Plastering and trough-pulling construction method of face brick wall surface and pull trough plate

A construction method and grooving technology, which are applied in covering/lining, construction, building structure, etc., can solve the problems of hollowing, falling off, and unsatisfactory construction methods of the facing brick wall, so as to prevent hollowing and facilitate construction. , Guarantee the effect of pasting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

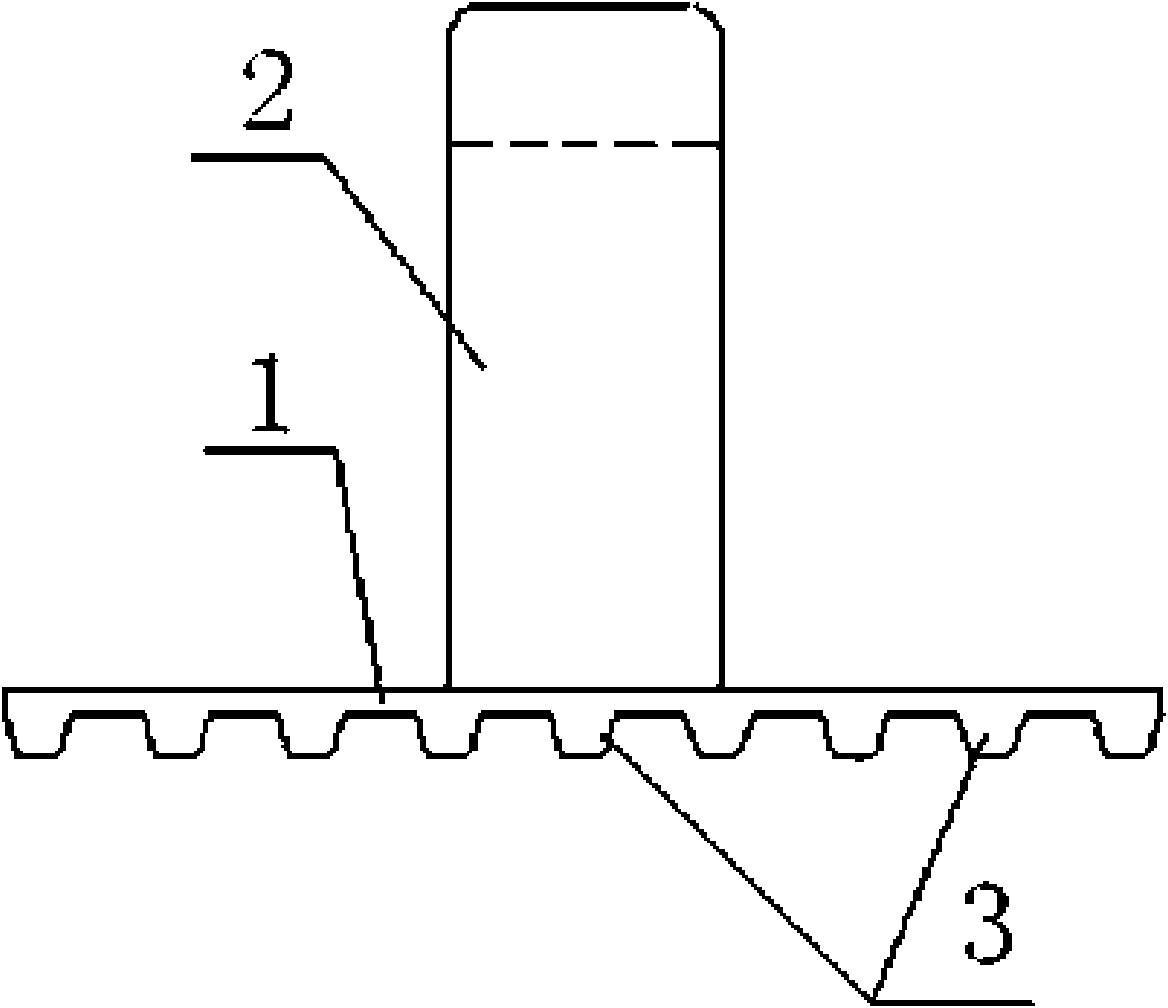

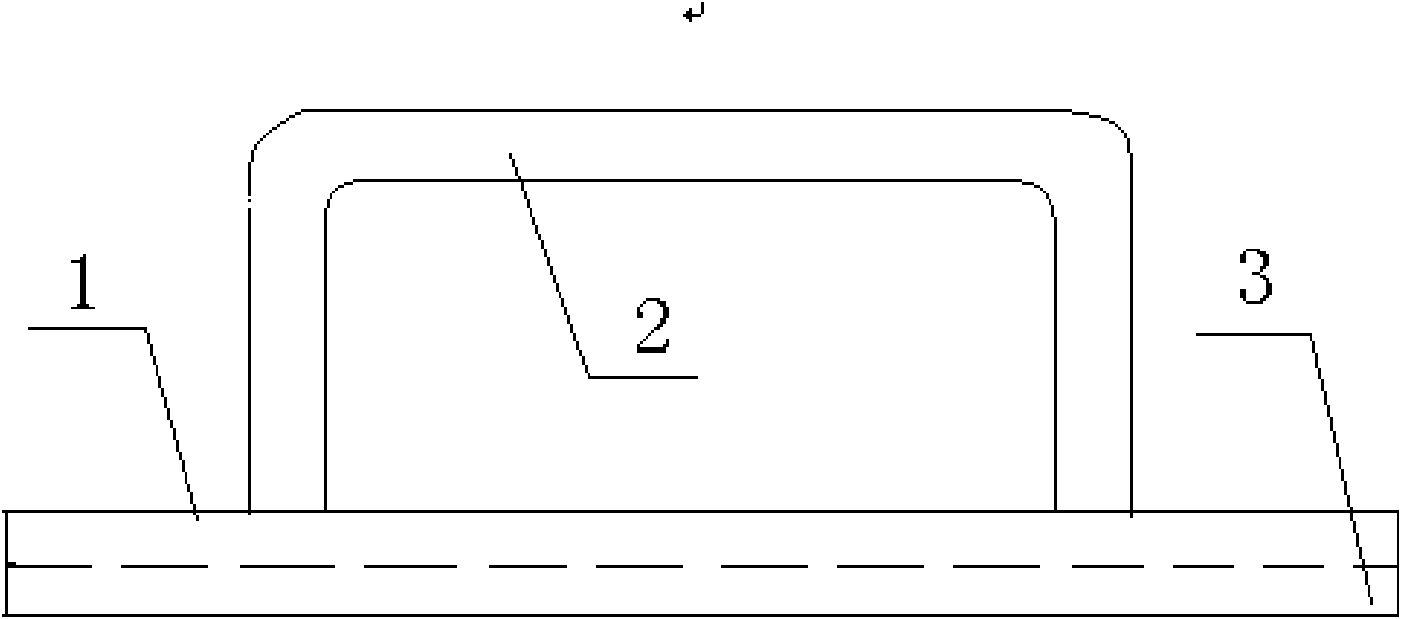

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

[0018] Embodiments of the present invention: when pasting facing bricks, first adopt a plastering groove construction method for facing brick walls of the present invention to process the wall surface, that is, for a wall surface where the base layer is a concrete surface or a ceramsite hollow brick, press The following methods are used to construct the wall surface that needs to be pasted with facing bricks:

[0019] 1) Basic treatment, that is, clean the wall surface, then brush and shake a layer of cement mortar layer with interface adhesive on the wall surface, and make the cement mortar layer solidify on the wall surface, and the interface adhesive agent and cement mortar layer The cement in the medium, the volume ratio ratio of sand are controlled by interface adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com