Rubber base plate for subway rail transit as well as composition and preparation method of rubber base plate

A technology for rail transit and rubber backing plates, which is applied in the field of rubber backing plates for subway rail transit and compositions for rubber backing plates for subway rail transit, which can solve problems such as poor mechanical properties, poor vibration damping effect, and insufficient elasticity, and achieve The effect of improving mechanical properties and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

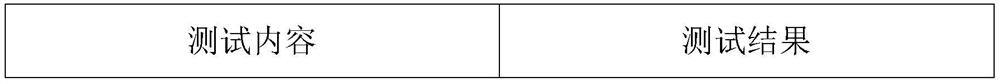

Embodiment 1

[0051] A kind of rubber pad composition for subway rail transit, it is prepared from following raw material by weight:

[0052]100 parts of NR-1# natural rubber, 25 parts of white carbon black, 1 part of silane coupling agent, 10 parts of zinc oxide, 1.5 parts of stearic acid, 1.5 parts of anti-aging agent SPC, 1 part of anti-aging agent 2246, 2 parts of microcrystalline wax , 1 part of WB215, 1.5 parts of PEG4000, 5 parts of titanium dioxide, 2 parts of chrome yellow, 0.8 parts of sulfur, 1 part of dibenzothiazole disulfide, 1 part of N-cyclohexyl-2-benzothiazole sulfenamide and 1 part Tetramethylthiuram disulfide.

[0053] The preparation method of the rubber pad composition for subway rail transit provided by the present embodiment is as follows:

[0054] Step 1, add 100 parts of NR-1# natural rubber into the internal mixer, after refining for 7 minutes, add 1 part of silane coupling agent, 10 parts of zinc oxide, 1.5 parts of stearic acid, 1.5 parts of anti-aging agent SP...

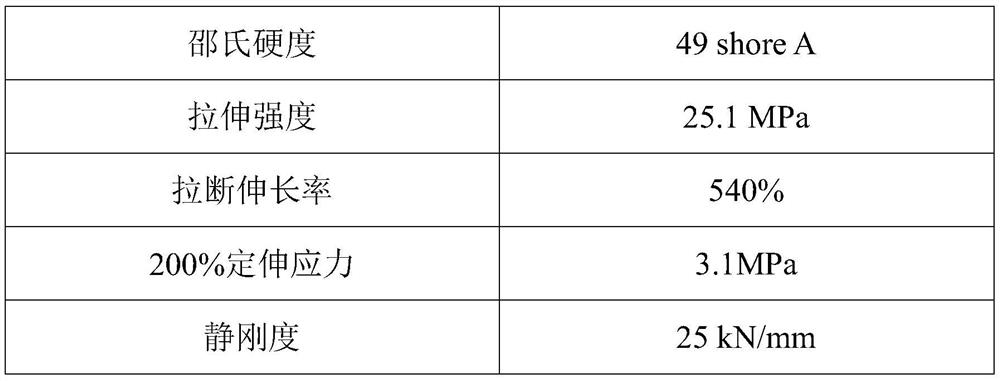

Embodiment 2

[0069] A kind of rubber pad composition for subway rail transit, it is prepared from following raw material by weight:

[0070] 100 parts of NR-1# natural rubber, 25 parts of white carbon black, 1 part of silane coupling agent, 30 parts of zinc oxide, 1.5 parts of stearic acid, 1.5 parts of anti-aging agent SPC, 1 part of anti-aging agent 2246, 2 parts of microcrystalline wax , 1 part of WB215, 1.5 parts of PEG4000, 5 parts of titanium dioxide, 0.3 parts of carbon black, 0.8 parts of sulfur, 1 part of dibenzothiazole disulfide, 2 parts of N-cyclohexyl-2-benzothiazole sulfenamide and 2 parts Tetramethylthiuram disulfide.

[0071] The preparation method of the rubber pad composition for subway rail transit provided by the present embodiment is as follows:

[0072] Step 1, add 100 parts of NR-1# natural rubber into the internal mixer, after refining for 7 minutes, add 1 part of silane coupling agent, 30 parts of zinc oxide, 1.5 parts of stearic acid, 1.5 parts of anti-aging agen...

Embodiment 3

[0084] A kind of rubber pad composition for subway rail transit, it is prepared from following raw material by weight:

[0085] 100 parts of NR-1# natural rubber, 50 parts of white carbon black, 25 parts of calcium carbonate, 2 parts of silane coupling agent, 2 parts of paraffin oil, 5 parts of zinc oxide, 1.5 parts of stearic acid, 1 part of anti-aging agent SPC, 1 Parts of anti-aging agent 2246, 3.5 parts of microcrystalline wax, 1 part of WB215, 3.5 parts of PEG4000, 5 parts of titanium dioxide, 2 parts of chromium oxide green, 2.3 parts of sulfur, 1.5 parts of dibenzothiazole disulfide, 1 part of N-cyclohexyl- 2-Benzothiazolesulfenamide and 0.3 parts of tetramethylthiuram disulfide.

[0086] In the present embodiment, the preparation method of the rubber pad composition for subway rail transit is as follows:

[0087] Step 1, add 100 parts of NR-1# natural rubber into the internal mixer, after refining for 7 minutes, add 2 parts of silane coupling agent, 2 parts of paraffi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com