Patents

Literature

61results about How to "Short stripping time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

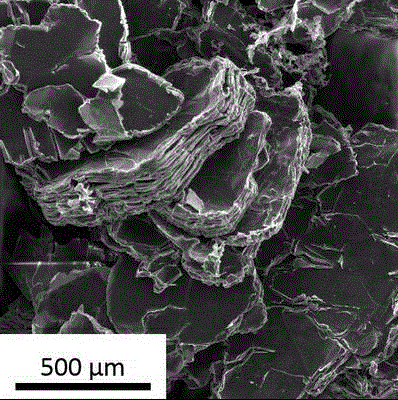

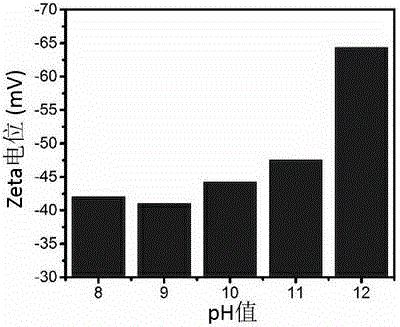

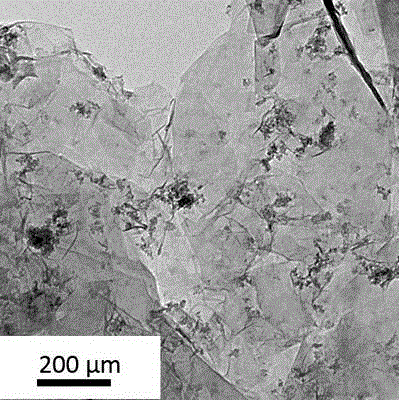

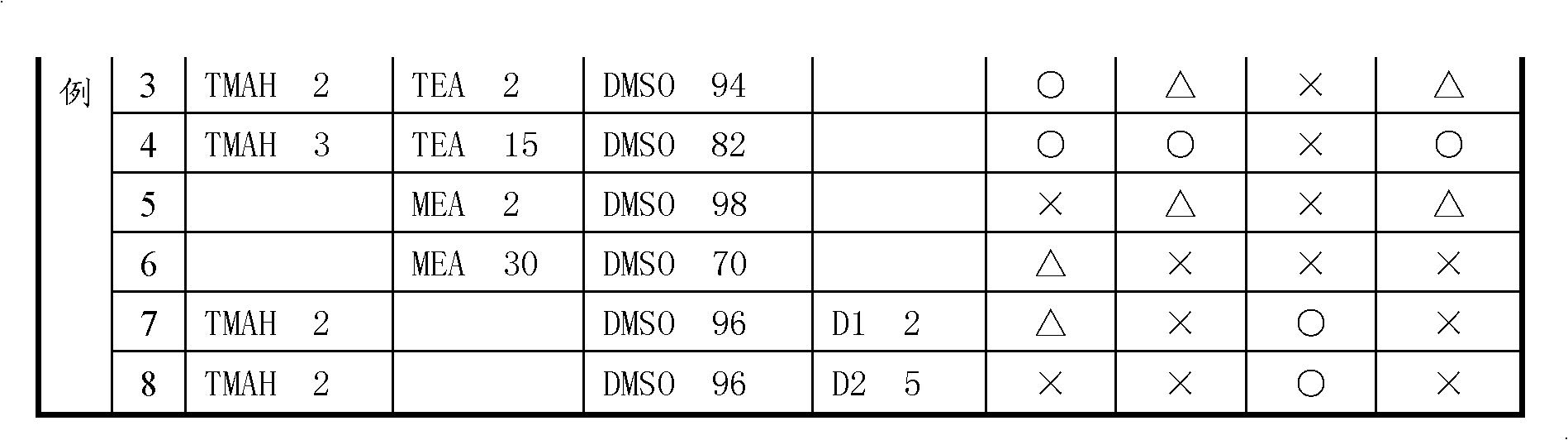

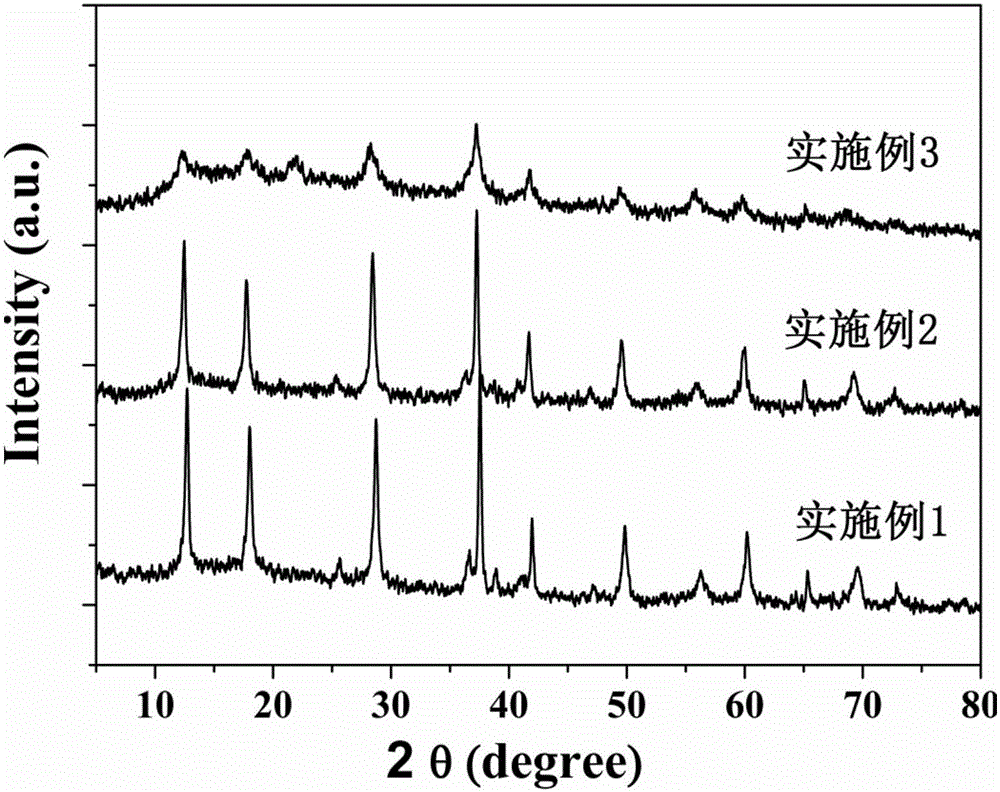

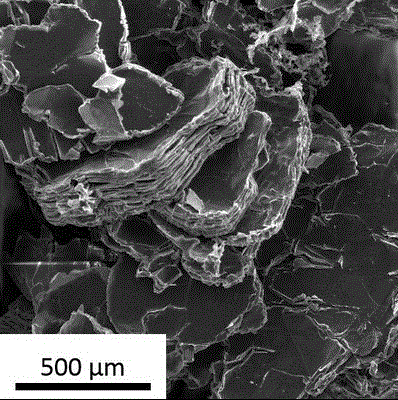

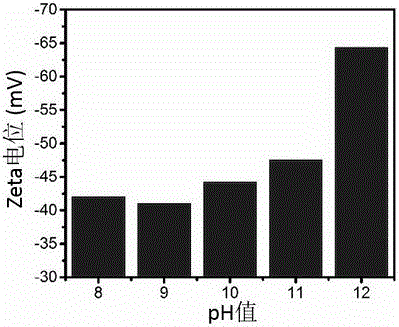

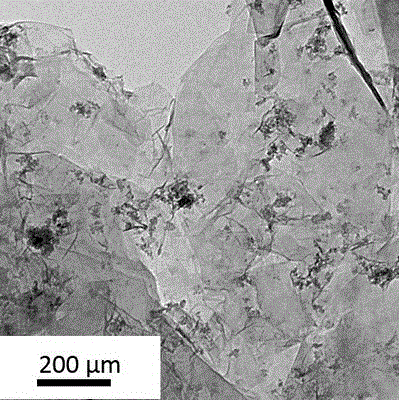

Method for preparing graphene through large-scale aqueous phase

The invention provides a method for preparing graphene through a large-scale aqueous phase. According to the method, graphite serves as a raw material. The method comprises the following steps: intercalating the graphite by adopting an intercalator, so that interlayer spacing between graphene sheet layers is enlarged, and the interaction force between the layers is weakened; and directly treating the intercalated graphite through ultrasonic waves, stripping and uniformly dispersing the graphite in an alkaline aqueous solution with the pH value of 10-14, wherein the content of graphene in the dispersion can be over 100mg / mL (about 10 weight percent of graphene), the content of single-layer graphene in the aqueous phase dispersion is more than 90 percent, the equivalent diameter of the graphene sheet layers can be over 1-10 microns, and a graphene film formed by filtering has a complete lattice structure and high electric conductivity. The prepared high-concentration aqueous phase graphene paste can be stored for a long time and is convenient to transport and use. The method is simple in process flow, high in production efficiency, low in energy consumption and low in cost, a commercially available low-cost reagent is adopted, the reagent is easy to recover, and the production process is environment-friendly and pollution-free.

