Patents

Literature

51results about How to "No need for secondary cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

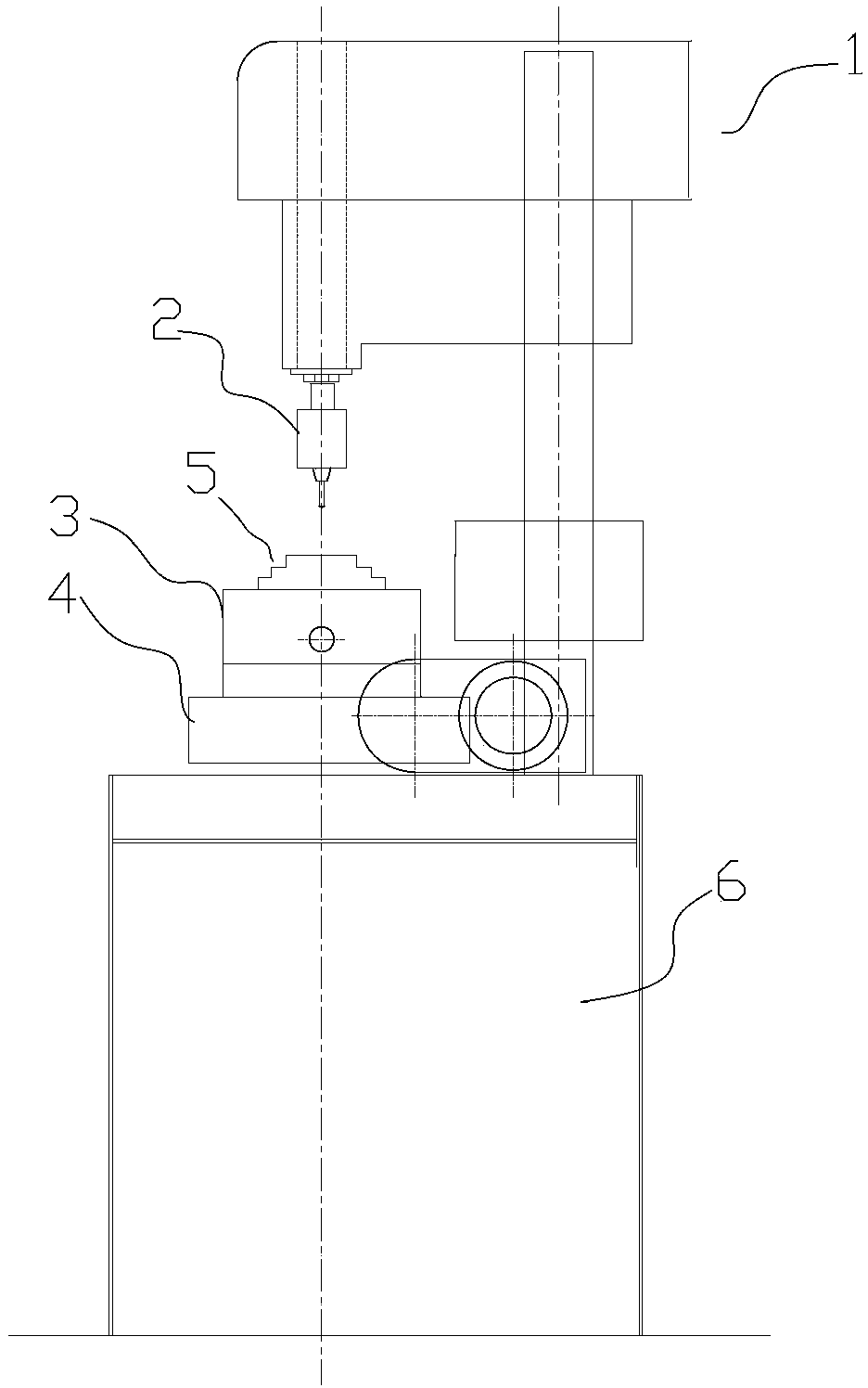

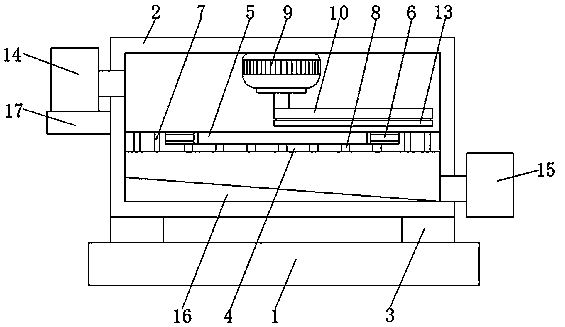

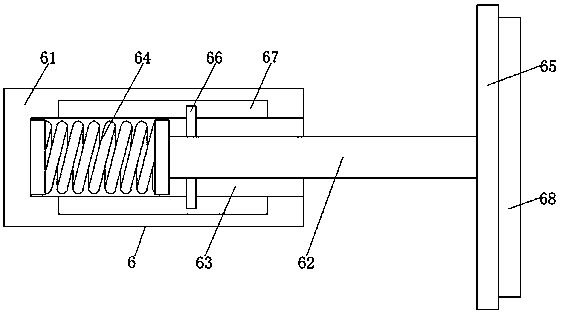

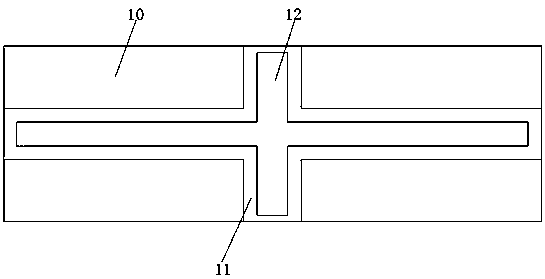

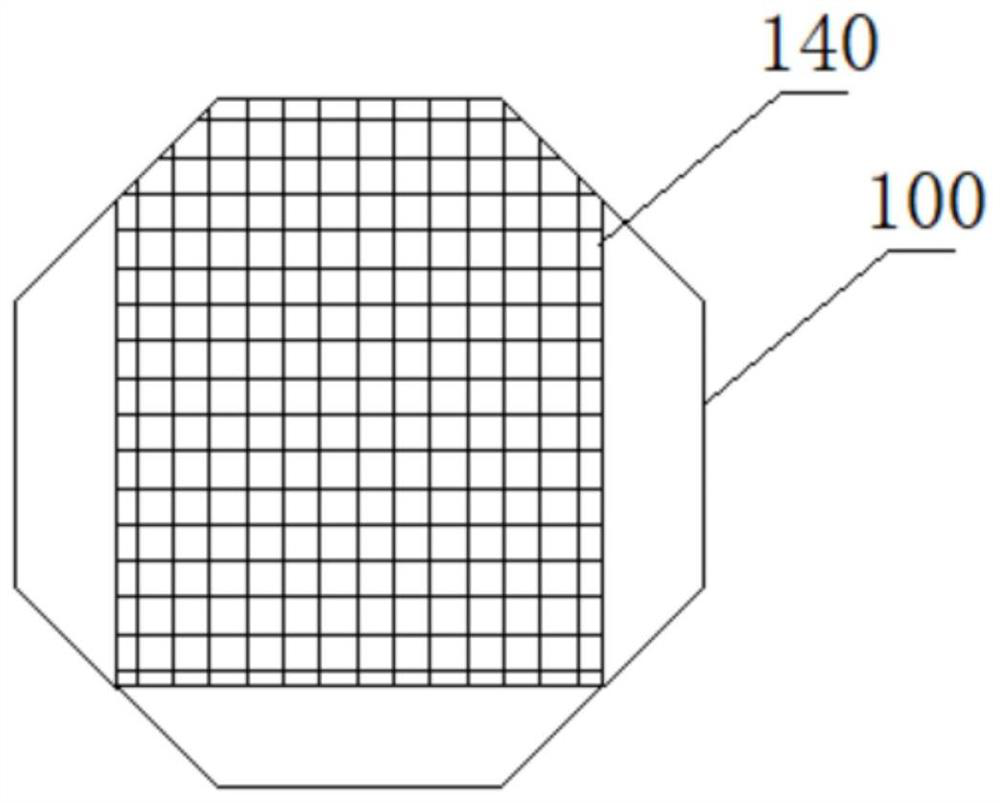

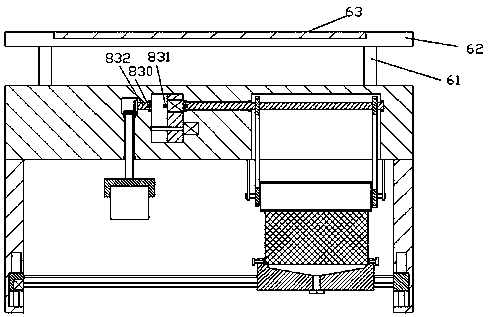

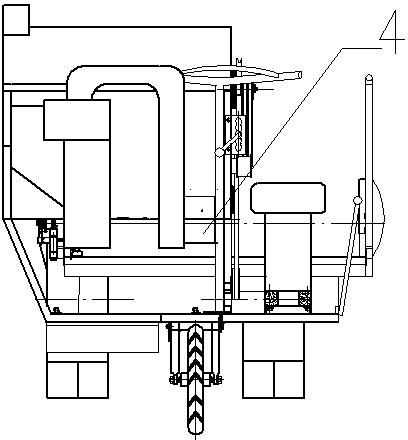

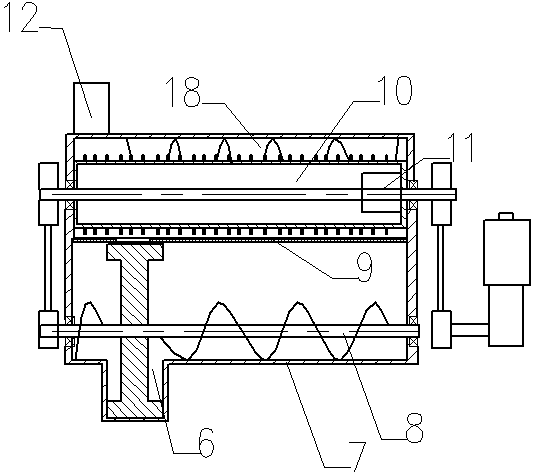

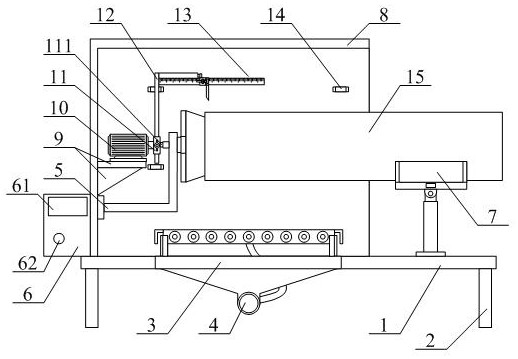

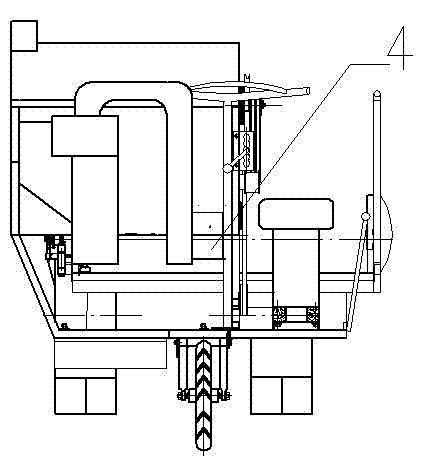

Numerical control drilling device

InactiveCN104117713AReduce scrap costsImprove processing efficiencyBoring/drilling componentsMaintainance and safety accessoriesNumerical controlEngineering

The invention belongs to the technical field of numerical control drilling devices, and particularly discloses a numerical control drilling device. The numerical control drilling device comprises a numerical control drilling mechanism. A numerical control rotating workbench is arranged below the numerical control drilling mechanism. A workpiece clamp is arranged on the numerical control rotating workbench. A cooling water pipe is arranged on the numerical control drilling mechanism. A water collection tank is arranged below the numerical control rotating workbench. By the adoption of the technical scheme, the numerical control drilling device greatly improves machining efficiency, and is convenient to operate, simple in structure, easy to maintain and low in cost; in addition, due to the fact that the numerical control technology is adopted for control, machining precision is high, the reject ratio is low, the scrap cost in production and machining of an enterprise is greatly reduced, and the surface of a machined piece is clean, so that no secondary cleaning is needed.

