Patents

Literature

54results about How to "Increase antibacterial" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-base lotus paint for inner and outer building wall and its prepn process

InactiveCN101089059AImprove performanceImprove environmental performanceEmulsion paintsWater basedEmulsion

The present invention relates to one kind of water-base lotus paint for inner and outer wall of building and its preparation process. The water-base lotus paint consists of dispersant, wetting agent, thickener, filming assistant, styrene-acrylic emulsion, antifreezing agent glycol, defoamer, bactericide, leveling agent, whitening agent and other ingredients. It is prepared through preparing pigment slurry, grinding and blending. It has the advantages of environment friendship, high adhesion, high wear resistance, etc.

Owner:赵青山

Chinlon spinning additive

ActiveCN104611912AHas UV protection propertiesThe solution function is relatively simpleFibre typesMontmorilloniteUltraviolet protection

The invention provides a chinlon spinning additive which includes the following constituents in parts by weight: 5-10 parts of zinc oxide, 3-5 parts of titanium dioxide, 2-6 parts of montmorillonite, 3-6 parts of vermiculite and 1-3 parts of a dispersing agent. The prepared additive is small in grain size and good in dispersing performance, improves the stability, ultraviolet protection and mold resistance of spinning oil after being added in the mold spinning oil.

Owner:JIANGSU WENFENG CHEM FIBER GROUP

Modified nanometer bamboo charcoal mask and manufacturing method thereof

InactiveCN104041963ALow costHigh adsorption propertiesFibre typesProtective garmentWoven fabricPolymer chemistry

Provided are a modified nanometer bamboo charcoal mask and a manufacturing method thereof. The modified nanometer bamboo charcoal mask comprises an inner mask and an outer mask, wherein the inner mask is provided with a dismounting opening, and a filer layer is arranged in the dismounting opening. The inner mask and the outer mask of the mask and a filer layer base plate are made of an electrets melt-blowing polypropylene fiber non-woven fabrics, the filer layer uses chitosan as a capsule wall material, microcapsules are made from modified nanometer bamboo charcoal powder, beewax is used as an adhesive for arranging the microcapsules on the non-woven fabrics. The modified nanometer bamboo charcoal powder are modified by adopting nanometer titanium dioxide. The modified nanometer bamboo charcoal mask is green, environment-friendly, safe and efficient, has the broad-spectrum antibacterial effect and has good washability due to the fact that the beewax is used as the adhesive to arrange the microcapsules on the non-woven fabrics.

Owner:广州市威普复合材料有限公司

Soil conditioner preparation method

InactiveCN104845639AOptimized areaImprove the phenomenon of dead treesAgriculture tools and machinesOther chemical processesSilicon dioxideHigh activity

The invention discloses a soil conditioner preparation method. The soil conditioner comprises, by weight, 10-25% of water-soluble nanometer silica, 10-20% of polymethyl methacrylate, 17-20% of Grondverbeteraar, 13-20% of carboxymethyl cellulose, 15-20% of high activity silicon-calcium-magnesium-potash fertilizer, 10-18% of bromomethane and 3-6% of calcium cyanamide. The soil conditioner is suitable for acidified soil and has pH o 3.3-4.5. In use, a tractor turns up the soil, water is poured into the field and immerses the field for 2-4 days, 4-5 tons of the soil conditioner is sown in the soil, after 5-7 days, the tractor levels the field and crops are planted in the soil. The soil conditioner can improve the soil. The used trace elements and bacterial depressants can improve acidic soil acidity, provide trace elements needed by plant growth and substantially improve a crop yield.

Owner:吴迪

Environment-friendly bamboo charcoal mask and manufacturing method thereof

ActiveCN104055246AStrong adsorption propertiesHigh adsorption propertiesProtective garmentPolymer scienceEngineering

The invention provides an environment-friendly bamboo charcoal mask and a manufacturing method thereof. The mask comprises an inner mask body and an outer mask body, the inner mask body is provided with a detachment opening, a filtering layer is arranged in the detachment opening, the inner mask body, the outer mask body and the filtering layer are all made of electret melt-blown polypropylene fiber non-woven fabrics, chitosan serves as a capsule wall material of the filtering layer, nanometer bamboo charcoal powder serves as a core material to be made into micro capsules, and the microcapsules are arranged on the non-woven fabrics through beewax serving as adhesive agents. The chitosan, the bamboo charcoal powder and the beewax are all natural materials, the obtained product is environmentally friendly, safe and efficient and has a broad-spectrum antibacterial function, the microcapsules are arranged on the non-woven fabrics through the beewax serving as the adhesive agents, and good washability is achieved.

Owner:维尼健康(深圳)股份有限公司

Preparation method for nano additive

InactiveCN104631095AIncrease antibacterialImproves UV protectionFibre typesTitanium dioxideBall mill

The invention provides a preparation method for a nano additive. The preparation method is finished by the following steps: firstly, adding 5-10 parts of zinc oxide, 3-5 parts of titanium dioxide and 1-3 parts of a dispersant into a ball mill; grinding at the rotary speed of 400r / min-450r / min for 5-10 hours to obtain dry powder A; mixing the dry powder A according to the ratio of adding 5ml of ethanol into 1g of the dry powder; adding the mixture into the ball mill and continually grinding; adjusting the rotary speed to 400r / min-500r / min and carrying out ball milling or 4-6 hours to remove the ethanol; drying in vacuum to obtain dry powder B; adding 2-6 parts of montmorillonoid and 3-6 parts of vermiculite, and the dispersant into the ethanol; putting the mixture into an ultrasonic field, carrying out ultrasonic dispersion and peeling for 2-4 hours; after dispersing, removing the ethanol; and putting the product and the dry powder B into the ball mill to be ground for 2-4 hours at the speed of 400r / min-500r / min to obtain the compound nano additive.

Owner:JIANGSU WENFENG CHEM FIBER GROUP

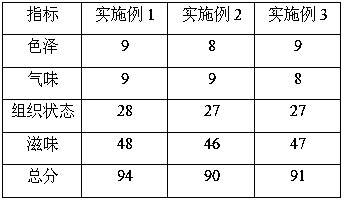

Pine pollen enzyme and preparation method thereof, as well as enzyme jelly prepared from pine pollen enzyme and preparation method of enzyme jelly

The invention provides pine pollen enzyme, a preparation method thereof, as well as enzyme jelly prepared from the pine pollen enzyme and a preparation method of the enzyme jelly. The pine pollen enzyme is mainly prepared from the following raw materials: pine pollen, pine nuts, edible flowers, edible fruits and vegetables, brown sugar, rock candy, an activated yeast liquid, a fermenting strain and water. The preparation method of the pine pollen enzyme comprises the following steps: (1) washing the pine pollen, pine nuts, edible flowers and edible fruits and vegetables, performing blanching,cooling and draining, and performing grinding with water, pulping and coarse filtering; (2) adding the brown sugar and rock candy into the mixture, and performing dissolving; (3) adding the activatedyeast liquid into the mixture, and performing fermentation; and (4) inoculating the mixture with the fermenting strain, and performing fermentation and post-fermentation. The enzyme jelly is mainly prepared from the following raw materials: the pine pollen enzyme, white granulated sugar, gelatin, agar, citric acid and water. The invention further discloses a method for preparing the enzyme jelly.The pine pollen enzyme has golden bright color, properly sour and sweet taste and excellent flavor; the enzyme jelly has a sour-sweet delicious taste and the enzyme flavor; and the methods are simple,have low cost, and are suitable for industrial production.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

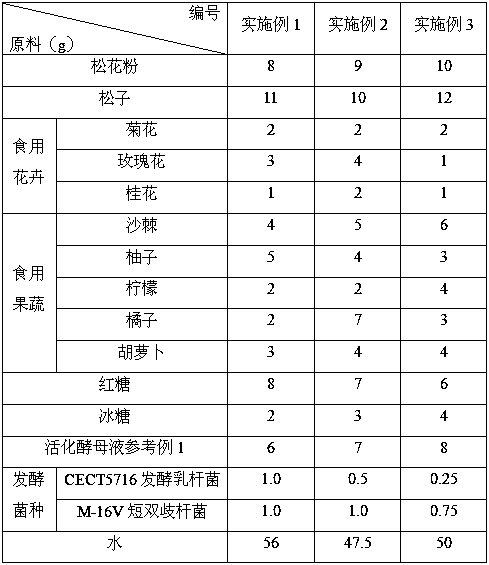

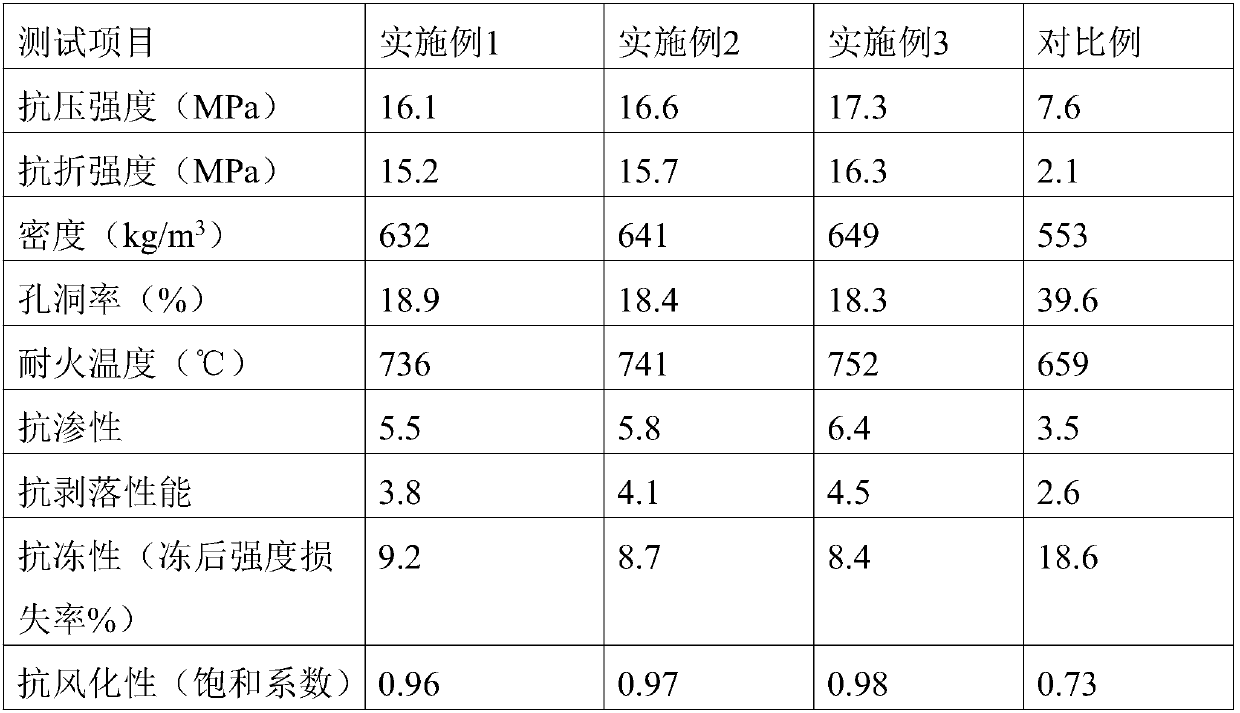

Preparation method of high-strength permeation-resistant aerated brick

InactiveCN108774028ACompact internal structureImprove mechanical strengthBuilding componentsCeramicwareIonBuilding material

The invention relates to the technical field of preparation of building materials, in particular to a preparation method of a high-strength permeation-resistant aerated brick. The preparation method includes the following steps of introducing metal ions into graphene oxide to obtain a metal composite, preparing a nano-silica hybridization modified polysiloxane composite, mixing the metal compositewith raw materials of the aerated brick to prepare the aerated brick, soaking an aerated brick green body in the nano-silica hybridized polysiloxane composite, and finally obtaining the high-strengthpermeation-resistant aerated brick through maintenance. The preparation method has the advantages that the prepared graphene oxide metal composite is added into the aerated brick, and accordingly, the aerated brick has ultrahigh strength and tenacity; through addition of silver, the aerated brick has antibacterial capability at the same time; modified polysiloxane and modified nano-silica are subjected to sol reaction to compound nanoscale hybridized polysiloxane, a super-hydrophobic film is formed on the surface of the aerated brick after the aerated brick is soaked in the nanoscale hybridized polysiloxane, the water contact angle is increased, permeation resistance of the aerated brick is improved, and accordingly, the aerated brick has a wide application prospect.

Owner:周荣

Preparation method of building bricks

The invention discloses a preparation method of building bricks. The preparation method comprises the following specific steps: (1) weighing the following components in parts by weight: 60-70 parts ofconcentrated sulfuric acid of which the mass percentage is 80-88%, 1-2 parts of sodium nitrate powder and 3-4 parts of graphite powder, putting the weighed components into a three-neck flask, placingthe three-neck flask in a water bath of which the temperature is 0-4 DEG C, performing stirring with a stirrer at the stirring speed being 310-350 r / min for 10-13 min, after stirring and mixing, adding 6-8 parts of the potassium permanganate powder, continuing performing stirring for 10-13 min, then raising the temperature of the water bath to 36-40 DEG C, and performing an isothermal reaction for 30-38 min so as to obtain pitchy liquid. According to the preparation method disclosed by the invention, prepared oxidized graphene metal compounds are introduced into filling bricks, chemical bondsand electronic structures between carbon atoms in graphene are closely relevant, and all the carbon atoms in the graphene are wholly tied onto the same plane, so that the building bricks have ultrahigh intensity and tenacity; besides, after the graphene is oxidized, hydroxyl, carboxyl, other epoxy functional groups and added silicon dioxide hybridized-and-modified-polysiloxane compounds can formnew covalent bonds and other chemical bond resultant force.

