Preparation method of chinlon FDY (Fully Drawn Yarn) oil agent

A technology of oil agent and nylon, which is applied in the field of preparation of nylon FDY oil agent, which can solve the problems of not endowing chemical fiber with functional properties and single components, and achieve the effects of not easy yellowing, good emulsification, and good anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

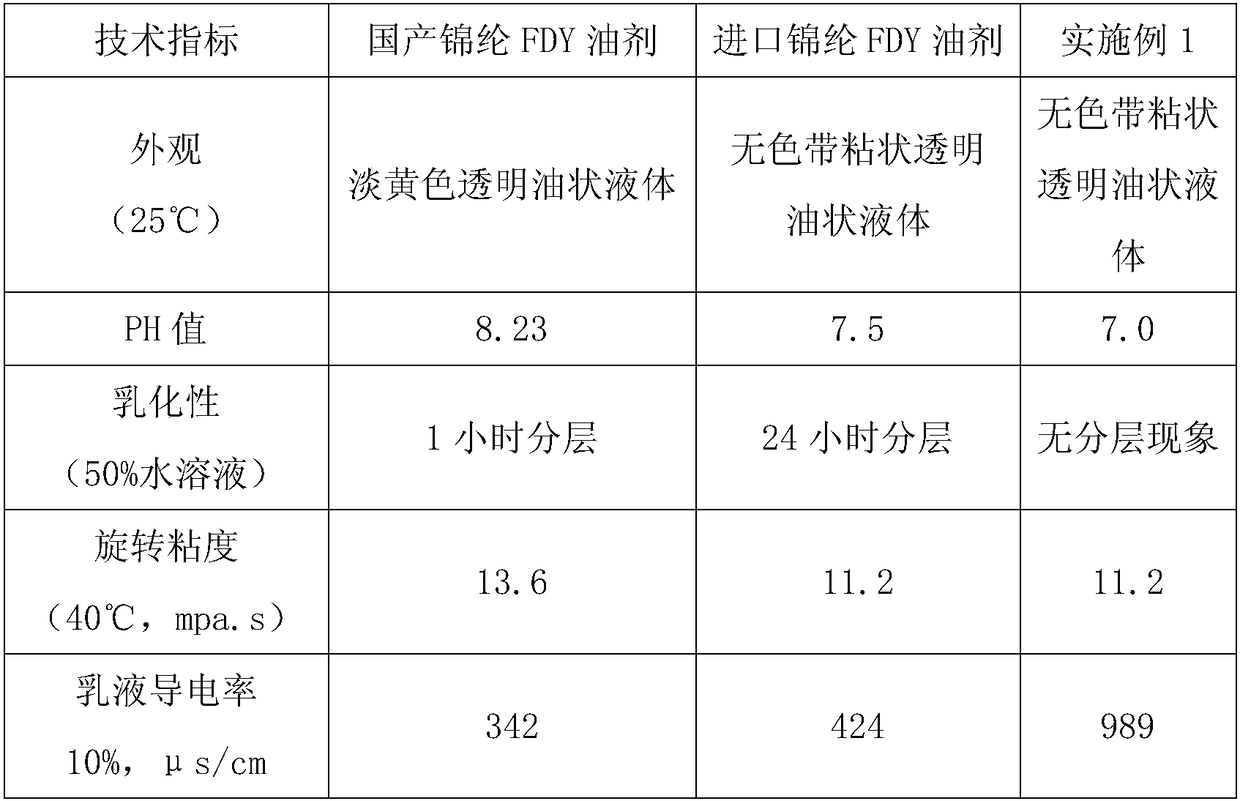

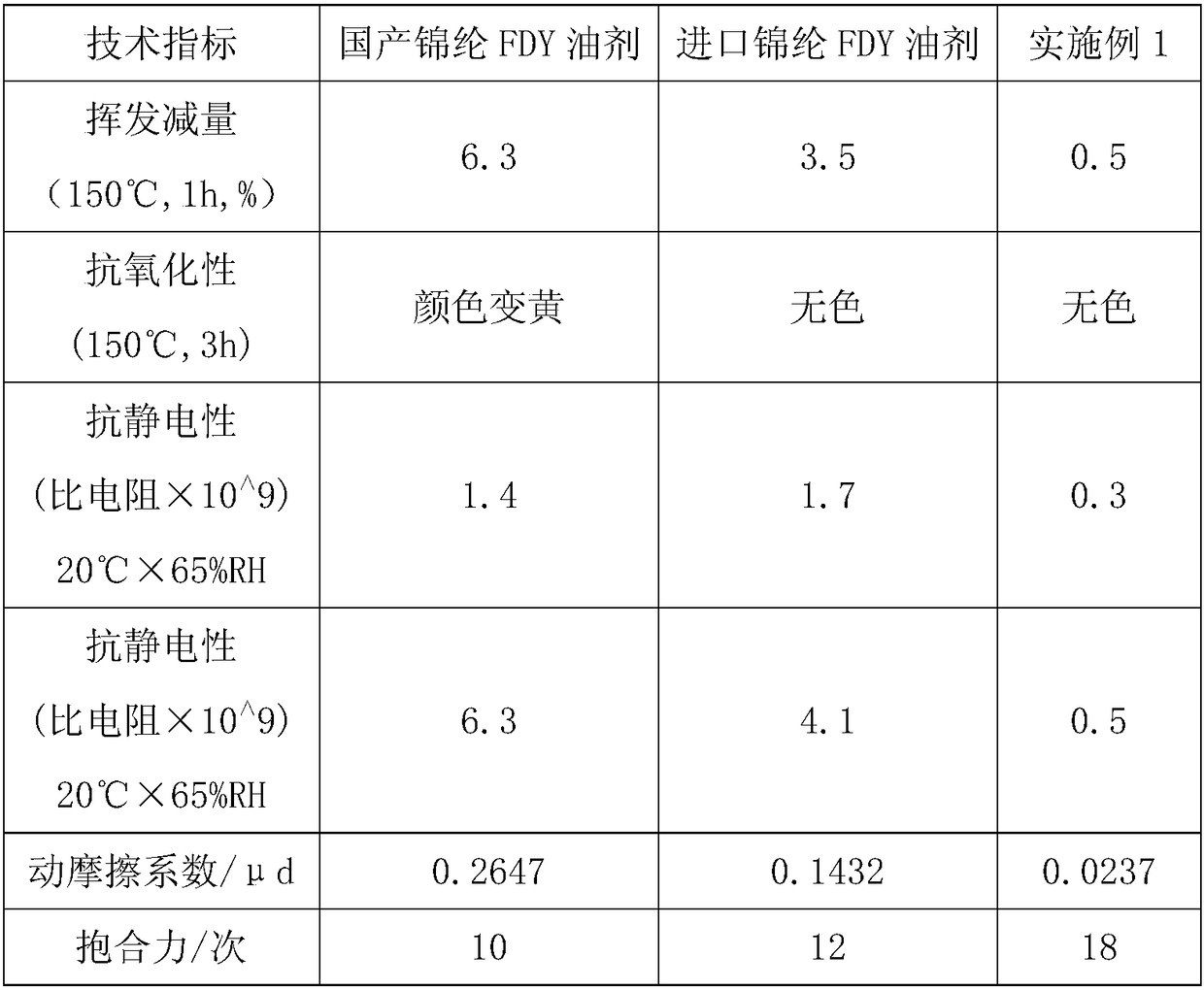

Examples

Embodiment 1

[0030] The preparation of nylon FDY oil agent in the present embodiment comprises the following steps:

[0031] Step 1, 1 part of graphene oxide, 5 parts of zinc oxide, and 3 parts of titanium dioxide are added to a ball mill, and the rotating speed of the ball mill is 100 revolutions / min, and ground for 6 hours to obtain dry powder A;

[0032] Step 2, the above-mentioned dry powder A is mixed with a ratio of 1 part of monoalkenyl succinimide (T151), and the mixture is added into an ultrasonic wave for ultrasonic dispersion and stripping for 3 hours to obtain a composite agent B;

