Graphite modified polytricyclopentadiene PTCPD composite material and preparation method thereof

A technology of polytricyclopentadiene and tricyclopentadiene is applied in the field of graphite-modified polytricyclopentadiene PTCPD composite material and its preparation, and can solve the problem of difficult thermal deformation, insufficient rigidity, poor heat resistance, etc. problems, to achieve the effects of not easy thermal deformation, enhanced wear resistance, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

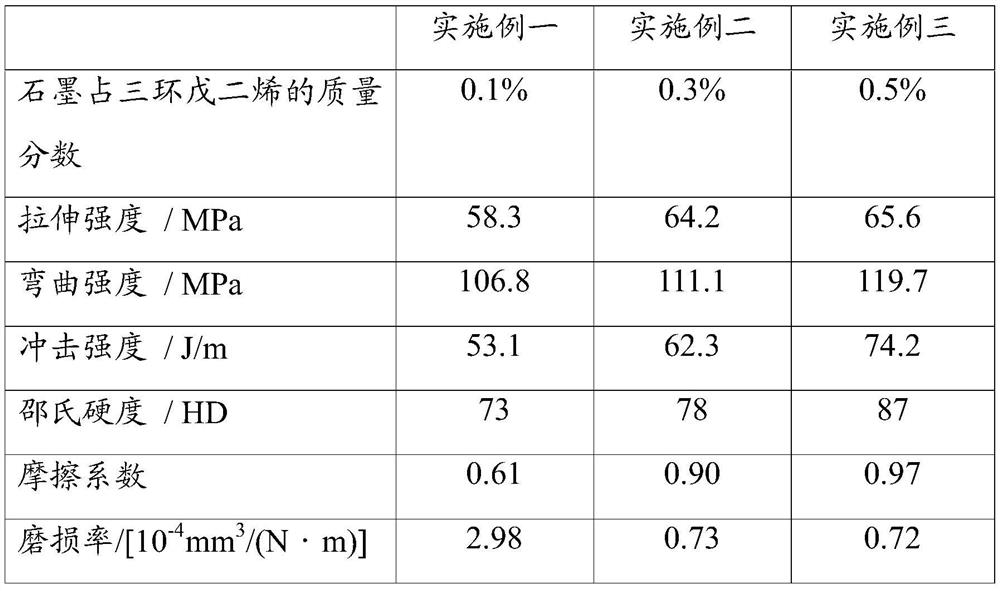

Embodiment 1

[0049] The embodiment of the present application provides a preparation method of graphite-modified polytricyclopentadiene PTCPD composite material, the steps are:

[0050] Step S1: pretreating the graphite; specifically:

[0051] Keep graphite at a temperature of 900°C for 60s to obtain expanded graphite;

[0052] Using silane coupling agent to modify the surface of expanded graphite;

[0053] Through surface modification, the expanded graphite and tricyclopentadiene TCPD monomer have good compatibility to achieve uniform dispersion;

[0054] Step S2: Mix the modified graphite and tricyclopentadiene TCPD monomer under the action of ultrasonic waves, the mass percentage of graphite in tricyclopentadiene TCPD monomer is 0.1%, and vacuumize to a vacuum degree of 0.8MPa , replaced with nitrogen, so that the mixture of graphite and TCPD monomer is in a nitrogen protection state;

[0055] Step S3: Prepare raw materials into two components A and B, component A contains the mixtur...

Embodiment 2

[0059] The embodiment of the present application provides a preparation method of graphite-modified polytricyclopentadiene PTCPD composite material, the steps are:

[0060] Step S1: pretreating the graphite; specifically:

[0061] Keep graphite at a temperature of 930°C for 45s to obtain expanded graphite;

[0062] The surface of expanded graphite is modified by titanate coupling agent;

[0063] Through surface modification, the expanded graphite and tricyclopentadiene TCPD monomer have good compatibility to achieve uniform dispersion;

[0064] Step S2: Mix the modified graphite and tricyclopentadiene TCPD monomer under the action of ultrasonic waves, the mass percentage of graphite in the tricyclopentadiene TCPD monomer is 0.3%, and vacuumize to a vacuum degree of 0.9MPa , replaced with nitrogen, so that the mixture of graphite and TCPD monomer is in a nitrogen protection state;

[0065] Step S3: The raw material is formulated into A and B two components, A component compr...

Embodiment 3

[0069] The embodiment of the present application provides a preparation method of graphite-modified polytricyclopentadiene PTCPD composite material, the steps are:

[0070] Step S1: pretreating the graphite; specifically:

[0071] Oxidize graphite to obtain graphite oxide; abundant polar groups such as hydroxyl and carboxyl groups are formed on the surface of graphite oxide, which expands the space for surface modification;

[0072] Use silane coupling agent to modify the surface of graphite oxide; through surface modification, graphite oxide and tricyclopentadiene TCPD monomer have good compatibility to achieve uniform dispersion effect;

[0073] Step S2: Mix the modified graphite and tricyclopentadiene TCPD monomer under the action of ultrasonic waves, the mass percentage of graphite in tricyclopentadiene TCPD monomer is 0.5%, and vacuumize to a vacuum degree of 0.9MPa , replaced with nitrogen, so that the mixture of graphite and TCPD monomer is in a nitrogen protection sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com