Chinlon spinning additive

An additive and spinning technology, which is applied in the field of additives in synthetic fiber processing technology, can solve problems such as environmental impact and increase of volatile substances, and achieve good heat resistance, increase antibacterial performance, and reduce friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

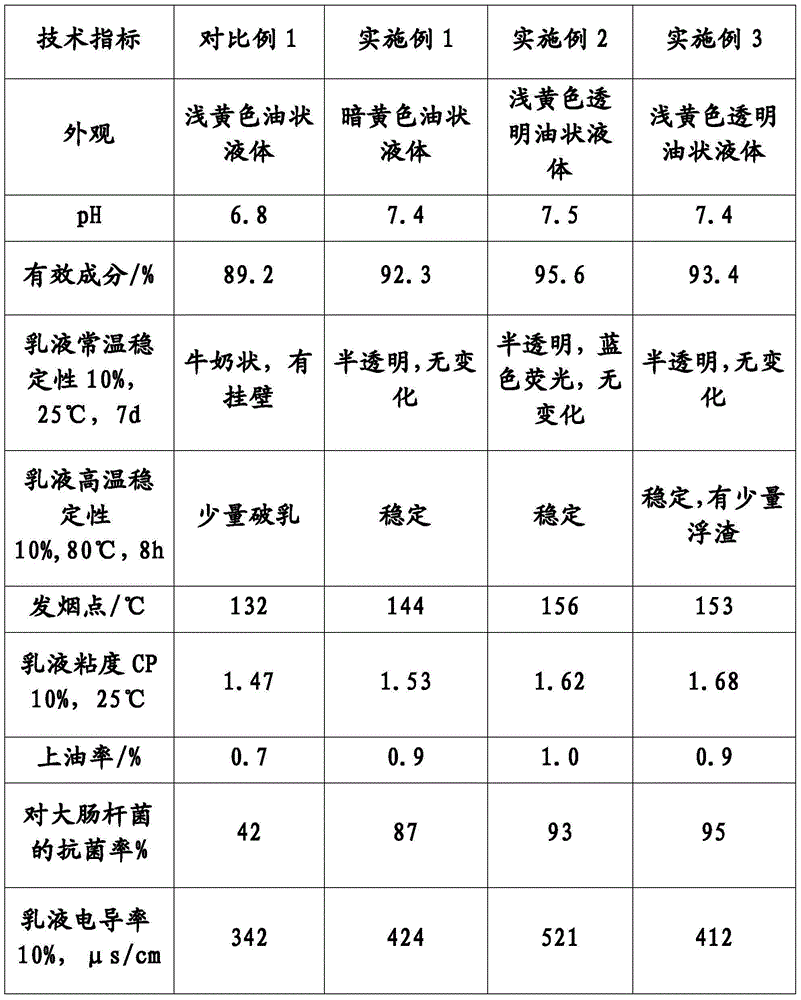

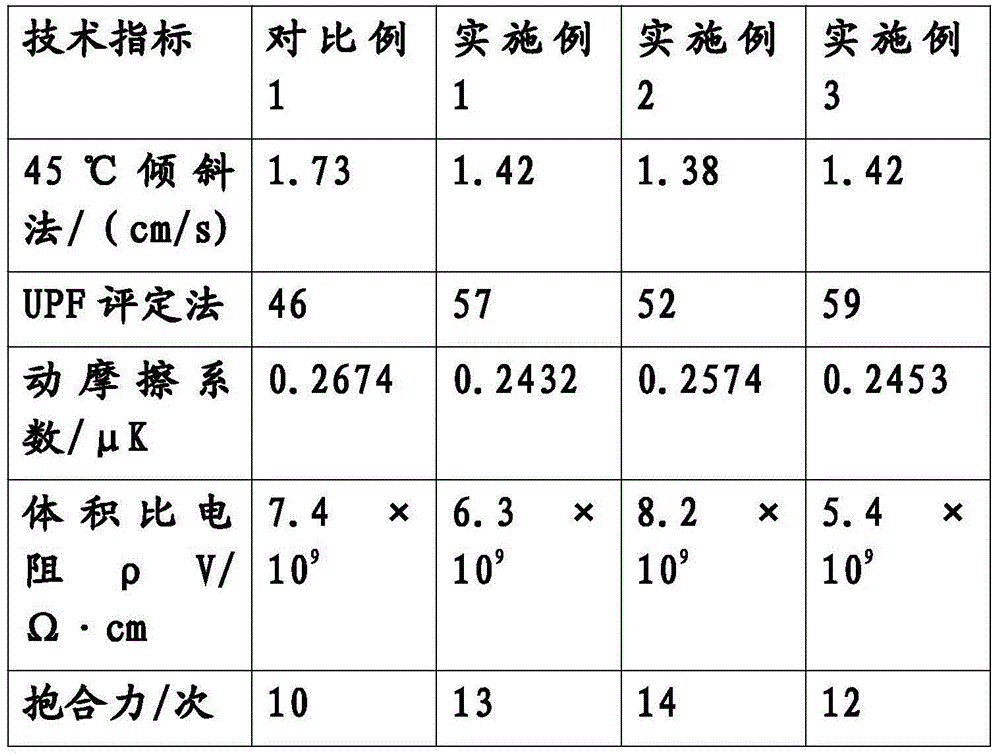

Embodiment 1

[0028] This embodiment provides an additive for nylon spinning, the composition of which is expressed in parts by weight:

[0030] Titanium dioxide 3,

[0031] Montmorillonite 2,

[0032] Vermiculite 3,

[0033] polyvinylpyrrolidone 1,

[0034] Sodium Dodecylbenzene Sulfonate 1.

[0035] The preparation technology of this nano-additive comprises the following steps:

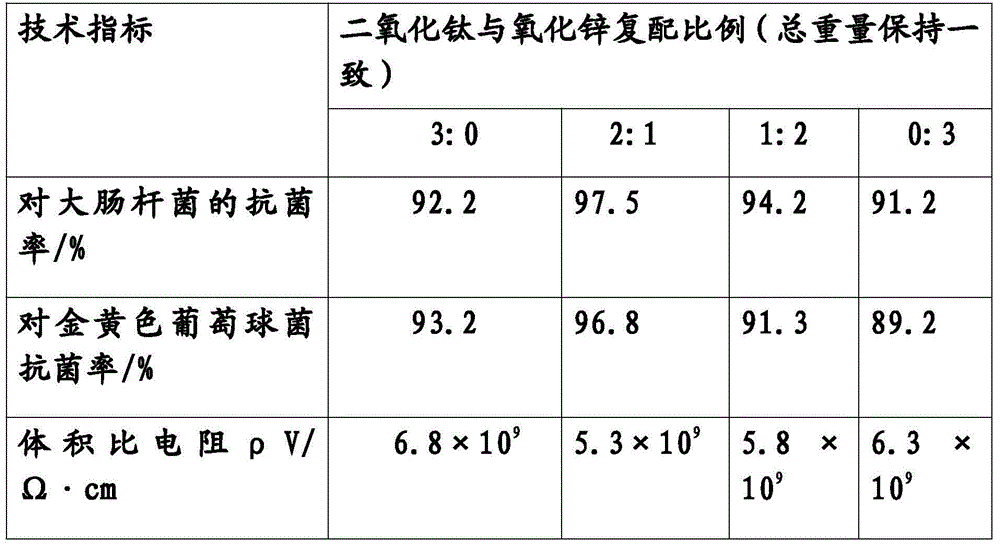

[0036] Step 1: First, add 5 parts of zinc oxide, 3 parts of titanium dioxide, and 1 part of polyvinylpyrrolidone into a ball mill, and grind for 6 hours to obtain dry powder A. Step 2: Mix dry powder A according to the ratio of 1g of dry powder to 5ml of ethanol, add to a ball mill, continue grinding, ball mill for 5 hours, remove absolute ethanol, and dry in vacuum to obtain nano dry powder B. Step 3: Add 2 parts of montmorillonite, 3 parts of vermiculite and 1 part of sodium dodecylbenzenesulfonate into absolute ethanol. The content of dispersant and inorganic mineral salt in this m...

Embodiment 2

[0038] This embodiment provides an additive for nylon spinning. The preparation method refers to Example 1. The composition of the additive is expressed in parts by weight as follows:

[0040] Titanium dioxide 5,

[0041] Montmorillonite 6,

[0042] Vermiculite 6,

[0043] Oleic acid 1.

Embodiment 3

[0045] This embodiment provides an additive for nylon spinning. The preparation method refers to Example 1. The composition of the additive is expressed in parts by weight as follows:

[0047] Titanium dioxide 3.5,

[0048] Montmorillonite 3,

[0049] Vermiculite 4,

[0050] Oleic acid 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com