Owner:张宏汉

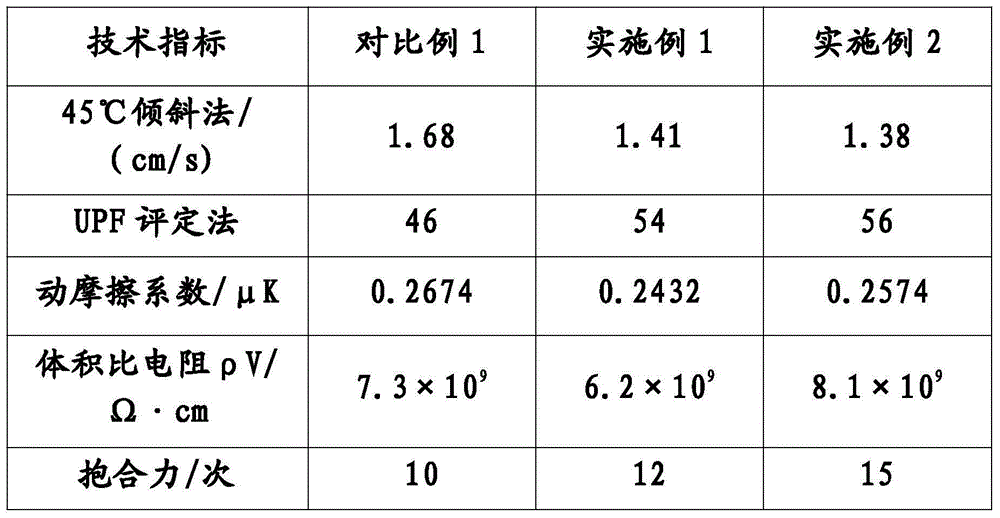

Multifunctional finishing additive

InactiveCN104562649AThe solution function is relatively simpleIncrease antibacterialFibre typesFire retardantMineral oil

The invention provides a multifunctional finishing additive which is composed of 4-8 parts of antibacterial agent, 2-7 parts of flame retardant, 2-5 parts of ultraviolet-resistant agent, 10-30 parts of 10# mineral oil and 2-6 parts of emulsifier. The multifunctional finishing additive solves the problem of single function in the nylon oil solution. The multifunctional additive can increase the cohesion of the filament bundle and lower the friction factor; more importantly, the ultraviolet-resistant agent, antibacterial agent, flame retardant and other functional assistants can be added to enhance the protective function of the oil solution, so that the oil solution can be stored for a long time.