Owner:TIANJIN KESAISI IND & TRADE

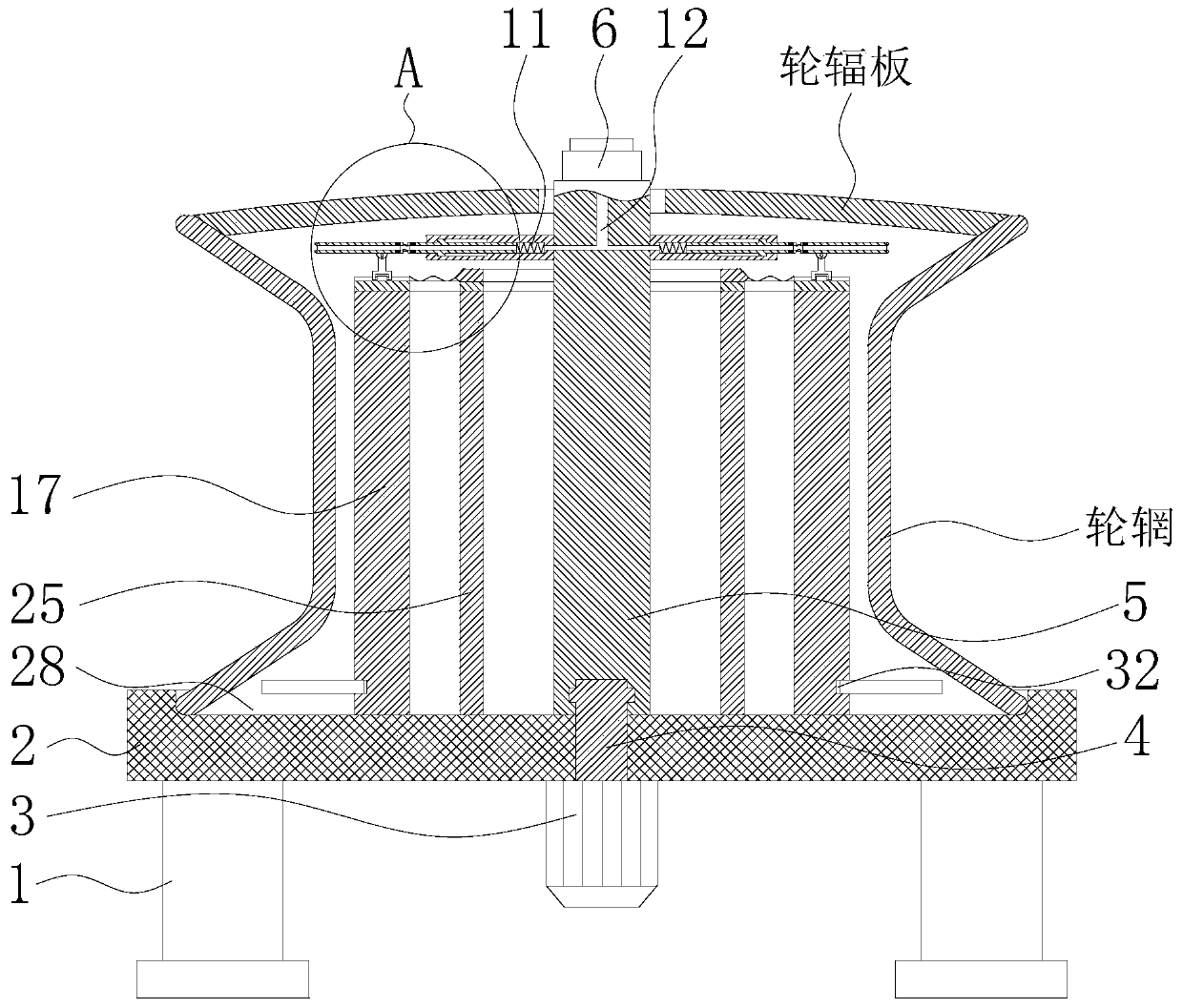

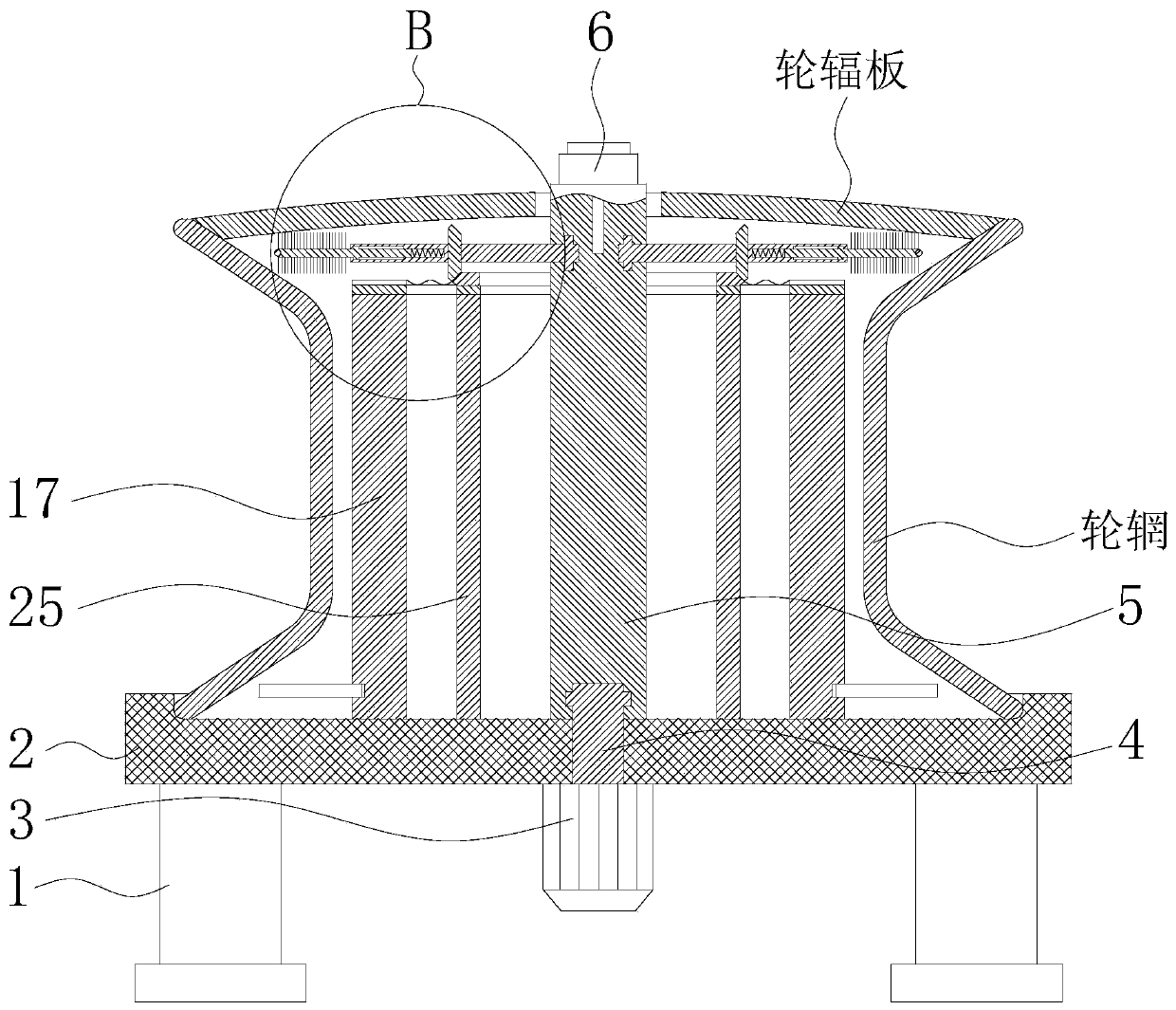

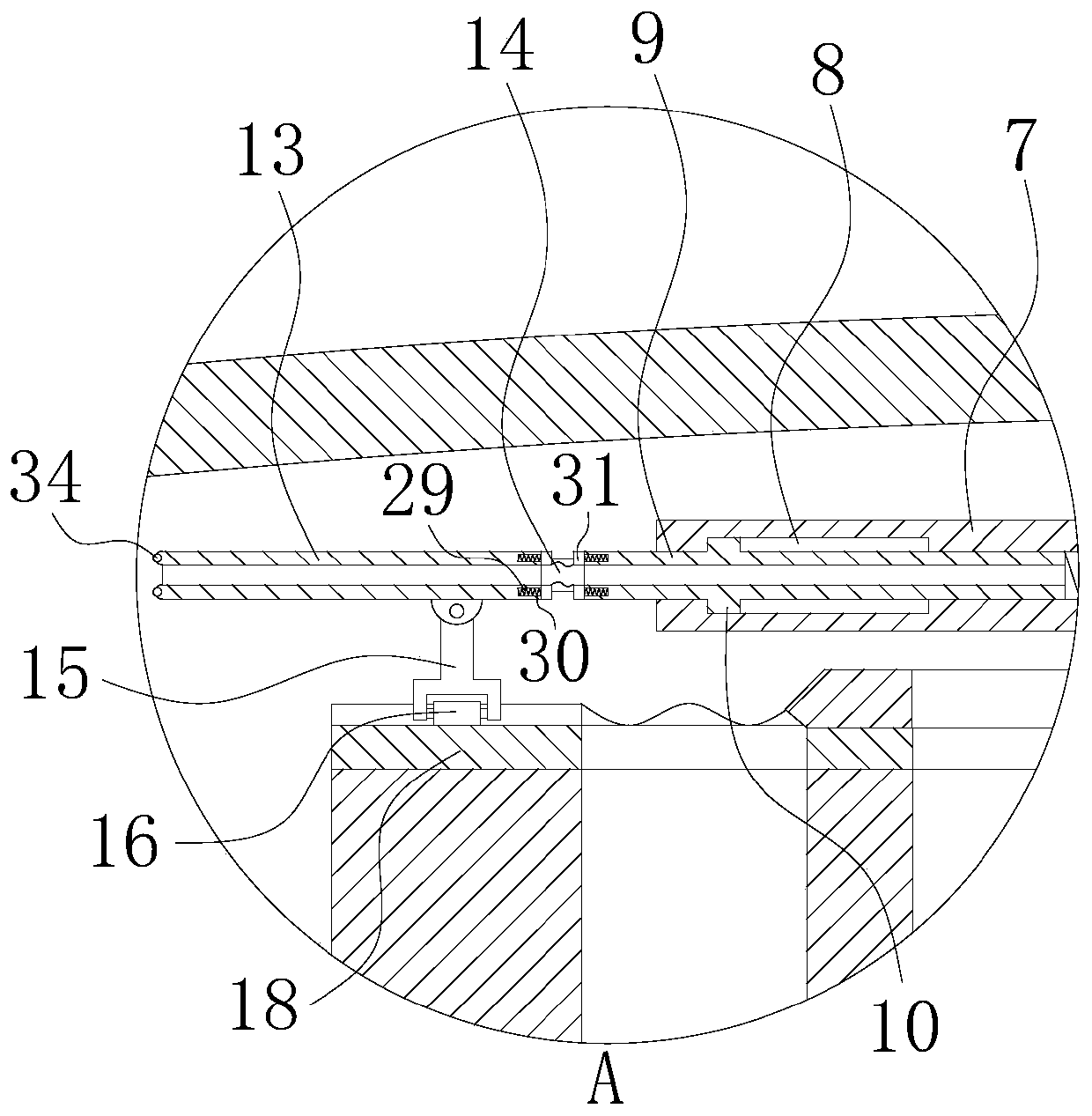

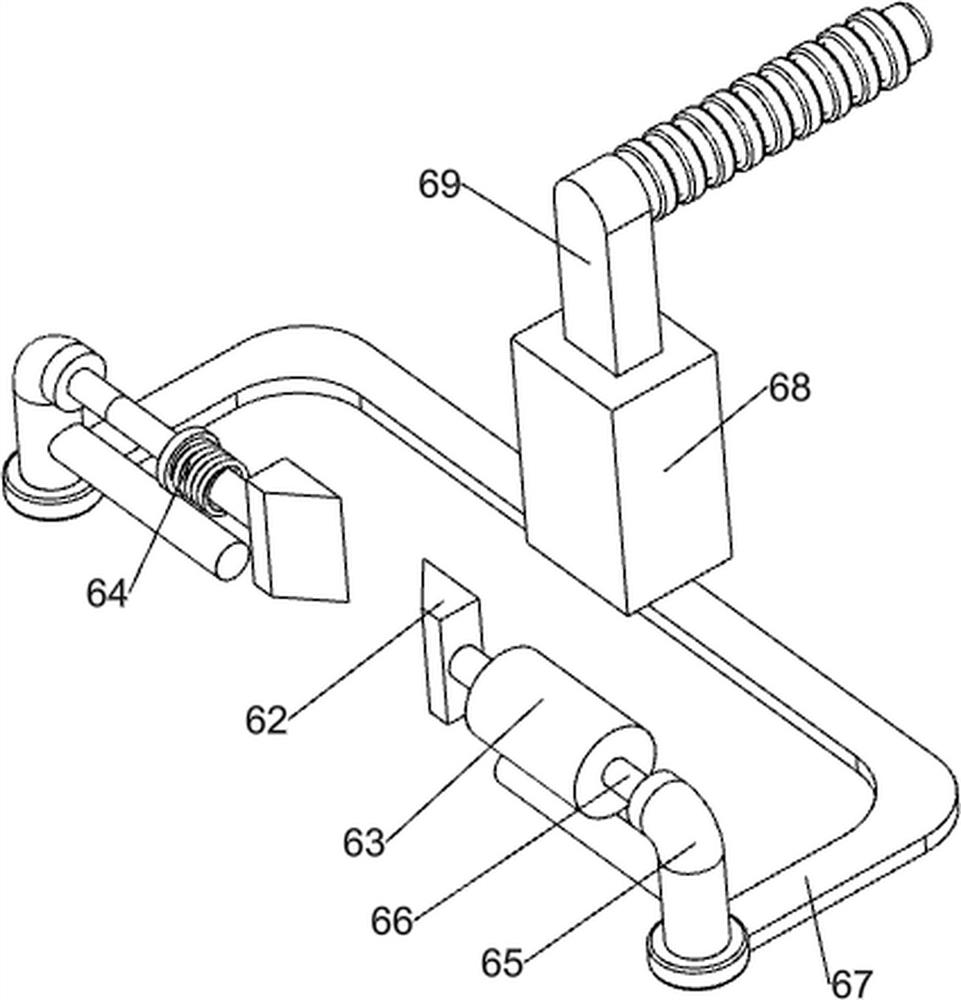

Slag cleaning and scraping machine for welding slag after butt welding of profile rims

ActiveCN110732532APrevent fallingEasy to cleanWelding/cutting auxillary devicesCleaning using toolsSlag (welding)Butt welding

The invention belongs to the technical field of rim manufacturing, and particularly relates to a slag cleaning and scraping machine for welding slag after butt welding of profile rims. The slag cleaning and scraping machine comprises a frame and a workbench, a rotating motor is arranged below the workbench, the rotating motor is fixedly connected with a mounting column, a high-pressure air pump isarranged at the top of the mounting column, a first sleeve is arranged on the mounting column, a first limiting groove is formed in the first sleeve and is in sliding fit with a first air delivery pipe, one end of the first air delivery pipe is connected with a first spring, an air passage is arranged inside the mounting column, the end part of the first air delivery pipe is hinged with a secondair delivery pipe, the second air delivery pipe is hinged with a bearing frame, a roll wheel is hinged on the bearing frame, a first bracket is fixedly arranged on the workbench, a guide ring with a concave-convex upper surface is arranged on the top of the first bracket, and the roller wheel is in rolling fit with the upper surface of the guide ring. When the slag cleaning and scraping machine isadopted to scrape the welding seam between the rim and the spoke plate, the welding slag in the crack between the rim and the spoke plate is cleaned by blowing air from the high-pressure air pump, and compared with the traditional scraper cleaning, the cleaning effect is better.

Owner:WENZHOU YIWO MASCH TECH CO LTD

PCB cleaning apparatus convenient to use

InactiveCN107708311AEasy to useEasy to cleanInsulating layers/substrates workingWork periodEngineering

