Graphene composite material and preparation method and application thereof

A composite material and graphene technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as single function, and achieve the effect of simple process flow, integrity retention, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 30 parts by weight of expanded graphite, 15 parts by weight of sulfonated poly(p-phenylene vinylene) (molecular weight is 20000), 15 parts by weight of aromatic polysulfide ketone (molecular weight is 20000) (that is, the total mass of macromolecular polymer is 30 parts by weight) , added together to 800 parts by weight of water and mixed evenly, then the mixed solution was added to a disc mill at a speed of 300r.p.m, and ground for 2h to obtain a graphene composite material dispersion, which was freeze-dried Product available.

[0038] It can be seen from the test that the average number of layers of the prepared graphene composite material is 3 layers, the thickness is 1.25nm, and the electrical conductivity is on the order of 10 4 s / m.

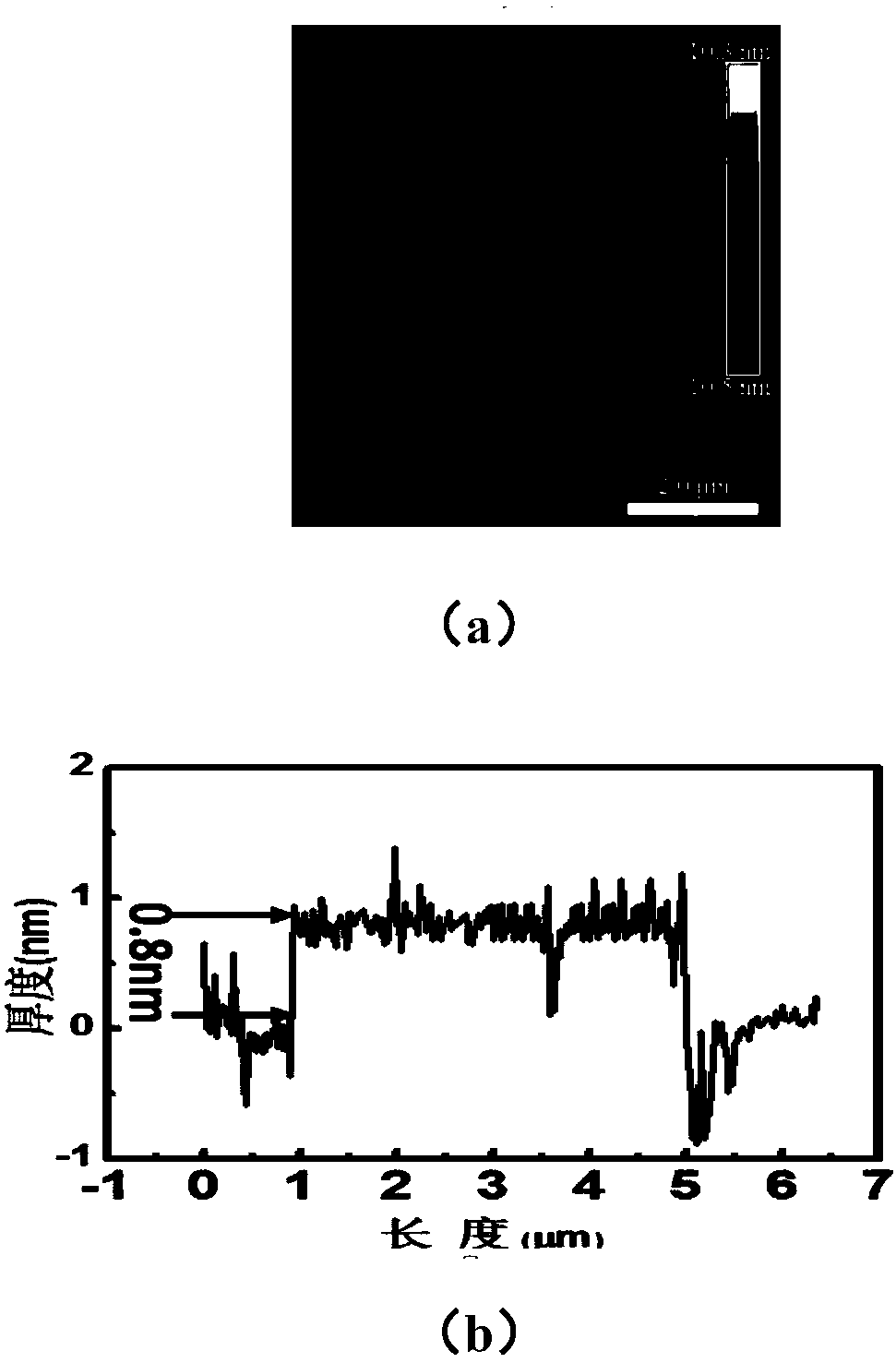

Embodiment 2

[0040] 30 parts by weight of graphite slurry, 15 parts by weight of sulfonated poly(p-phenylene vinylene) (molecular weight is 20000), 15 parts by weight of aromatic polysulfide ketone (molecular weight is 20000) (that is, the total mass of macromolecular polymer is 30 parts by weight) ), were added together into 1000 parts by weight of water and mixed evenly, then the mixed solution was added to a disc mill at a speed of 500r.p.m, ground for 20min, and then ultrasonically dispersed using an ultrasonic disperser with an ultrasonic frequency of 15KHz. The time is 20 minutes to obtain the graphene composite material dispersion liquid, and the product can be obtained after the dispersion liquid is freeze-dried.

[0041] After testing, it can be seen that the average number of layers of the prepared graphene composite material is 2 layers, the thickness is 0.8nm, and the electrical conductivity is on the order of 10 4 s / m.

Embodiment 3

[0043] Claim 5 parts by weight of graphite slurry, 5 parts by weight of expanded graphite (that is, the total mass of multilayer graphite is 10 parts by weight), 15 parts by weight of sulfonated polyparaphenylene vinylene (molecular weight is 20000), polyaromatic polysulfide ketone ( The molecular weight is 20000) 25 parts by weight (that is, the total mass of the macromolecular polymer is a total of 40 parts by weight), and they are added to 1000 parts by weight of water and mixed evenly, and then the mixed solution is added to the disc mill at a speed of 500r. p.m, and grind for 40 minutes to obtain a graphene composite material dispersion, which can be freeze-dried to obtain the product.

[0044] It can be seen from the test that the prepared graphene composite material is a single-layer graphene thickness, about 0.34nm, and the electrical conductivity is on the order of 10 5 s / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity quantity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com