Owner:JIANGSU WENFENG CHEM FIBER GROUP

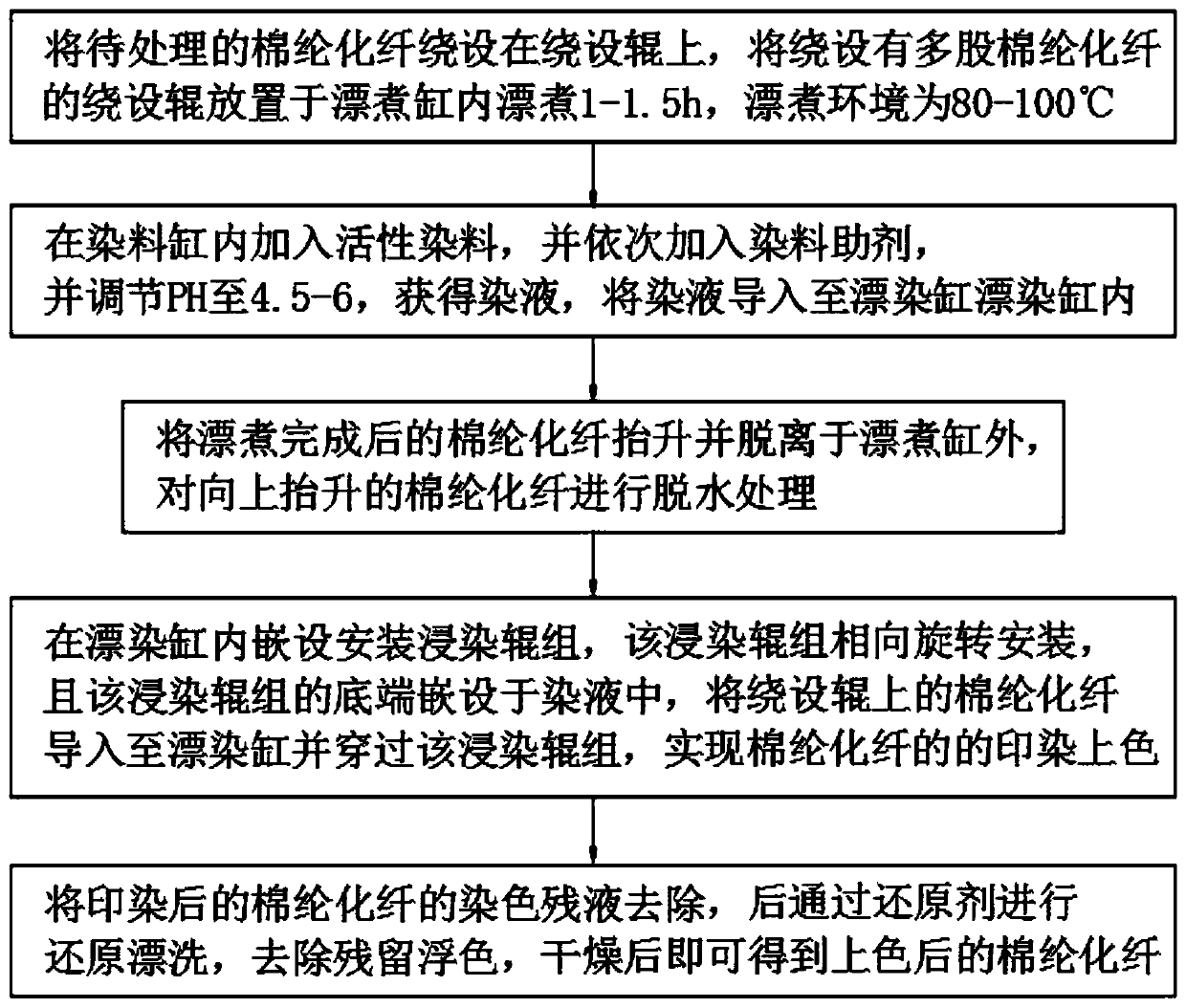

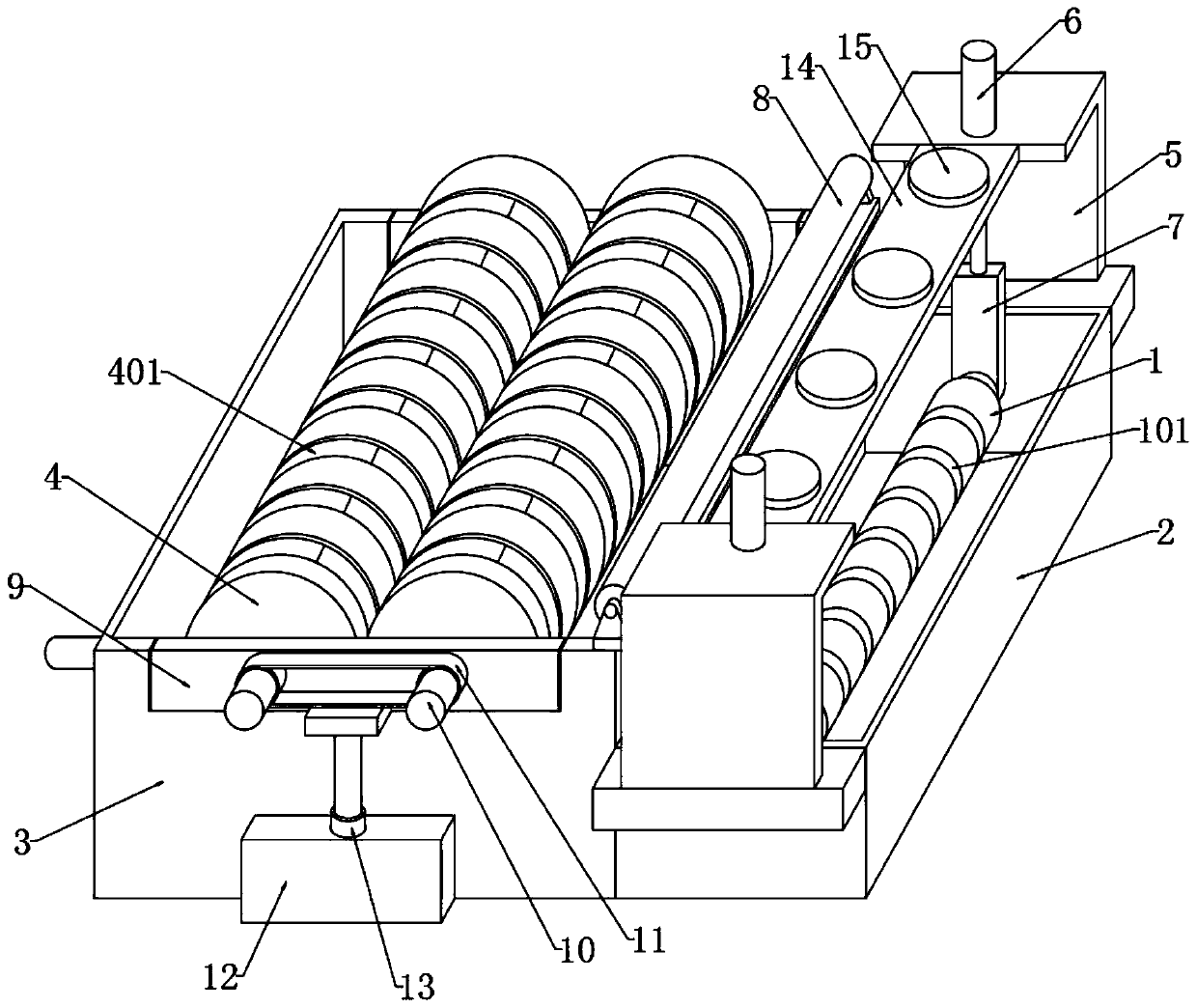

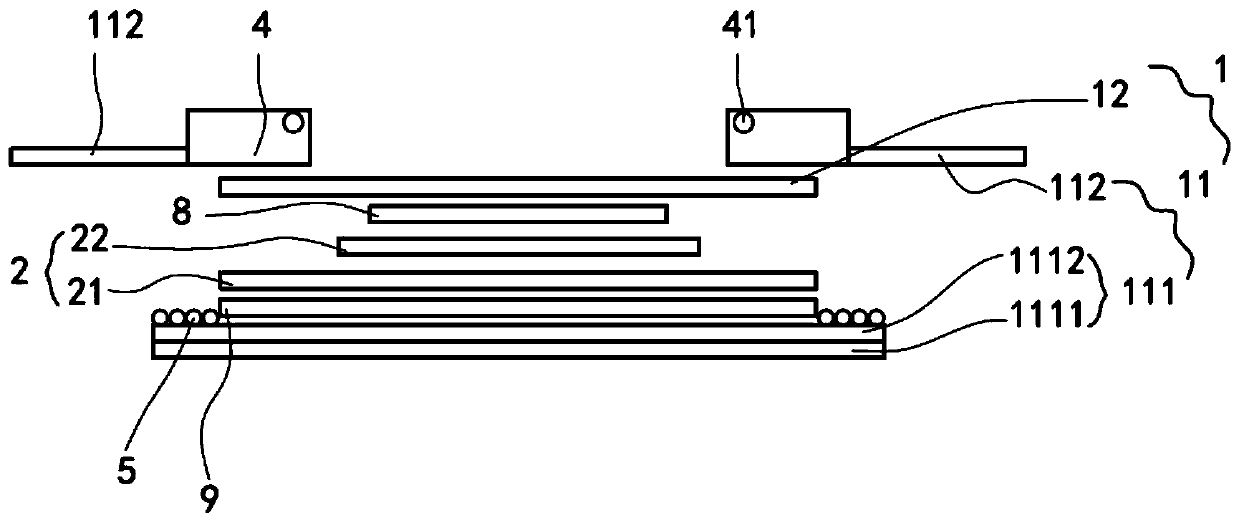

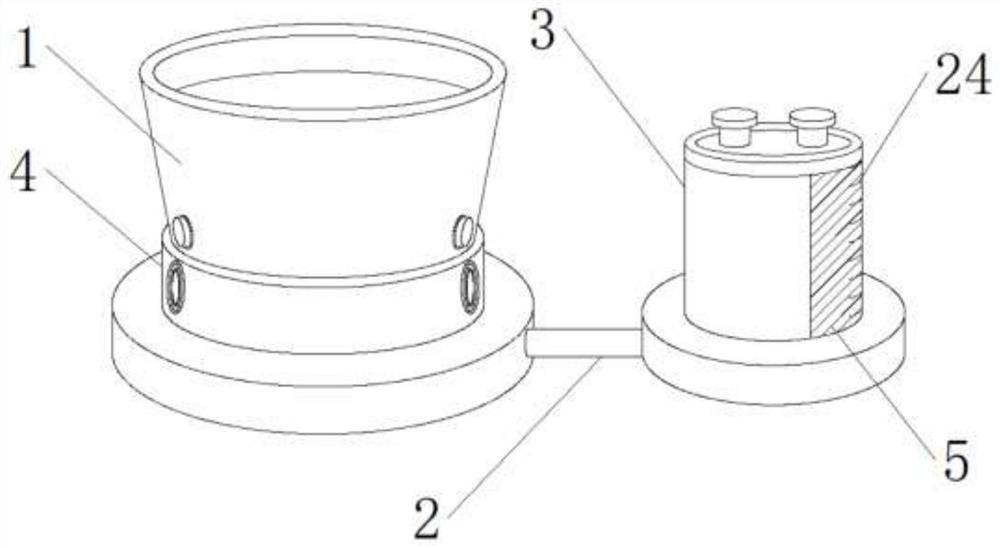

Coloring process for modified polypropylene chemical fiber processing

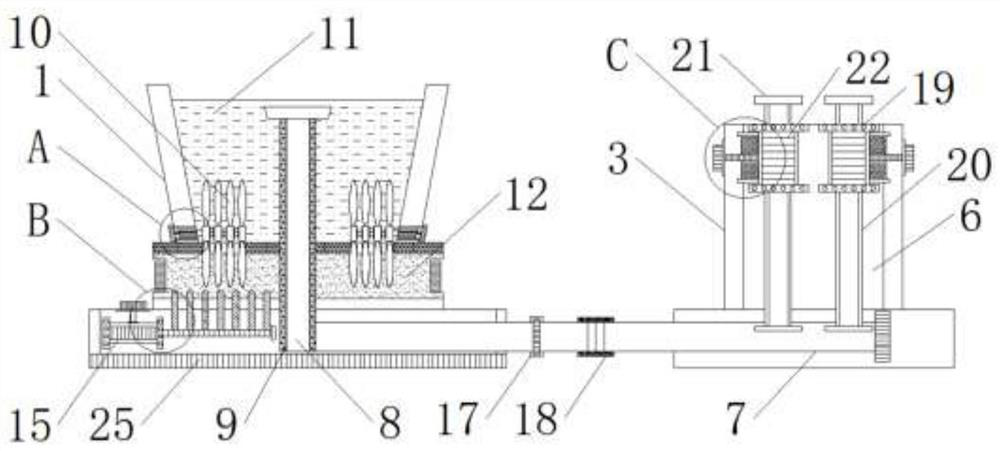

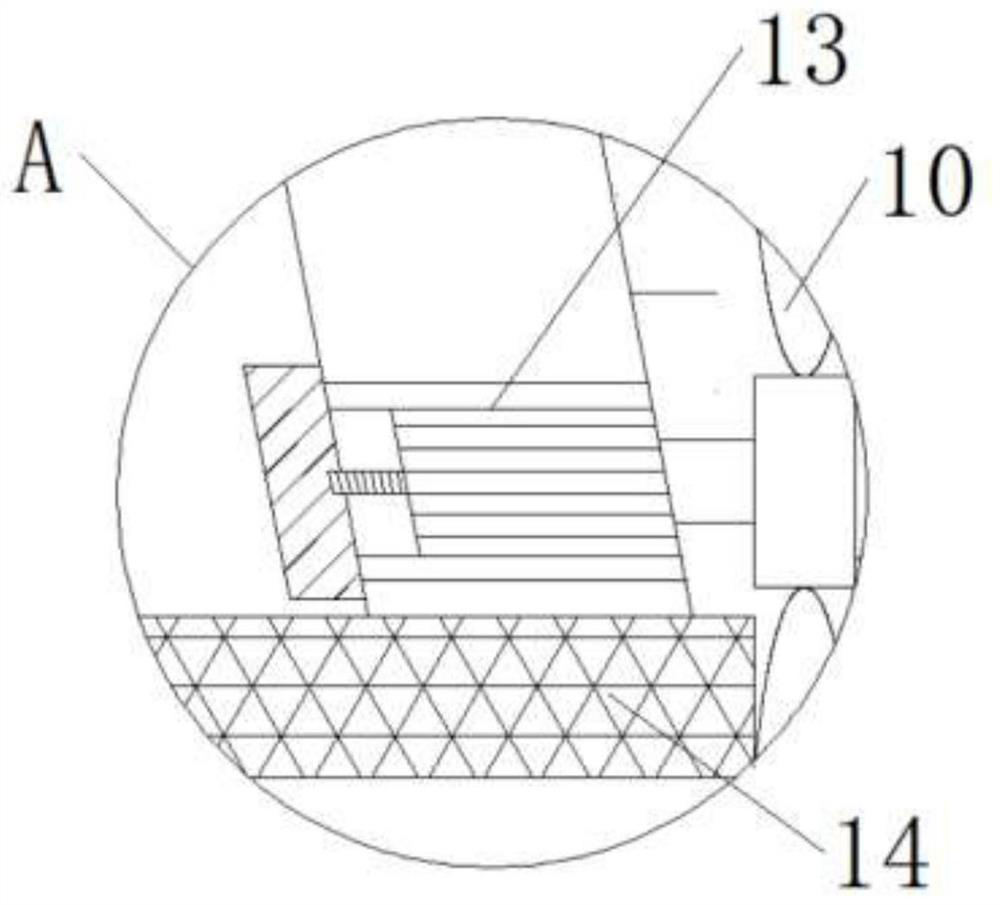

ActiveCN111270535ASimplify the operation processImprove operation effectBiochemical fibre treatmentHeat resistant fibresPolypropylenePolymer chemistry

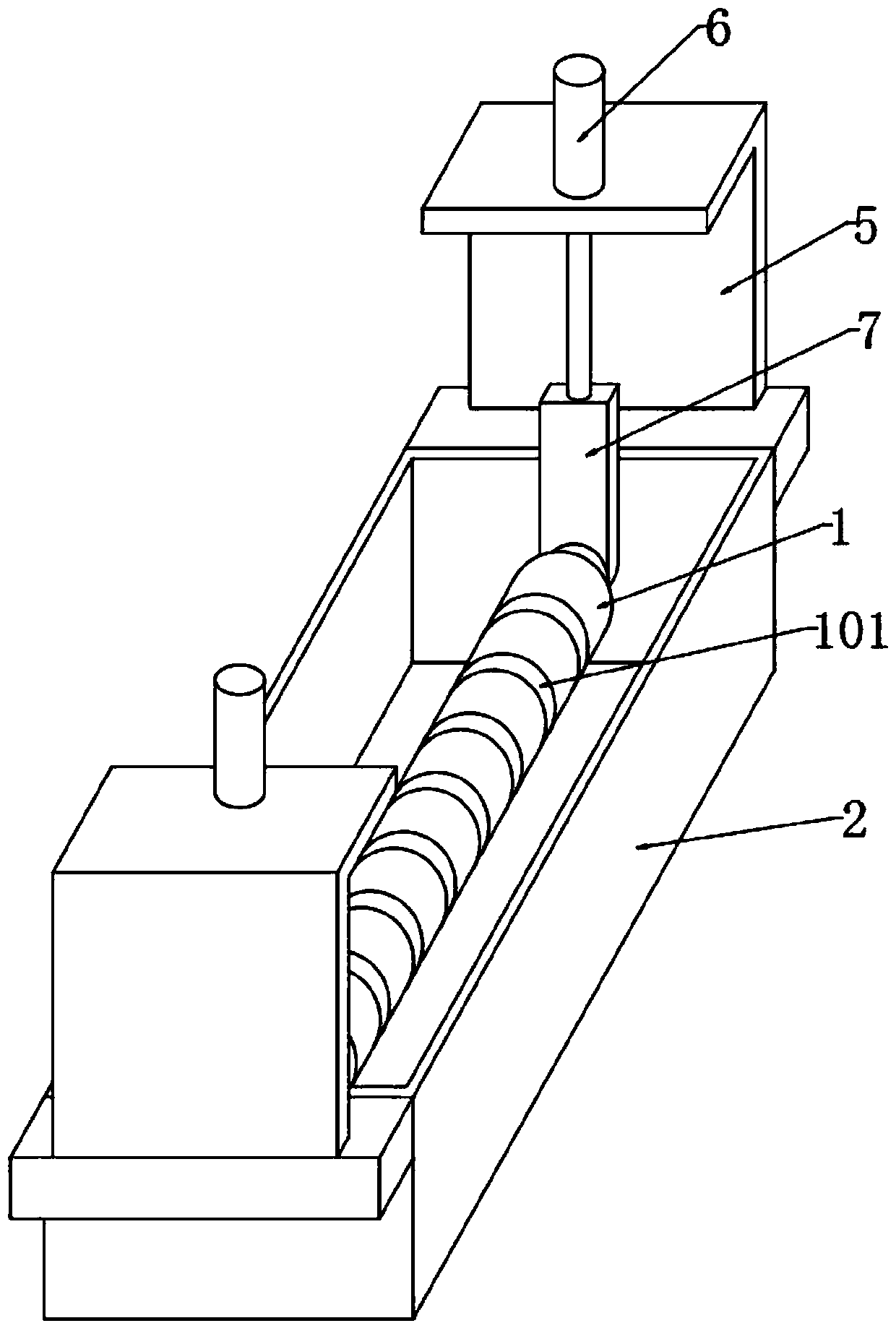

The present invention discloses a coloring process for modified polypropylene chemical fiber processing, and belongs to the technical field of modified polypropylene chemical fiber production processes. According to the coloring process for modified polypropylene chemical fiber processing, a soaking vat used for soaking modified polypropylene chemical fibers is additionally arranged on one side ofa bleaching and dyeing vat, and the soaked modified polypropylene chemical fibers are dewatered and dried, so that the operation process is simplified and the operation efficiency is effectively improved; by cooperation of a winding roller and a dip dyeing roller set, the modified polypropylene chemical fibers are uniformly dip-dyed; the modified polypropylene chemical fibers on the winding roller are guided into dyeing liquid in the bleaching and dyeing vat and are guided up to outside through the dip-dyeing roller set; the dip-dyeing roller set which does opposite rotational motion can remove excess dyeing liquid on the modified polypropylene chemical fibers on one hand and effectively improves the dip-dyeing uniformity of the modified polypropylene chemical fibers on the other hand; and the modified polypropylene chemical fibers penetrate through the dip-dyeing roller set and then are pressed by the dip-dyeing roller set which rotates, so that the permeability of the dyeing liquidto the modified polypropylene chemical fibers is further improved, the coloring effect is effectively improved, and the color fastness of the modified polypropylene chemical fibers is improved.