Owner:安徽百特新材料科技有限公司

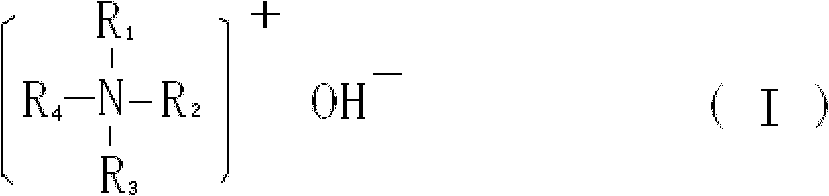

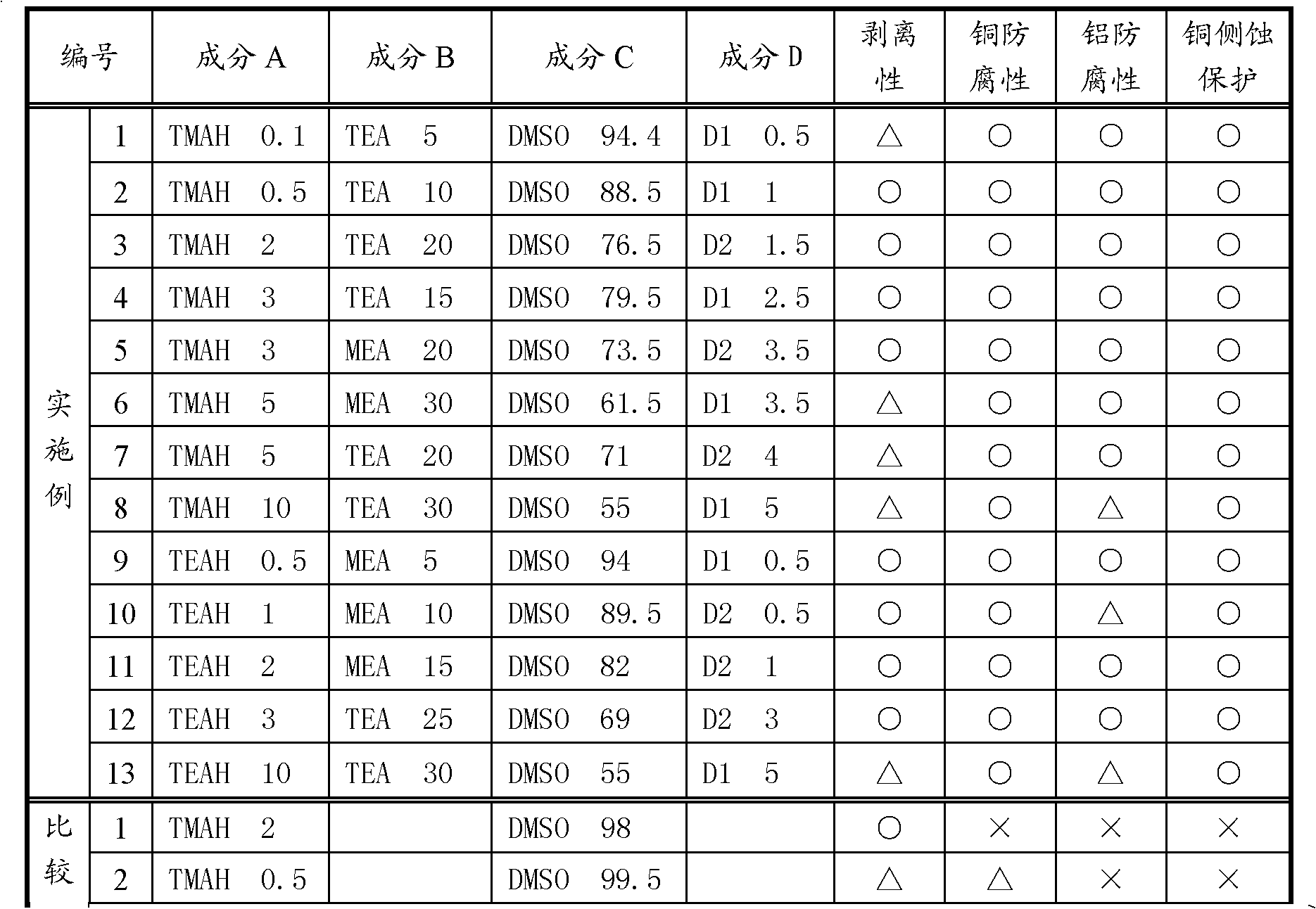

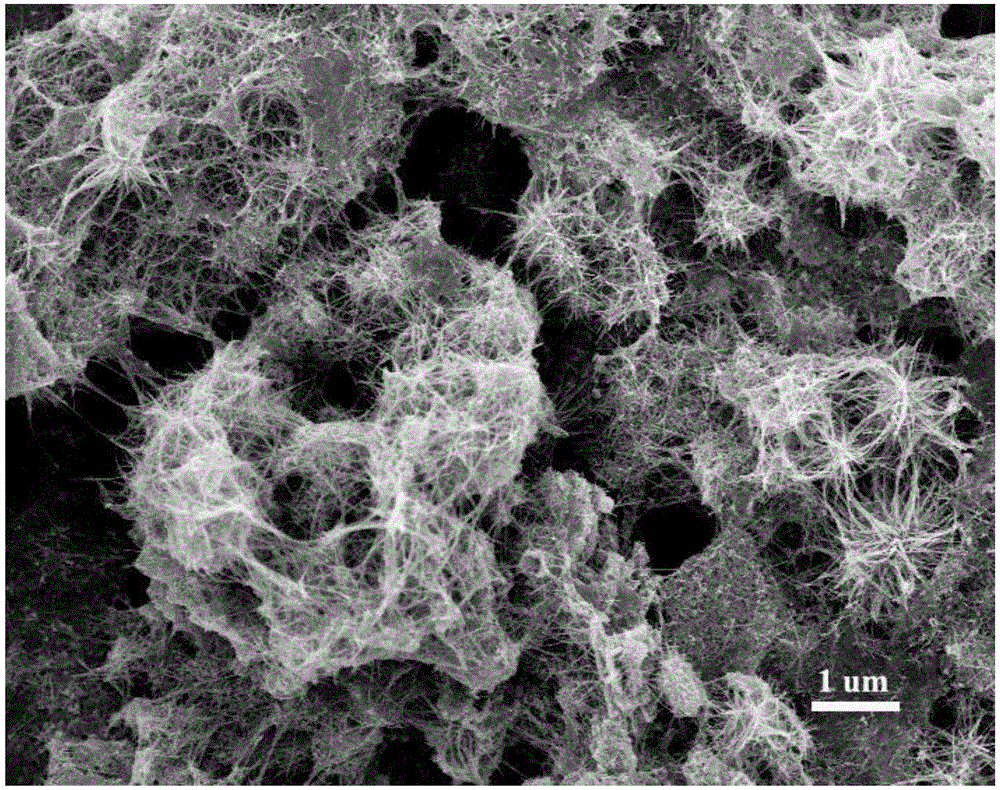

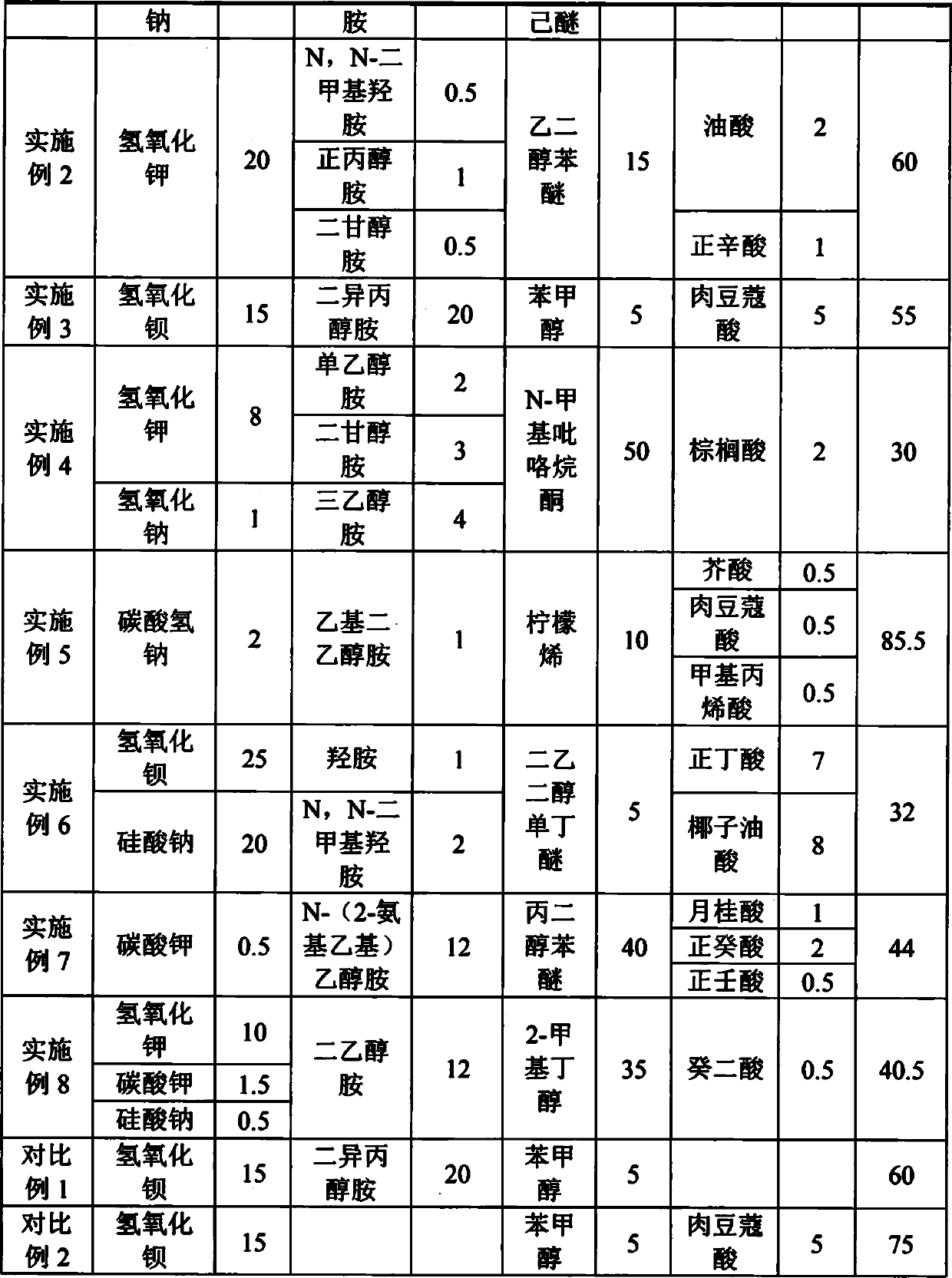

Photoresist peeling solution composition with metal protection

InactiveCN102141743AShort stripping timeExcellent peelabilityPhotosensitive material processingAlcohol sugarsSolvent

The invention discloses a photoresist peeling solution composition with metal protection. The photoresist peeling solution composition consists of the following substances in percentage by weight: 0.1 to 10 percent of quaternary ammonium hydroxide, 5 to 30 percent of water-soluble alkanol amine, 55 to 94.4 percent of water-soluble organic polar solvent and 0.5 to 5 percent of sugar alcohol additive, wherein the water-soluble organic polar solvent is sulfone, sulfoxide, amide or lactam solvent. Compared with the conventional peeling solution composition, the photoresist peeling solution composition has excellent corrosion resistance to a metal-based coating covered by photoresist, particularly copper and aluminum at the same time of ensuring excellent photoresist peeling performance, and has excellent side corrosion protection effect on the copper. Meanwhile, the peeling solution composition has low volatility and low toxicity, is easily cleaned by using deionized water, and has good maneuverability. The composition is used for peeling and dissolving a photoresist mask in a semiconductor element manufacturing process.

Owner:SHANGHAI PHICHEM MATERIAL CO LTD

Preparation method of graphene oxide/manganese dioxide composite material

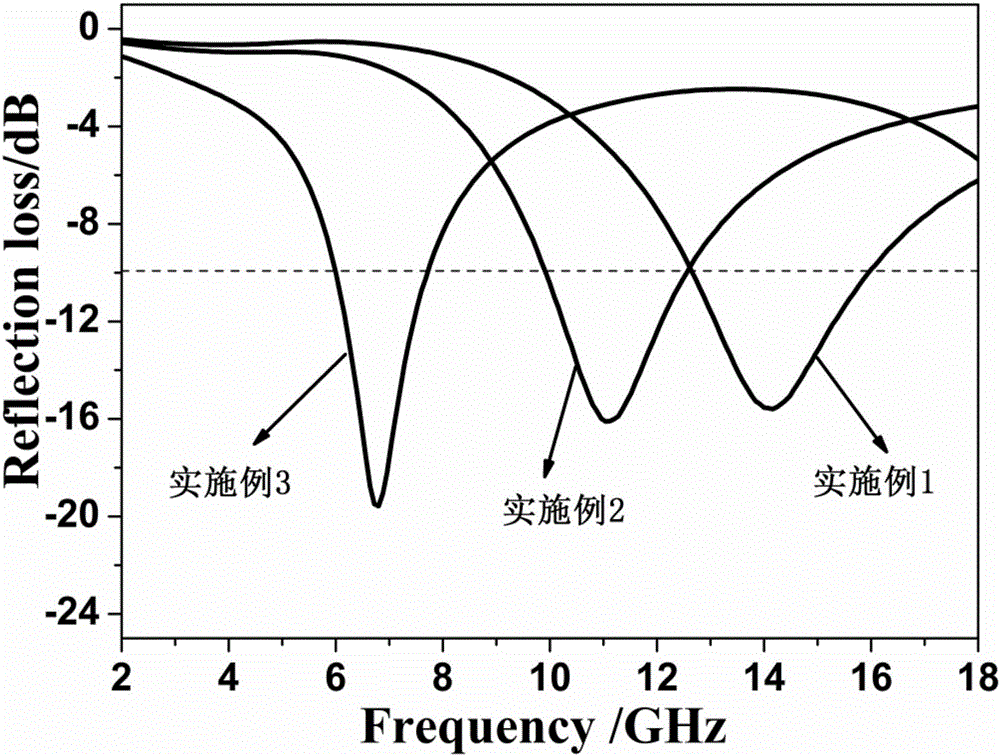

ActiveCN106698412AImprove structure dispersionImprove absorbing performanceMaterial nanotechnologyCarbon compoundsDispersityEnergy consumption

The invention provides a preparation method of a graphene oxide / manganese dioxide composite material. The method comprises the following steps of firstly mixing graphite, an intercalator, an oxidant and water and then reacting to obtain a graphene solution which is not completely oxidized; and then mixing the graphene solution which is not completely oxidized in the previous step and a manganese source again and reacting to obtain the graphene oxide / manganese dioxide composite material. According to the preparation method provided by the invention, a hydrogen peroxide reduction process, a later separate oxidation reduction process and a repeated cleaning process are not needed; and after intercalation and exfoliation of graphite, a one-step oxidation-reduction hydrothermal method is directly utilized to prepare the composite material in situ on the basis of incomplete oxidation, so that the operation steps are greatly reduced, the energy consumption is reduced, the exfoliation time is shortened and the structure dispersity of the composite material is also improved. The preparation method is simple in process, mild in condition, safe, environment-friendly and suitable for large-scale industrial production; and the composite material has relatively good wave absorbing property and absorption width.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

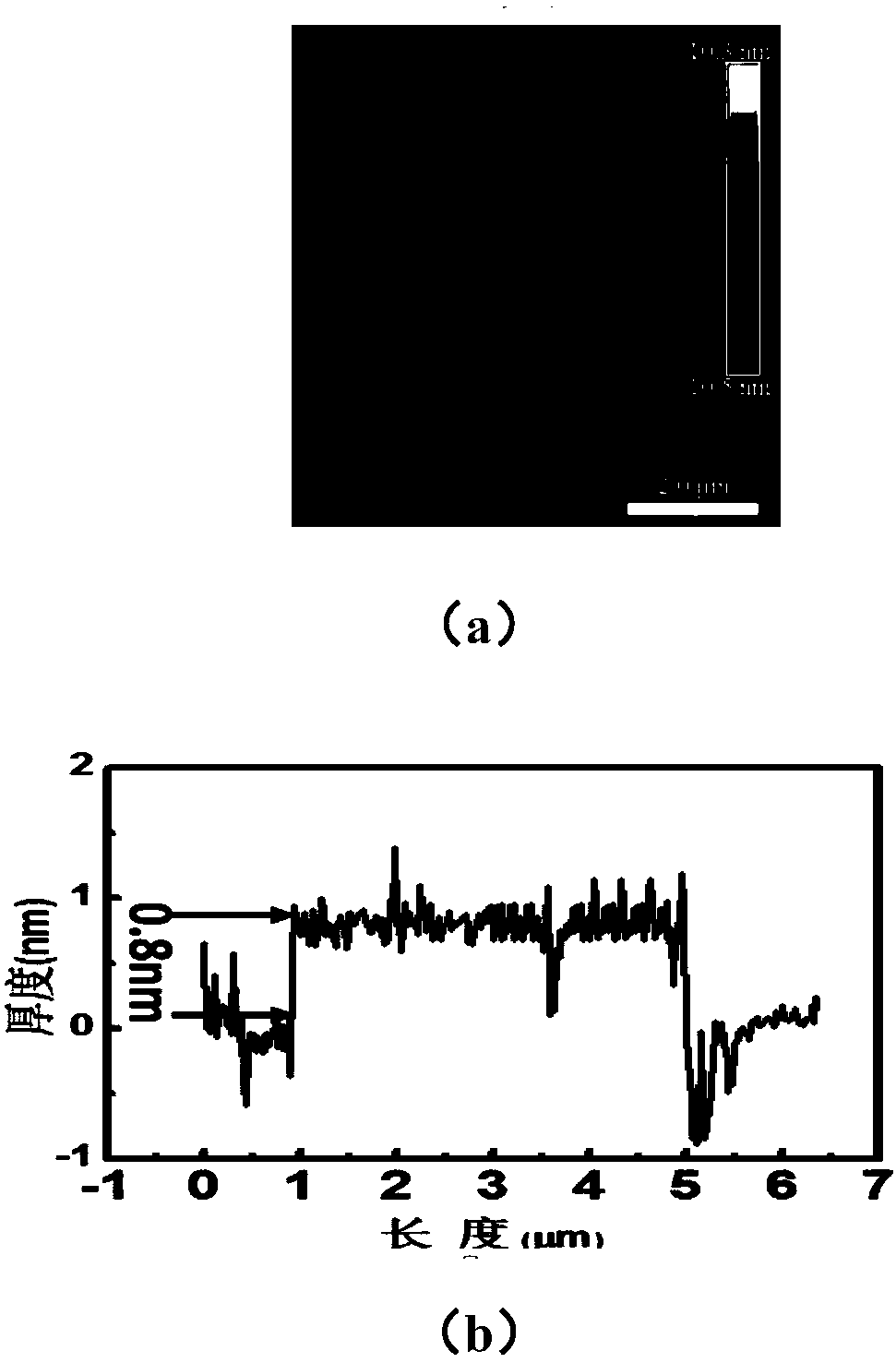

Graphene composite material and preparation method and application thereof

The invention relates to a graphene composite material and a preparation method and application thereof. The average number of layers of the graphene composite material is 1, 2 or 3 layers, the thickness is 0.34-1.25nm, and the order of magnitude of conductivity is 104-105s / m. The preparation method of the graphene composite material includes the following steps of: taking water as a solvent, adding multi-layer graphite and a macromolecular polymer to the water, uniformly mixing, grinding and / or performing ultrasonic treatment to obtain graphene composite material dispersion liquid, and then freezing and drying to prepare the graphene composite material. According to the scheme of the invention, the macromolecular polymer is added to the multi-layer graphite aqueous solution, the viscosityof the system is increased, the peeling and dispersion of graphite can also be realized by using the shearing force, and thus the single-layer or few-layer graphene composite material with less defects, relatively high quality and good conductivity can be prepared.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

ABS (acrylonitrile butadiene styrene) plastic paint remover

InactiveCN107236353APromote degradationHigh activityChemical paints/ink removersEmulsionLiquid state

The invention discloses an ABS (acrylonitrile butadiene styrene) plastic paint remover and belongs to the technical field of paint removal. A main micromolecule solvent, water and a cosolvent are stirred and mixed, a compound surfactant is added, the mixture is stirred and mixed at a high speed, a mixed emulsion is obtained, an activator, a fermentation product, a corrosion inhibitor, a thickening agent and a defoaming agent are added to the mixed emulsion, dispersed at a high speed and subjected to vacuum defoaming, and the ABS plastic paint remover is obtained. The fermentation product is prepared as follows: a soil suspension obtained by mixing soil at the roots of podocarpus macrophyllus and water is mixed with a liquid-state culture medium and then the mixture is subjected to shake cultivation, filtration and concentration. The ABS plastic paint remover has the benefits as follows: the ABS plastic paint remover has high paint removal efficiency and is small in volatility, large in paint removal amount, short in paint removal time and worth popularization and use.

