Welding device for lower end plug of guide pipe of pressurized water reactor nuclear power fuel assembly

A fuel assembly and welding device technology, applied in the direction of electrode support devices, welding equipment, arc welding equipment, etc., to meet the process requirements, easy to observe, fast and accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

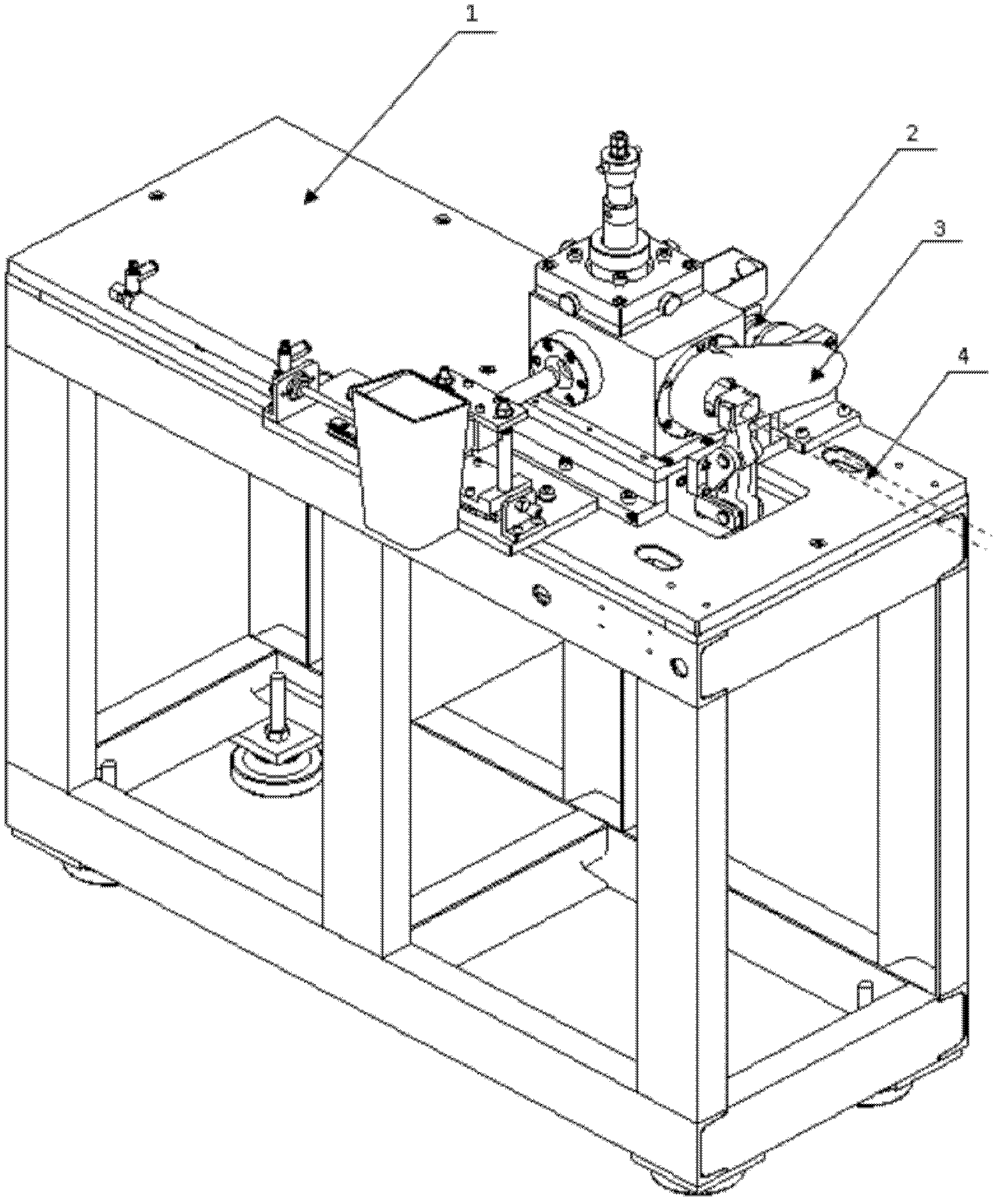

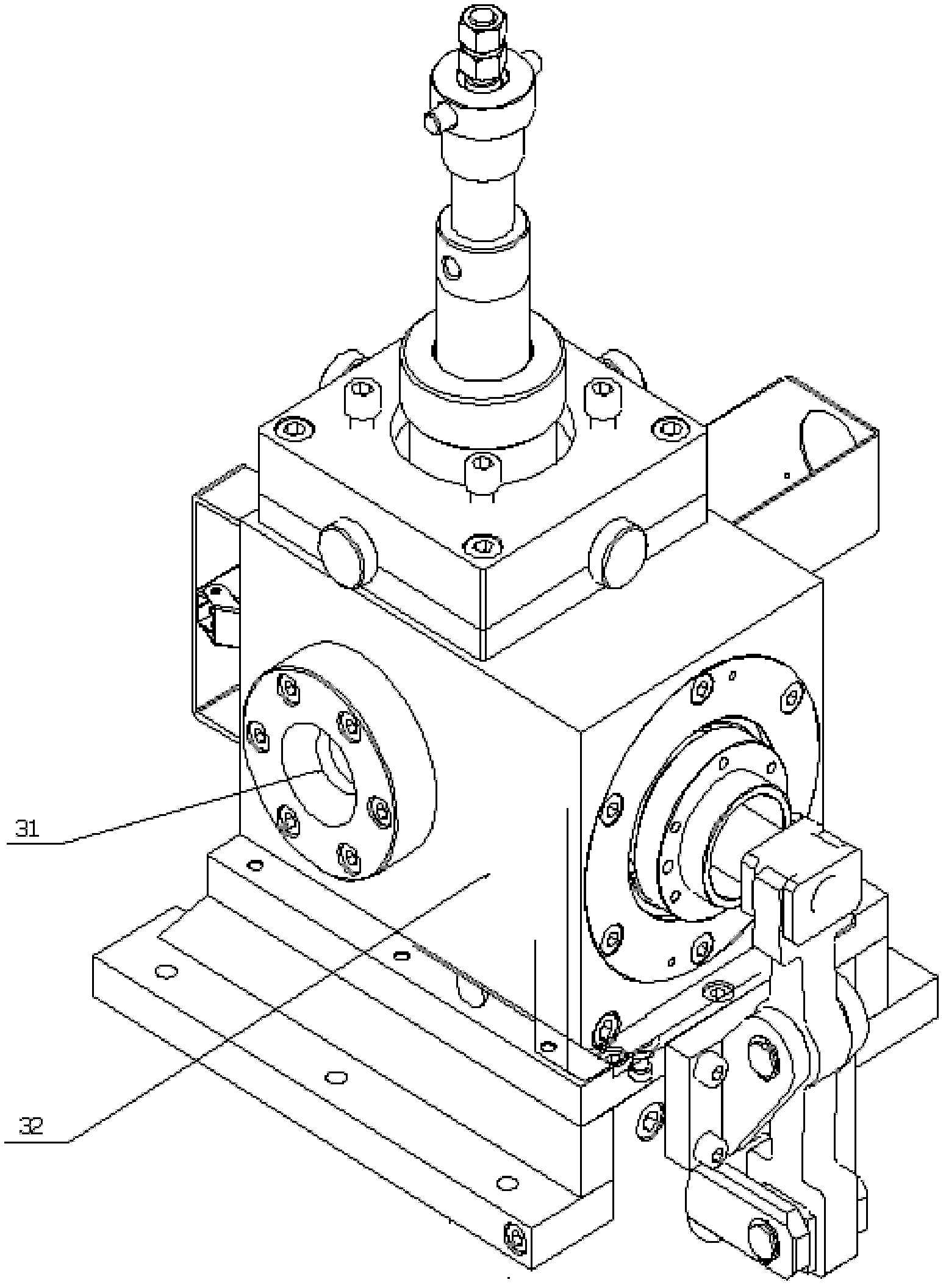

