Room-temperature aqueous paint remover and preparation and use methods thereof

A paint remover and water-based technology, which is applied in the field of normal temperature water-based paint remover and its preparation, can solve the problems of low paint remover efficiency and high energy consumption, and achieve the effect of short paint removal time and high paint removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

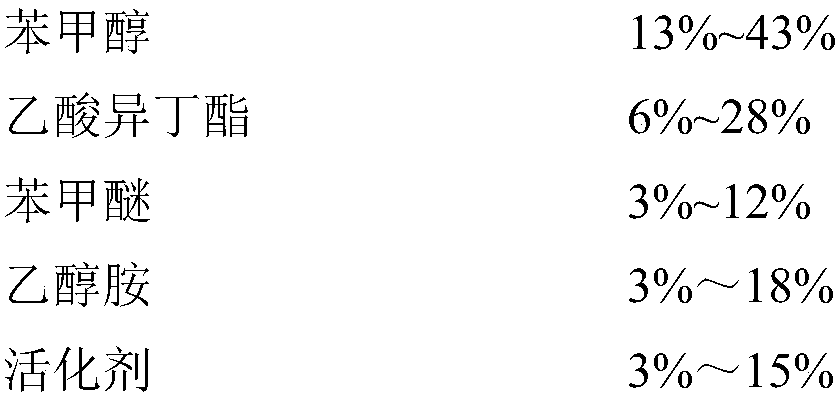

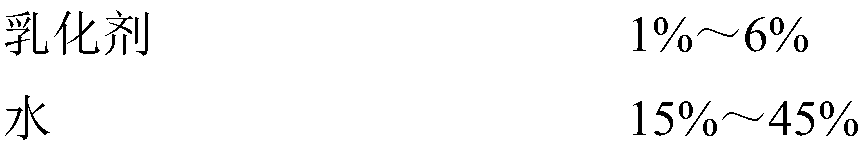

Method used

Image

Examples

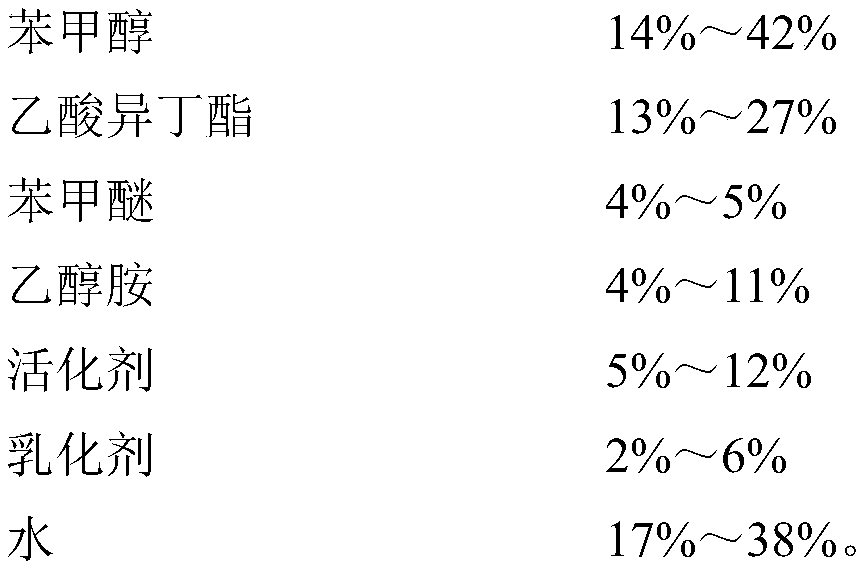

Embodiment 1

[0034] Paint remover formula (wt%): benzyl alcohol 24%, isobutyl acetate: 15%; Anisole 5%, ethanolamine 10%, activator (methyl alcohol): 10%; Emulsifier (dodecylbenzene sulfonate Sodium Acid): 3%; Water: 33%.

[0035] Preparation method: (1) Dissolve sodium dodecylbenzene sulfonate in water at 30(±1)°C, stir for 10min to dissolve completely. (2) Add the main solvent (benzyl alcohol, isobutyl acetate), co-solvent (anisole, ethanolamine), and activator (methanol) into another container, and stir to make it evenly mixed. (3) Add the mixed solution in step (2) into the aqueous solution in step (1), stir for 30 minutes, and mix evenly to obtain the prepared paint remover.

Embodiment 2

[0037] Paint remover formula (wt%): benzyl alcohol 42%, isobutyl acetate 13%; Anisole 4%, ethanolamine 4%; Activator (ethanol): 5%; Emulsifier (dodecylbenzenesulfonic acid Sodium): 4%; Water: 28%.

Embodiment 3

[0039] Paint remover formula (wt%): benzyl alcohol 27%, isobutyl acetate 14%; Anisole 5%, ethanolamine 5%; Activator (n-propanol): 7%; Emulsifier (dodecyl sulfonate Sodium Acid): 5%; Water: 37%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com