Amino compound rubber additive as well as preparation and application thereof

An amino compound and additive technology, applied in the preparation of organic compounds, cyanide reaction preparation, hydrogenated polysulfide/polysulfide preparation, etc., can solve the problems of heat accumulation and tear resistance, excess, deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

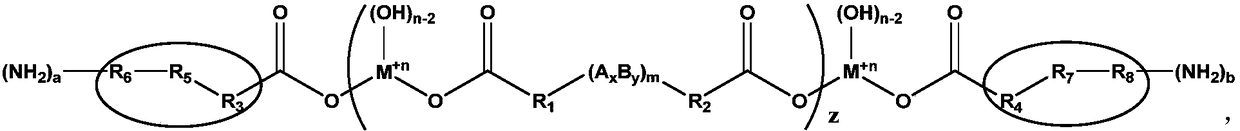

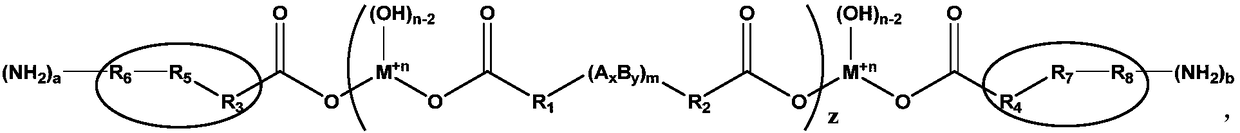

[0053] A preparation method of amino compound rubber additive, comprising the following steps:

[0054] (1) Take dicarboxylic acid and alkali, or directly take the salt of dicarboxylic acid and place it in a polar solvent, and heat until the solution is completely transparent to obtain dicarboxylate solution A;

[0055] (2) Take amino acid and alkali, or directly take the salt of amino acid and place it in a polar solvent, heat until the solution is completely transparent, and obtain amino acid salt solution B;

[0056] (3) Under stirring conditions, mix dicarboxylate solution A, amino acid salt solution B and metal M salt solution, react to obtain a solid product, filter, wash, and dry to obtain the target product amino compound rubber additive;

[0057] The structural formula of the dicarboxylic acid is: HOOC-R 1 -(A x B y ) m -R 2 -COOH;

[0058] The structural formula of the amino acid is:

[0059] That is to say, the structural formula of amino acid is: (NH 2 ) ...

Embodiment 1

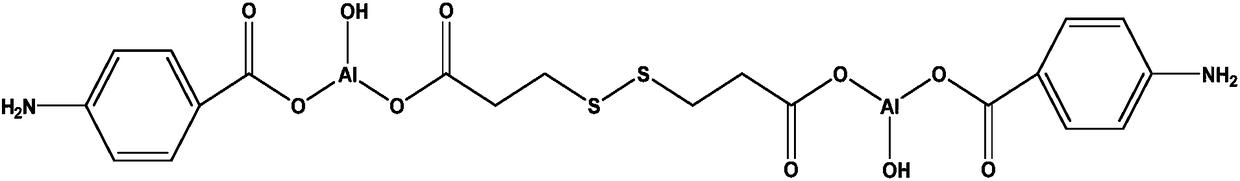

[0081] A kind of amino compound, its chemical structural formula is:

[0082]

[0083] The preparation method of above-mentioned additive comprises the following steps:

[0084] (1) Add 1 L of distilled water and 16 g of solid sodium hydroxide (purity ≥ 97%, purchased from Aladdin) in a 2 L beaker. After the sodium hydroxide was completely dissolved, 42.05 g of 3,3'-dithiodipropionic acid (purity ≥ 99.0% (GC) (T), purchased from TCI) was added. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution A)

[0085] (2) Add 1 L of distilled water and 16 g of solid sodium hydroxide (purity ≥ 97%, purchased from Aladdin) in a 2 L beaker. After the sodium hydroxide was completely dissolved, 54.85 g of 4-aminobenzoic acid (purity ≥ 98%, purchased from Aladdin) was added. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution D)

[0...

Embodiment 2

[0090] A kind of amino compound, its chemical structural formula is:

[0091]

[0092] The preparation method of above-mentioned additive comprises the following steps:

[0093] (1) Add 1 L of distilled water and 16 g of solid sodium hydroxide (purity ≥ 97%, purchased from Aladdin) in a 2 L beaker. After the sodium hydroxide was completely dissolved, 42.05 g of 3,3'-dithiodipropionic acid (purity ≥ 99.0% (GC) (T), purchased from TCI) was added. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution A)

[0094] (2) Add 1 L of distilled water and 80.52 g of 11-aminoundecanoic acid (purity 97%, purchased from Aladdin) into a 2 L beaker. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution D)

[0095] (3) Another 4L beaker was taken, and 1L of distilled water and 189.76g of potassium aluminum sulfate dodecahydrate (purity ≥ 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com