Owner:杨帮燕

Grinding medium for peeling graphene by paste grinding

The invention belongs to the technical field of graphene and particularly relates to a grinding medium for peeling graphene by paste grinding. The grinding medium is prepared from the following components in percentage by weight: 30%-45% of an amphiphilic polymer, 25%-30% of nano modified hydrotalcite, 10%-15% of a micro-expanding agent, 5%-15% of an adhesive, 5%-10% of cyclodextrin and 5%-10% of urea. After the grinding medium and a graphite material are mixed, the graphite is peeled primarily through the surface bonding function of the grinding medium, graphite is subjected to expansion and intercalation peeling through the micro-expanding agent and a urea intercalator which are wrapped in a network structure of the grinding medium, finally, the graphite is peeled under the action of mechanical force, and the grephene is obtained. The grinding medium is used for preparation of graphene through liquid peeling, use of organic solvents is reduced, the peeling efficiency of graphene is increased by 40% or higher, and the obtained graphene with a single layer or a few layers has higher dispersion performance.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

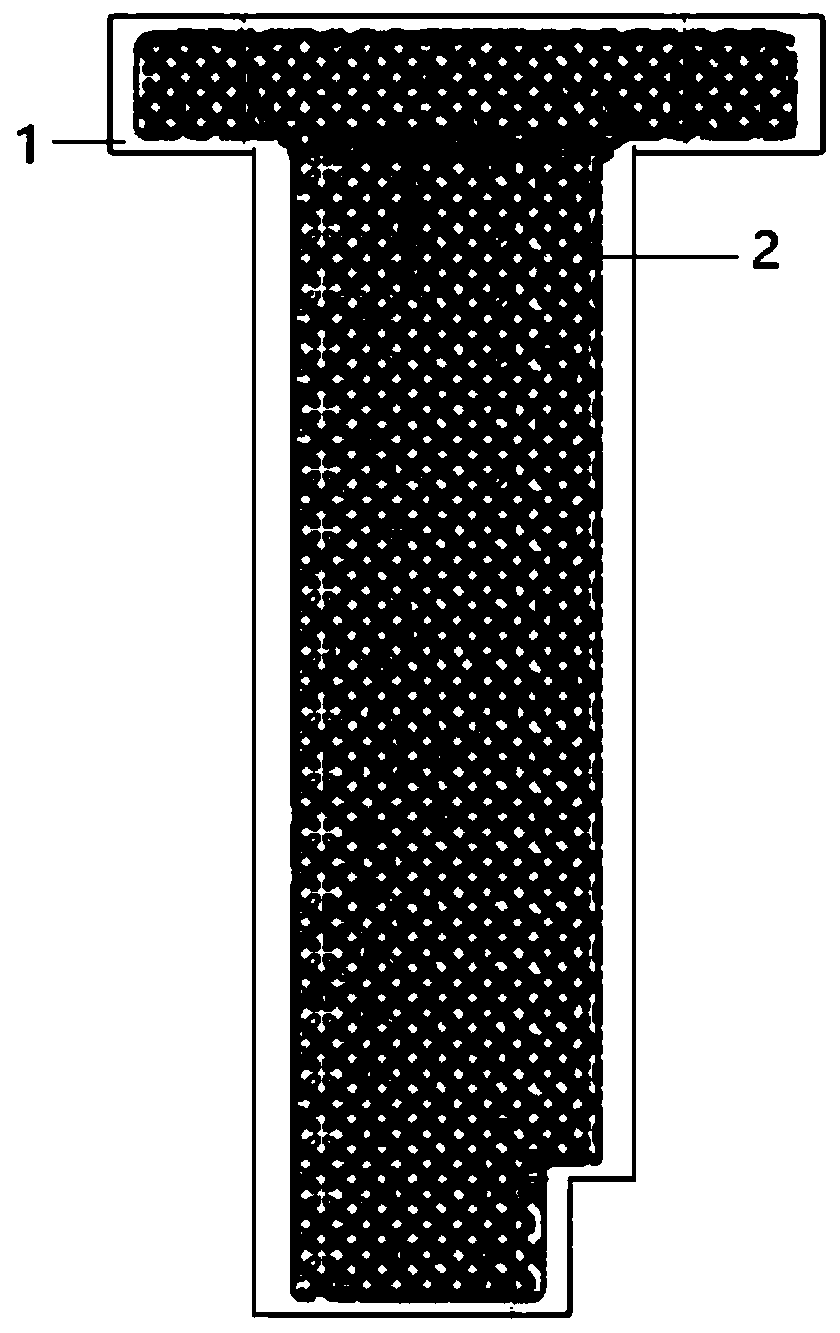

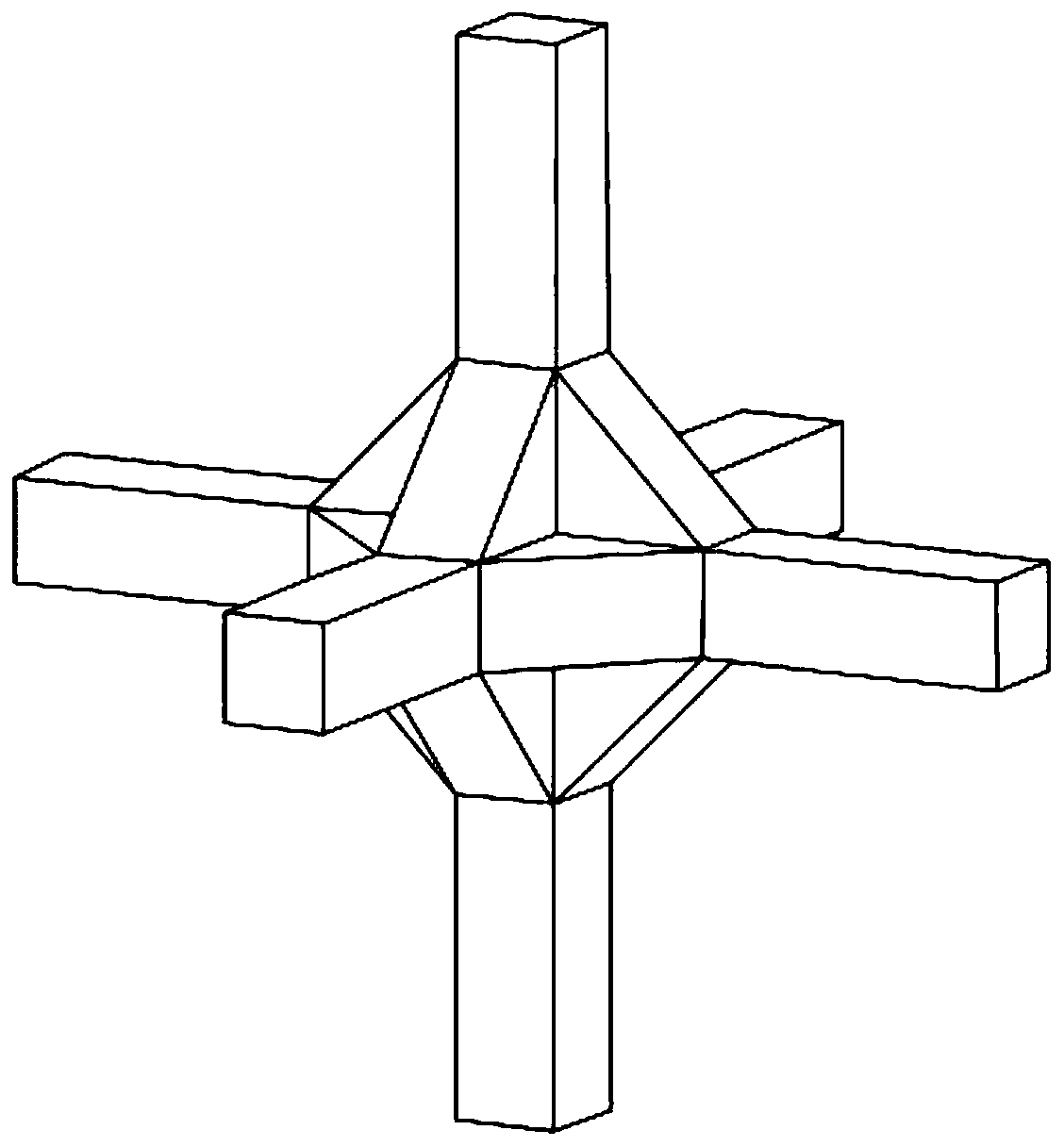

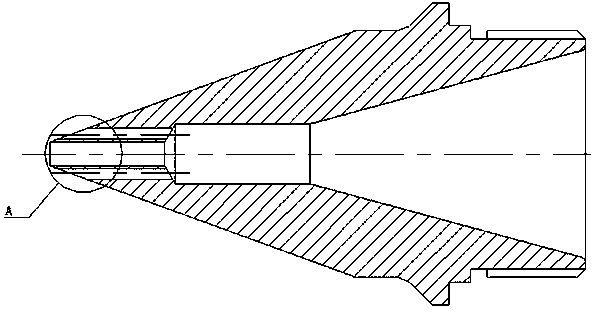

Hollow blade easy-to-remove aluminum oxide ceramic core and preparation method thereof

ActiveCN110773700AEasy to removeGuaranteed impact resistanceAdditive manufacturing apparatusFoundry mouldsOxide ceramicSlurry

The invention provides a hollow blade easy-to-remove aluminum oxide ceramic core and a preparation method thereof. According to the ceramic core, a shell and a space lattice structure in the shell arecombined, and when the relative density of the space lattice structure is 20 to 50 percent and the thickness of the shell is 0.4 to 0.5 mm, high void ratio of the ceramic core is realized and the deflection and the bending resistance of the ceramic core are guaranteed; and according to the preparation method, stable printing is facilitated by high flowability and low viscosity of ceramic slurry,the properties of the ceramic core are improved well by cooperating with the space lattice structure, the ceramic slurry is printed into a needed forming green body by 3D printing equipment, and the formed ceramic core is obtained by degreasing and sintering the formed green body. The ceramic core has high strength and short core removing time, saves ceramic materials, shortens process flow and provides an efficient solution for the problem about removal of the aluminum oxide ceramic core.

Owner:武汉因泰莱激光科技有限公司

Rare earth coated and magnesium oxide based ceramic core

InactiveCN104070141AShort stripping timeSimple stripping equipmentFoundry mouldsFoundry coresThin walledMagnesium

The invention discloses a rare earth coated and magnesium oxide based ceramic core which is characterized by comprising the following raw materials by weight percent: 5% to 10% of mineralizer, 10% to 17% of plasticizer, 1% to 1.5% of polyethylene powder and the balance being rare earth coated magnesium oxide powder. The ceramic core disclosed by the invention can be preferably dissolved in acid and has the advantages of short stripping time, simple stripping equipment, no pollution in a stripping process, safety, reliability and good high-heat resistant performance, the precision casting cost is reduced, and the phenomenon of heat cracks generated in the process of casting hollow thin-wall castings is avoided.

Owner:WUHU ZHEXIN NEW ENERGY

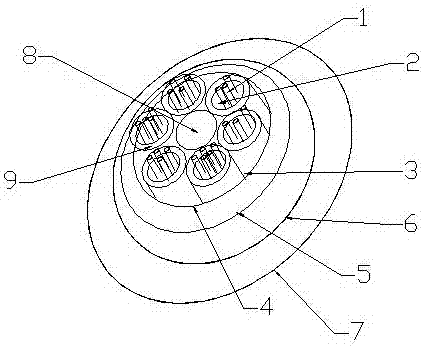

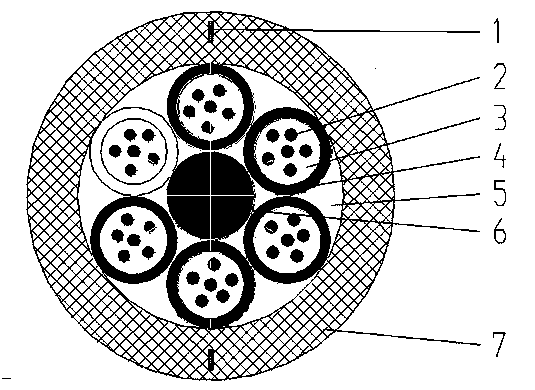

Optical cable

InactiveCN107976755AComplete structureImprove mechanical propertiesFibre mechanical structuresYarnEngineering

The invention discloses an optical cable which comprises optical fibers, fiber paste and a center shaft. A plurality of loose sleeves wrap the optical fibers, the fiber paste is arranged in gaps between the optical fibers and the loose sleeves, the center shaft is tightly enclosed by the multiple loose sleeves, spaces between the multiple loose sleeves are filled with cable paste, and a waterprooflayer, an inner protective layer, aramid yarns and an outer protective layer are sequentially connected with the outer sides of the loose sleeves in a tightly clinging manner. The optical cable has the advantages that the optical cable is simple in structure; internal structures can be effectively protected by outer sheaths, and the optical cable can be easily stripped by workers without damage on the optical fibers.

Owner:徐州亚都环境科技有限公司

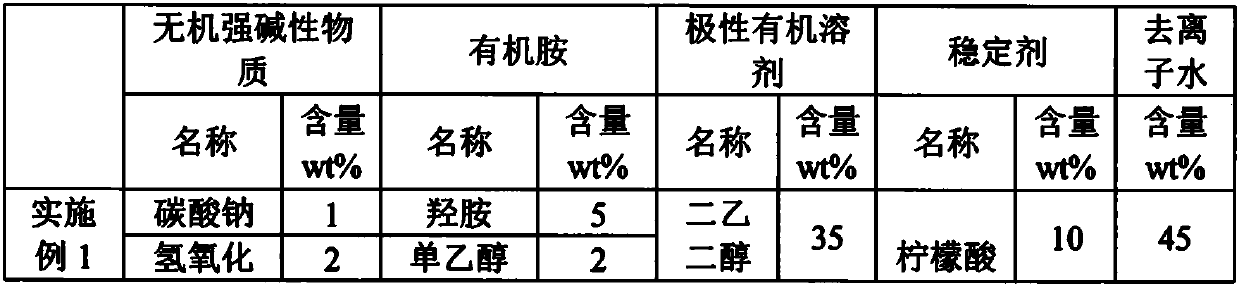

Color filter photoresist stripping liquid composition

PendingCN110597025AEasy to makeAvoid stratificationPhotosensitive material processingVolatilesNon toxicity

The invention discloses a color filter photoresist stripping liquid composition, and belongs to the technical field of microelectronic materials. The key point is that the composition comprises the following components in terms of mass percentage: 0.5-45% of inorganic strong alkaline substance, 0.1-50% of organic amine, 0.1-55% of polar organic solvent, 0.1-20% of stabilizer and 30-99.2% of water.The composition has the advantages of high stripping performance, short stripping time, low operation temperature, little corrosion to the glass substrate and the like, and the glass substrate can bereused after stripping. Meanwhile, the composition also has the characteristic of non-toxicity, non-corrosiveness, no low boiling point organic volatiles, no pollution to the environment, low foam and the like.

