Preparation method for chinlon spinning oiling agent composition

A technology of composition and oil agent, applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve problems such as environmental impact, increase of volatile substances, etc., achieve good heat resistance, improve stability, and reduce friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

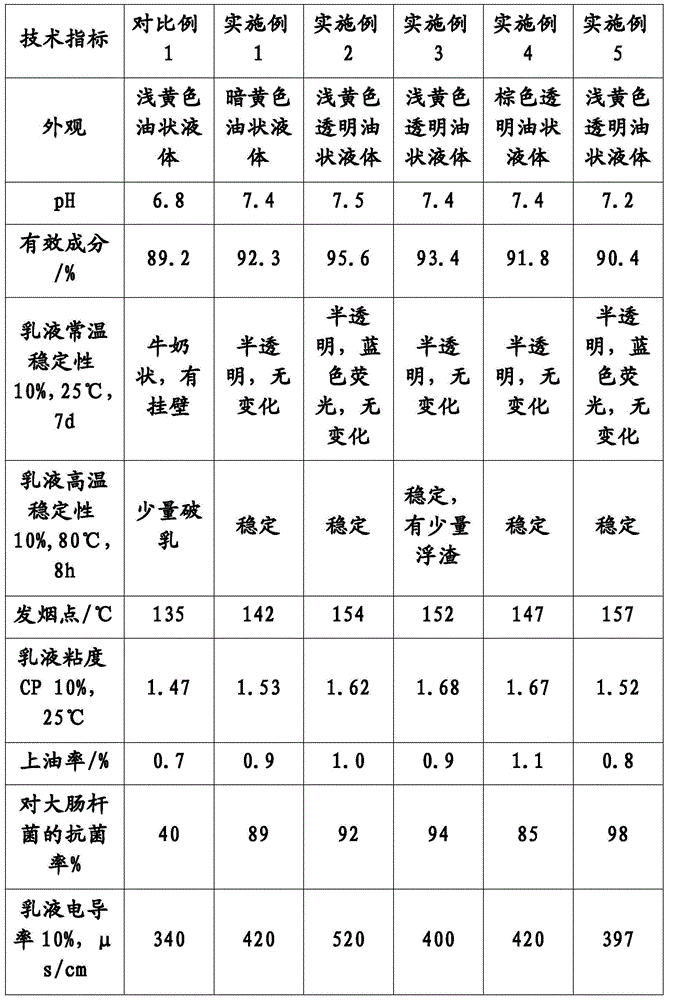

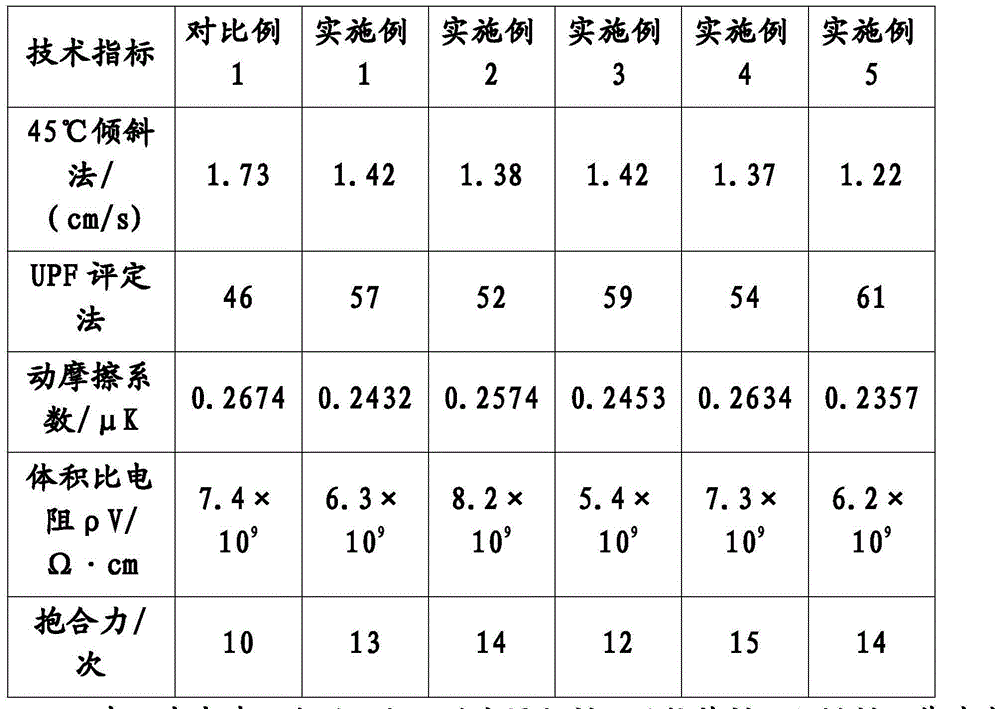

Examples

Embodiment 1

[0016] This embodiment relates to a preparation method of an oil composition for nylon spinning, and the specific preparation method includes the following steps:

[0017] Step 1, under stirring conditions, add 25 parts of 10# mineral oil, 25 parts of 12# mineral oil, 3 parts of potassium stearyl phosphate, 5 parts of castor oil polyoxyethylene ether, 2 parts of lauric acid diester 1 part, 1 part of pentaerythritol, 3 parts of polyisobutylene, put into the reaction kettle, heat up to 40°C, fully mix several substances, keep warm for 20min, and obtain oil agent A;

[0018] Step 2: Cool the oil agent A to room temperature, then slowly add 1 part of triethanolamine to the oil agent A, stir at room temperature for 10 minutes, and obtain the oil agent B,

[0019] Step 3: Add 2 parts of zinc oxide into the oil agent B, accelerate the stirring of the mixed solution, raise the temperature to 40°C, and disperse 2 parts of the nano-additive zinc oxide evenly in the oil agent, and finall...

Embodiment 2

[0021] This embodiment relates to a preparation method of an oil composition for nylon spinning, the preparation method comprising the following steps:

[0022] Step 1, under stirring conditions, add 70 parts of fatty acid glycerides, 7 parts of cationic surfactants, 15 parts of polyoxyethylene laurate, 5 parts of propylene glycol, 4 parts of sorbitol, and polyvinyl n-butyl ether according to parts by weight 6 parts, 15 parts of dibromonitroethanol, 7 parts of benzotriazole, 5 parts of phosphate ester. Add to the reaction kettle, raise the temperature to 40°C, fully mix several substances, and keep warm for 30 minutes to obtain oil agent A;

[0023] Step 2: Cool the oil agent A to room temperature, then slowly add 4 parts of potassium trihydroxide into the oil agent A, stir at room temperature for 10 minutes, and obtain the oil agent B,

[0024] Step 3: Add 4 parts of magnesium oxide into the oil agent B, accelerate the stirring of the mixed solution, raise the temperature to...

Embodiment 3

[0026] This embodiment relates to a preparation method of an oil composition for nylon spinning, which comprises the following components in parts by weight:

[0027] Step 1, under stirring conditions, add 55 parts of 15# mineral oil, 4 parts of stearyl phosphate potassium salt, 7 parts of castor oil polyoxyethylene ether, 2.5 parts of lauric acid diester, 2 parts of pentaerythritol, poly Put 4 parts of vinyl n-butyl ether into the reaction kettle, raise the temperature to 50°C, fully mix several substances, and keep it warm for 30 minutes to obtain oil agent A;

[0028] Step 2: Cool the oil agent A to room temperature, then slowly add 2 parts of triethanolamine to the oil agent A, stir at room temperature for 30 minutes, and obtain the oil agent B.

[0029] Step 3, add 2.5 parts of titanium dioxide to the oil agent B, accelerate the stirring of the mixed solution, raise the temperature to 50°C, so that the nano-additives are evenly dispersed in the oil agent, and finally add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com