Owner:朱爱民

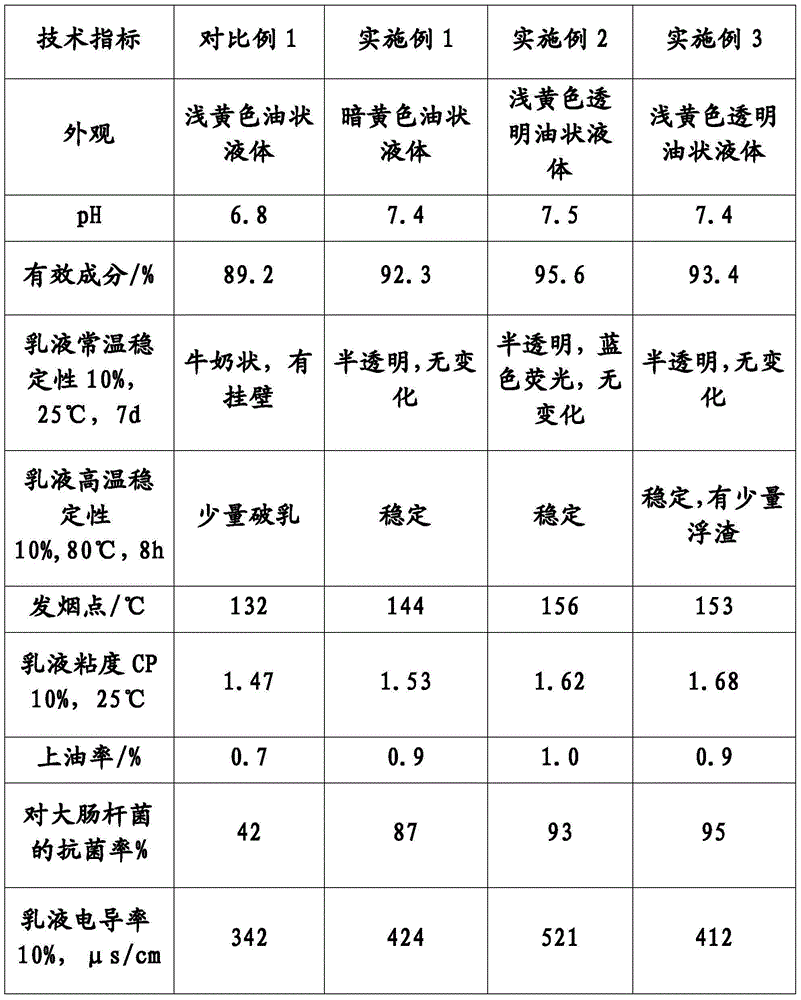

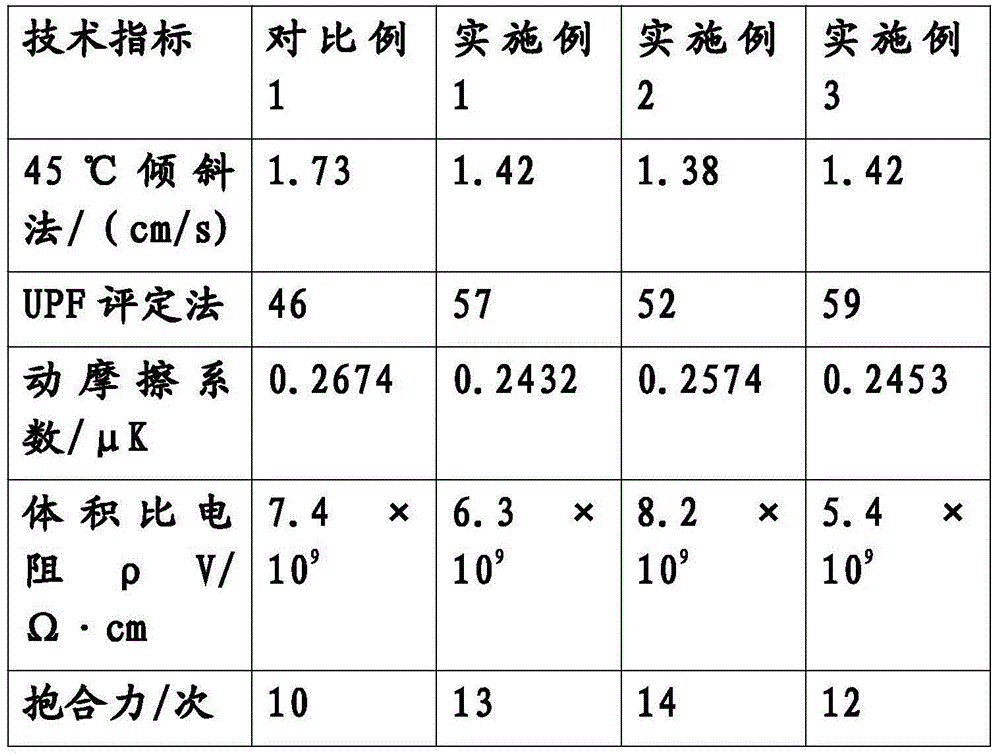

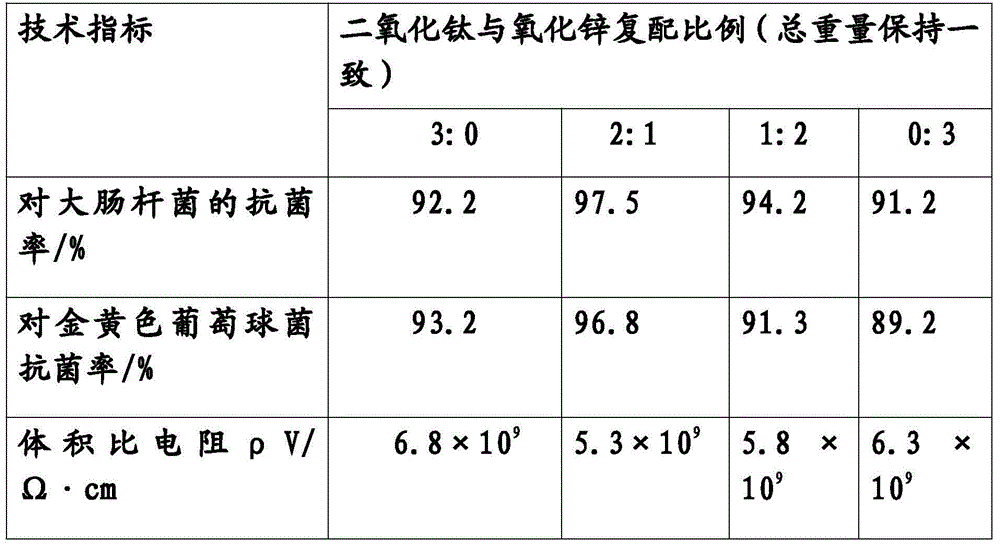

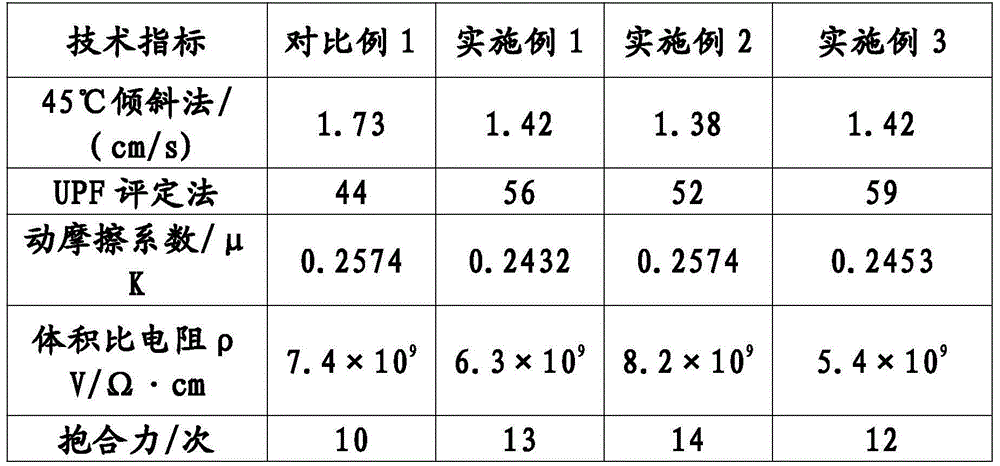

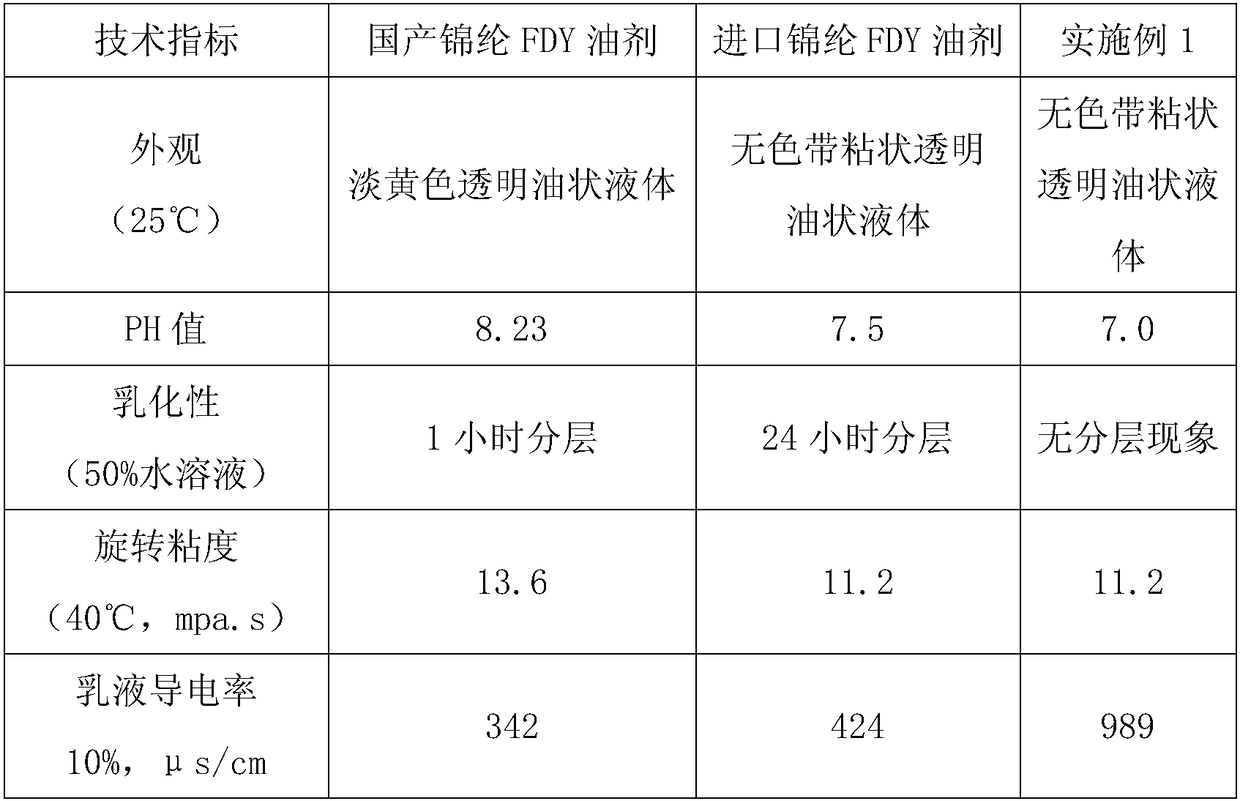

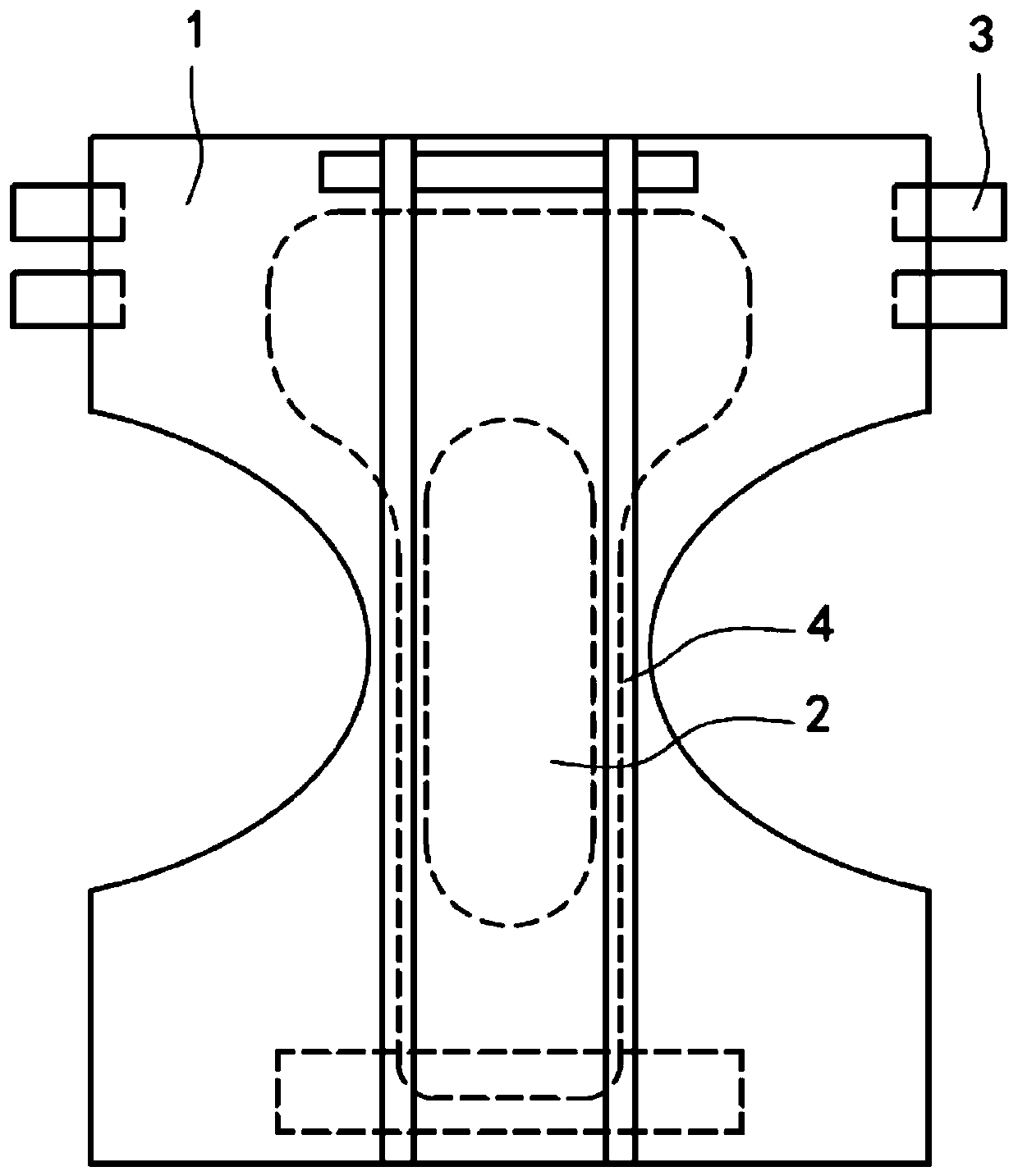

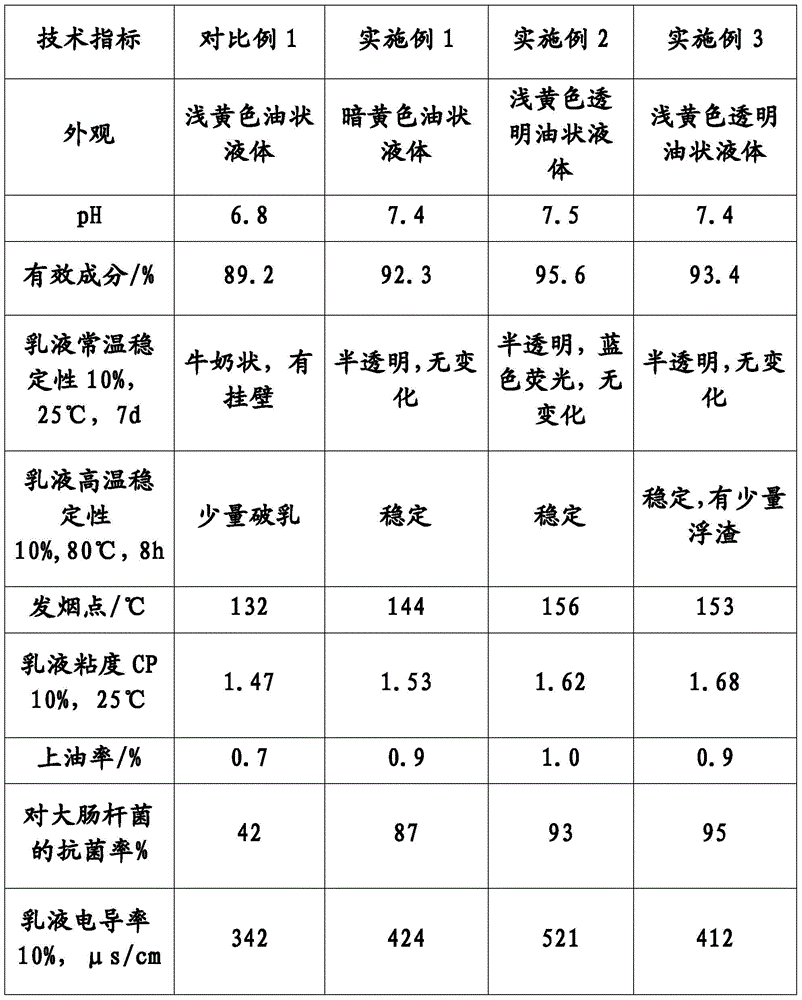

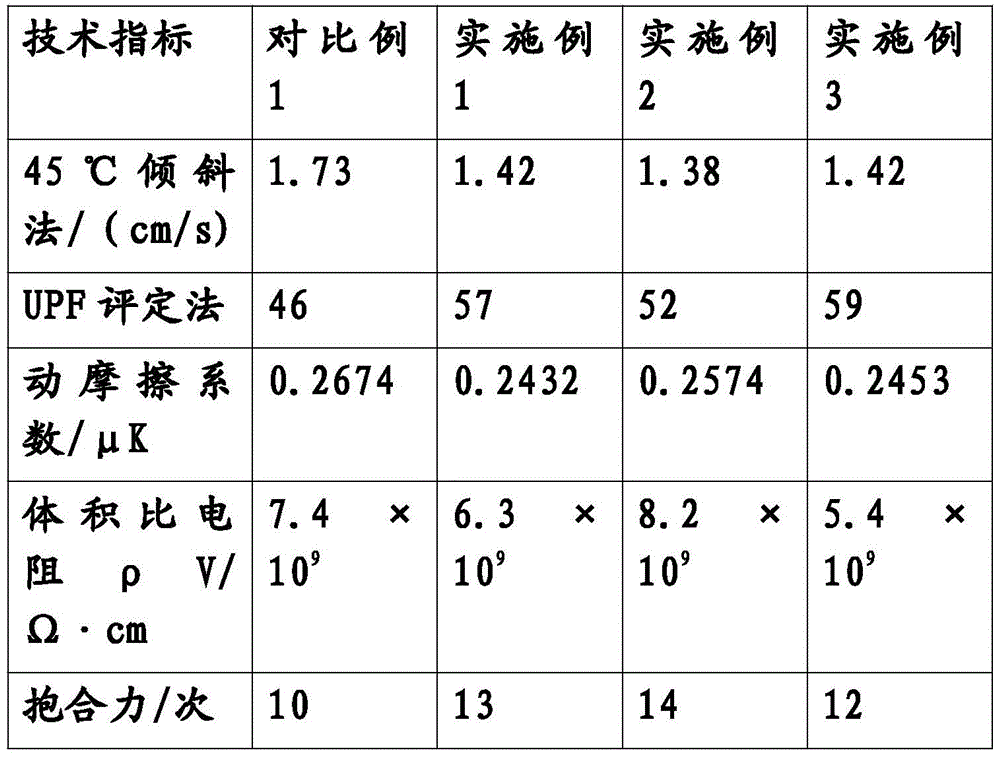

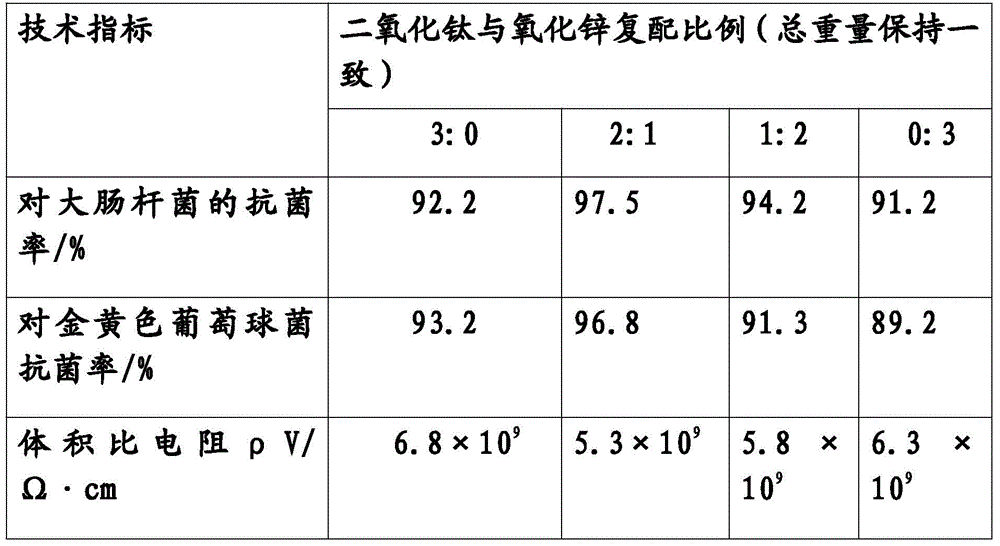

Preparation method of chinlon FDY (Fully Drawn Yarn) oil agent

InactiveCN108221387AThe solution function is relatively simpleGood dispersionBiochemical fibre treatmentLight resistant fibresYarnZinc