Owner:华璞微电子科技(宁波)有限公司

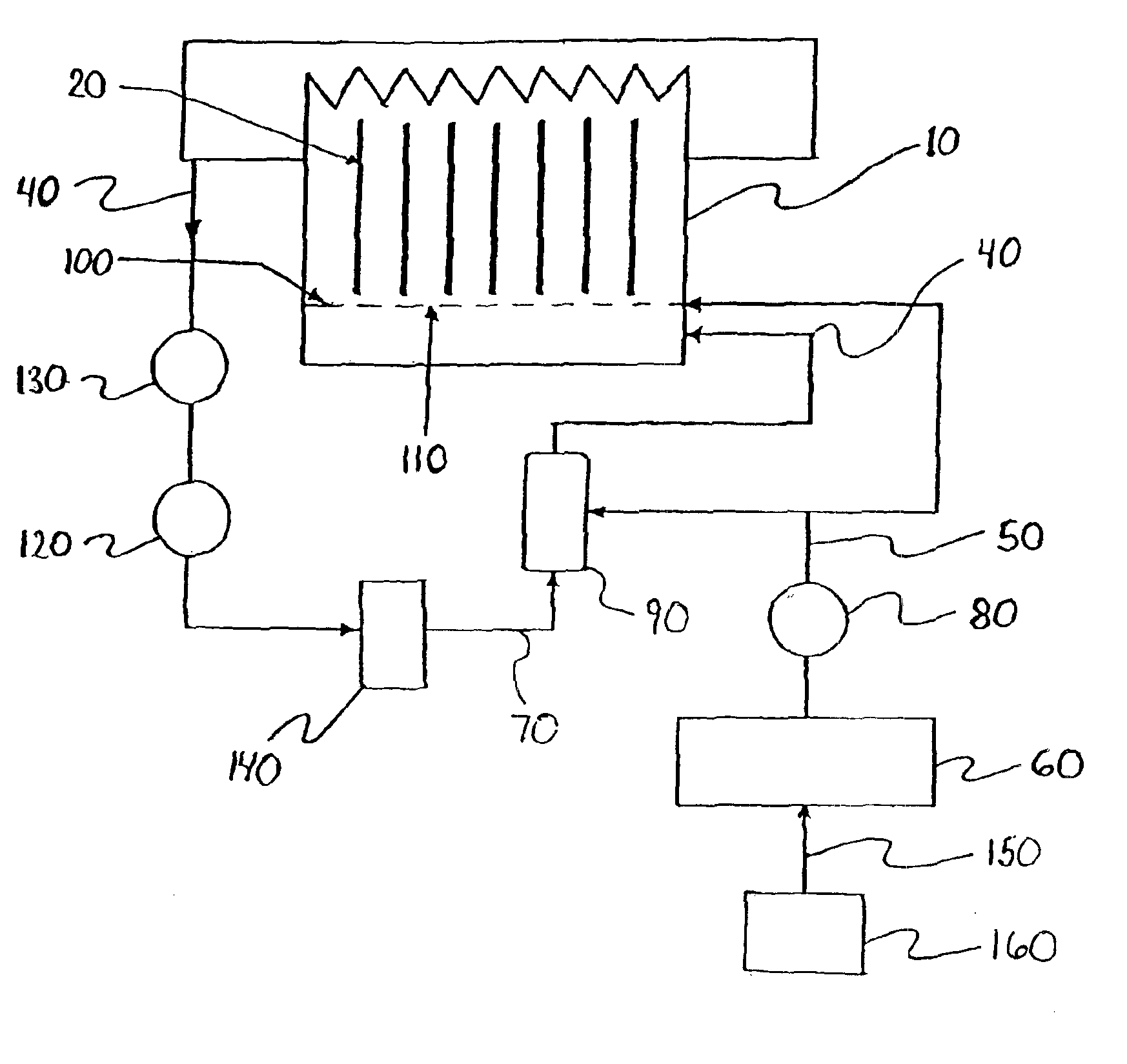

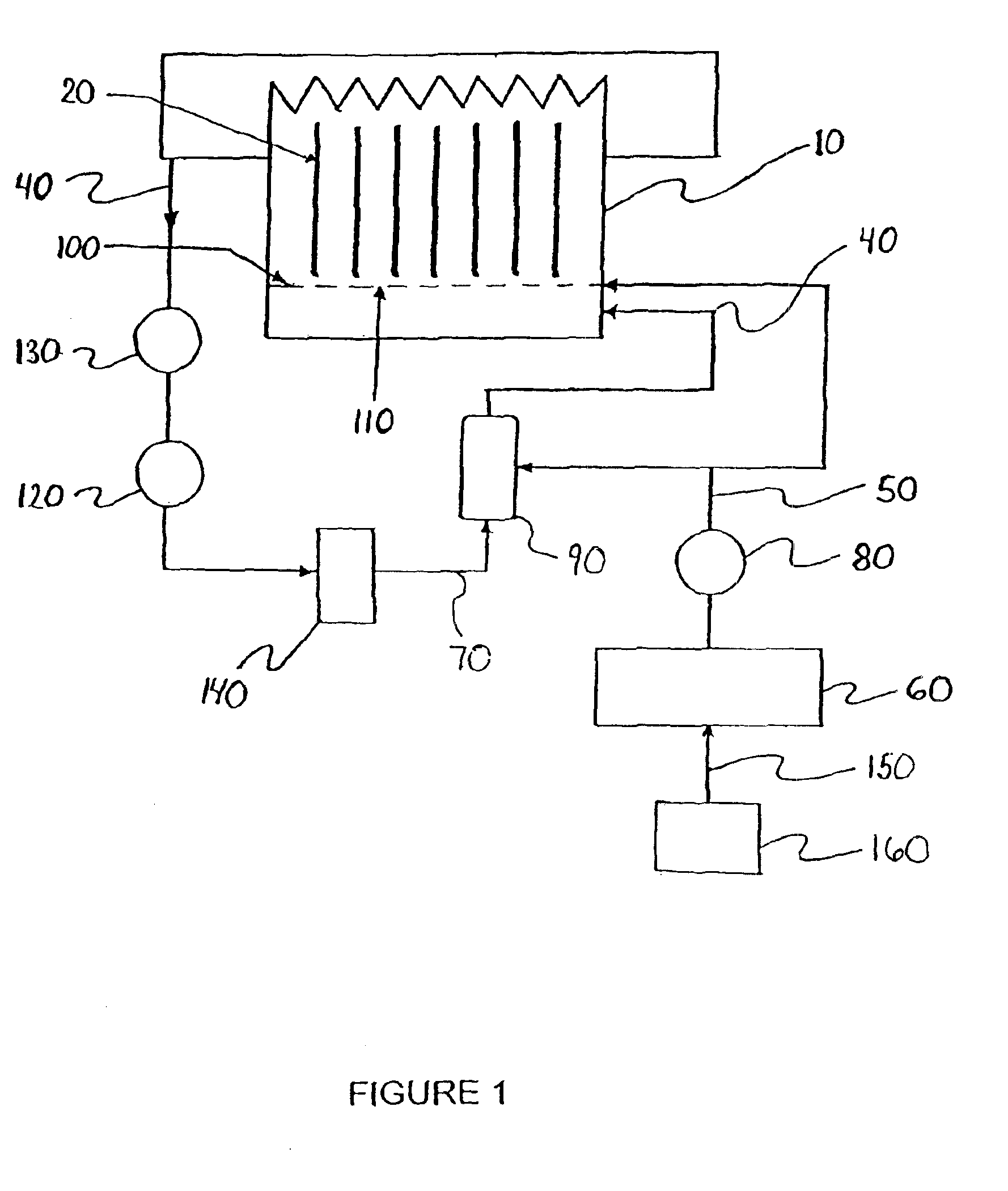

Method for removal of photoresist using sparger

InactiveUS6863836B2Fast wayIncrease ratingsDecorative surface effectsElectrostatic cleaningEnvironmental engineeringPhotoresist

A method of removing photoresist from semiconductor wafers through the use of a sparger plate. According to the inventive method, at least one semiconductor wafer is positioned in a process tank above the sparger plate. A mixture of ozone and deionized water is introduced into the process tank at a position below the sparger plate. The mixture of ozone and deionized water is then introduced across the wafer via the sparger plate at an increased flow velocity while the wafer is submerged in the mixture of deionized water and ozone.

Owner:NAURA AKRION INC

Novel portable metal sheath stripper for fireproof cable

ActiveCN110350448APrevent looseningPreventer biasApparatus for removing/armouring cablesMechanical engineeringMetal

The invention discloses a novel portable metal sheath stripper for a fireproof cable. The novel portable metal sheath stripper structurally comprises the fireproof cable, a metal sheath stripping device and an anti-skid sleeve, wherein the fireproof cable runs through the metal sheath stripping device; and the anti-skid sleeve sleeves the outside of the metal sheath stripping device. Compared withthe prior art, the novel portable metal sheath stripper has the beneficial effects that a device does not need to be manually pulled to move back and forth on the cable and directly sleeves the cable, so that the device is always parallel to the cable, the metal sheath can be cut open once, the stripping time is short, cutting interruption of the metal sheath can be avoided and the stripping efficiency is improved; cutting knives can be adjusted once on the basis of spring characteristics and the adjusting speed is high, so that improvement of the stripping speed is facilitated; and four rotary cutting knives can cut the metal sheath at the same time and the cutting depths are the same, so that concave parts and convex parts of the corrugated metal sheath all can be cut, meanwhile, a cable core is not cut, the effect on the cutting effect due to different cutting depths is avoided, cutting is complete and secondary cutting and stripping are not needed.