The invention relates to the technical field of PCB processing equipment, and discloses a PCB cleaning apparatus convenient to use. The PCB cleaning apparatus comprises a base and a machine body; themachine body is fixedly connected with the upper surface of the base through supporting legs; a bearing plate is horizontally mounted in the middle part of an inner cavity of the machine body; a storage groove is formed in the middle part of the upper surface of the bearing plate; and clamping apparatuses are fixedly connected with two side inner walls of the storage groove respectively. The PCB cleaning apparatus is provided with a driving motor, a rotary plate, a cleaning brush, an exhaust fan and an air blower; chippings are blown off by the air blower, and meanwhile, the chippings are exhausted through the exhaust fan along a first through hole and a second through hole; meanwhile, by matching with the rotary plate, the chippings in the holes and the attached chippings are cleaned off,so that the chippings can be cleaned more completely without needing secondary cleaning; and the PCB cleaning apparatus is convenient to use and capable of saving working time, lowering workload andworking intensity and improving working efficiency.

Owner:周言鑫

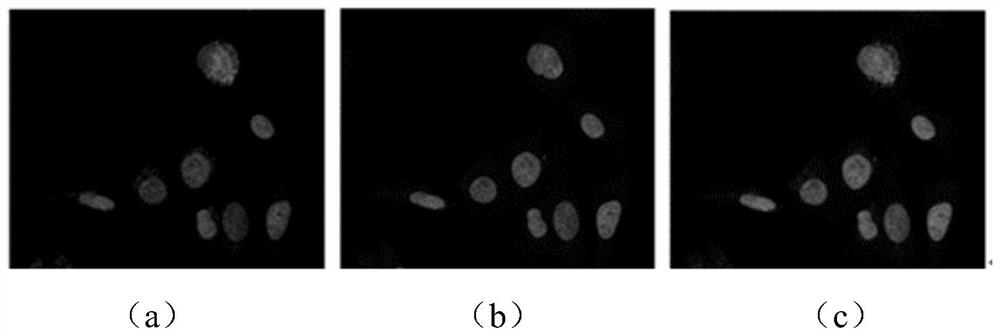

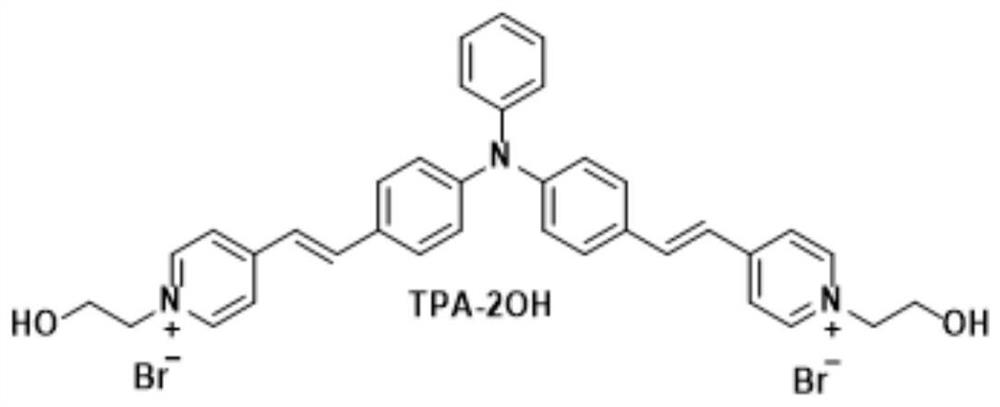

Red fluorescent water-soluble cell nucleus targeting probe with V-shaped structure and application

PendingCN112300060AGood water solubilityImprove universalityOrganic chemistryMethine/polymethine dyesStainingRed fluorescence

The invention belongs to the field of new materials, and discloses a red fluorescence water-soluble cell nucleus targeting probe with a V-shaped structure and application. The probe is an aggregation-induced emission fluorescence probe material with lipophilicity and hydrophilicity, the probe has a structural general formula shown as a formula (I) or a formula (II), M is a hydrophobic aromatic ring, and A is a hydrophilic nitrogen heterocyclic cation. According to the aggregation-induced emission fluorescent probe material, due to the particularity of the structure, the probe material has amphipathy and has better universality to the physiological environment of cells, the probe can independently target and position cell nucleuses and dye the cell nucleuses, background fluorescence is avoided, and no-clean imaging can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