The invention provides a preparation method of a chinlon FDY (Fully Drawn Yarn) oil agent. The preparation method comprises the following steps: (1) adding 3-6 parts of metal oxide and 1-3 parts of high-efficiency composite dispersing agent, wherein the rotating speed of a ball mill is 100-200r / min, and grinding for 6 hours to obtain dry powder A; the metal oxide is prepared from the following components in parts by weight: 1-1.5 parts of graphene oxide, 5-10 parts of zinc oxide and 3-5 parts of titanium dioxide; (2) adding the dry powder A into 1-3 parts of th high-efficiency composite dispersing agent, mixing, adding a mixture into an ultrasonic waves to carry out ultrasonic dispersion and peeling for 3 hours to obtain a composite agent B; (3) preparing the composite oil agent, adding the composite agent B into 30-50 parts of the composite oil agent, and under the conditions that the power is 800-1200W and the transmitting frequency is 20-35kHz, carrying out water-bathing ultrasonicvibration for 2 hours to obtain the chinlon FDY oil agent.

Owner:JIANGSU WENFENG CHEM FIBER GROUP

Formaldehyde-removing, bacteria-removing and antifouling furniture board and preparation process thereof

InactiveCN111469223AImprove antifouling performanceEasy to cleanWood veneer joiningFiberCarbon fibers

The invention provides a formaldehyde-removing, bacteria-removing and antifouling furniture board. The formaldehyde-removing, bacteria-removing and antifouling furniture board comprises a base board,wherein a UV adhesion layer is attached to the upper surface of the base board in a pressed mode, a UV pattern printed layer is printed on the upper surface of the UV adhesion layer, transparent environment-protecting coating films are sprayed to the upper surface and the side edges of the UV pattern printed layer, and the lower surface of the base board is coated with anti-corrosion paint. Nano titanium dioxide can decompose dirt attached to the surface, and the environment-protecting coating films enable the surface of the furniture board to be smooth and easy to clean, so that the antifouling property of the furniture board is improved; nano-zinc oxide and nano-titanium dioxide are widely used physical sun-screening agents so that the influence of illumination on the UV pattern printedlayer can be reduced; the furniture board is sealed through the anti-corrosion sprayed paint and the environment-protecting coating films, and moisture is prevented from entering the board, so that the service life of the furniture board is prolonged, and the antibacterial performance of the furniture board is improved; and single plates are arranged in a criss-cross mode and bonded with carbon fiber cloth, so that the structural strength of the furniture board is improved.

Owner:山东卓远装饰材料有限公司

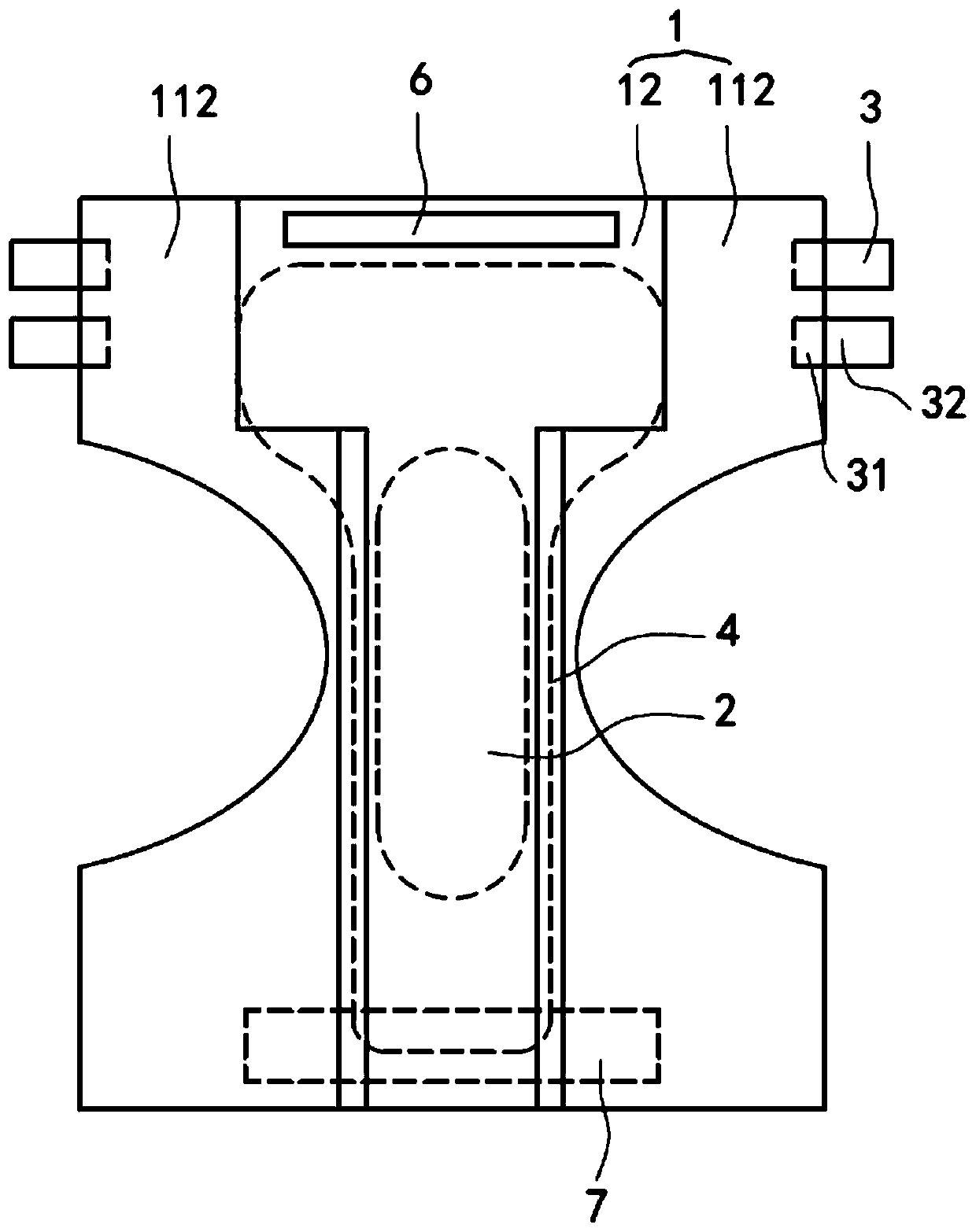

Disposable absorption product

InactiveCN111568644AWill not cause back leakagePlay the role of waterproofBandagesEngineeringMechanical engineering

The invention relates to the technical field of hygienic products, in particular to a disposable absorption product. The disposable absorption product comprises an outer body and an absorption core, wherein the outer body comprises a permeable area and a non-permeable area, the upper portions, the middle portions and the lower portions of the outer body and the absorption core are a hip area, a middle area and an abdomen area respectively, and the width of the hip area of the absorption core is larger than that of the middle area of the absorption core; the absorption product further comprisestwo leakage-proof flanges which extend from the abdomen area to the hip area, the upper ends of the leakage-proof flanges are located on the hip area of the absorption core, and a first distance is formed between the upper ends of the leakage-proof flanges and the upper edge of the hip area of the absorption core; and water permeable areas are arranged above the upper ends of the leakage-proof flanges and above the surface of the absorption core between the two leakage-proof flanges. When liquid exists on the hip core, the area above the upper ends of the leakage-proof flanges is not blockedby the leakage-proof flanges, the liquid can freely and rapidly diffuse to the two outer sides through the water permeable areas and the surface of the absorption core, and the phenomenon that the absorption product leaks backwards is avoided.

