High-transparency, high-hardness and anti-yellowing epoxy resin AB glue for surfaces of environment-friendly building materials

A technology for changing the surface of epoxy resin and building materials, applied in the direction of epoxy resin glue, adhesive, polymer adhesive additives, etc., can solve the problems of poor weather resistance, poor UV resistance, cracking of the adhesive layer, etc., and achieve UV resistance Good, anti-yellowing time, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

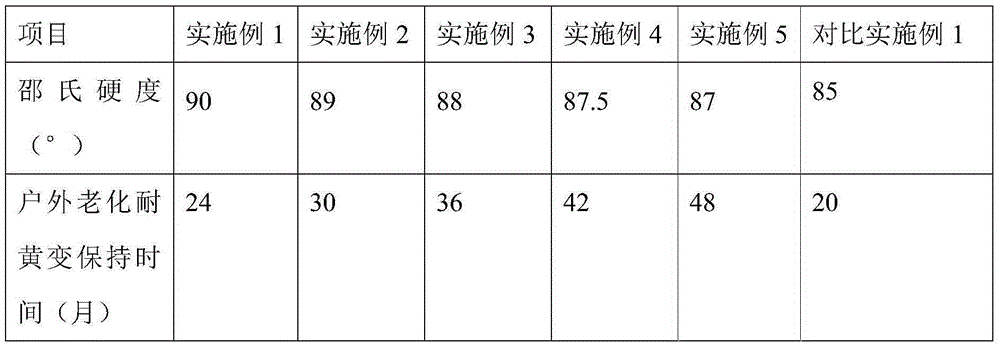

Examples

Embodiment 1

[0023] A high-transparency, high-hardness, anti-yellowing epoxy resin AB glue for the surface of environmentally friendly building materials, which consists of components A and B, and the components contained in component A and their mass parts are:

[0024] 80 parts of bisphenol A epoxy resin, 20 parts of nano-scale silica / epoxy polymer toughening agent, 0.05 part of wetting and anti-cratering additive, 0.2 part of nanometer anti-UV blocker, 0.5 part of silane coupling agent part; wherein, the epoxy equivalent of the bisphenol A epoxy resin is 184-190g / eq; the epoxy equivalent of the epoxy polymer in the nano-scale silica / epoxy polymer toughening agent is 220 -230g / eq, the particle size of the nano-scale silicon dioxide is 10-50nm, the mass percentage of the nano-scale silicon dioxide is not more than 45%; the wetting and anti-cratering additive is organic silicon The twin-structure surfactant, the nano anti-UV blocker is a transparent liquid with a viscosity of 10-15CPS.

...

Embodiment 2

[0033] A high-transparency, high-hardness, anti-yellowing epoxy resin AB glue for the surface of environmentally friendly building materials, which consists of components A and B, and the components contained in component A and their mass parts are:

[0034] 82.5 parts of bisphenol A epoxy resin, 17.5 parts of nano-scale silica / epoxy polymer toughening agent, 0.08 part of wetting and anti-cratering additive, 0.35 part of nano-scale anti-UV blocker, 0.6 part of silane coupling agent part; wherein, the epoxy equivalent of the bisphenol A epoxy resin is 184-190g / eq; the epoxy equivalent of the epoxy polymer in the nano-scale silica / epoxy polymer toughening agent is 220 -230g / eq, the particle size of the nano-scale silicon dioxide is 10-50nm, the mass percentage of the nano-scale silicon dioxide is not more than 45%; the wetting and anti-cratering additive is organic silicon The twin-structure surfactant, the nano anti-UV blocker is a transparent liquid with a viscosity of 10-15CP...

Embodiment 3

[0043] A high-transparency, high-hardness, anti-yellowing epoxy resin AB glue for the surface of environmentally friendly building materials, which consists of components A and B, and the components contained in component A and their mass parts are:

[0044]85 parts of bisphenol A epoxy resin, 15 parts of nano-scale silica / epoxy polymer toughening agent, 0.12 part of wetting and anti-cratering additive, 0.5 part of nano-anti-UV blocker, 0.7 part of silane coupling agent part; wherein, the epoxy equivalent of the bisphenol A epoxy resin is 184-190g / eq; the epoxy equivalent of the epoxy polymer in the nano-scale silica / epoxy polymer toughening agent is 220 -230g / eq, the particle size of the nano-scale silicon dioxide is 10-50nm, the mass percentage of the nano-scale silicon dioxide is not more than 45%; the wetting and anti-cratering additive is organic silicon The twin-structure surfactant, the nano anti-UV blocker is a transparent liquid with a viscosity of 10-15CPS.

[0045]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com