Owner:湖北艾克电缆有限公司

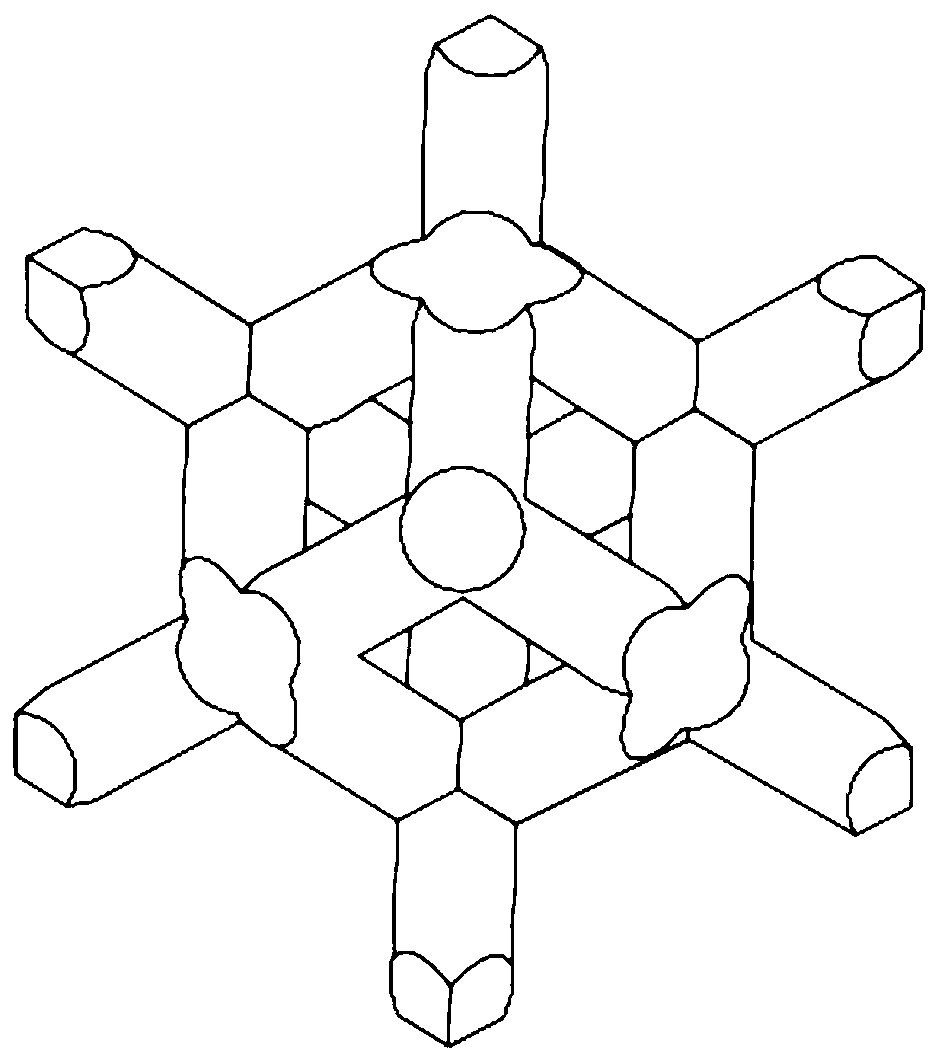

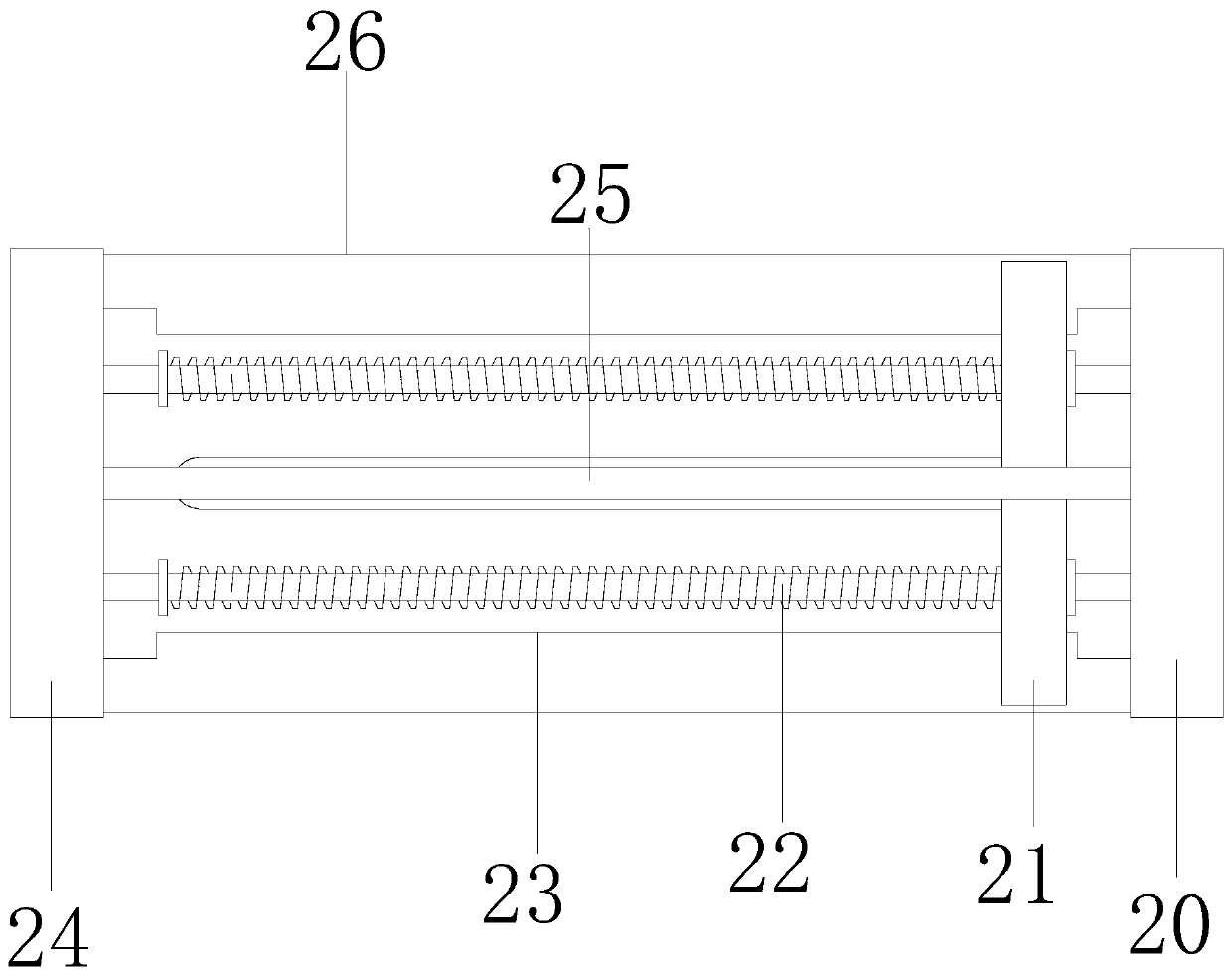

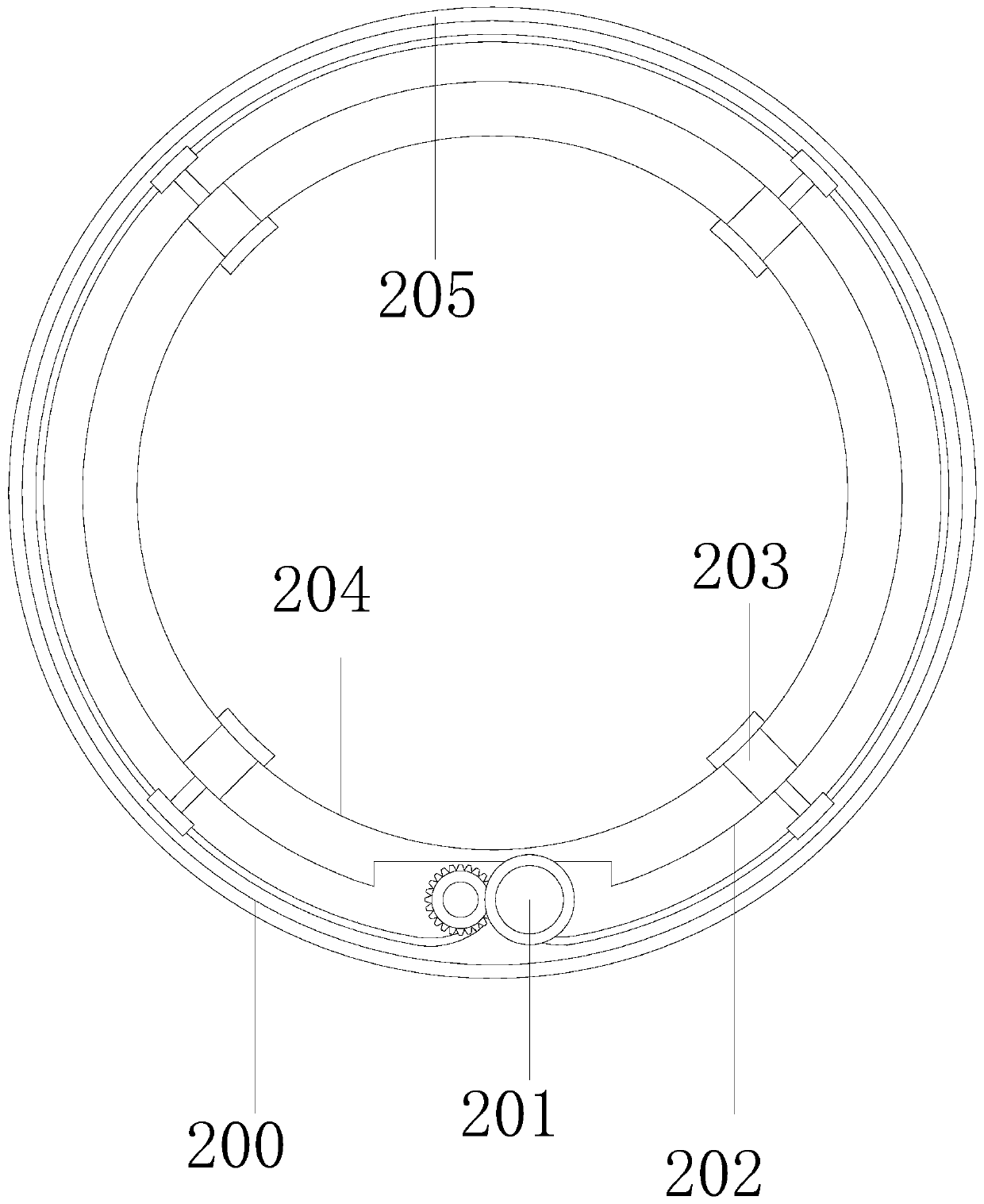

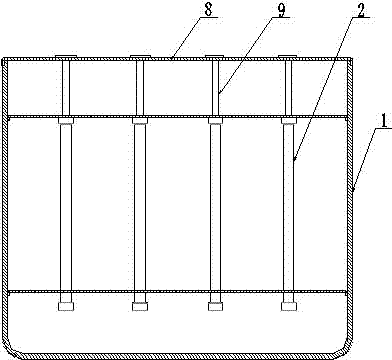

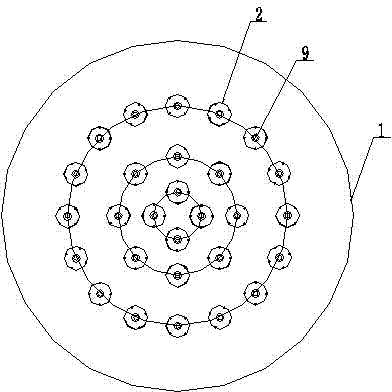

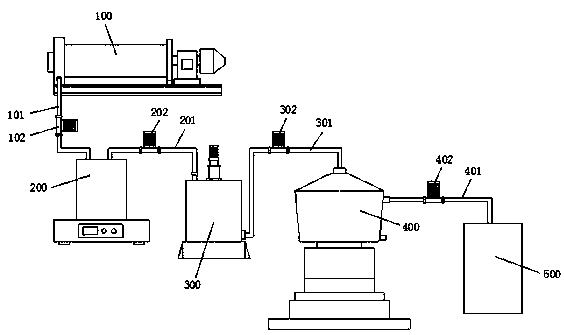

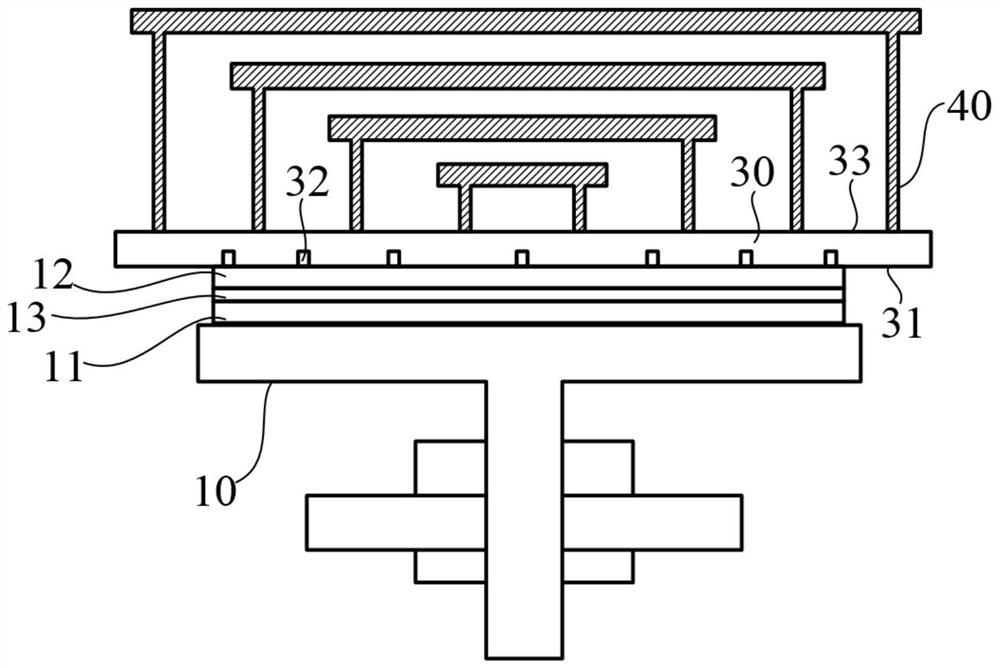

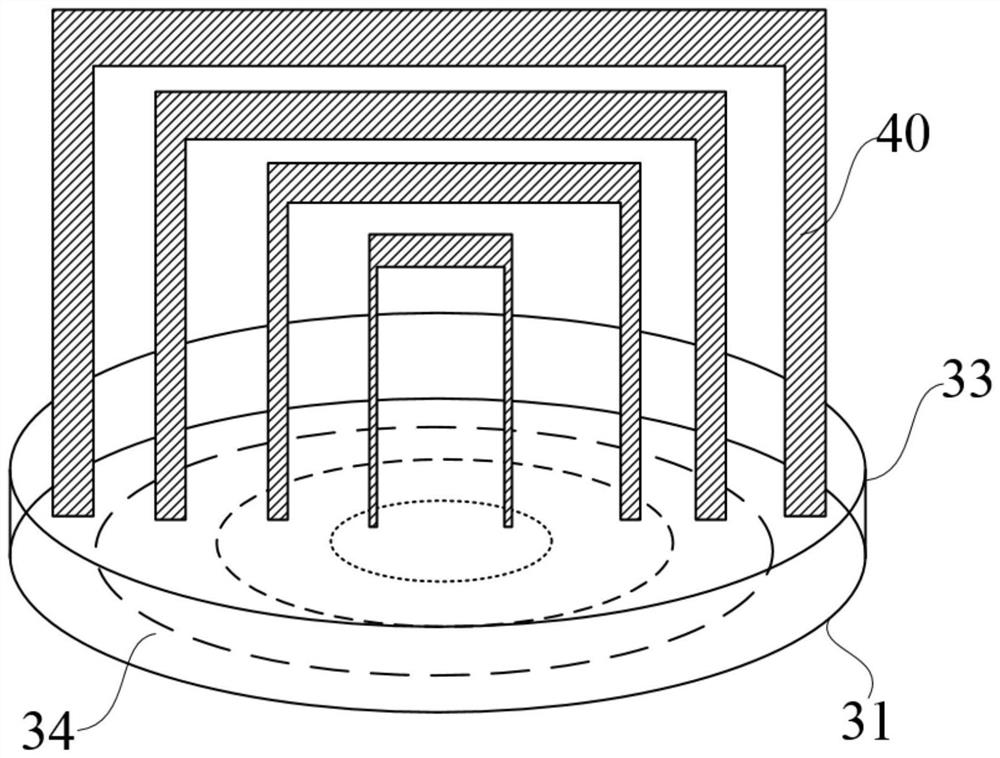

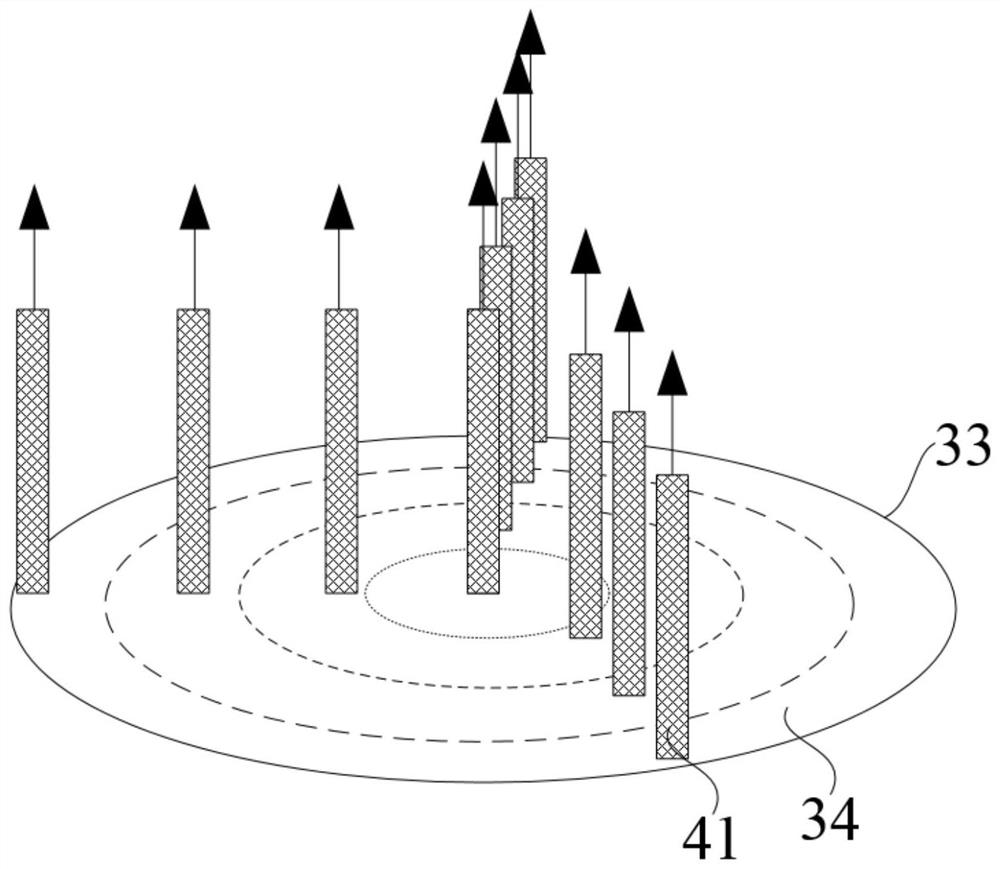

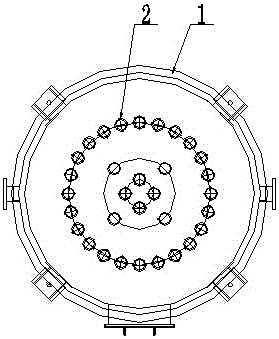

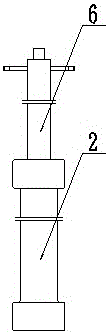

Ultrasonic peeling device for preparing graphene

The invention discloses an ultrasonic peeling device for preparing graphene. The ultrasonic peeling device comprises a tank and a plurality of ultrasonic vibrating spears, wherein the plurality of ultrasonic vibrating spears are vertically fixed in the tank and are annularly distributed in the same frontal projection plane. The ultrasonic peeling device can ultrasonically irradiate the inner zone of the tank in all directions, thus achieving the purpose of remarkably increasing the power density of ultrasonic waves and shortening the peeling time.

