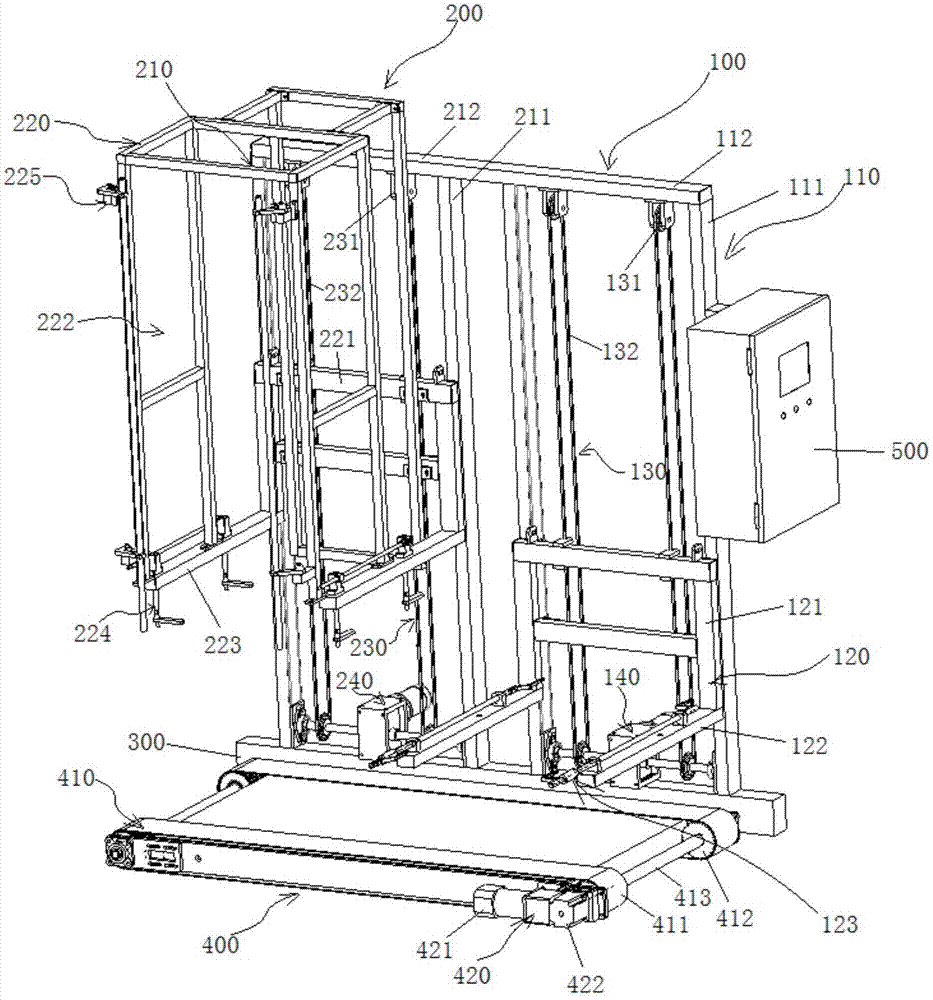

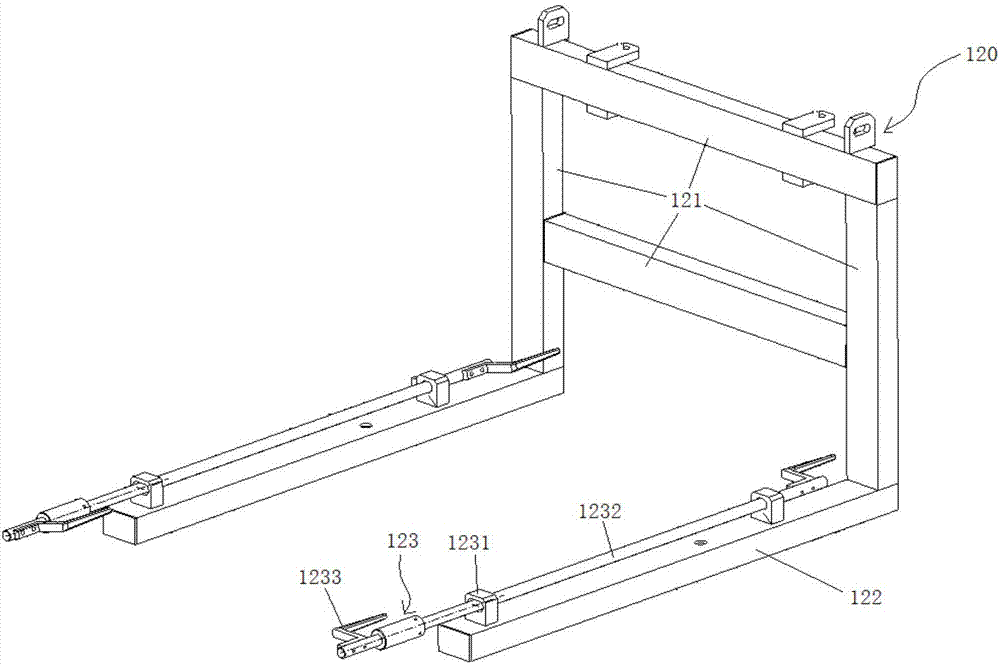

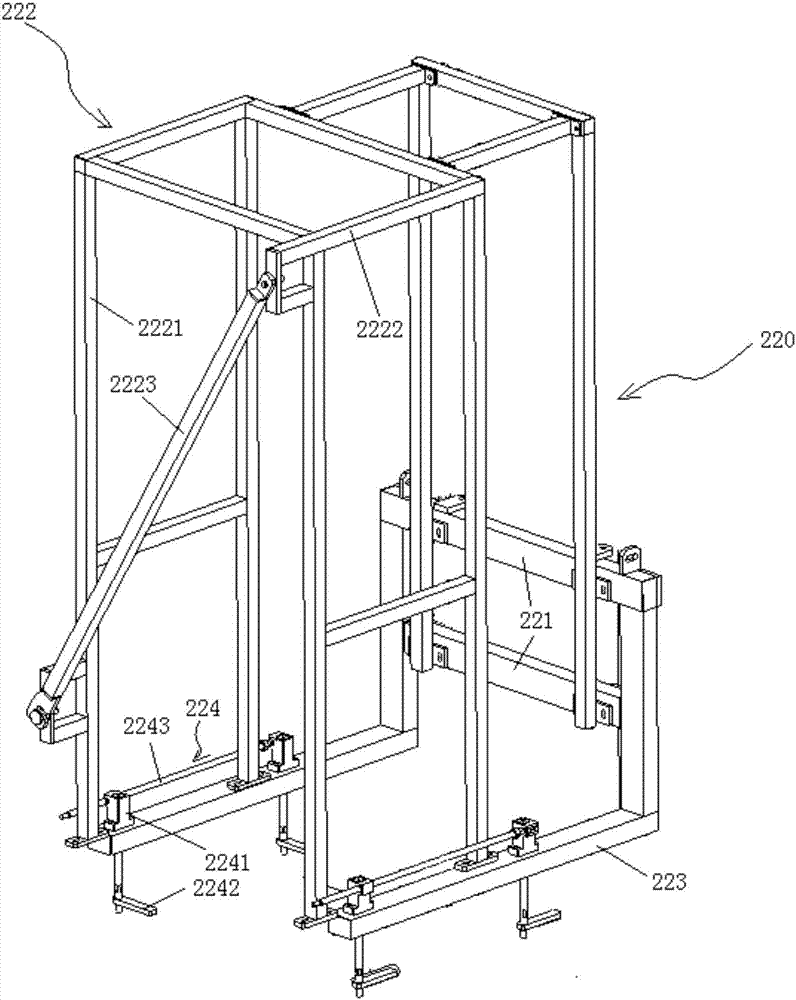

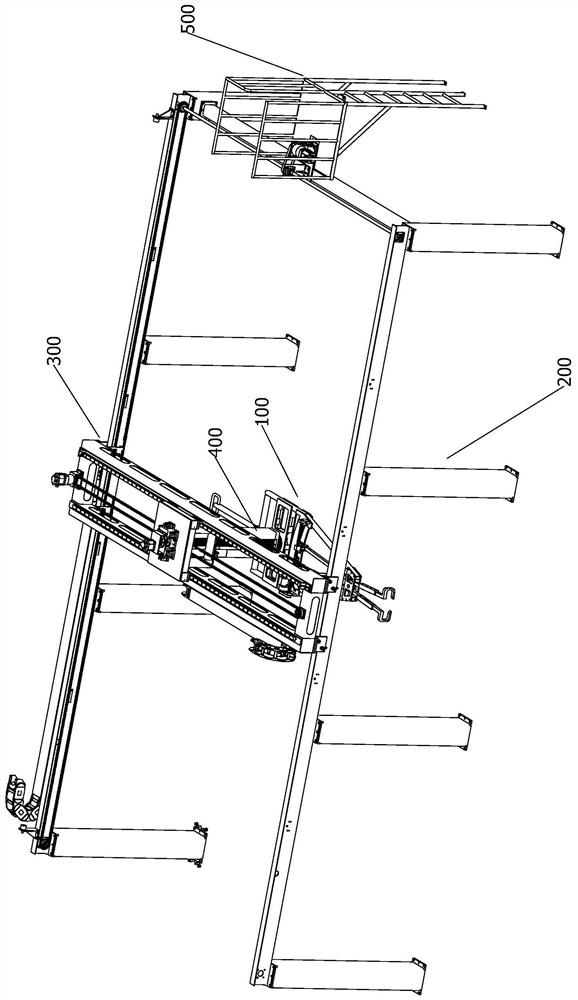

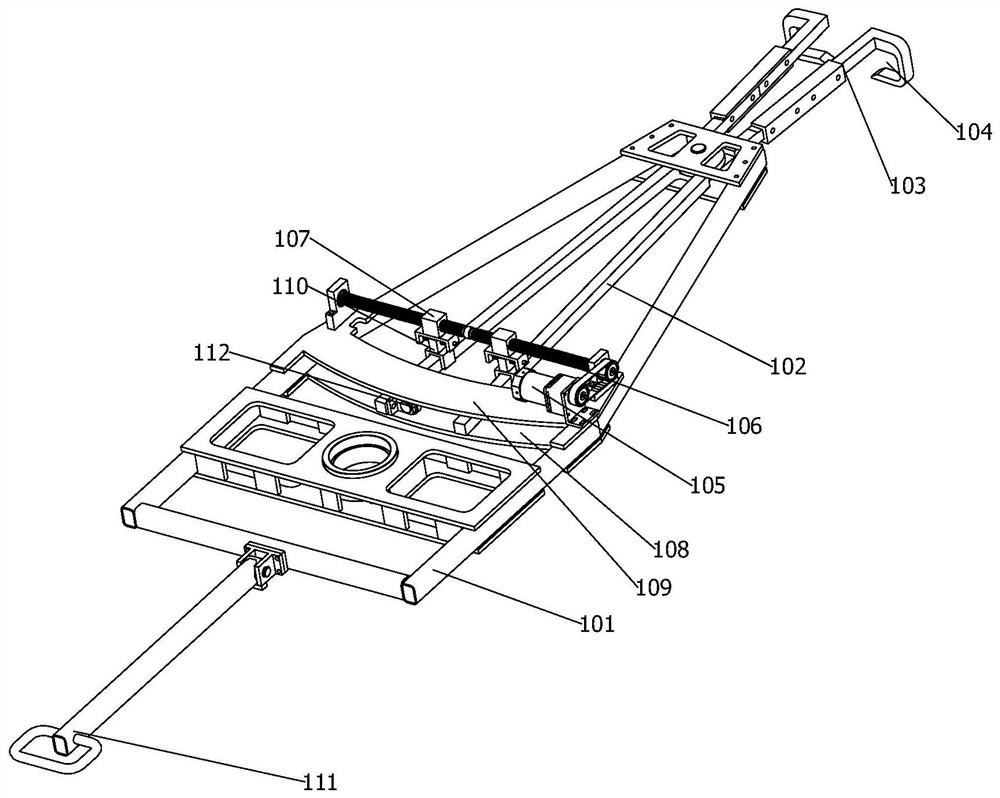

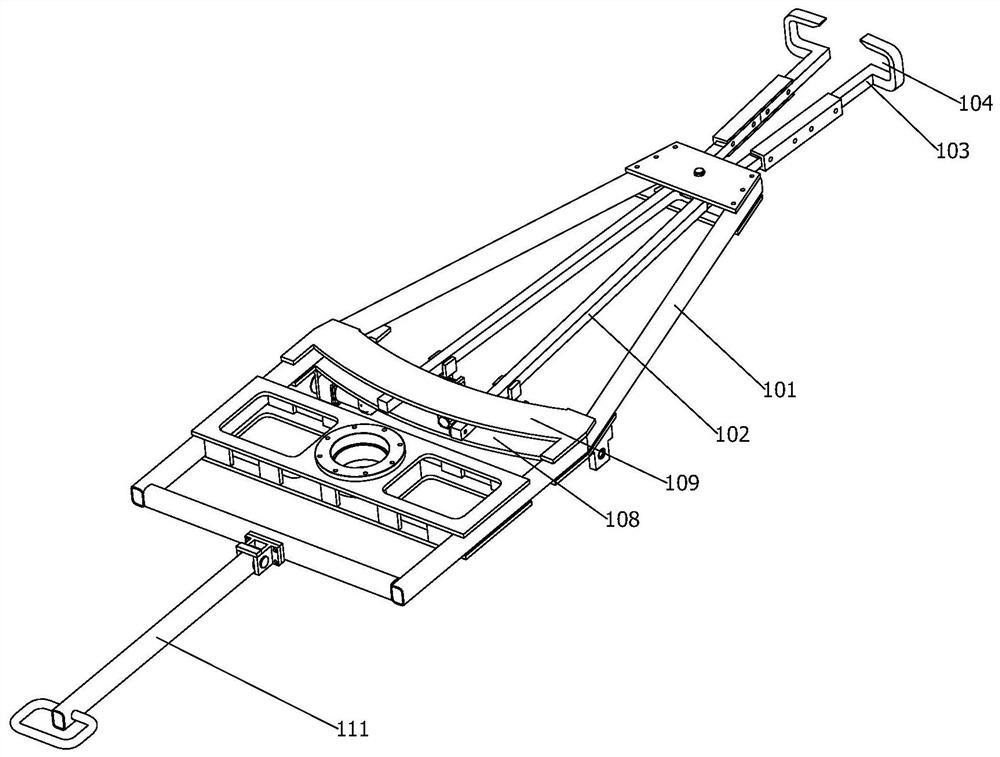

Transverse double-station semi-automatic stacking machine

PendingCN107473136AEasy accessPositioning accuracyLifting devicesAutomotive engineeringLogistics management

The invention relates to a transverse double-station semi-automatic stacking machine which comprises a logistics unit loading and unloading station (100), a chassis accessing station (200) and a base (300), wherein the logistics unit loading and unloading station (100) and the chassis accessing station (200) are transversely arranged on the base (300) in parallel; and an electric transmission platform (400) is further arranged on the base (300) and movably positions a logistics unit chassis (50) on the logistics unit loading and unloading station (100) or the chassis accessing station (200). The transverse double-station semi-automatic stacking machine can conveniently and rapidly transfer logistics units, and the chassis accessing station is arranged to enable access of the logistics unit chassis to be convenient, so that the situation that the chassis is looked for everywhere when the logistics unit chassis is needed is avoided.

