A lithium ion battery Z-shaped laminating device and process thereof

A lithium-ion battery and lamination technology, which is applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of high purchase and maintenance costs, low efficiency, long logistics lines, etc., to save The effect of pole piece transfer device and facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

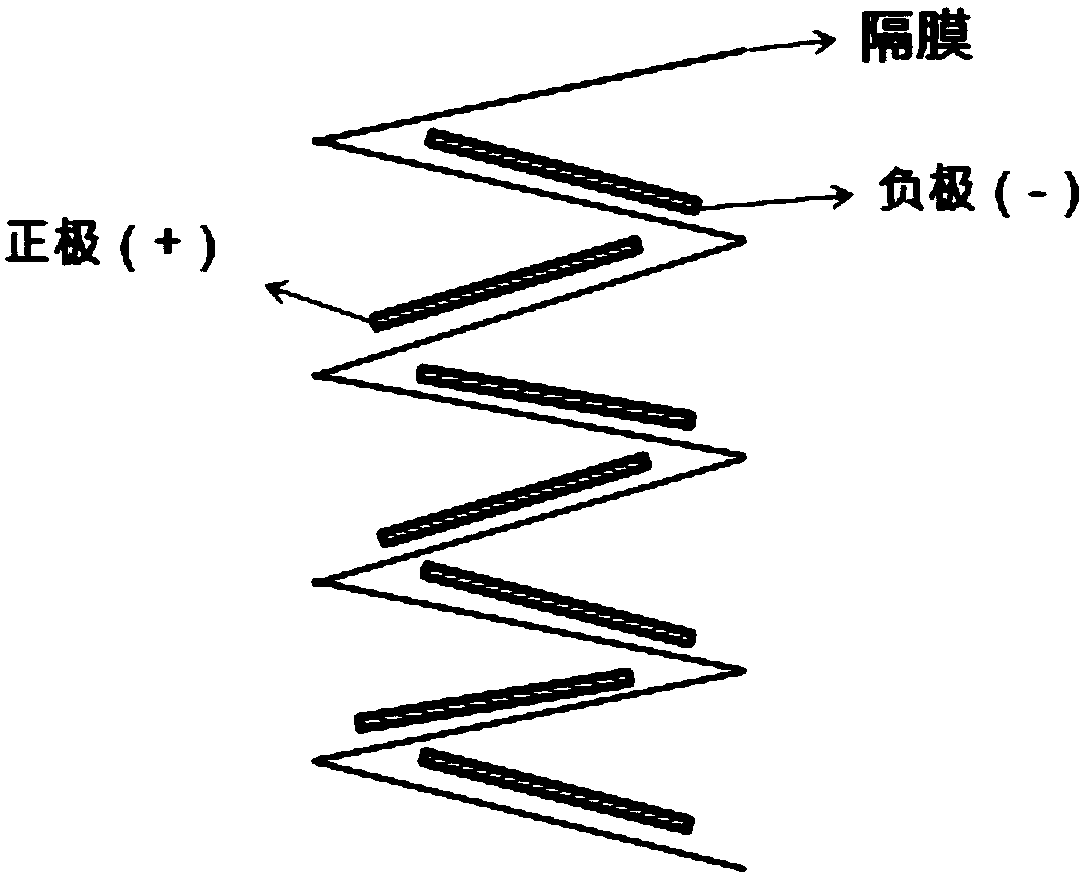

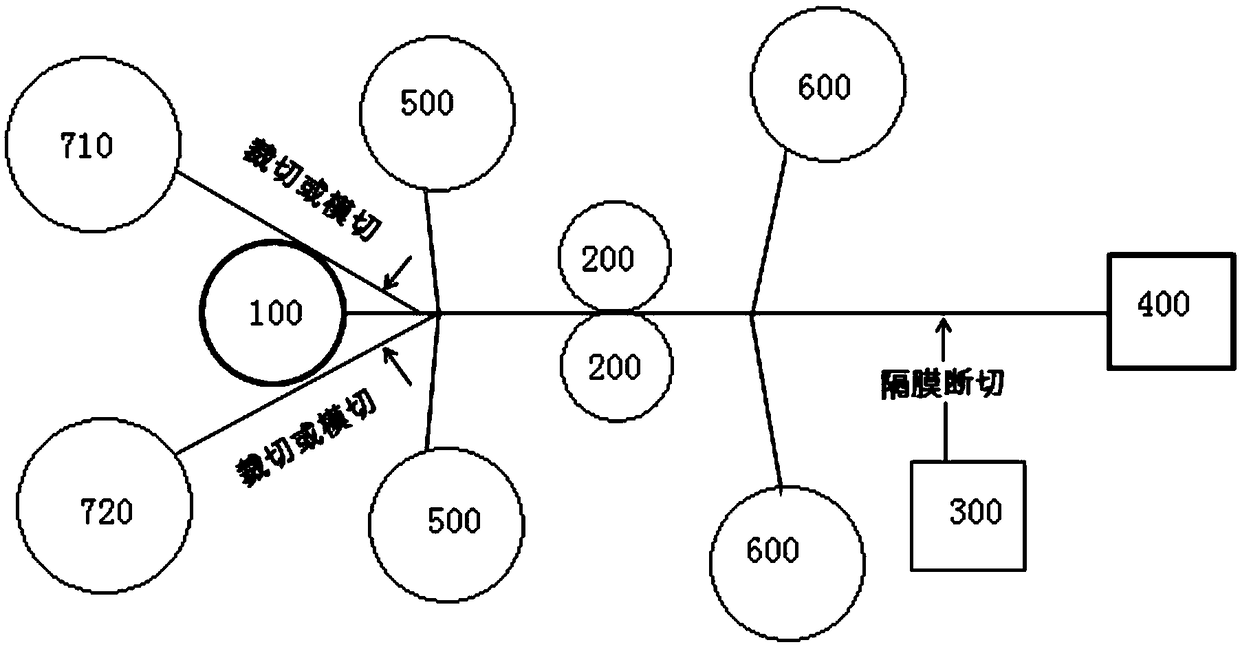

[0040] see Figure 3 to Figure 6 , the lithium ion battery zigzag stacking equipment provided by the present invention includes a separator 100 , a hot-press lamination device 200 , a separator cutting device 300 and a stacking mechanism 400 .

[0041] The separator 100 is used to connect several negative electrode sheets and several positive electrode sheets into one body, and ensure that the negative electrode sheets and positive electrode sheets are alternately distributed thereon.

[0042] Specifically, adhesive layers can be respectively provided on the upper surface and the lower surface of the separator 100, and the negative electrode sheet and the positive electrode sheet after the positive electrode roll 710 and the negative electrode r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com