Method for improving shore degree of sound insulation cotton

A sound-insulating cotton, Shaw's technology, applied in the field of sound-insulating cotton materials, can solve the problems that sound-absorbing materials cannot meet environmental protection, decoration, flame retardancy, aging resistance, hardness, and small smoke generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047]The embodiment of the present embodiment is in the embodiment 1 is:

[0048]A method of improving sound of cotton Shawa, the specific steps are as follows:

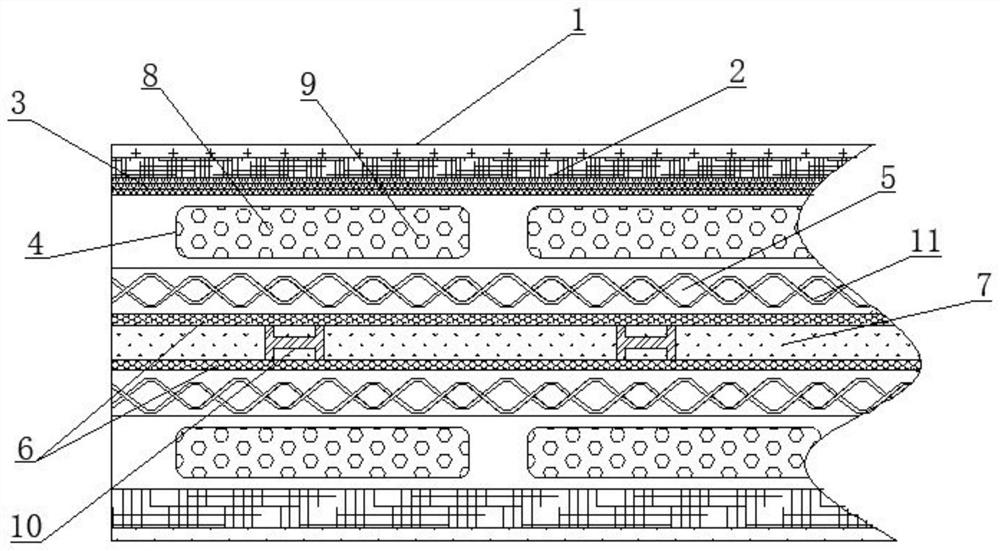

[0049]1). Weaving: Light metal fibers that make up the light metal mesh 3 are orthogonate, ensuring that the braided light metal web layer 3 porosity is 0.2;

[0050]The hollow metal fibers constituting the hollow metal mesh 6 are orthogonate, ensuring that the woven light metal web layer 3 porosity is 0.8;

[0051]2). Mosch: A plurality of square grooves are opened on the foam layer 7, embed in the square groove 10 in the foam layer 7, and then attach the orthogonal knitting hollow metal web layer 6 to the foam layer. 7 of the upper and lower surface;

[0052]3). Fill: The elastic layer 5 is performed through the drilling, and then the light metal fibers that make up the light metal web layer 3 is filled inside to ensure that the light metal fibers are fill the elastic layer 5 and embedded in the flexibility of the elastic layer 5. Lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com