[0033] Step 3, configure the composite oil agent, mix 30 parts of fatty alcohol polyoxyethylene ether, 30 parts of C8-C18 fatty acid ester, and 10 parts of high molecular weight polyoxypropylene ether, add 9 parts of water, and stir while adding, to obtain a composite Oil agent: add compound agent B obtained in step 2 into the compound oil agent, and under the condition of power of 800W and transmis...

Embodiment 2

[0035] The preparation of nylon FDY oil agent in the present embodiment comprises the following steps:

[0036]Step 1, adding 1.5 parts of graphene oxide, 10 parts of zinc oxide, and 5 parts of titanium dioxide into a ball mill, the speed of the ball mill is 200 rpm, and grinding for 6 hours to obtain dry powder A;

[0037] Step 2, adding the above-mentioned dry powder A to 3 parts of monoalkenyl succinimide (T151) and mixing in a ratio, adding the mixture to ultrasonic waves for ultrasonic dispersion and stripping for 3 hours to obtain composite agent B;

[0038] Step 3, configure the composite oil agent, mix 50 parts of fatty alcohol polyoxyethylene ether, 30 parts of C8-C18 fatty acid ester, and 30 parts of high molecular weight polyoxypropylene ether, add 8 parts of water, and stir while adding, to obtain a composite Oil agent: add the composite agent B obtained in step 2 into the composite oil agent, and under the condition of power of 1200W and transmission frequency of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com