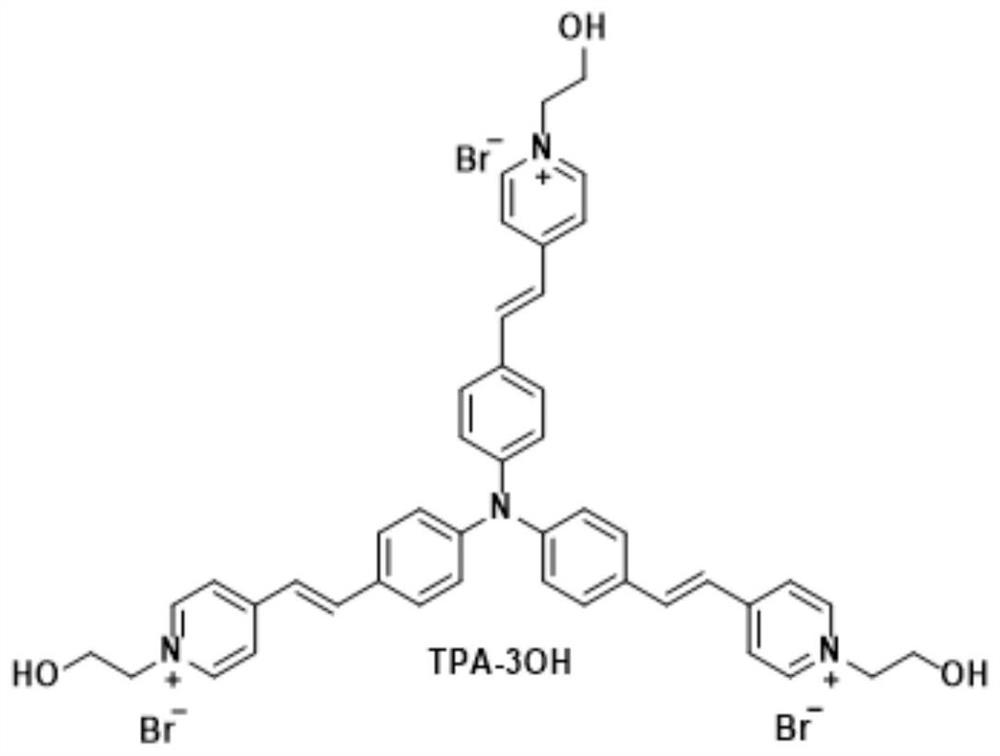

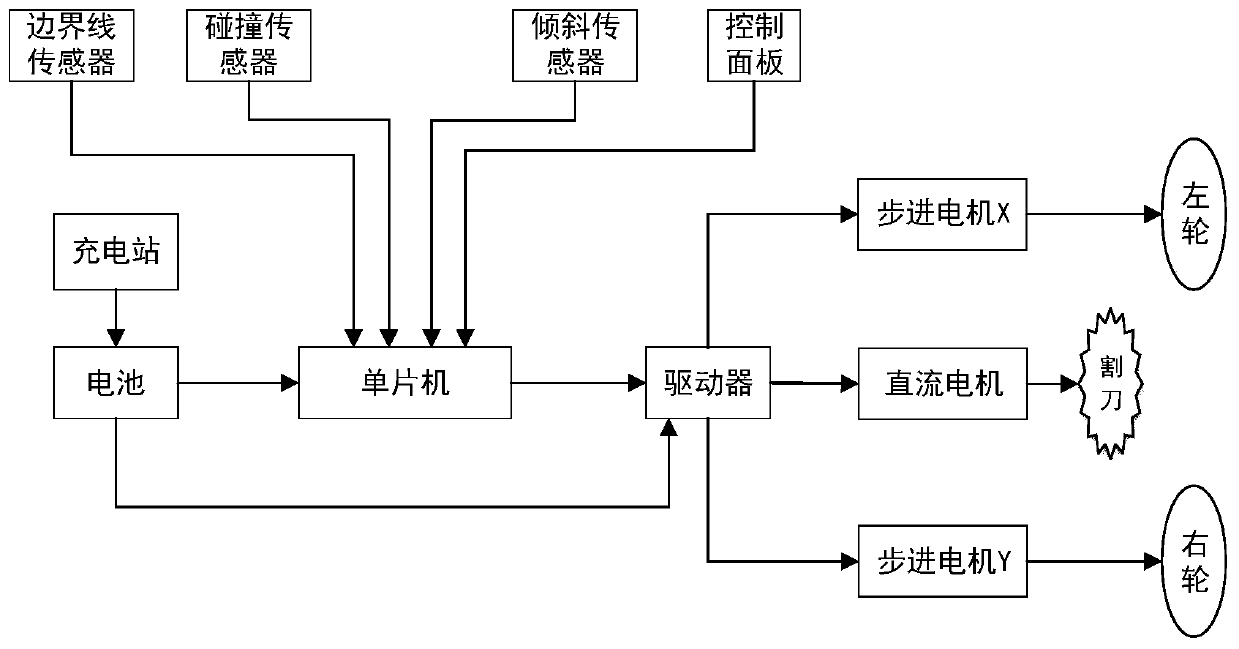

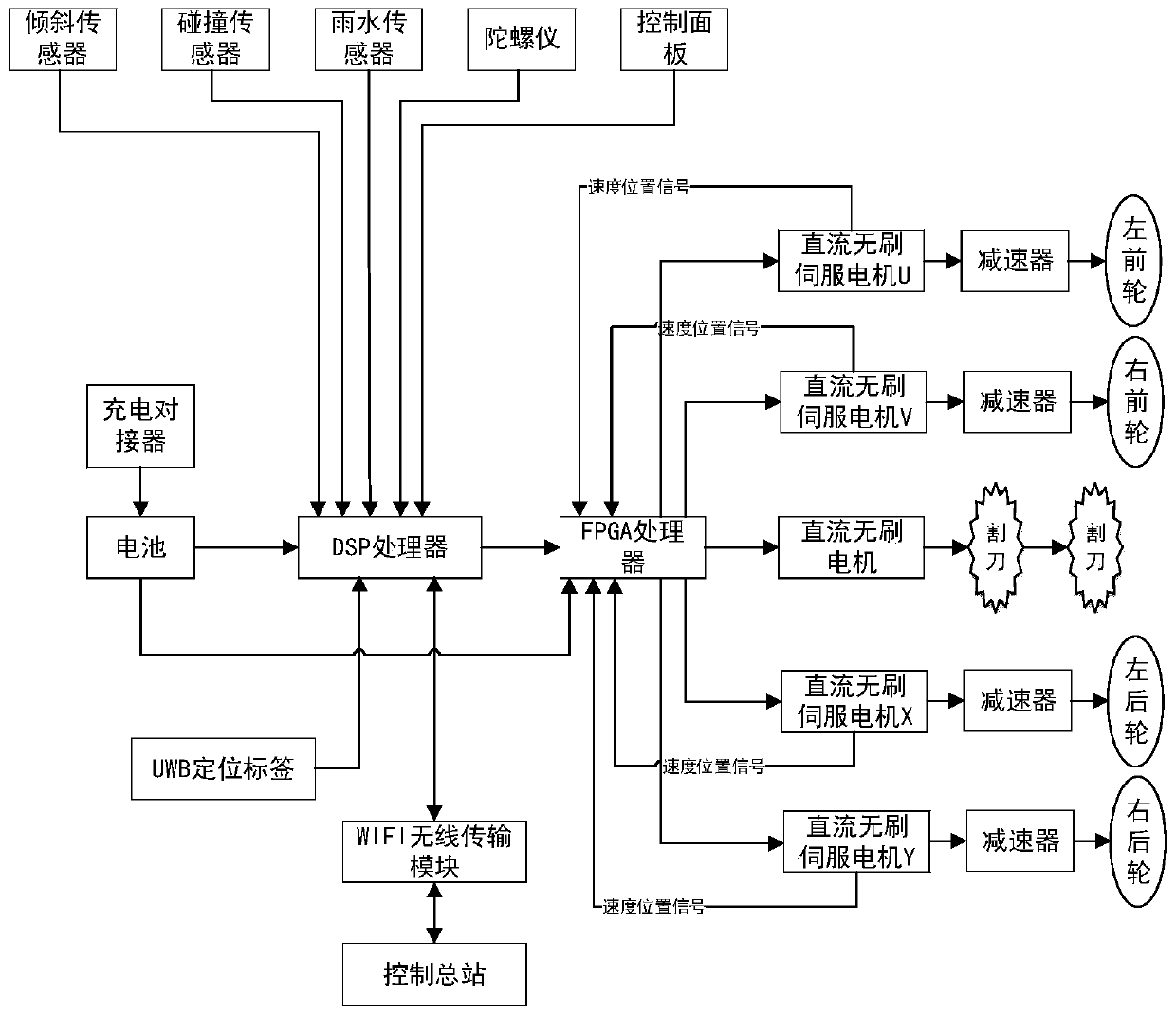

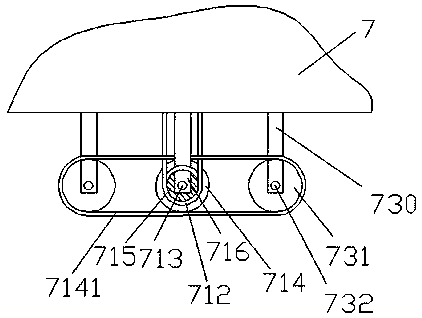

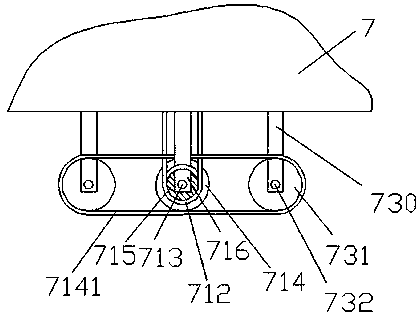

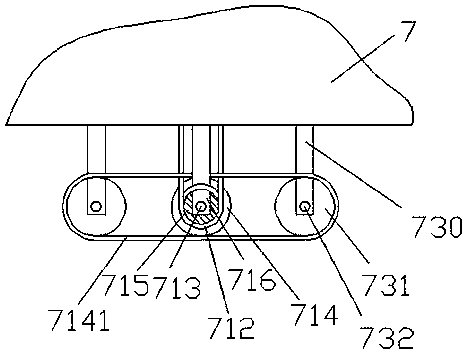

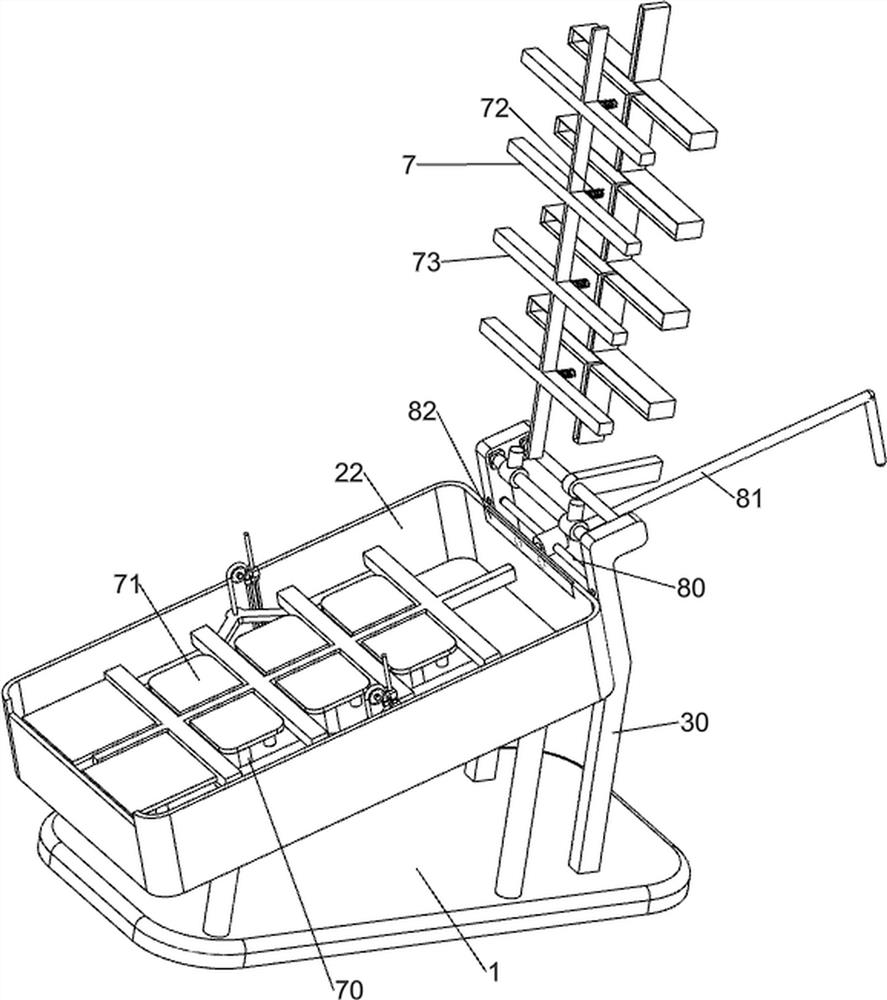

Dual-core four-wheel drive UWB positioning mowing robot capable of being wirelessly controlled and control method of dual-core four-wheel drive UWB positioning mowing robot

ActiveCN110989578APrecise position controlExtend your lifeTransmission systemsVehicular energy storageEmbedded technologyWireless control

The invention discloses a dual-core four-wheel drive UWB positioning mowing robot capable of being wirelessly controlled and a control method of the dual-core four-wheel drive UWB positioning mowing robot. The mowing robot uses the UWB wireless positioning system; pre-embedded boundary line can be avoided, manpower saving is achieved, a self-precise position can be avoided, a DSP + FPGA dual-coreprocessor cooperative work design is adopted. The operation speed and the control precision are greatly improved; a WIFI wireless transmission module is adopted, the mowing robot can be accessed to the Internet; even if a user is traveling outside, the work of the mowing robot at home can be monitored and controlled anytime and anywhere; the mowing robot is more practical and convenient, based ona servo system of the latest embedded technology, an intelligent mowing task program is adopted, a mowing area grid map is established, global coverage path planning is carried out, a mowed area and an unmowed area are marked, the mowing efficiency can be greatly improved, and the phenomenon of missing mowing of grassland is reduced.

Owner:苏州博迷科技有限公司 +1

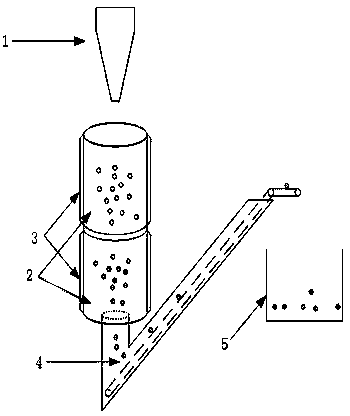

Wax-sealed water blasting bead and preparation method and device thereof

The invention relates to a wax-sealed blasting bead for cigarettes and a preparation method and device thereof. The blasting bead is of a wall-core structure, a wall material is wax, and a core material is water and liquid water-based perfume or water-soluble perfume. The device is cylindrical, the top end is open, the device comprises two sections and is heated in the circumferential direction, and a hole can be formed in the bottom. The preparation method comprises the steps: dropwise adding an inner core component into wax in a liquid form at a certain temperature to form a wax sealing material. The wax-sealed blasting bead is simple in structure, low in cost, capable of effectively moistening cigarette smoke and suitable for large-scale production of dropping pills.

