Semiconductor light-emitting device and manufacturing method of the same

A technology of light-emitting devices and semiconductors, which is applied to semiconductor devices, electric solid-state devices, electrical components, etc., and can solve the problems of reduced output, picking failure, and the inability of robotic equipment to pick up semiconductor light-emitting devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Here, a semiconductor light emitting device having a plurality of light emitting units (ie, a multi-chip type semiconductor light emitting device) is exemplified.

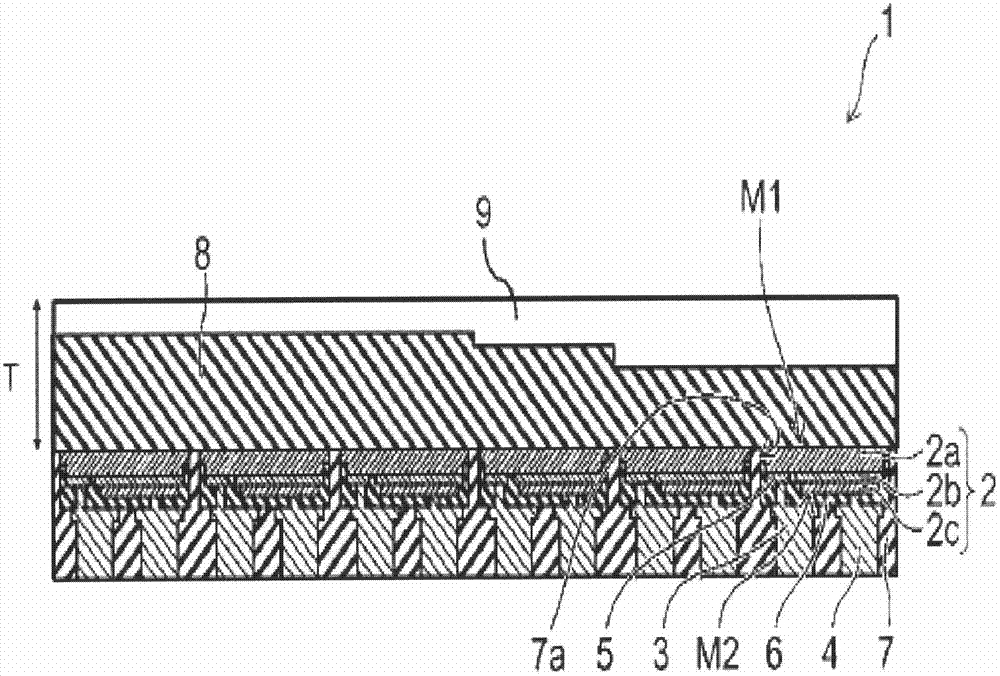

[0018] figure 1 is a cross-sectional view illustrating a semiconductor light emitting device 1 manufactured according to an embodiment disclosed herein. Such as figure 1 As shown, in a semiconductor light emitting device 1 , a light emitting unit 2 , an electrode part 3 , an electrode part 4 , a bonding part 5 , a lead part 6 , a sealing part 7 and a wavelength conversion unit 8 are provided. The light emitting unit 2 comprises a plurality of light emitting subunits which, when used together, constitute the light emitting unit 2 . Although the semiconductor light emitting device 1 may include a plurality of light emitting units 2, only a single light emitting unit 2 is described in detail herein.

[0019] The light emitting unit 2 includes a main surface M1 and a main surface M2. The main surface M2 is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com