Clamp for quickly clamping and positioning cylindrical components

A positioning fixture, a cylindrical technology, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve the problems of low reuse rate of positioning holes, waste of time for positioning holes, and waste, so as to prolong the working time of the machine and shorten the working time of the machine. The effect of processing cycle and reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

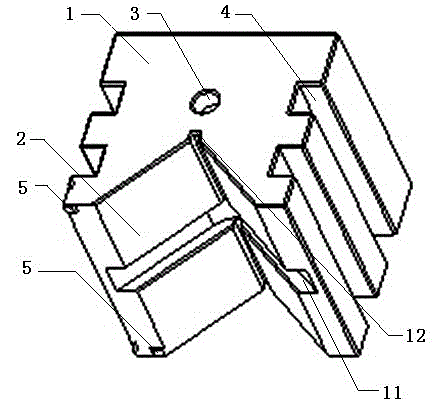

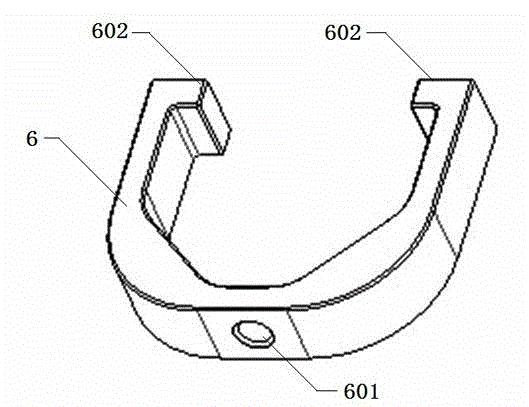

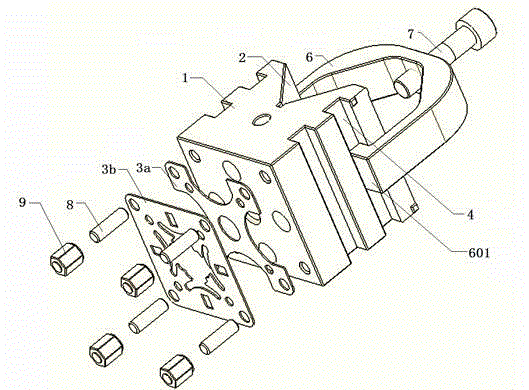

[0021] like figure 1 As shown, the front part of the main body 1 of the present invention is provided with a V-shaped positioning groove 2, the upper part is provided with a positioning hole 3, two positioning grooves 4 are respectively provided on both sides, and a group of verticality reference positioning blocks 5 are provided on the side of the main body 1 . In the V-shaped positioning groove 2, there is a workpiece hanging table avoidance groove 11. Since there are three constraints in the actual use and installation of general cylindrical parts, first, the coaxial constraint is on the outer peripheral surface; second, the axial direction Third, the rotation around the axis is constrained by the anti-rotation device. The escape groove 11 in the present invention is used to avoid the hanging platform with a thickness of 2-10mm, and can simultaneously clamp two ide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com