Owner:SHENZHEN LIYIJIUJIU NETWORK TECH CO LTD

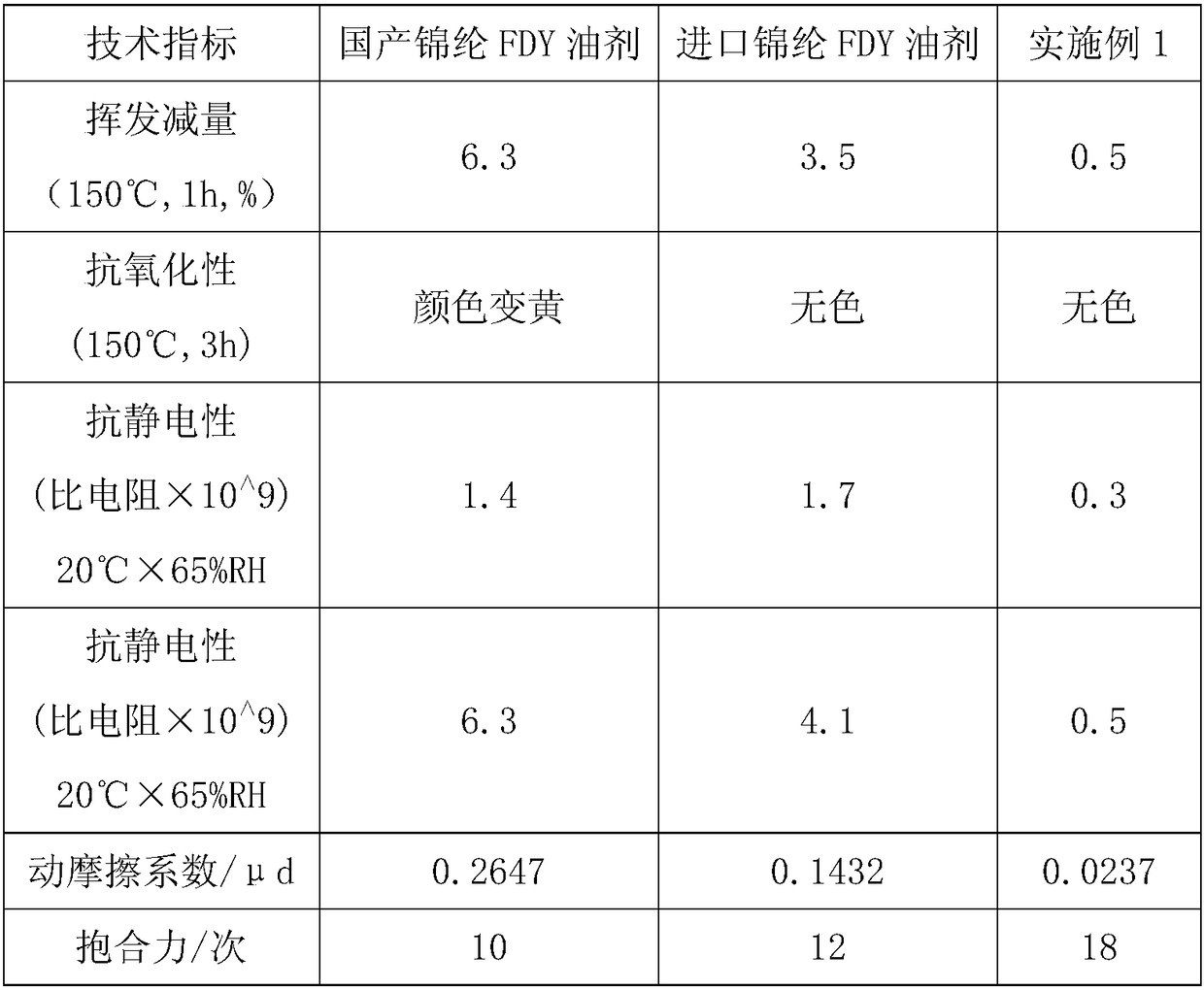

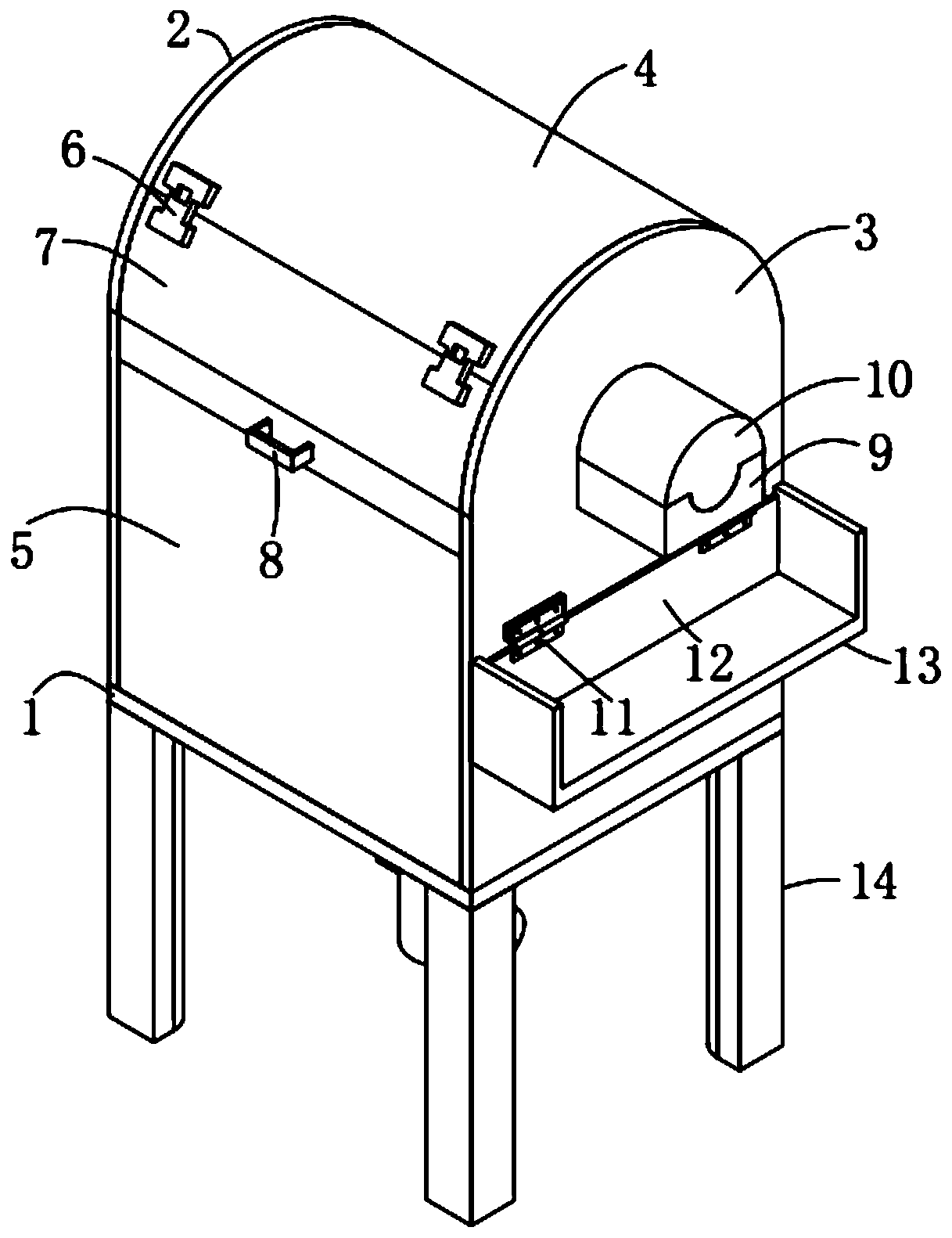

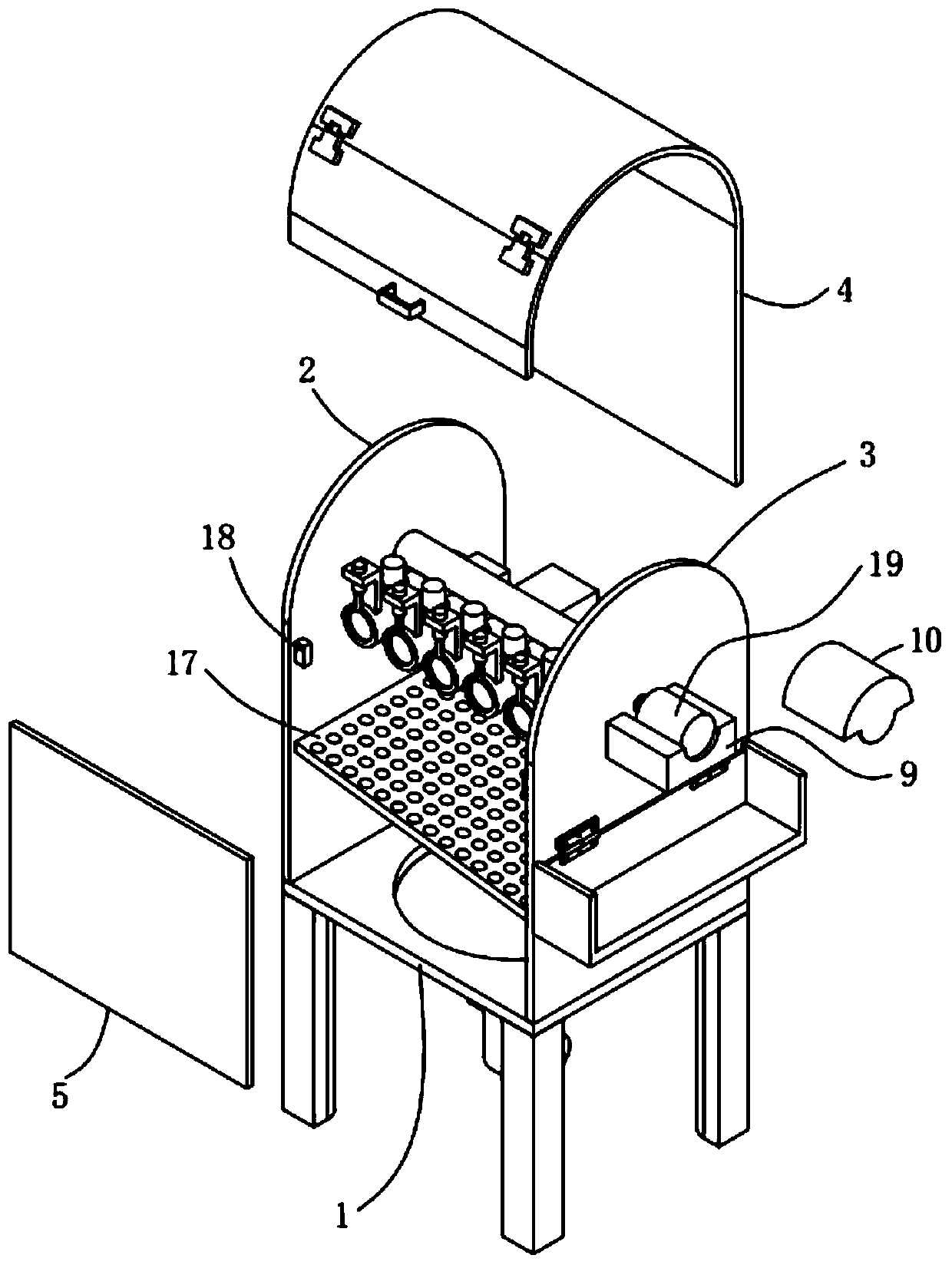

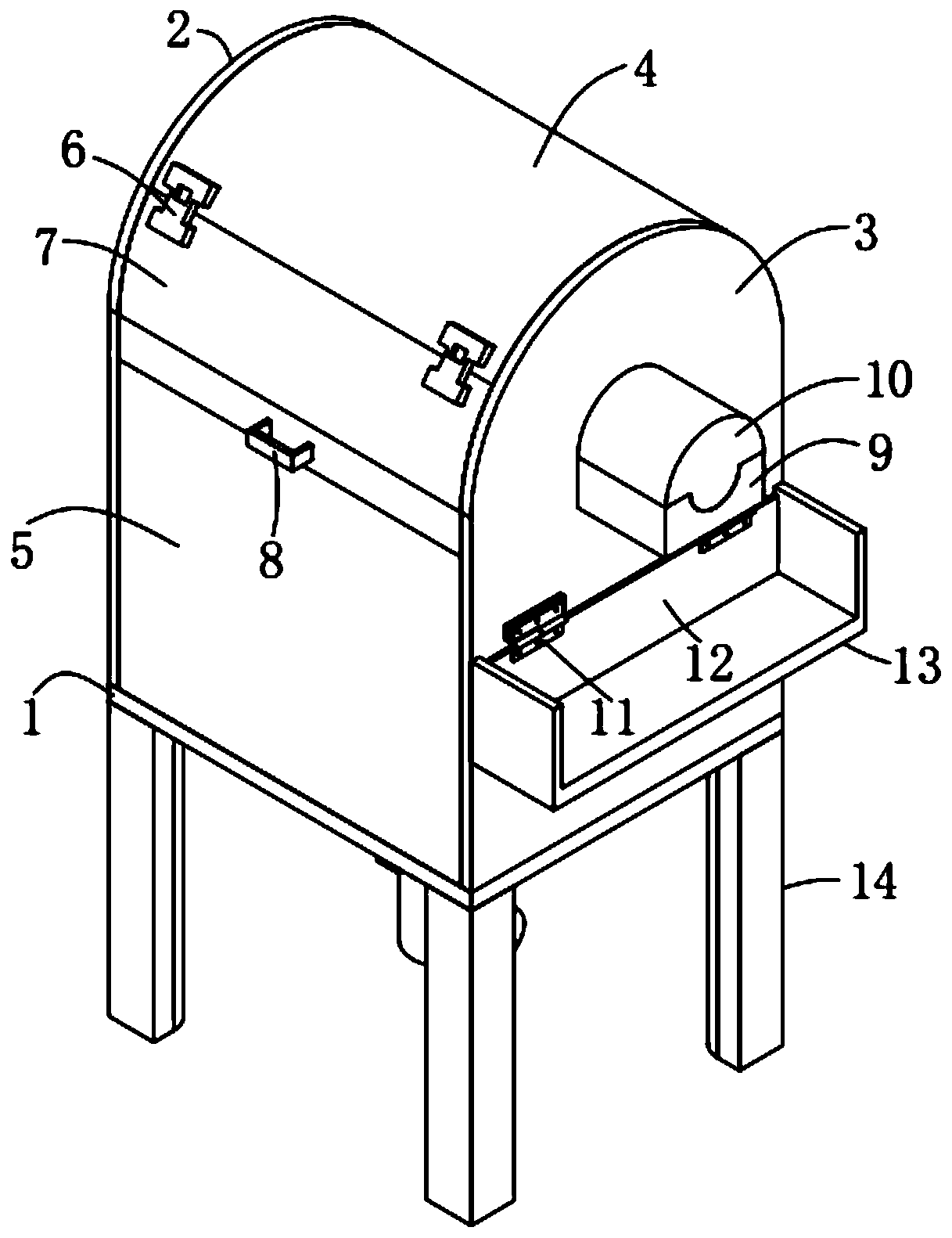

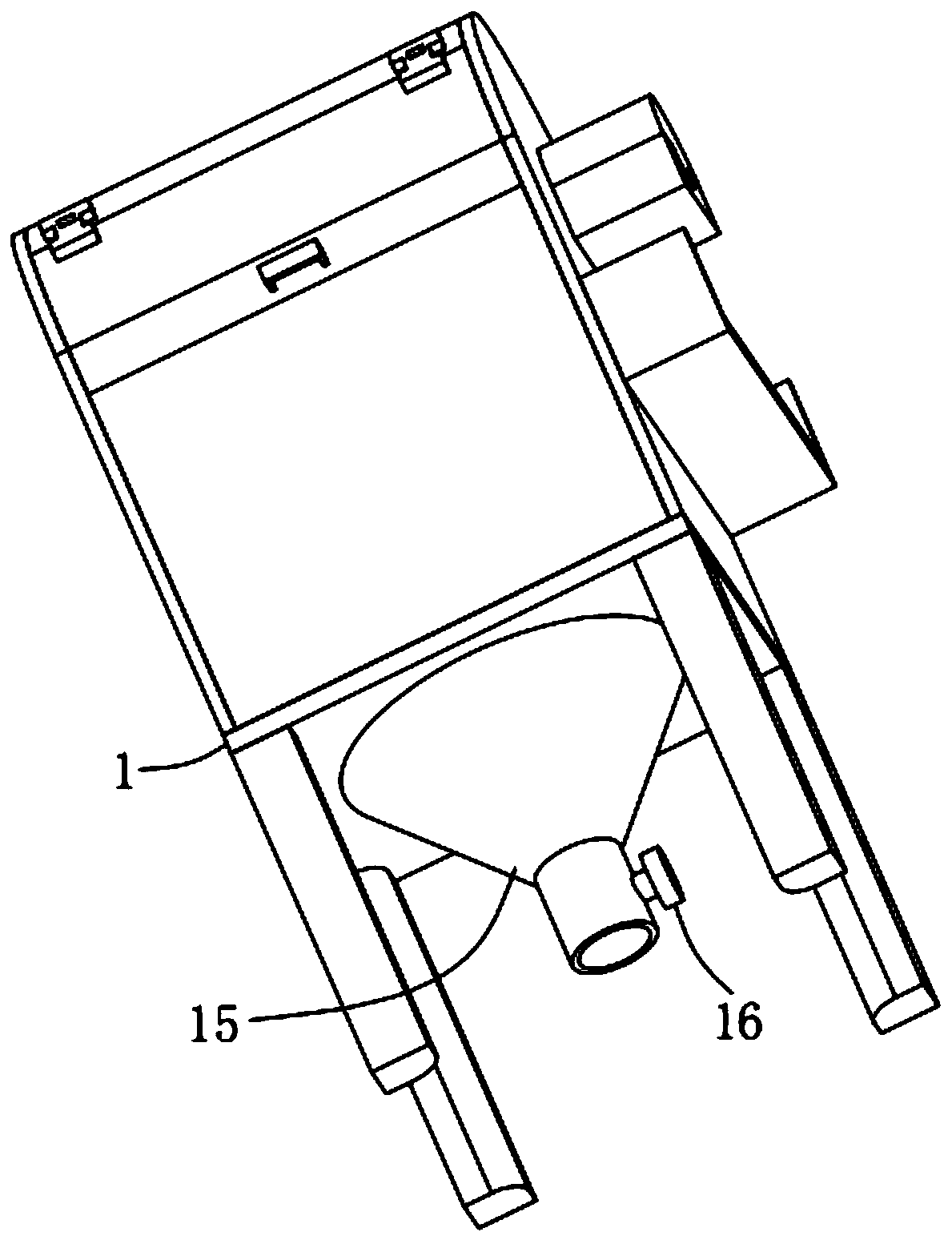

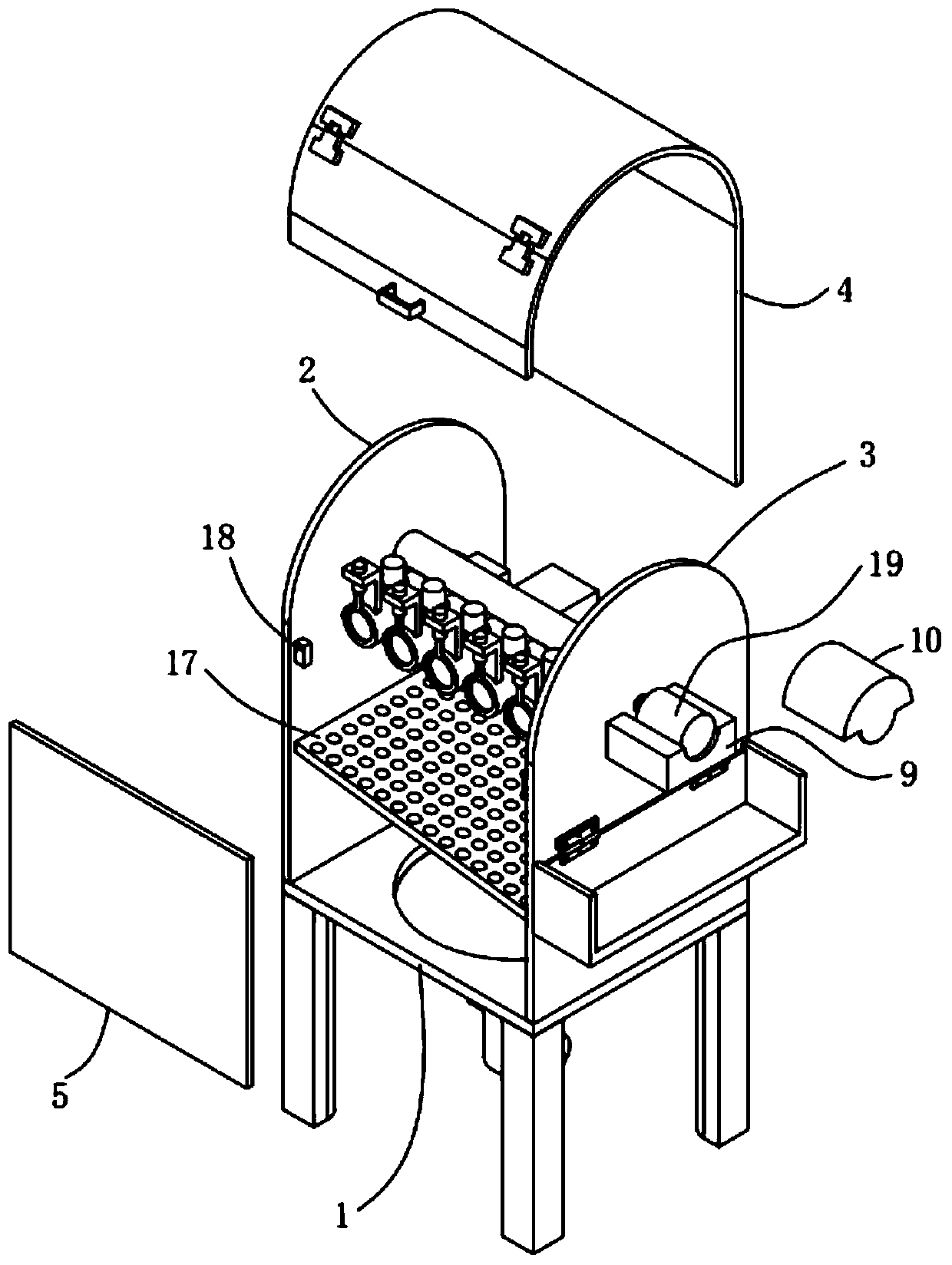

Sorting device realizing concentrated treatment of dismantling and draining for dry powder can

ActiveCN110624942ARealize classified collectionFacilitate subsequent unified processingSolid waste disposalCoatingsEngineeringTherapeutic effect

The invention discloses a sorting device realizing concentrated treatment of dismantling and draining for a dry powder can. The device comprises a bottom plate, four supporting legs, a first side plate, a second side plate, a front cover plate, a rear cover plate, a driving turnover unit, a dismantling and draining unit, a separating plate and a collecting hopper, wherein the four supporting legsare fixedly mounted at four corners of the bottom of the bottom plate in a symmetrically mode, and the first side plate and the second side plate are fixedly mounted on the two sides of the upper portion of the bottom plate correspondingly. According to the sorting device, the used dry power can can be treated without using manual operation, the working efficiency is effectively improved, and thethe working intensity is effectively reduced; the dismantled dry power can, dry power and water can be classified and collected for facilitating subsequent unified treatment; the residual quantity ofthe dry powder and water on the inner wall of the dry powder can can be effectively reduced, and the good treatment effect for the used dry power is achieved; and meanwhile, a prepared protective layer can prevent a large amount of residual dry powder and water being adhered to the inner surface of the collecting hopper, so that internal cleaning of the dry powder can is convenient, and cleaning can be carried out only by flushing with water.

Owner:THE FIRST PEOPLES HOSPITAL OF CHANGZHOU

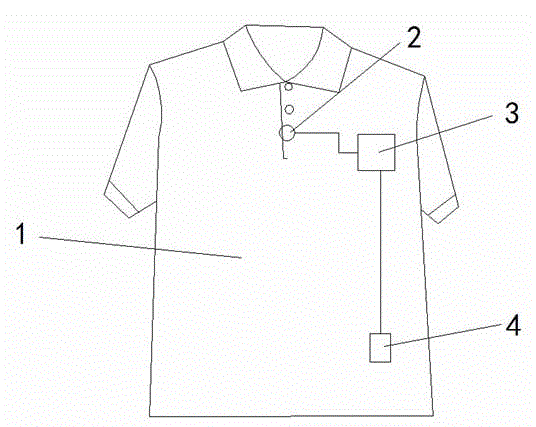

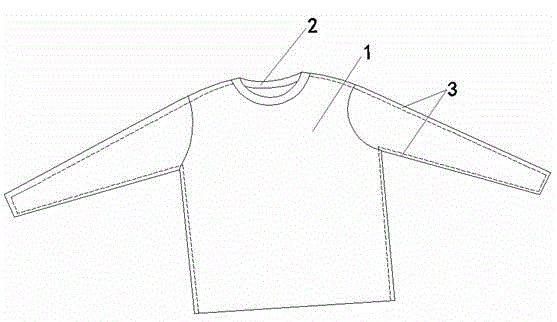

Soundproof garment with videoing function

InactiveCN104413800ASoft touchGood drapabilityGarment special featuresProtective garmentYarnSurface layer

The invention relates to a soundproof garment with a videoing function. The soundproof garment comprises a garment body (1), a front body of the garment body (1) is provided with a micro camera (2), and an upper pocket of the garment body (1) is provided with videoing equipment (3) while a lower pocket of the same is provided with storage equipment (4). The garment body is made by fabric which comprises a surface layer and a lining layer, the surface layer and the lining layer form a whole by interweaving warp and weft, a bamboo charcoal layer is additionally arranged on the outer surface of the lining layer, the surface layer is formed by low stretch yarn, and the lining layer is formed by optical long yarn. When a criminal and illegal event occurs, the videoing equipment can video criminal personnel and the criminal and illegal event, and video can be copied from the storage equipment to serve as evidence to protect harmed personnel. The soundproof garment is soundproof.

Owner:JIANGYIN CHUNZHILAN SPECIAL YARN

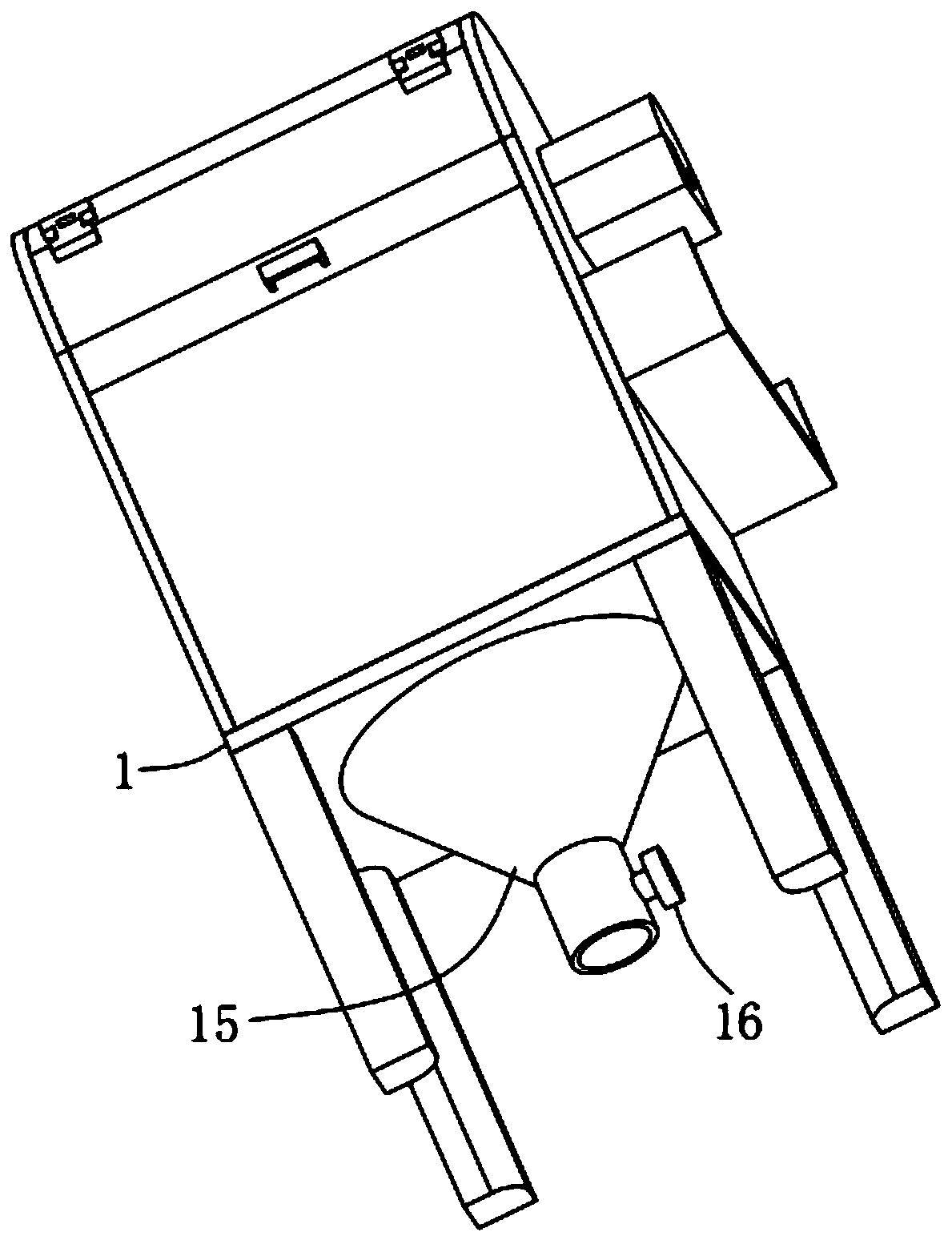

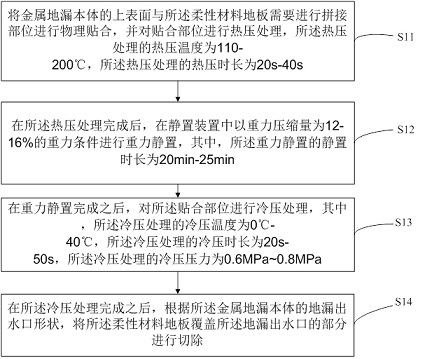

Flexible material floor and floor drain combination process and product

PendingCN114571734ANo gapsIncrease antibacterialSewerage structuresClimate change adaptationFloorcoveringStructural engineering