Owner:DEYANG CARBONENE TECH

A kind of large-scale aqueous phase prepares the method for graphene

Owner:安徽百特新材料科技有限公司

A grinding medium for slurry grinding exfoliated graphene

The invention belongs to the technical field of graphene and particularly relates to a grinding medium for peeling graphene by paste grinding. The grinding medium is prepared from the following components in percentage by weight: 30%-45% of an amphiphilic polymer, 25%-30% of nano modified hydrotalcite, 10%-15% of a micro-expanding agent, 5%-15% of an adhesive, 5%-10% of cyclodextrin and 5%-10% of urea. After the grinding medium and a graphite material are mixed, the graphite is peeled primarily through the surface bonding function of the grinding medium, graphite is subjected to expansion and intercalation peeling through the micro-expanding agent and a urea intercalator which are wrapped in a network structure of the grinding medium, finally, the graphite is peeled under the action of mechanical force, and the grephene is obtained. The grinding medium is used for preparation of graphene through liquid peeling, use of organic solvents is reduced, the peeling efficiency of graphene is increased by 40% or higher, and the obtained graphene with a single layer or a few layers has higher dispersion performance.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

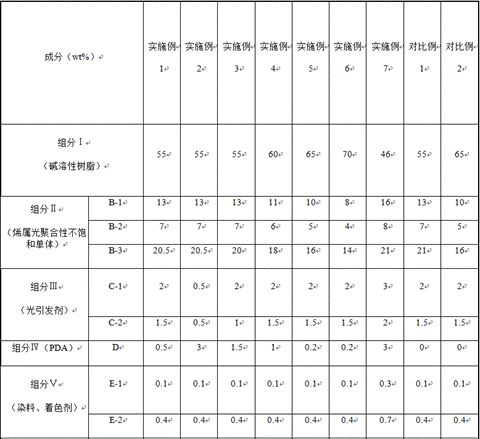

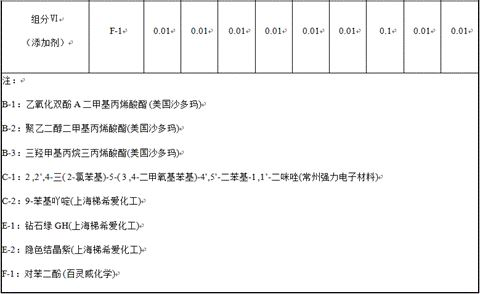

Photosensitive resin composition, photosensitive resin mixture and a corresponding printed circuit board

ActiveCN111812944AImprove bindingSensitiveConductive material chemical/electrolytical removalPhotosensitive materials for photomechanical apparatusComposite materialPolymer chemistry

The invention relates to a photosensitive resin composition, a photosensitive resin mixture and a corresponding printed circuit board, and belongs to the technical field of preparation of circuit printed elements. The photosensitive resin composition comprises, by weight, 46-70% of alkali-soluble copolymer resin, 26-45% of an ethylenically photopolymerizable unsaturated monomer, 1-5% of a photopolymerization initiator, 0.2-3% of polydopamine particles, 0.5-1% of a coloring agent and 0.01-0.1% of an additive. A photosensitive dry film resist DFR prepared from the composition has especially excellent high adhesion and resist stripping performance, and also has the advantages of excellent analytical performance, high film stripping speed and good film breakage morphology, the application range of the DFR is widened, and the production efficiency and yield of the PCB are improved.

Owner:HANGZHOU FIRST ELECTRONIC MATERIAL CO LTD

Nonmetallic surface paint remover

InactiveCN104277572AShort stripping timeClean paintChemical paints/ink removersOrganic acidChemistry

The invention relates to a nonmetallic surface paint remover which is prepared from 25-45 parts of composite glycol ether, 15-35 parts of organic acid, 5-10 parts of surfactant, 10-35 parts of sodium hydroxide, 1-10 parts of sodium dodecyl benzene sulfonate, 40-70 parts of water-soluble film formation resin, 20-30 parts of thickener, 2-9 parts of preservative and 100-200 parts of water. The paint remover is mainly used for removing the paint coating on the nonmetallic surfaces of floor, cement, bricks, stone and the like. The paint remover does not have any dissolution action on the materials above, and thus, does not influence the properties of the materials. The nonmetallic surface paint remover has the advantages of no toxicity, environmental protection, no environmental pollution, short paint removal time, simple production technique, low paint removal cost and favorable market prospects; and the paint surface subjected to paint removal is clean, and can not have the phenomenon of unclean paint removal.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

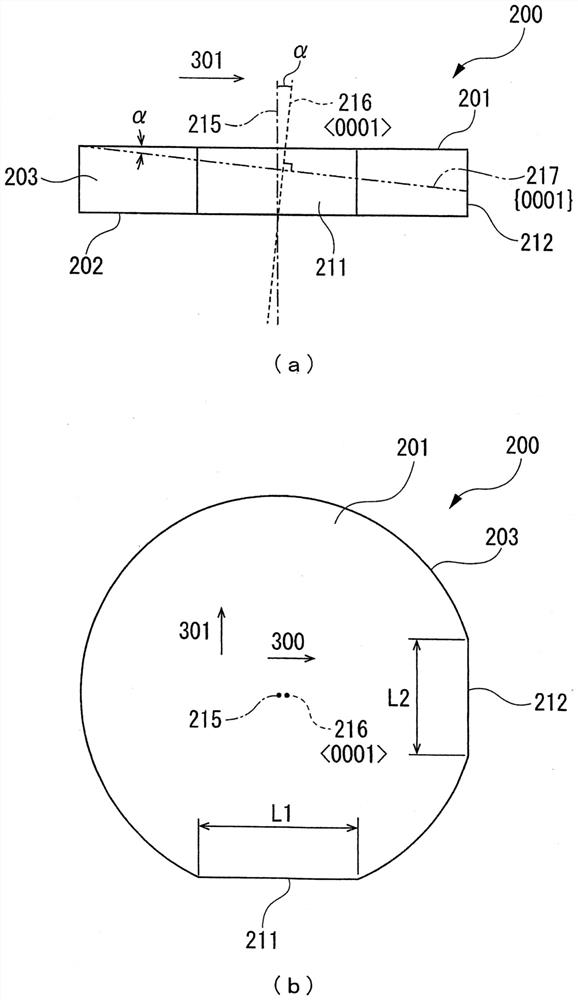

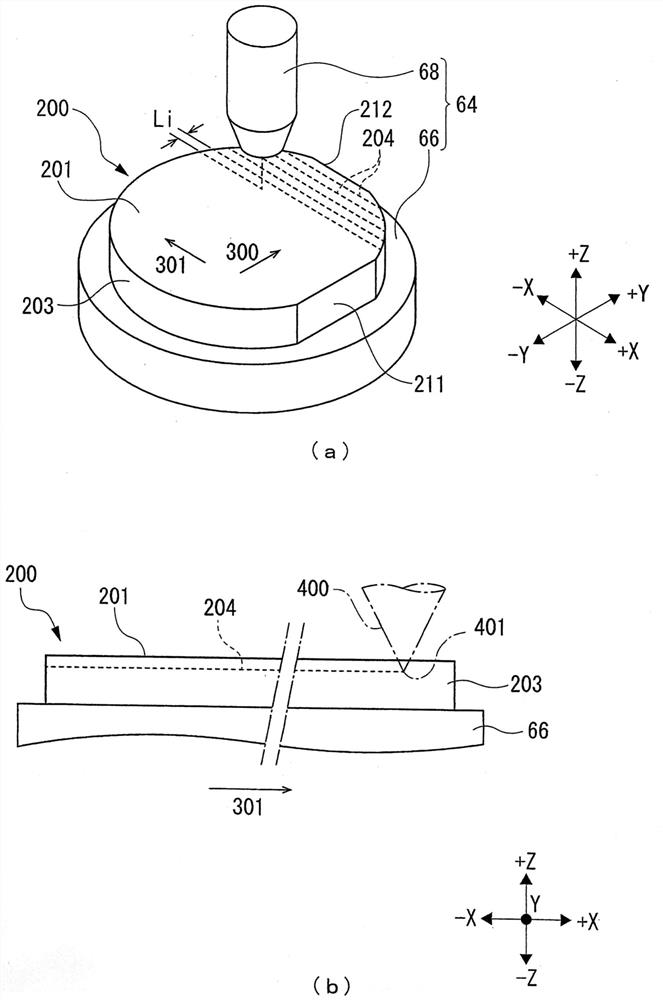

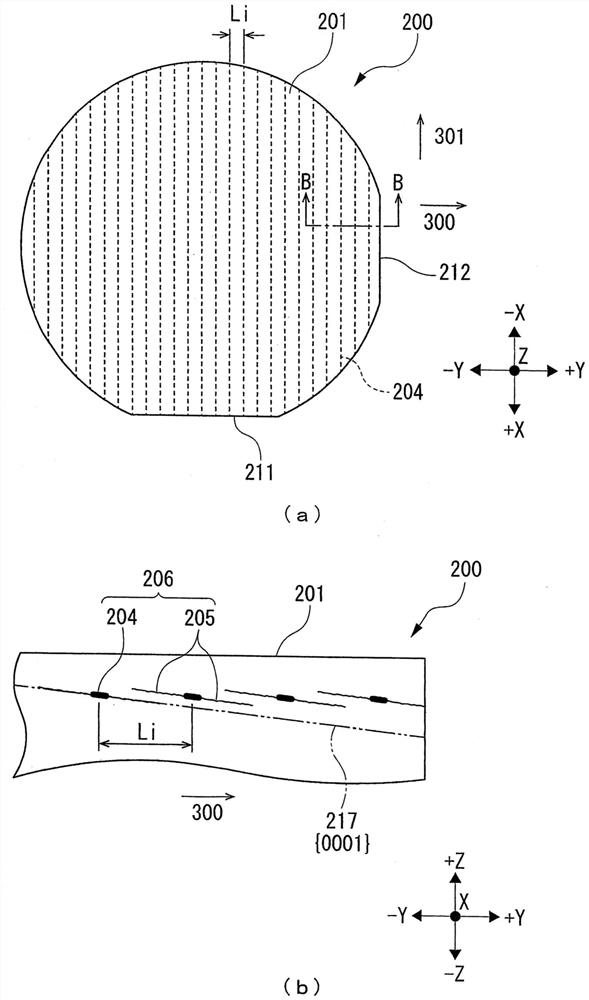

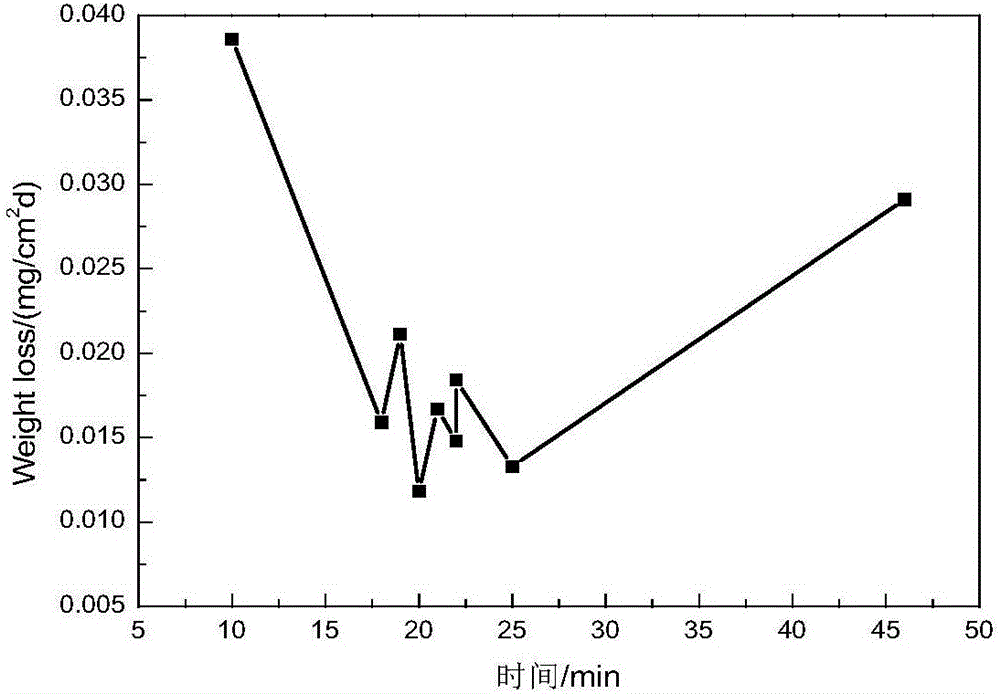

Production method of wafer

PendingCN113580398AShort stripping timeLow efficiencySemiconductor/solid-state device manufacturingFine working devicesWaferingEngineering

The invention provides a method for producing a wafer. The purpose of the present invention is to shorten the peeling time when a wafer is generated from the peeling of a SiC ingot. The wafer production method includes a wafer production step in which ultrasonic water is sprayed onto an end surface of an ingot on which a peeling layer is formed to peel the wafer from the ingot, thereby producing the wafer. Therefore, compared with a structure of simultaneously transmitting ultrasonic vibration to the whole end face of the ingot to strip the wafer, the stripping time can be shortened, and the ultrasonic water spraying nozzle and the ultrasonic vibration plate of the ultrasonic water spraying nozzle can be miniaturized. As a result, it is possible to achieve efficiency and cost reduction related to wafer peeling.