Owner:CHINA TOBACCO YUNNAN IND

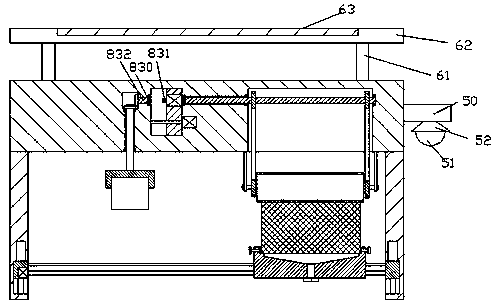

Improved communication chassis device

PendingCN108453587ASimple structureEasy to operateLighting applicationsMechanical apparatusEngineeringChassis

The invention discloses an improved communication chassis device which comprises support frames symmetrically arranged on the bottom end surface of an installation plate in a left-and-right mode. A left turn groove, a middle groove and a right turn groove are arranged in an inner wall body of the installation plate; a sliding block is arranged in the middle groove in a slide fit way; a first screwrod is arranged in the sliding block in a matching way; the extending tail end of the left side of the first screw rod is connected with an inner wall of the left side of the middle groove in a running fit way; the extending tail end of the right side of the first screw rod is connected with a first driver; the outer surface of the first driver is fixedly arranged on an inner wall of the right side of the middle groove; a second driver is fixedly arranged in the sliding block on the upper side of the first screw rod; the extending tail end of the left side of the second driver is connected with a first spline shaft; and the extending section of the right side of the second driver is connected with a second spline shaft. The improved communication chassis device provided by the invention is simple in structure, convenient to operate, and beneficial to reducing the labor intensity.

Owner:广州酷汇电子科技有限公司

Recycling method of cobalt, nickel and manganese in ternary battery positive electrode waste

InactiveCN112813273ALow costReduce impurityProcess efficiency improvementElectrical batteryManganese

The invention relates to a method for recycling cobalt, nickel and manganese in a ternary battery positive electrode waste. The method comprises the following steps: 1, reducing and dissolving with sulfuric acid; 2, removing iron and aluminum; 3, removing copper and zinc; 4, removing calcium and magnesium; and 5, removing fluorine. According to the technical scheme, cobalt, nickel and manganese do not need to be separated, any extraction is not needed, and the cobalt, nickel and manganese mixed solution capable of being synthesized by the ternary precursor is directly obtained.