The invention provides a flexible material floor and floor drain combination process and product, and the flexible material floor and floor drain combination process comprises the following steps: physically laminating the upper surface of a metal floor drain body and a part, needing to be spliced, of a flexible material floor, and carrying out hot pressing treatment on the laminated part at the hot pressing temperature of 110-200 DEG C for 20-40 seconds; after hot pressing treatment is completed, gravity standing is carried out in a standing device under the gravity condition that the gravity compression amount is 12-16%, and the standing time of gravity standing is 20-25 min; after gravity standing is completed, cold pressing treatment is conducted on the attached portion, the cold pressing temperature ranges from 0 DEG C to 40 DEG C, the cold pressing duration ranges from 20 s to 50 s, and the cold pressing pressure ranges from 0.6 MPa to 0.8 MPa; and after cold pressing treatment is completed, the part, covering the floor drain water outlet, of the flexible material floor is cut off according to the shape of the floor drain water outlet of the metal floor drain body. The flexible material floor is naturally bent and shaped, no gap is generated, and the antibacterial effect is improved.

Owner:恳盈环保科技(上海)有限公司

Additives for Nylon Spinning

ActiveCN104611912BHas UV protection propertiesThe solution function is relatively simpleFibre typesPolymer scienceSpinning

The present invention provides a chinlon spinning additive. The additive consists of the following components in parts by weight: 5 to 10 parts of zinc oxide, 3 to 5 parts of titanium dioxide, 2 to 6 parts of montmorillonite, 3 to 6 parts of vermiculite, and 1 to 3 parts of dispersing agent. The additive prepared in the present invention has a small grain size and good dispersing performance, and can improve the stability of spinning oil, ultraviolet prevention and antibacterial performance of the spinning oil after the additive is added into the spinning oil.

Owner:JIANGSU WENFENG CHEM FIBER GROUP

Water storage self-suction type plant cultivation device

ActiveCN113068470AAchieve flipping effectImprove the cultivation effectSpadesWatering devicesWater storageWater storage tank

The invention discloses a water storage self-suction type plant cultivation device which comprises a device body, a device communicating pipe and a water storage tank. One side of the bottom of the device body is fixedly connected with the device communicating pipe; one end of the device communicating pipe is fixedly connected with the water storage tank; the bottom of the device body is fixedly connected with a soil fertilizer filling layer; one side of the water storage tank is fixedly connected with a water level observation window; one side of the bottom of the device body is fixedly connected with a sterilization power source; and one end of the sterilization power source is fixedly connected with a built-in sterilization lamp. The built-in sterilization lamp well improves the antibacterial property of the device; a one-way control valve can well prevent water flow in a pipeline from flowing backwards under the influence of gravity; a water level observation mechanism well achieves the effect of obtaining soil water level data; a cultivation effect of the device is well improved through a fertilizer irrigation and soil loosening mechanism; and a water storage and water injection mechanism well embodies water pumping and water injection integrated convenience of the device, so that the device is suitable for being used in the technical field of cultivation devices and has wide development prospects in the future.