Owner:DISCO CORP

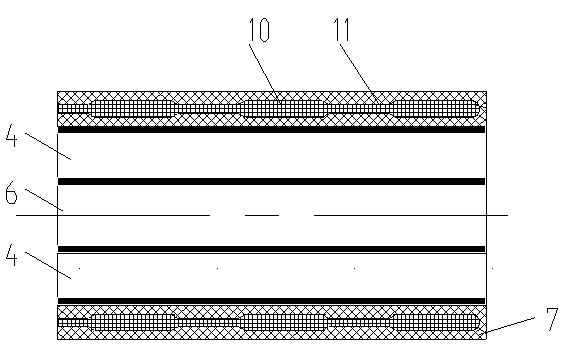

Optical cable

ActiveCN103472552ASmall appearanceReduce constructionFibre mechanical structuresMaterials scienceCore (optical fiber)

The invention relates to an optical cable which comprises a cable core and an outer protection sleeve arranged outside the cable core. The cable core comprises optical fibers, loose tubes and a reinforcing piece, the optical fibers are arranged in the loose tubes which are arranged surrounding the reinforcing piece, and every two adjacent loose tubes are hinged together. The optical cable is characterized in that a plurality of band-shaped separation belts extending in the axial direction are embedded in the outer protection sleeve. In the construction process, the outer protection sleeve can be easily peeled from the optical cable through manpower, physical agility loss of optical cable constructors is lowered, and construction efficiency is improved; the skylight opening operation of the optical cable can be carried out more conveniently, and optical cable construction and maintenance risks can be lowered; the outer protection structure of the optical cable is complete, and any performance of the optical fiber is not affected.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

Furniture surface paint remover and preparation method thereof

InactiveCN106833105AGood paint removal effectHealth hazardChemical paints/ink removersPhenyl EthersPhosphate

The invention discloses a furniture surface paint remover which is prepared from the following components in parts by weight: 42-45 parts of 3,4-hexanedione, 25-30 parts of bromoacetaldehyde ethylene acetal, 12-15 parts of polyethylene glycol dimetyl ether, 19-23 parts of di(isooctyl) phosphate, 12-14 parts of diphosphonic acid, 20-25 parts of propylene glycol phenyl ether, 22-24 parts of tetrachloroethylene, 8-10 parts of sodium dodecyl benzene sulfonate, 2-4 parts of ammonium bisulfate and 8-10 parts of deionized water. The furniture surface paint remover is environment-friendly, does not harm the health of an operator, is significant in effect, and has an excellent paint removal effect on multiple paints on the furniture surface; according to the paint remover, paint removal is carried out in a brushing form, the operation is simple, the paint removal time is short and the re-painting effect on the furniture surface from which the paint is removed is significant.

Owner:ANHUI BORUITE HOUSEHOLD DECORATIONS CO LTD

Multifunctional chorine-free and benzene-free compound paint stripper and production method thereof

InactiveCN101684213BNo pollution in the processNot corrosiveChemical paints/ink removersSolventSealant

The invention discloses a multifunctional chorine-free and benzene-free compound paint stripper and a production method thereof. The multifunctional chorine-free and benzene-free compound paint stripper is a composition, which is characterized in that: the composition comprises the following components in part by weight: 30 to 60 parts of main solvent, 5 to 30 parts of latent solvent, 5 to 30 parts of solubilizer, 2 to 15 parts of accelerant, 2 to 15 parts of activating agent, 1 to 6 parts of osmotic agent, 0.5 to 2.5 parts of inhibitor, 1 to 8 parts of sealant, and 0.1 to 0.6 parts of thickening agent. The production method comprises the following steps: adding the main solvent in a reaction kettle; adding the latent solvent, the activating agent and the accelerant to the main solvent dropwise with stirring; stirring the mixture until the mixture is dissolved completely; adding the thickening agent and stirring the mixture until the thickening agent is dissolved; adding the thickening agent to the mixture again and mixing with the solubilizer; and finally, adding the sealant and the inhibitor and stirring the mixture uniformly. The pain stripper in the invention avoids harm to a human body, environmental pollution and causticity, and has a large foaming area, a short paint stripping time, little dosage and high frequency when demoulding. The production method in the inventionis simple in process, less in device investment, rich in raw material resource and low in product cost.

Owner:CHANGSHU NANJING NORMAL UNIV DEV RES INST

Method and equipment for stripping layered material nanosheet

InactiveCN111099580AImprove stripping efficiencyShort stripping timeGrapheneNanotechnologyWet grindingUltrasound assisted

The invention belongs to the technical field of nano materials, and particularly relates to a method and equipment for stripping a layered material nanosheet, and the method comprises the following steps: S1, taking out a layered crystal material, mixing the layered crystal material with a liquid phase medium, putting the mixture into wet grinding equipment for wet grinding, and obtaining a wet grinding mixture after wet grinding; S2, placing a wet grinding mixture obtained after wet grinding in the step S1 in vibration equipment to be vibrated, and achieving sufficient mixing; and S3, addingthe wet grinding mixture obtained by fully mixing in the step S2 and an organic solvent into high-pressure heating equipment, and performing stripping to obtain a suspension solution formed by the nanosheet and the organic solvent and unstripped crystal powder. According to the invention, the wet grinding mixture can be fully mixed, the stripping efficiency can be improved, the stripping time is short, the yield is high, ultrasonic-assisted stripping is not needed, nanosheet size reduction and nanosheet structure defects are avoided, high universality is achieved, the method and the equipmentfor stripping a layered material nanosheet are suitable for large-scale production, the total production efficiency is effectively improved, and the production cost is reduced.

Owner:南京二维纳米科技有限公司

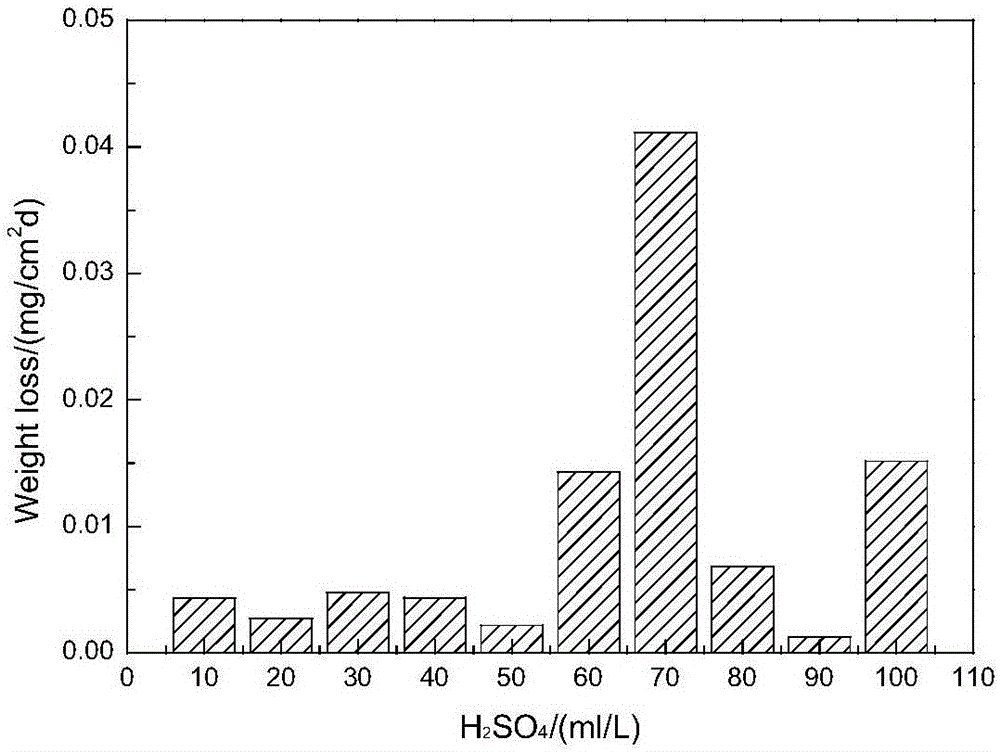

Waste ring-pull can surface paint remover and preparation method and application thereof

ActiveCN106752293AAvoid secondary damageSuitable for removalChemical paints/ink removersPhytic acidPhosphoric acid

The invention relates to a waste ring-pull can surface paint remover and a preparation method and application thereof, and belongs to the technical field of paint removing. The paint remover is formed by taking sulfuric acid as a base solution and then compounding with other inorganic acids, a surfactant and an additive, wherein other inorganic acids include phytic acid and phosphoric acid; the surfactant is one of fluorocarbon, fatty alcohol-polyoxyethylene ether and nonylphenol polyoxyethylene ether; and the additive is one of lauryl sodium sulfate, sodium n-alkyl benzene sulfonate and triethanolamine. Compared with other organic waste pull-ring can paint removers, the paint remover disclosed by the invention has the advantages of being low in toxicity, low in volatilization, little in environment influence, and safe in use.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

Room-temperature aqueous paint remover and preparation and use methods thereof

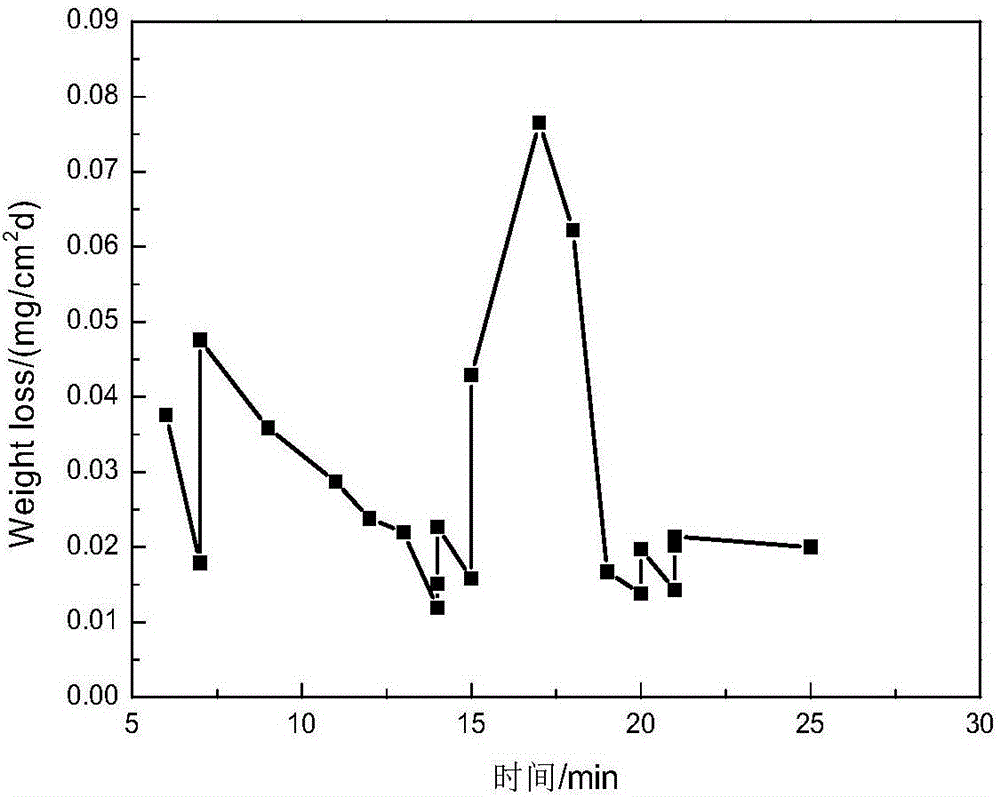

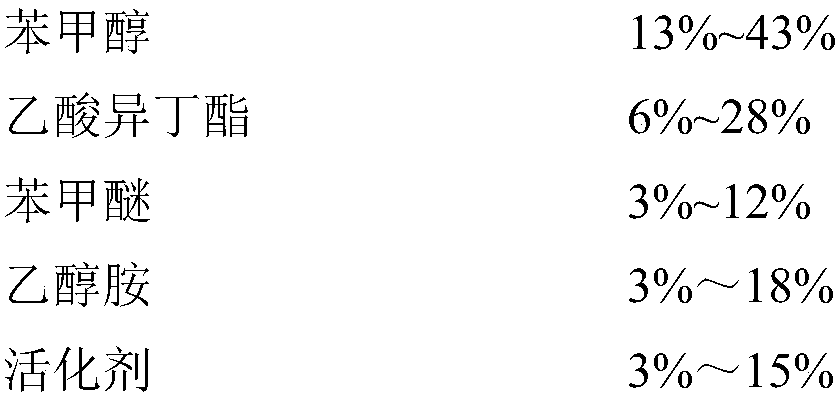

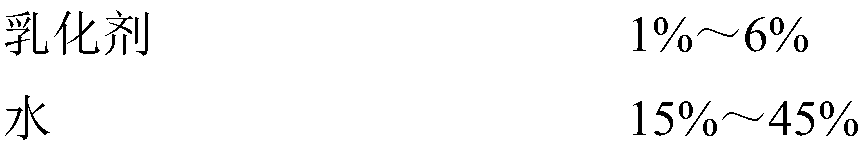

InactiveCN109135407AEnvironmentally friendlyNo need for secondary cleaningChemical paints/ink removersRoom temperatureIsobutyl acetate

The invention discloses a room-temperature aqueous paint remover and preparation and use methods thereof. The paint remover comprises, by mass, the following components: 13-43% of benzyl alcohol, 6-28% of isobutyl acetate, 3-12% of anisole, 3-18% of ethanolamine, 3-15% of activator, 1-6% of emulsifier and 15-45% of water, wherein the mass ratio of benzyl alcohol to isobutyl acetate is 3:1-3:2, themass ratio of anisole to ethanolamine is 1:1-1:3. The aqueous paint remover has the advantages of environmental protection, quick paint removal, low energy consumption and room-temperature operation.

