Insulation monitoring and positioning device and method for main shaft of generator

An insulation monitoring and positioning device technology, applied in the direction of motor generator testing, measuring devices, measuring electricity, etc., can solve problems such as false alarms, single measurement, monitoring and positioning of parts that cannot be insulated and reduced, and achieve timely and accurate positioning. Measuring Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

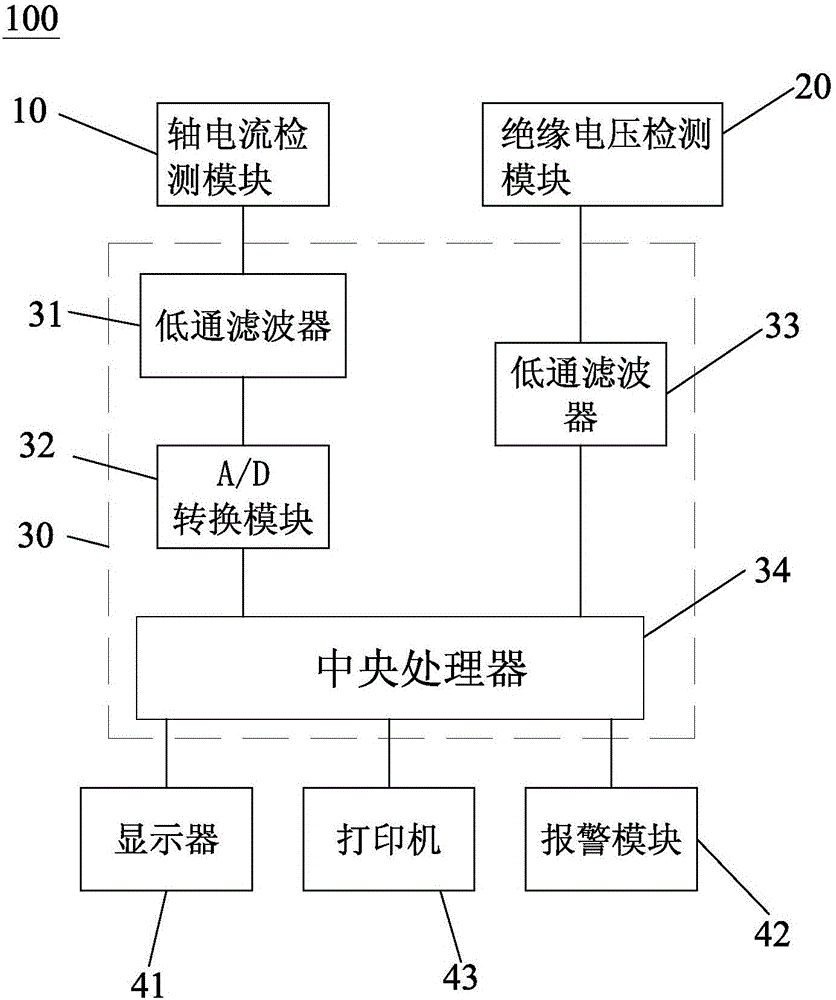

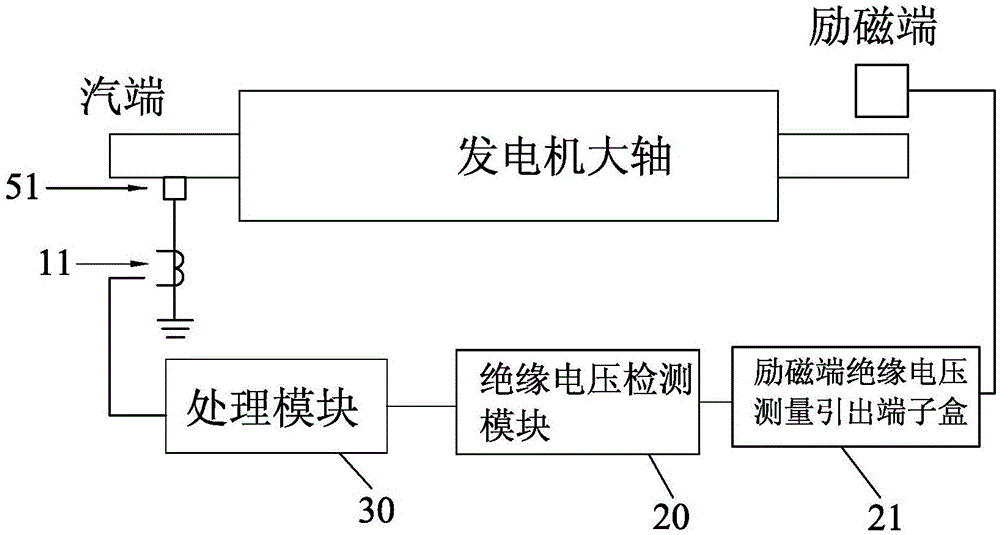

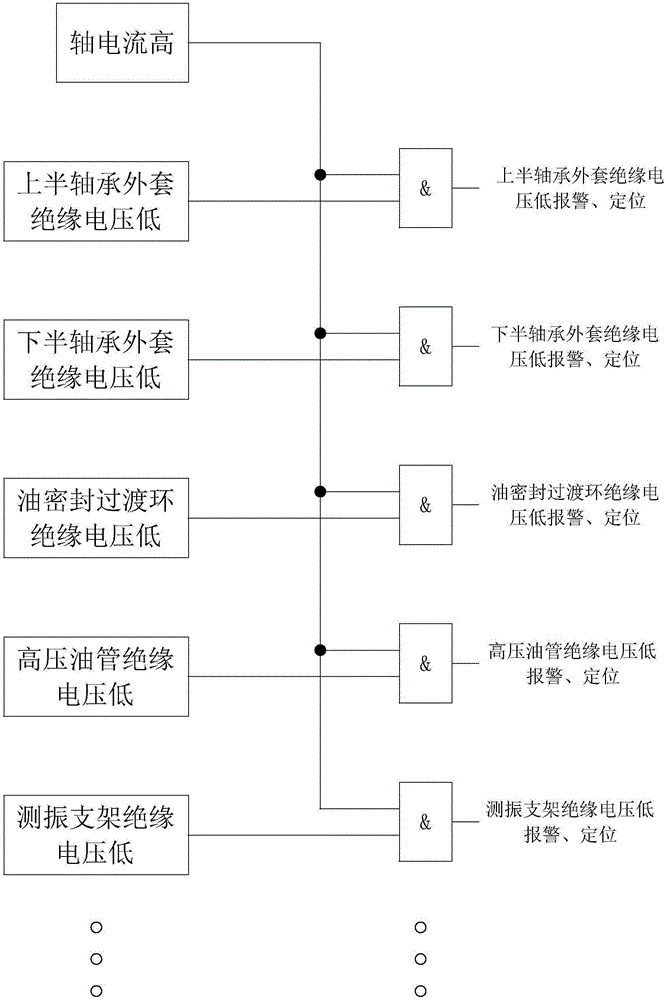

[0025] refer to figure 1 , the present invention discloses a generator shaft insulation monitoring and positioning device 100, including a shaft current detection module 10, an insulation voltage detection module 20 and a processing module 30, the shaft current detection module 10 detects the shaft of the steam end of the generator shaft current, the insulation voltage detection module 20 respectively detects the insulation voltage of several excitation ends of the main shaft of the generator to the ground insulation components, and the processing module 30 processes the shaft current and insulation voltage, and when the shaft current is high When the first preset value and any one of the insulation voltages is lower than the second preset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com