Owner:南通北新新能科技股份有限公司

Plane fish scale remover

The invention discloses a plane fish scale remover, comprising a stander, a fish scale and waste collecting hopper, a control switch arranged on the stander, a power source arranged at the bottom of the stander and a motor arranged at the bottom of the stander and connected with the power source, wherein a driving wheel is arranged on a rotating shaft of the motor and is connected with a driven wheel arranged at the upper end of the stander by a driving belt; the driven wheel is arranged at one end of a spindle; a tube type scraper is arranged on the spindle; a containing groove is arranged at the upper end of the stander; a cavity is arranged at the bottom of the containing groove; and the distance extending out of the cavity from the upper part of the tube type scraper is arranged at the bottom of the containing groove. The fish scale remover has the following advantages: the fish scale remover has lower manufacturing cost, the whole fish scale removing process is completed by one step under voluntary control of the operators, the fish scale remover is fast and efficient, can not damage the fish body, is safe to use and can not scratch the hand of the operators and dispenses with secondary removal.

Owner:冯金根

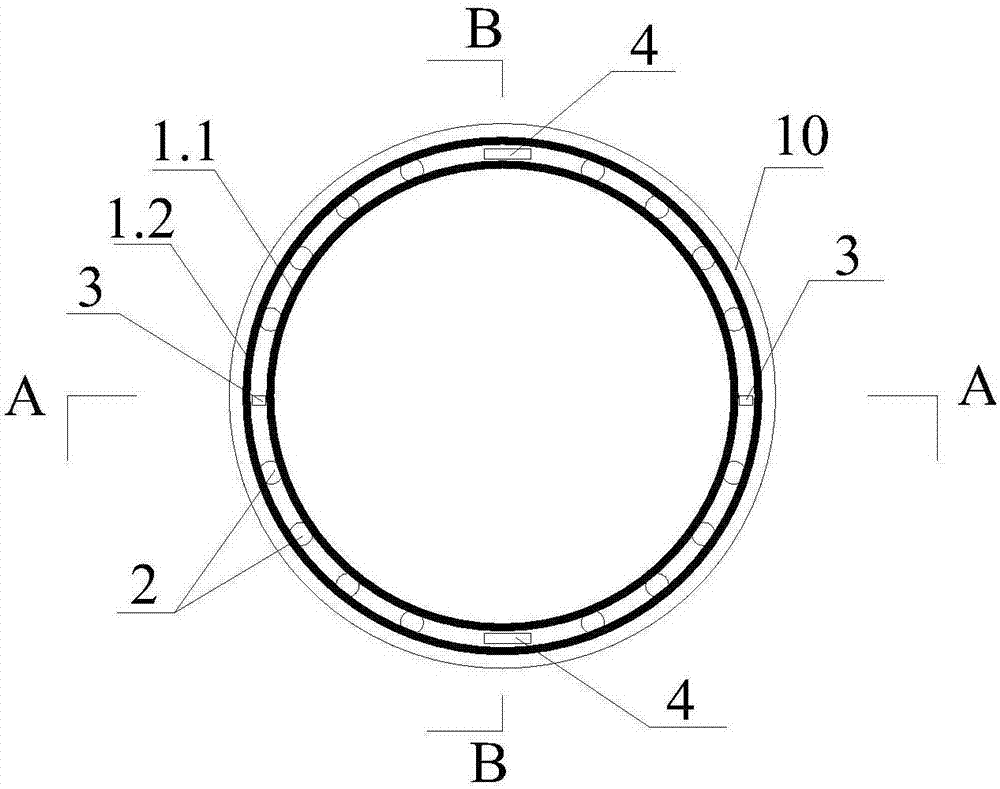

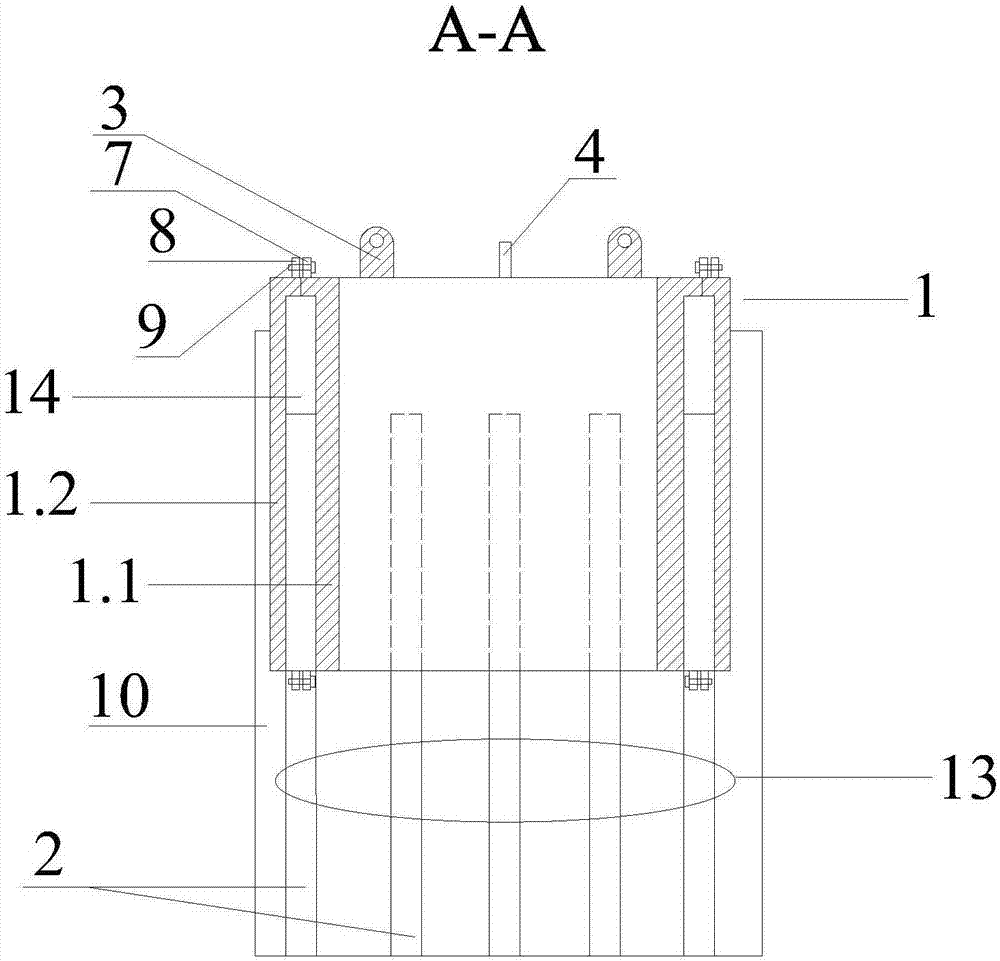

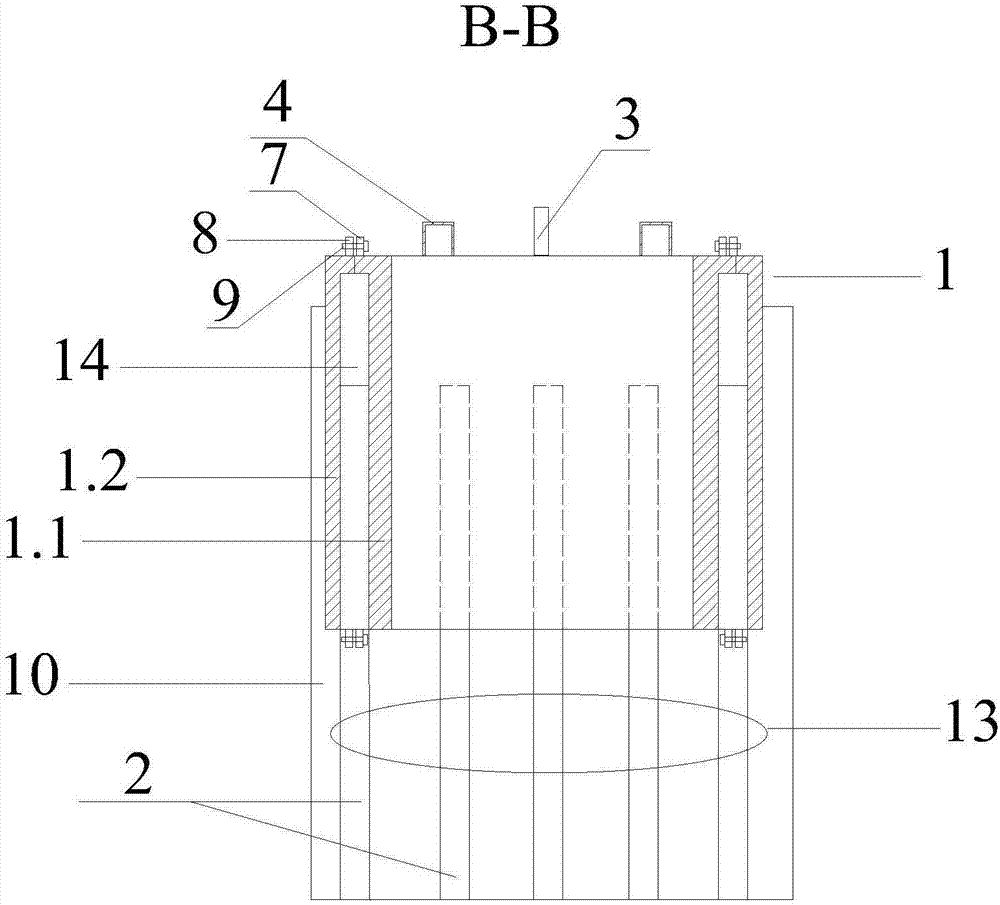

Breaking device of cast-in-place concrete pile head and construction method thereof