Owner:SICHUAN UNIV

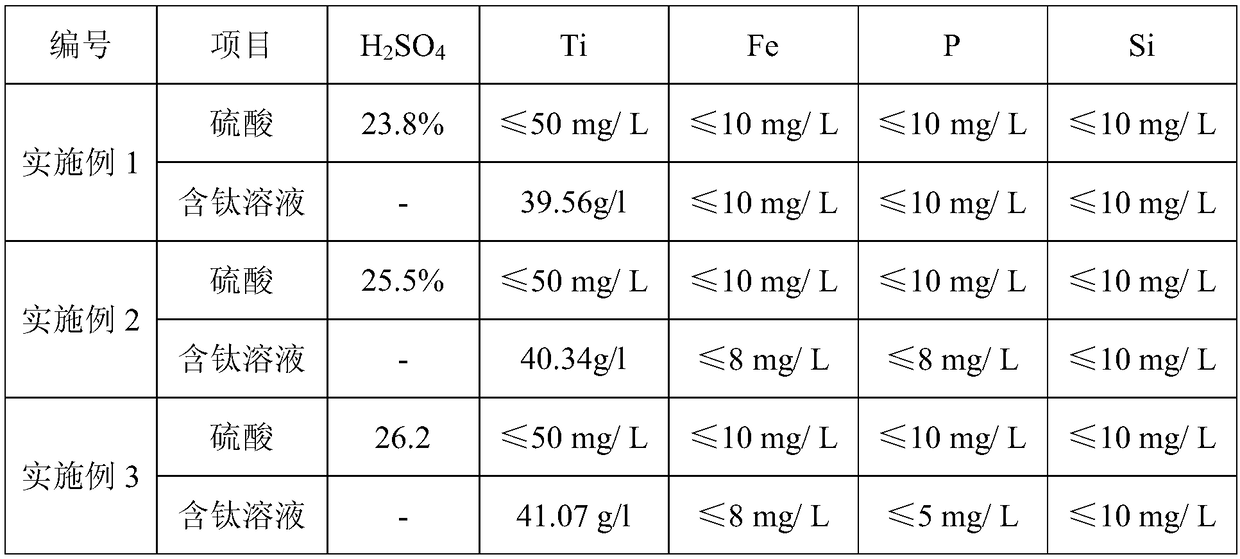

A method for recovering titanium by centrifugal extraction from titanium white waste sulfuric acid

ActiveCN106929682BLow costLow retention fluidProcess efficiency improvementStationary phaseSingle stage

The invention discloses a method for centrifugally extracting and recovering titanium from titanium white waste sulfuric acid. The method comprises the following steps: 1) primary amine centrifugally extracts titanium in waste sulfuric acid, and performs centrifugal extraction reaction with waste sulfuric acid produced by sulfuric acid method to produce titanium dioxide; 2) dilute sulfuric acid single-stage washes the titanium-rich organic phase, and 1) The extracted titanium-rich organic phase is single-stage washed in a container with stirring equipment, the washing liquid is dilute sulfuric acid with a mass concentration of 5-10%, and the phases are separated after single-stage washing; 3) The titanium-rich organic phase is centrifugally stripped , mixing the washed titanium-rich organic phase obtained in step 2) with lye with a concentration of 0.5-1 mol / L, and performing centrifugal stripping, and stripping the titanium-rich organic phase to obtain a titanium-containing solution and a blank organic phase. The method of the present invention does not need a synergistic extraction agent, and the cost is low, and the single-stage washing process of the titanium-rich organic phase is added, which can reduce the iron content in the titanium-rich organic phase, and the titanium-rich organic phase is centrifugally stripped with lye, The stripping time is short and the stripping rate is high.

Owner:CHUZHOU UNIV

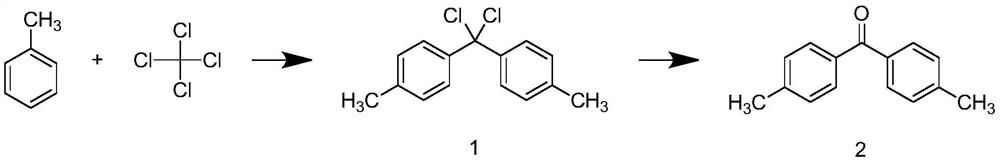

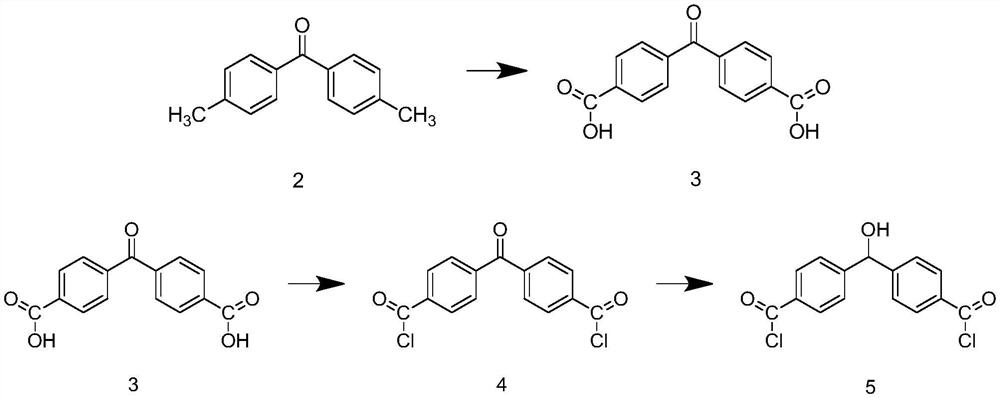

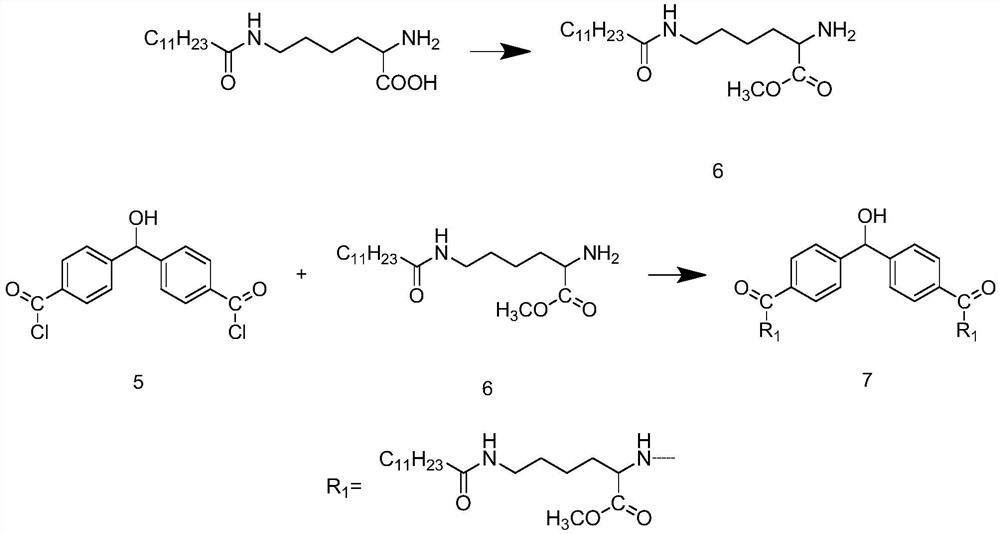

Reworking liquid for CF Rework color film process and preparation method thereof

PendingCN114167691AFacilitate strippingDoes not require high temperature environmentOrganic chemistryPhotosensitive material processingIsobutanolActive agent

The invention discloses reworking liquid for a CF Rework color film process and a preparation method of the reworking liquid. The reworking liquid comprises the following raw materials in percentage: 5-15% of inorganic alkali, 3-5% of a surfactant, 30-50% of a main solvent, 10-15% of a cosolvent, 5-8% of an activating agent and the balance of water, the preparation method comprises the following steps: treating N epsilon-lauroyl-L-lysine to obtain an intermediate 6, reacting an intermediate 5 with the intermediate 6 to obtain an intermediate 7, brominating isobutanol to obtain an intermediate 8, reacting imidazole with the intermediate 8, reacting with 1-bromododecane, distilling, and reacting a substrate, dibromoethane and the intermediate 7 to obtain the surfactant. The surfactant can well strip the photoresist, does not need a high-temperature environment, and is short in stripping time.

Owner:江苏中德电子材料科技有限公司

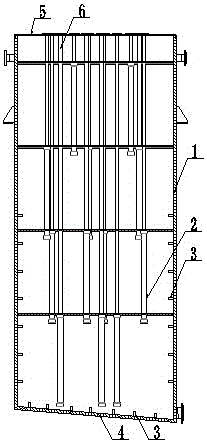

Objective table assembly and laser de-bonding device

PendingCN113851396APrevent re-condensation bondingShorten the timeSolid-state devicesSemiconductor/solid-state device manufacturingLaser scanningEngineering

The invention provides an objective table assembly and a laser de-bonding device. The objective table assembly comprises an objective table, a suction cup and lifting assemblies. The first layer structure is fixed on the objective table. The suction cup is provided with an adsorption end face and a connecting end face, the adsorption end face is divided into at least three adsorption areas, and the adsorption areas comprise a circular adsorption area located in the center of the suction cup and at least two annular adsorption areas sequentially arranged from the circular adsorption area to the outside. The number of the lifting assemblies is at least three, and each lifting assembly is used for upwards pulling up the corresponding adsorption area after the bonding layer at the corresponding adsorption area position is heated by laser and subjected to phase change, so that the first layer structure and the second layer structure are separated at the corresponding adsorption area position. After part of the bonding layer area is scanned by laser, the corresponding adsorption area of the suction cup can be immediately lifted, so that the two layer structures at the adsorption area are separated, the situation that the bonding layer in the molten state is condensed and bonded again due to the fact that the part of the bonding layer area is heated by the laser is prevented, the stripping difficulty is reduced, the stripping time is shortened, and the stripping efficiency is improved.

Owner:北京中科镭特电子有限公司

A kind of method for preparing graphene

The invention discloses a graphene preparation method. The method comprises the processes of liquid phase expansion treatment, ultrasonic peeling and drying, and the ultrasonic peeling process comprises the following steps: adding a peeling solution and wormlike graphene aggregation obtained after the liquid phase expansion treatment into a tank body provided with a plurality of ultrasonic vibration rods in proportion, introducing compressed air into the tank body to bubble and stir in order to make the wormlike graphene aggregation dispersed and suspending in the peeling solution, and controlling the ultrasonic vibration rods to carry out ultrasonic vibration treatment for 0.5-20h in order to obtain a flocculent graphene suspension. The method allows the wormlike graphene aggregation to be uniformly dispersed in the peeling solution, so the peeling effect is improved, and the peeling time is shortened.

Owner:DEYANG CARBONENE TECH

Baking varnish stripping composition, preparation method and applications thereof

InactiveCN107722710ALow costReduce pollutionChemical paints/ink removersSodium metasilicatePhysical chemistry

The present invention discloses a baking varnish stripping composition, which comprises, by mass, 2.5-5% of urea, 1-3% of sodium metasilicate pentahydrate, 10-17% of butyl acetate, 2-5% of phenol, 0-1% of benzotriazole, and the balance of water. According to the present invention, the baking varnish stripping composition has advantages of low cost, less pollution, short paint stripping time, strong penetration, no corrosion on the substrate, strong paint stripping effect, no dead angle and no residue, can completely separate the coating material and the substrate within a short time, can be used for the stripping of a variety of different baking varnishes, and can provide the technical support for the development of industrial cleaning agents.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

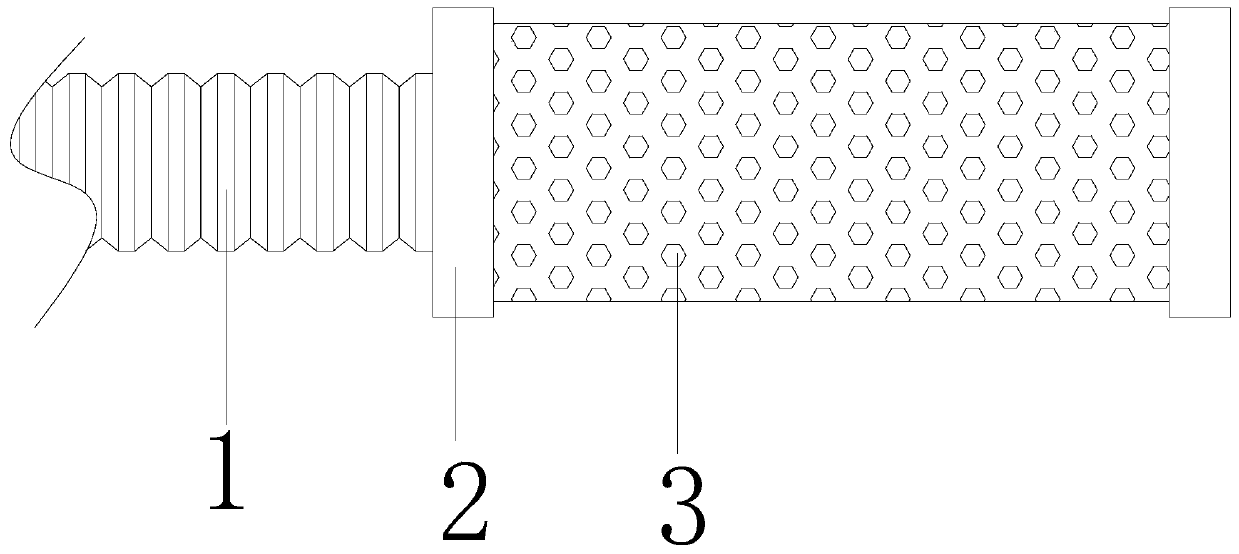

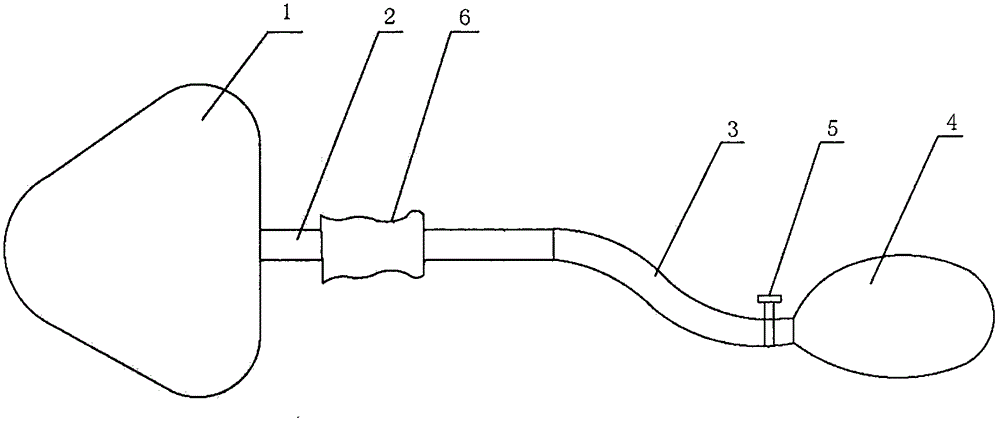

Pneumatic separation type stripper

InactiveCN106037837AHas blunt stripping propertiesSimple structureMammary implantsSurgeryBreast augmentationEngineering

The invention discloses a pneumatic separation type stripper which is characterized by comprising an expansion air bag (1). An air inlet of the expansion air bag (1) is connected with one end of a hard inflation tube (2), the other end of the hard inflation tube (2) is connected with one end of an air delivery tube (3), the other end of the air delivery tube (3) is connected with an air outlet of an inflation handle (4), and a valve (5) is further arranged on the hard inflation tube (2) or the air delivery tube (3). The pneumatic separation type stripper has the advantages that shortcomings of severe bleeding and injury and difficulty in mastering layers during surgery in the past can be effectively overcome, gaps in non-traditional breast lacuna striping during domestic and overseas breast augmentation surgery can be filled, the pneumatic separation type stripper is simple in structure, convenient to operate, soft in texture and free of optional injury to human bodies, toxicity and peculiar smell and can be repeatedly disinfected and used, and obvious effects can be realized.

Owner:王月玲 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com