Owner:GUANGDONG SUNWILL PRECISING PLASITC CO LTD

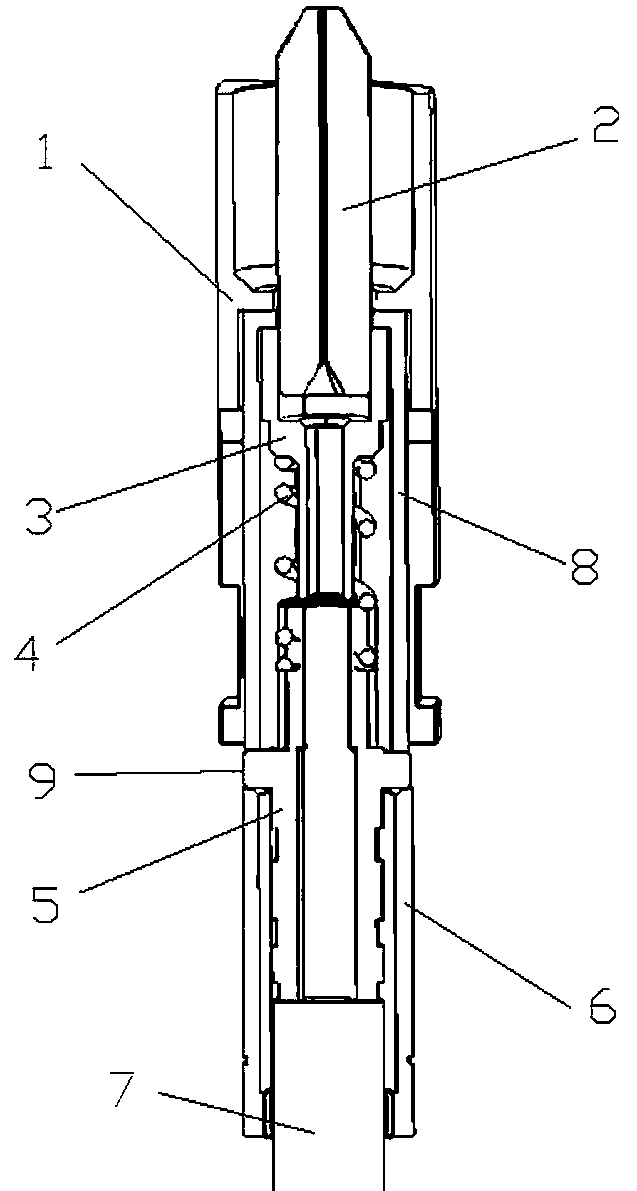

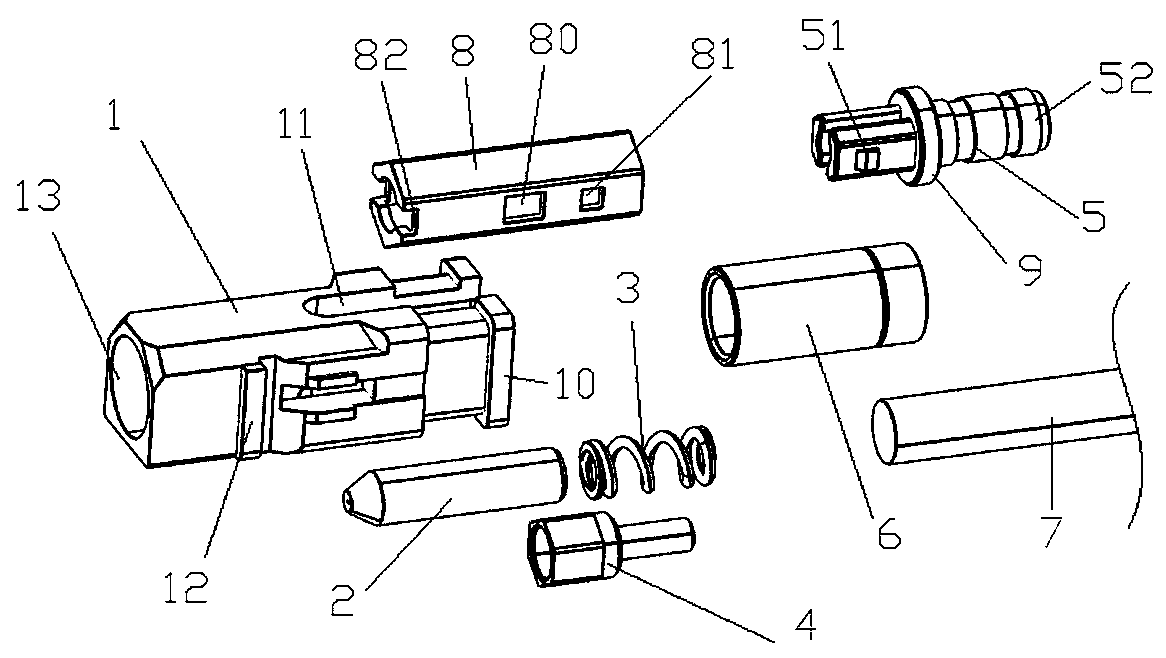

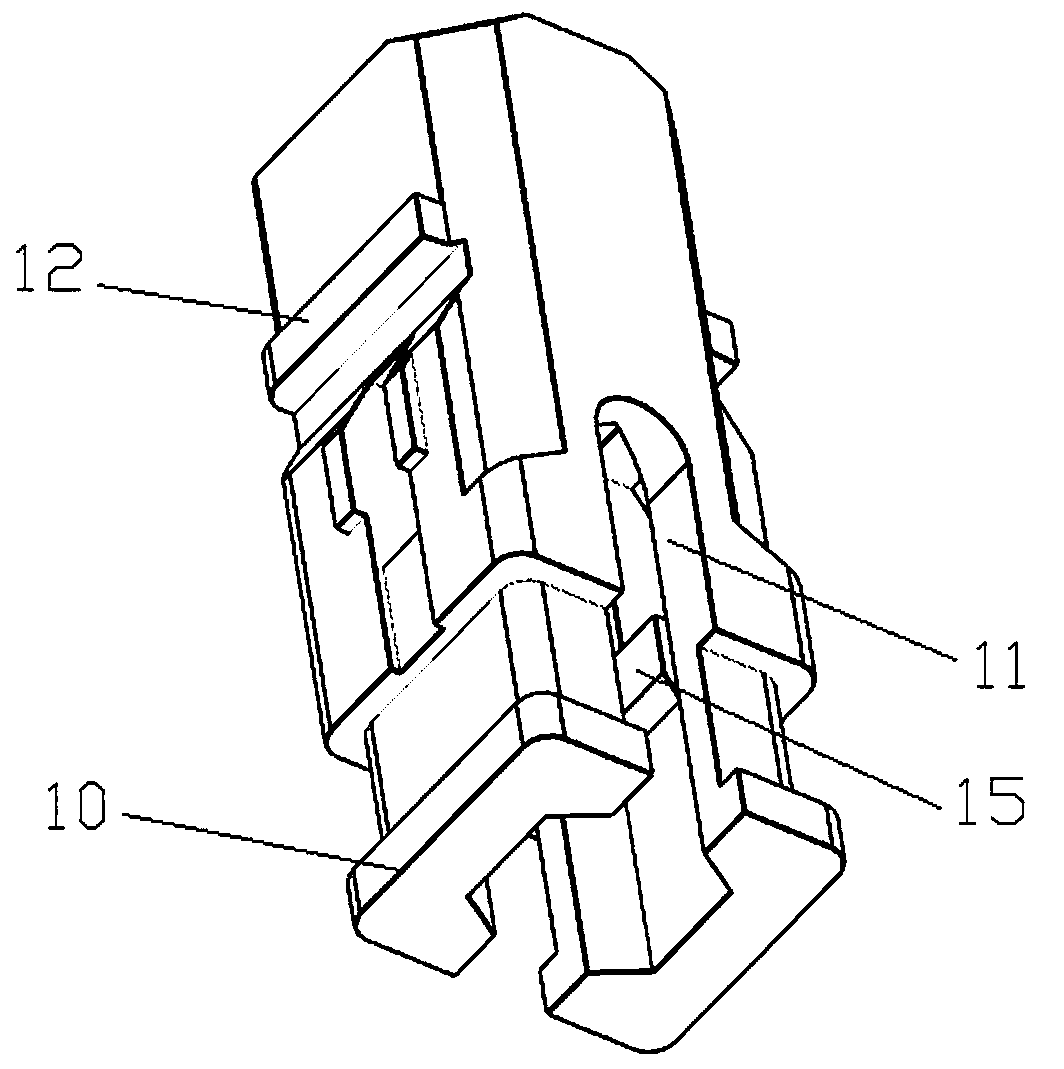

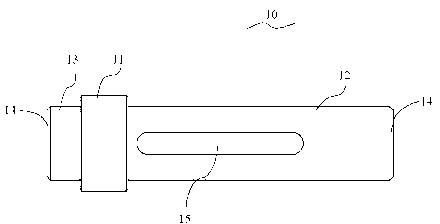

SC pre-assembled connector

PendingCN111580223ACompact and reliablePositioning accuracyCoupling light guidesPhysicsCore (optical fiber)

The invention relates to an SC pre-assembled connector. The device comprises a white inner core, an insertion core, a tail handle, a spring, a supporting tube, a tail ring and a tail tube, the tail end of the insertion core is arranged in the tail handle; the lower end of the tail handle is inserted into the spring; the other end of the spring is fixed in the supporting pipe; the other end of thesupporting pipe is sleeved in the tail ring; the lower end of the tail ring is connected with the tail pipe; the outer sides of the tail handle, the spring and the supporting pipe are sleeved with a positioning sleeve; the outer contour of the section of the positioning sleeve is polygonal; the white inner core is arranged on the outer side of the positioning sleeve in a sleeving manner; the outline