Owner:NANYANG NORMAL UNIV

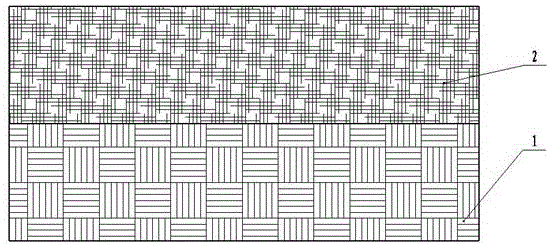

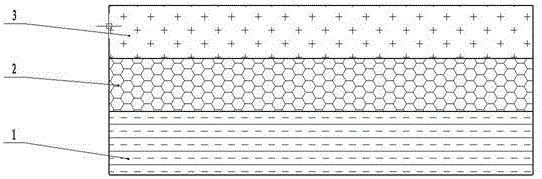

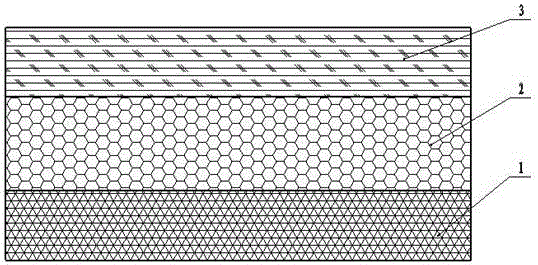

Machine washable easy-care shirt fabric soft in hand feeling and good in drapability

InactiveCN106183060AImprove wear resistanceSave comfortSynthetic resin layered productsClothingsSurface layerPolyurethane adhesive

The invention relates to a machine-washable non-ironing shirt fabric with soft handfeel and good drapability, comprising a fabric bottom layer (1), an anti-wrinkle layer (2) on the surface of the fabric bottom layer, and a water-based polyurethane adhesive compounded between the fabric bottom layer and the anti-wrinkle layer together. The back of the bottom layer is provided with a lining fabric layer. The lining fabric layer includes a surface layer and an inner layer. The surface layer and the inner layer are interwoven with warp and weft yarns to form a whole, and a bamboo charcoal layer is provided on the surface of the inner layer. The invention has good comfort, absorbs sweat and inhibits bacteria, and can be machine washed. The invention has soft hand feeling and good drapability.

Owner:JIANGYIN CHUNZHILAN SPECIAL YARN

A sorting device for centralized treatment of dry powder tanks, demolition and discharge liquid

ActiveCN110624942BRealize classified collectionFacilitate subsequent unified processingSolid waste disposalSpecial surfacesStructural engineeringProcess engineering

The invention discloses a sorting device realizing concentrated treatment of dismantling and draining for a dry powder can. The device comprises a bottom plate, four supporting legs, a first side plate, a second side plate, a front cover plate, a rear cover plate, a driving turnover unit, a dismantling and draining unit, a separating plate and a collecting hopper, wherein the four supporting legsare fixedly mounted at four corners of the bottom of the bottom plate in a symmetrically mode, and the first side plate and the second side plate are fixedly mounted on the two sides of the upper portion of the bottom plate correspondingly. According to the sorting device, the used dry power can can be treated without using manual operation, the working efficiency is effectively improved, and thethe working intensity is effectively reduced; the dismantled dry power can, dry power and water can be classified and collected for facilitating subsequent unified treatment; the residual quantity ofthe dry powder and water on the inner wall of the dry powder can can be effectively reduced, and the good treatment effect for the used dry power is achieved; and meanwhile, a prepared protective layer can prevent a large amount of residual dry powder and water being adhered to the inner surface of the collecting hopper, so that internal cleaning of the dry powder can is convenient, and cleaning can be carried out only by flushing with water.

Owner:THE FIRST PEOPLES HOSPITAL OF CHANGZHOU

Antistatic fabric with fluffy hand feeling and good drapability

InactiveCN106113782AExtended service lifeAchieve anti-static effectSynthetic resin layered productsClothingsSurface layerEngineering

The invention relates to an antistatic fabric with a fluffy hand feeling and good drapability. The antistatic fabric with the fluffy hand feeling and the good drapability comprises an inner layer (1), wherein a basic layer (1) and a static electricity removing layer (3) are arranged in sequence outside the inner layer. The back surface of the inner layer is provided with a lining fabric layer; the lining fabric layer comprises a surface layer and an internal layer; the surface layer and the internal layer are interlaced through warps and wefts to form a whole; the surface of the internal layer is additionally provided with a bamboo charcoal layer. The antistatic fabric with the fluffy hand feeling and the good drapability can be used for prolonging the service life of the fabric, is resistant to water scrubbing and is antistatic. The antistatic fabric has the fluffy hand feeling and the good drapability.

Owner:JIANGYIN SHANGFENG TEXTILE

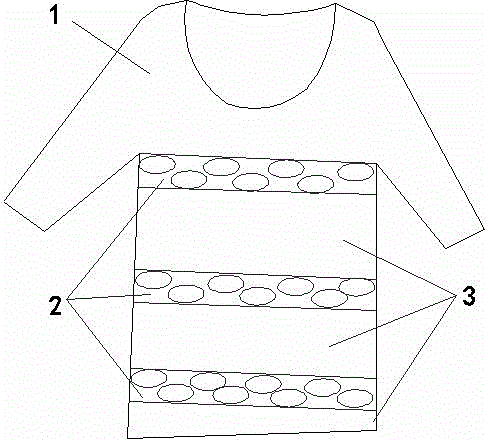

Odor removing clothing with hollows alternating with solid stripes

InactiveCN104413848AAdd dimensionEnhance layeringGarment special featuresCurtainsSurface layerEngineering

The invention relates to an article of odor removing clothing with hollows alternating with solid stripes. The odor removing clothing with hollows alternating with solid stripes comprises a clothing body (1), three hollow strips (2) are formed in the front body of the clothing body, and solid stripe strips (3) are arranged between the hollow strips (2); fabric of the clothing body (1) is composed of a surface layer and a lining layer, the surface layer and lining layer are weaved into a single unit through warps and weft yarns, a bamboo charcoal layer is arranged at the outer surface of the lining layer, the surface layer is composed of low stretch yarns, and the lining layer is composed of lustrous filaments. The odor removing clothing with hollows alternating with solid stripes increases the artistry and fashionability of the clothing. The bamboo charcoal layer plays roles of removing odor, sterilizing, preventing corrosion and preventing mildew.

Owner:JIANGYIN MINGPIN KNITTING

Water-base lotus paint for inner and outer building wall and its prepn process

InactiveCN100427557CImprove environmental performanceImprove performanceEmulsion paintsEmulsionWhitening Agents

The present invention relates to one kind of water-base lotus paint for inner and outer wall of building and its preparation process. The water-base lotus paint consists of dispersant, wetting agent, thickener, filming assistant, styrene-acrylic emulsion, antifreezing agent glycol, defoamer, bactericide, leveling agent, whitening agent and other ingredients. It is prepared through preparing pigment slurry, grinding and blending. It has the advantages of environment friendship, high adhesion, high wear resistance, etc.

Owner:赵青山

Easily-dressed garment with good drapability

InactiveCN104413973AThe dressing process is simpleEasy to dressProtective garmentSpecial outerwear garmentsMedicineEngineering

The invention relates to an easily-dress garment with good drapability. The easily-dress garment comprises a front portion (1) and a rear portion (2), wherein magnetic stripes (3) are respectively arranged on the two sides and the upper side of each of the front portion (1) and the rear portion (2); a shell fabric adopted by the front portion (1) and the rear portion (2) consists of a surface layer and a lining layer, the surface layer and the lining layer are interwoven through warps and wefts to form a whole, a bamboo charcoal layer is additionally arranged on the outer surface of the lining layer, the surface layer is composed of low stretch yarns, and the lining layer consists of lustrous filaments. When a user needs to dress a person with limb disability, the user can put the front portion and the rear portion of the garment closely onto the body of the person and adheres the front portion and the rear portion together through the magnetic stripes, so that the dressing process is concise, convenient and rapid. Due to the arrangement of the bamboo charcoal layer, the garment additionally has the characteristics of odor removal, sterilization, corrosion prevention and mildew prevention. Moreover, the shell fabric has sponginess and good drapability.

Owner:JIANGYIN HAIYING WOOLEN GOODS

Fiber fabric with high sponginess and drapability and feeling cool

The invention relates to a fiber fabric with high sponginess and drapability and feeling cool. The fiber fabric comprises an inner layer (1), wherein a sweat guiding layer (2) and an outer layer (3) are arranged on the outer surface of the inner layer (1) in sequence, a lining fabric layer is arranged on the back side of the inner layer and comprises a surface layer and an inside layer, the surface layer and the inside layer are integrated through warp and weft interweaving, and a bamboo charcoal layer is arranged on the surface of the inside layer. The fiber fabric has high flexibility, washing resistance and weather resistance are greatly improved, and sponginess and drapability are high.

Owner:JIANGYIN DONGFA GARMENT MAKING

Modified nano bamboo charcoal mask and preparation method thereof

InactiveCN104041963BStrong adsorption propertiesHigh adsorption propertiesFibre typesProtective garmentPolymer scienceAdhesive

Provided are a modified nanometer bamboo charcoal mask and a manufacturing method thereof. The modified nanometer bamboo charcoal mask comprises an inner mask and an outer mask, wherein the inner mask is provided with a dismounting opening, and a filer layer is arranged in the dismounting opening. The inner mask and the outer mask of the mask and a filer layer base plate are made of an electrets melt-blowing polypropylene fiber non-woven fabrics, the filer layer uses chitosan as a capsule wall material, microcapsules are made from modified nanometer bamboo charcoal powder, beewax is used as an adhesive for arranging the microcapsules on the non-woven fabrics. The modified nanometer bamboo charcoal powder are modified by adopting nanometer titanium dioxide. The modified nanometer bamboo charcoal mask is green, environment-friendly, safe and efficient, has the broad-spectrum antibacterial effect and has good washability due to the fact that the beewax is used as the adhesive to arrange the microcapsules on the non-woven fabrics.

Owner:广州市威普复合材料有限公司

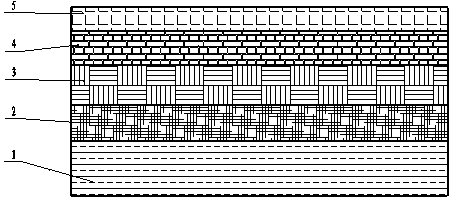

Wear-resistant fabric with soft hand feel and good drapability

InactiveCN107724098AImprove tensile strengthImprove wear resistanceSynthetic resin layered productsCoatingsSurface layerWear resistant

The invention relates to a wear-resistant fabric with soft hand feeling and good drapability, which comprises an inner layer (1), and a base fabric layer (2), a breathable layer (3), a wear-resistant layer (4) and a coating layer are sequentially arranged outside the inner layer (5), the air-permeable layer is woven from three-dimensional mesh microfiber base cloth; the coating layer is polytetrafluoroethylene coating. The back of the inner layer is provided with a lining fabric layer. The lining fabric layer includes a surface layer and an inner layer. The surface layer and the inner layer are interwoven with warp and weft yarns to form a whole, and the surface of the inner layer is additionally provided with a bamboo charcoal layer. The invention improves the tensile strength and wear resistance of the fabric. The invention has soft hand feeling and good drapability.

Owner:黄磊

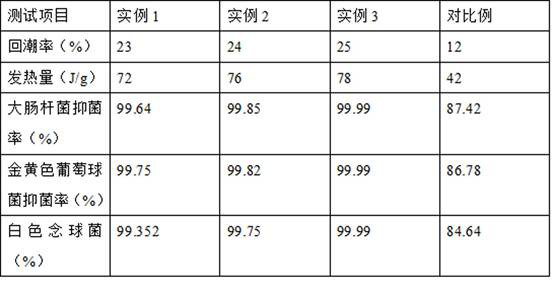

Preparation method of moisture-absorbing, heat-generating and anti-bacterial yarn

ActiveCN108221179BImprove moisture absorption and heat generation performanceDecreased polar forceMonocomponent synthetic polymer artificial filamentNon-woven fabricsYarnMoisture absorption

The invention discloses a method for preparing moisture-absorbing, heat-generating and anti-bacteria yarn, which belongs to the technical field of yarn preparation. Firstly, polyacrylonitrile is modified by alkaline solution and soybean protein. The alkaline solution contains a large number of hydroxyl groups, so that water vapor molecules are adsorbed on the surface of the substrate, thereby improving the moisture absorption and heat generation performance of the yarn. In addition, these hydrophilic groups can make The polar force between polyacrylonitrile molecules is weakened, which is conducive to the improvement of the moisture absorption and heat generation performance of the yarn; the present invention utilizes the chitin in the crab shell to prepare chitosan through a fermentation method, thereby improving the solubility of chitosan, and in addition Adding chitosan in the matrix is beneficial to improve the antibacterial properties of the yarn. In addition, the self-made chitosan is further modified with silver nitrate solution, and the generated hydroxyl radicals and active oxygen ions can destroy bacterial proliferation and achieve antibacterial. After the bacterial cell loses its activity, the silver ions are freed from the bacterial cell to achieve long-lasting antibacterial, thereby improving the antibacterial property of the yarn, and has a wide application prospect.

Owner:普宁市新栩纺织有限公司

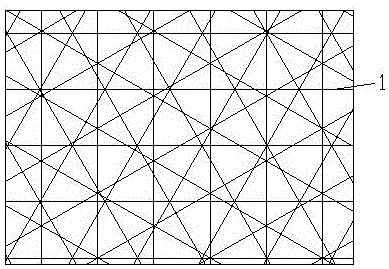

Multilayer net-face fabric with floppy hand feeling and good drapability

InactiveCN106239996ARich layersBright colorLayered productsClothingsSurface layerBiomedical engineering

The invention relates to a multilayer net-face fabric with the floppy hand feeling and the good drapability, and belongs to the field of spinning fabrics. The multilayer net-face fabric comprises a plurality of net face layers (1), the net face layers (1) sequentially rotate by an angle and then are connected up and down through bright silk yarns (2). Lining fabric layers are arranged on the back faces of the net face layers, and comprise surface layers and inner layers, the surface layers and the inner layers are interwoven to be a whole through warp yarns and weft yarns, and bamboo charcoal layers are additionally arranged on the surfaces of the inner layers. According to the multilayer net-face fabric with the floppy hand feeling and the good drapability, the bright color is added, the hand feeling is floppy, and the drapability is good.

Owner:JIANGYIN HONGWU TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com