Gear pair for a helical gear transmission, helical gear transmission with such a gear pairing and use of such a gear pair in spur gear transmissions

A transmission, helical gear technology, applied in the field of gear pairs, to achieve the effect of reducing the risk of jamming, increasing wear, noise formation and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

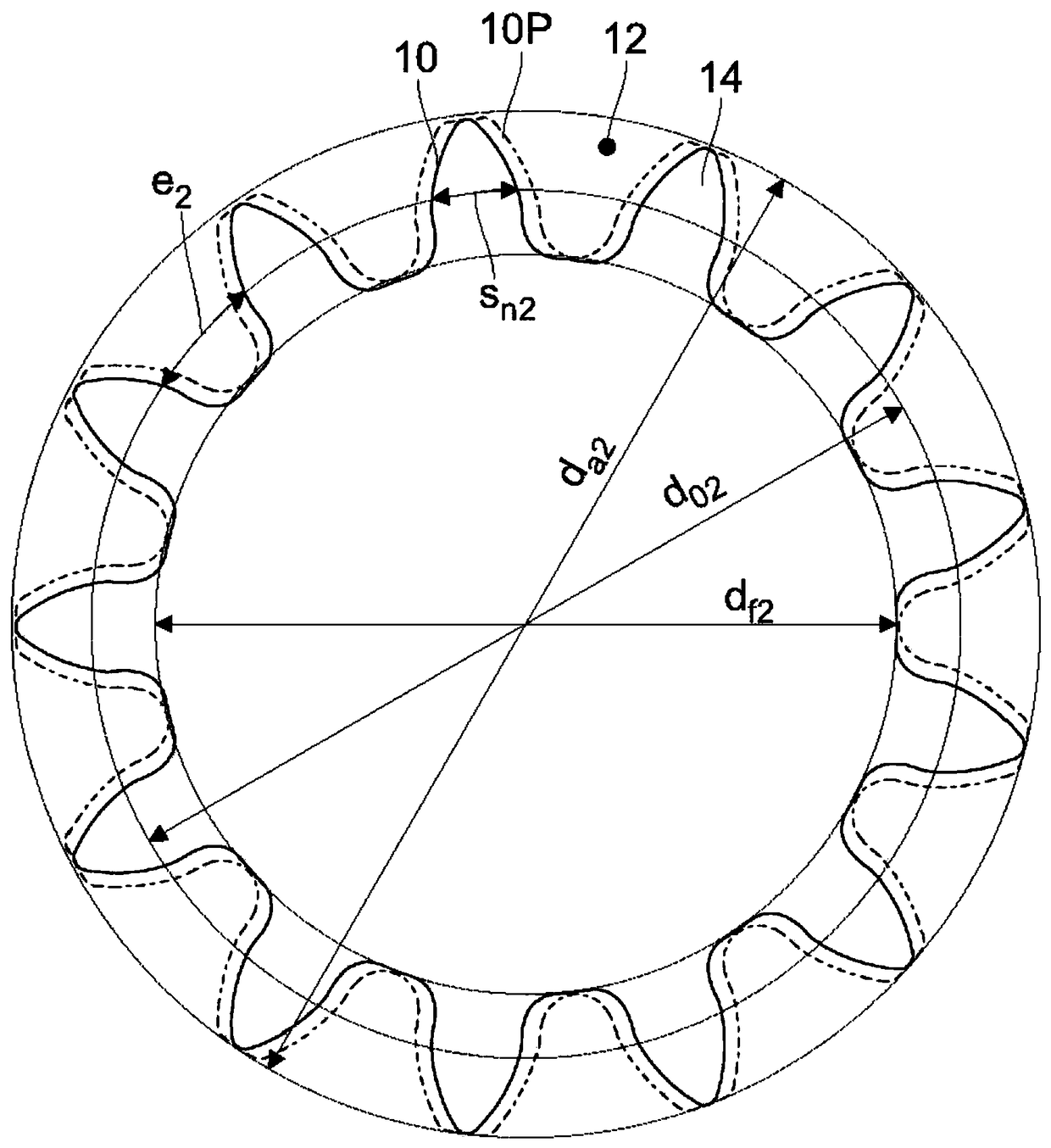

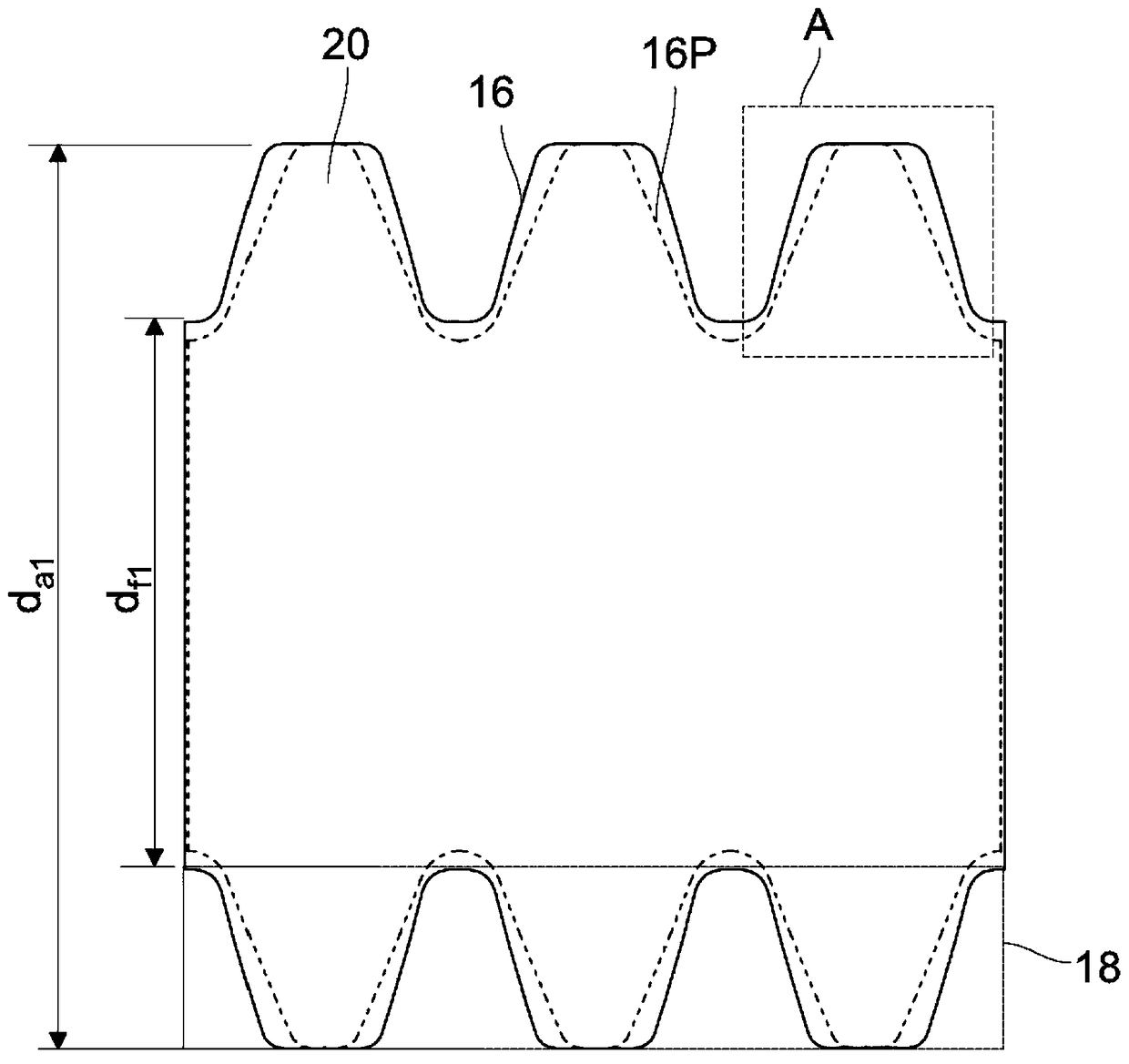

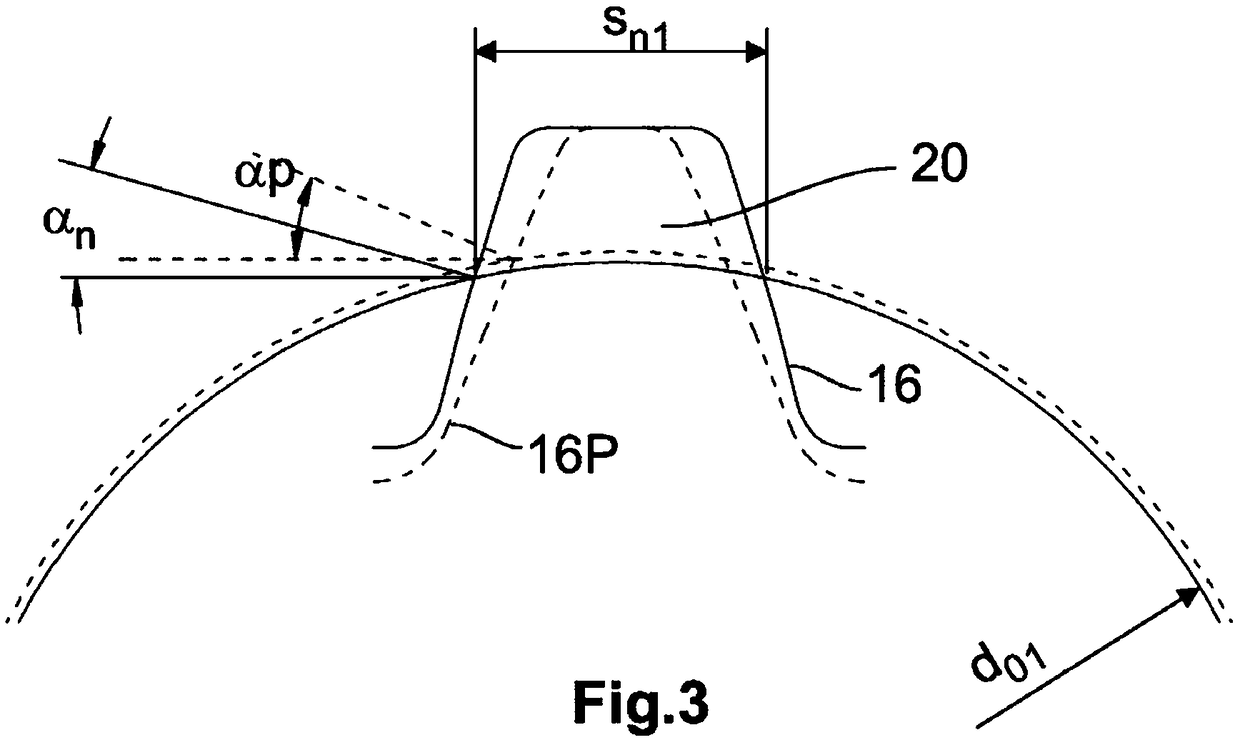

[0030] exist figure 1 A cross-sectional view of a helical gear 10 according to an embodiment of the present invention compared with a helical gear 10P based on a reference tooth profile is shown in . Here, the solid line indicates the helical gear 10 according to the present invention, and the broken line indicates the helical gear 10P, which has been mass-produced by the present applicant.

[0031] The helical gear 10 shown is entirely made of metal. The helical gear 10 has a first toothing section 12 in which a plurality of teeth 14 are located. The radial inner side of the first toothing section 12 has a root circle diameter d f2 The dedendum circle is delimited, while the radially outer side of the first toothing section 12 is defined by a dedendum circle diameter d a2 The addendum circle is defined by .

[0032] Furthermore, the teeth 14 of the helical gear 10 have a normal tooth thickness s n2 , the normal tooth thickness s n2 Indicates that the teeth 14 of the hel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com