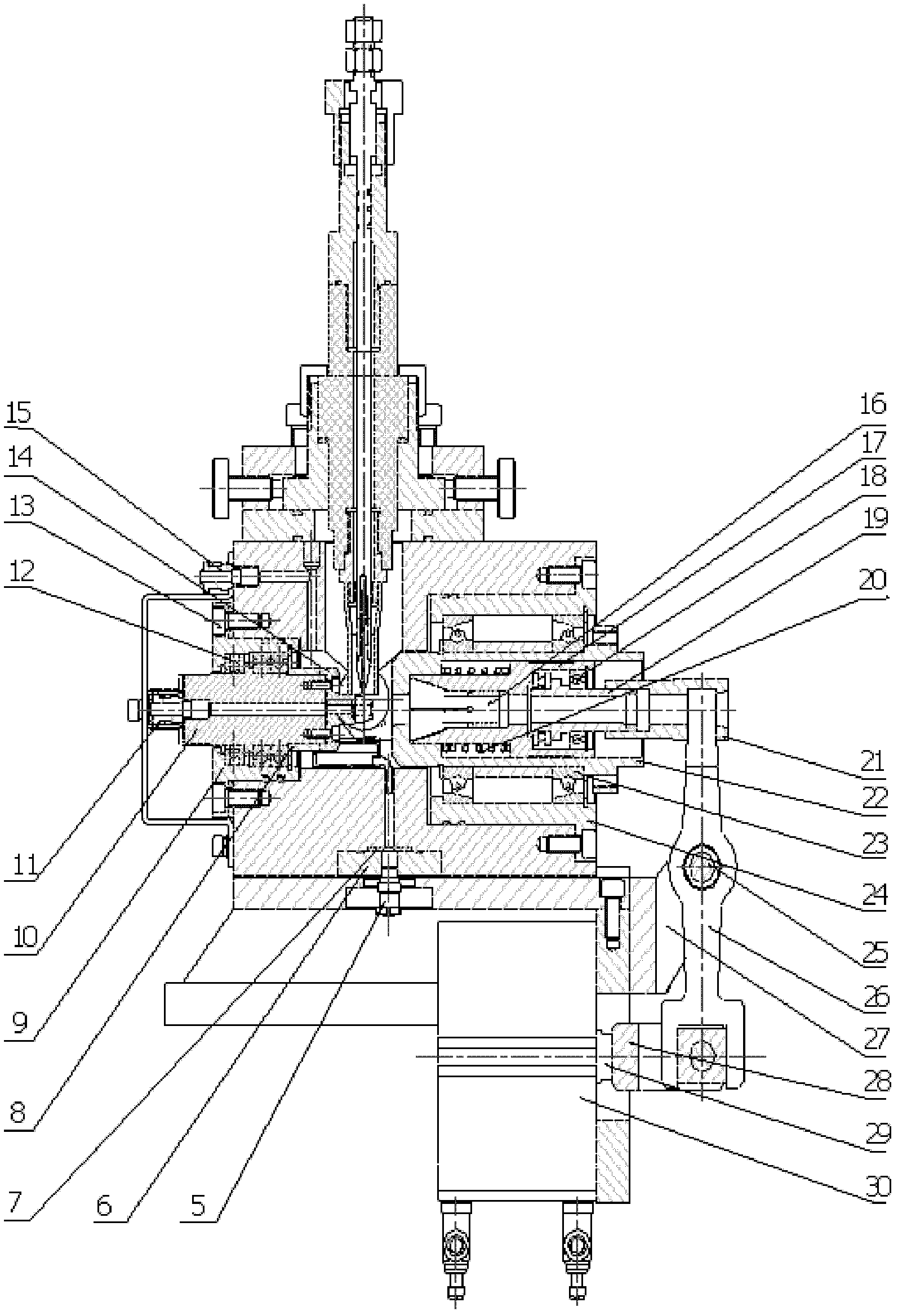

[0025] like Figure 1~6As shown, a welding device for the lower end plug of the guide tube of the PWR nuclear power fuel assembly, the device includes a workbench 1, a welding chamber part, a rotating mechanism and an optical projection imaging system, and the welding chamber part includes a welding chamber 32, a welding torch adjustment mechanism, an end Plug follower mechanism and clamping mechanism, wherein, the welding chamber 32 is a square shell structure with interconnected cavities on the side wall and the upper end, and a welding torch adjustment mechanism is installed in the cavity at the upper end of the welding chamber 32, and the welding chamber 32 side The wall is equipped with a sight glass 31 that can observe the inside of the welding chamber 32, and an end plug follower mechanism and a clamping mechanism are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com