Special boring clamp

A technology for boring fixtures and bushing holes, which is used in clamping, manufacturing tools, drilling dies for workpieces, etc., can solve the problems of dislocation of processing and clamping and high processing scrap rate, achieve accurate and rapid positioning, and reduce scrap rate. , The effect of improving the clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

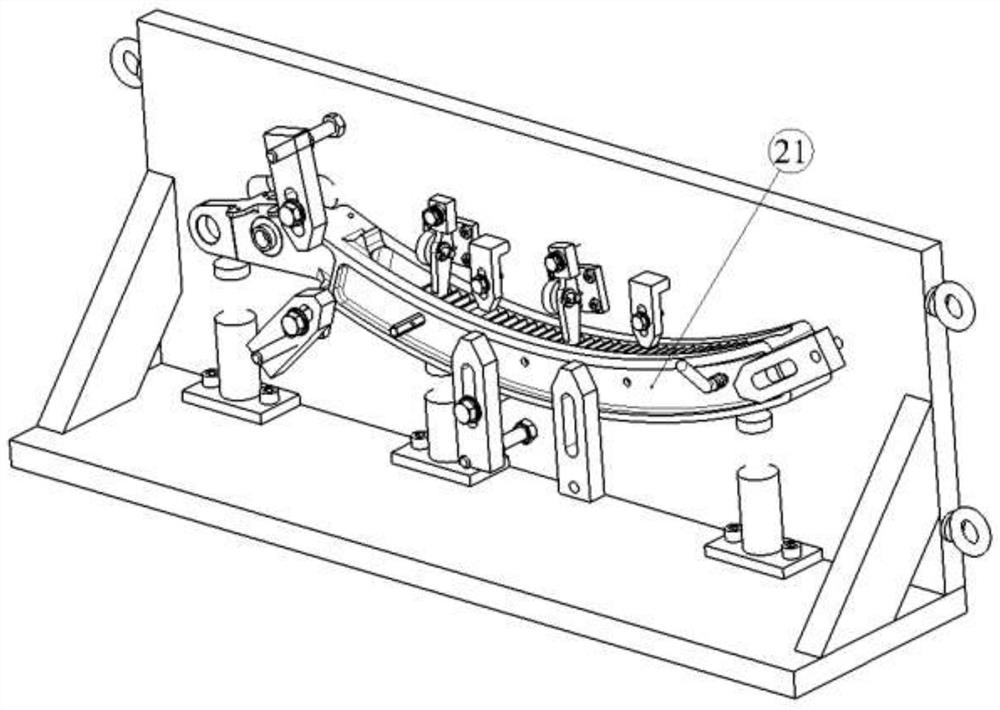

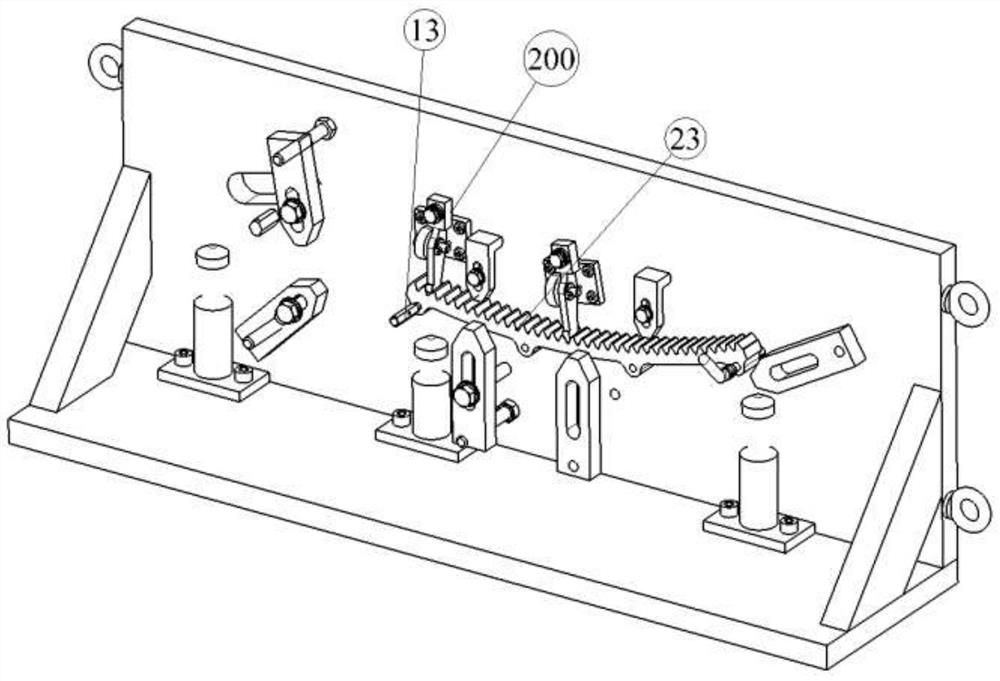

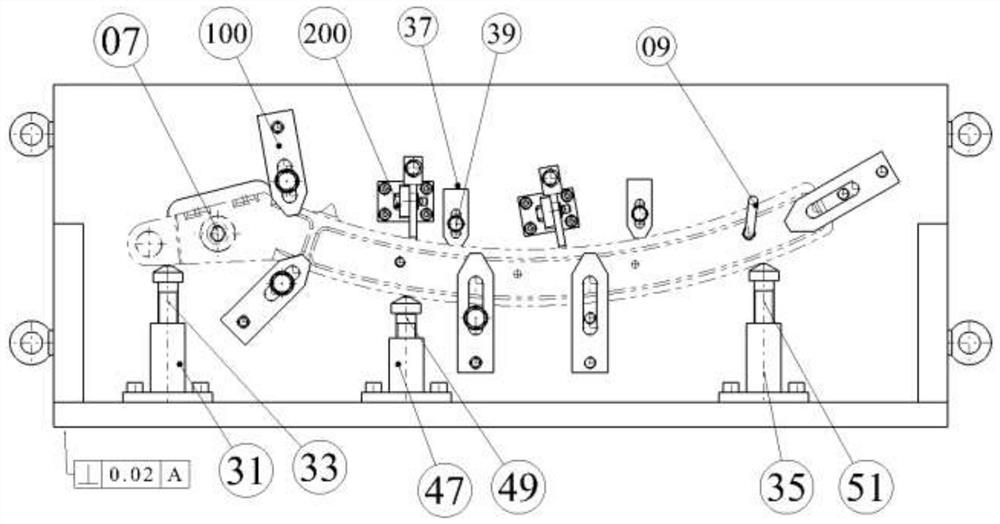

[0023] see Figure 1~9 , a special boring jig, consisting of a main positioning plate 01, a base plate 03, a reinforcing plate 05, a positioning origin bushing 11, a diamond-shaped positioning pin 07, a drilling mold assembly, a first platen assembly 100, a second platen assembly, the first The jacking support assembly, the second jacking support assembly, the third jacking support assembly, and the internal rack pressing assembly 200 are composed. The main positioning plate is provided with an avoidance groove 46, the two sides of the main positioning plate are provided with eyebolt bottom holes, and four eyebolts 29 are fixedly installed on both sides of the main positioning plate, which is convenient for hoisting. The hole jig is heavy in weight. The two planes of the main positioning plate are ground and processed to ensure the parallelism within 0.02. The main positioning plate is vertically installed on the bottom plate through the screw pin structure, and the two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com