of an inner cavity of the white inner core is matched with the outer outline of the positioning sleeve; the structure of the white inner core and the structure of the internal plug adopt an ingenious polygonal outline and buckle matching form, so that positioning and combination are very convenient, the size is smaller due to the compact structure, arrangement and installation of an optical fiber line become efficient and quick, and upgrading and updating of a 5G communication facility are facilitated.

Owner:惠州市飞博康实业有限公司

Second motion shaft

Owner:WUXI BAISHUN MACHINERY PLANT

Forge piece grabbing and moving equipment

PendingCN113798425APositioning accuracyLower requirementForging/hammering/pressing machinesThermal radiationReciprocating motion

The invention provides forge piece grabbing and moving equipment. The forge piece grabbing and moving equipment comprises a supporting frame, a forge piece grabbing manipulator, a lifting mechanism and a moving mechanism, the lifting mechanism is connected with the forge piece grabbing manipulator, and the lifting mechanism is used for driving the forge piece grabbing manipulator to move up and down in a reciprocating mode, the moving mechanism is arranged on the supporting frame and connected with the lifting mechanism, the forge piece is grabbed through the forge piece grabbing manipulator; the forging grabbing manipulator is driven by the lifting mechanism to reciprocate up and down, so that the height of the forging is changed; the lifting mechanism is driven by the moving mechanism to move in the horizontal direction, and therefore the forged piece can freely move in the space. When the forge piece grabbing and moving equipment is used, damage to human skin caused by heat radiation when a clamp is manually used for clamping a workpiece is avoided, accurate and rapid positioning can be achieved when the forge piece grabbing manipulator is used for clamping the forge piece, the requirement of the work for operators is lowered, the risk that workers are scalded by high temperature is lowered, efficient and safe forge piece clamping work is guaranteed, and the work efficiency is improved, and the forge piece can be produced on a large scale.

Owner:QINGHAI KANGTAI CASTING MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com