PendingCN106968251AFast and efficient truncationQuick and efficient liftingBulkheads/pilesGrip forceEngineering

The invention discloses a breaking device of a cast-in-place concrete pile head. The breaking device comprises an annular main rib positioning protection cylinder, a main rib positioning groove corresponding to a main rib is formed in the main rib positioning protection barrel, and the top of the main rib positioning protection cylinder is fixedly provided with lifting lug plates and steel bar penetrating supports which allow supporting steel bars of a steel bar cage to penetrate through and position the supporting steel bars of the steel bar cage; the main rib positioning protection barrel comprises an annular inner protective barrel and an annular outer protective barrel which are coaxial, and the outer wall of the annular inner protective barrel is attached and fixed to the inner wall of the annular outer protective barrel; and the main rib positioning groove comprises a first main rib positioning half-groove which is formed in the outer wall of the annular inner protective barrel, and a second main rib positioning half-groove which corresponds to the first main rib positioning half-groove and is formed in the inner wall of the annular outer protective barrel. According to the breaking device, the gripping force between the main rib and the pile head concrete is reduced, the risk of damaging the main rib is eliminated, meanwhile, the pile head becomes smaller and smaller and can be broken block by block, the performance requirements for hoisting equipment are reduced, the construction work efficiency is improved and the application range is expanded.

Owner:CCCC SECOND HARBOR ENG

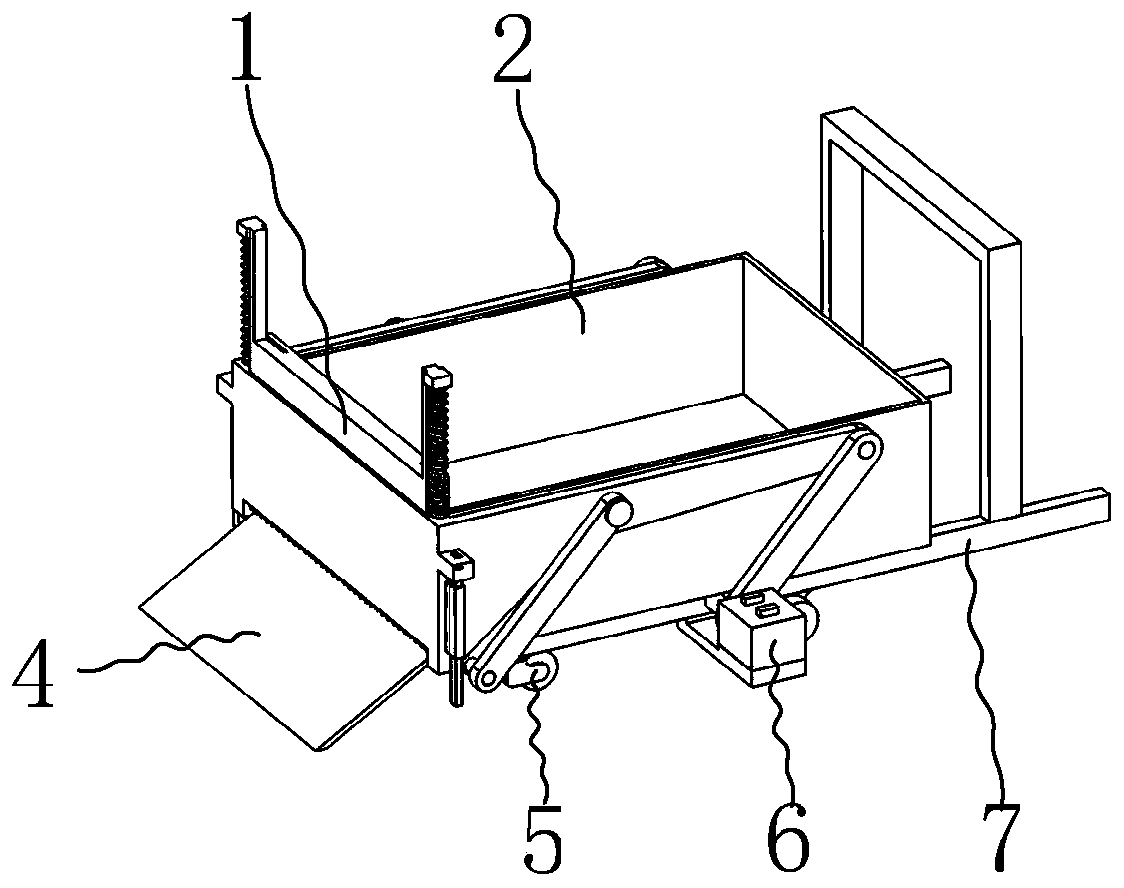

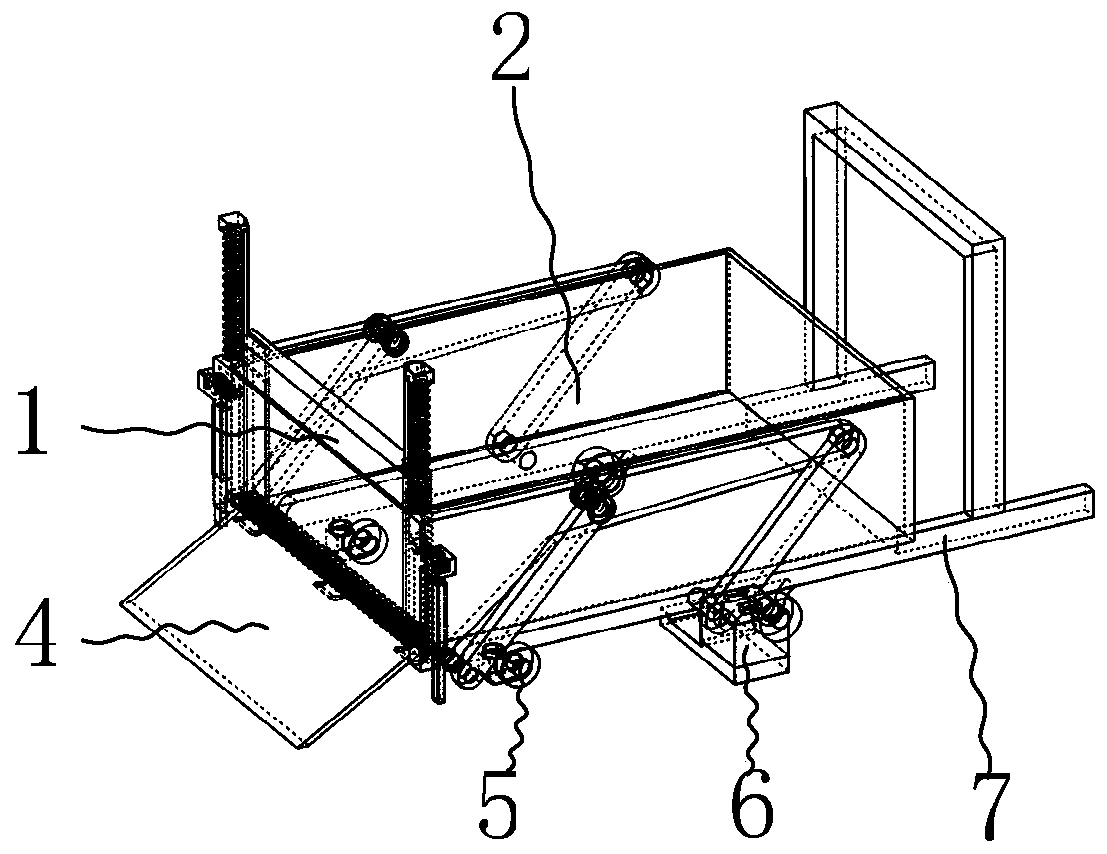

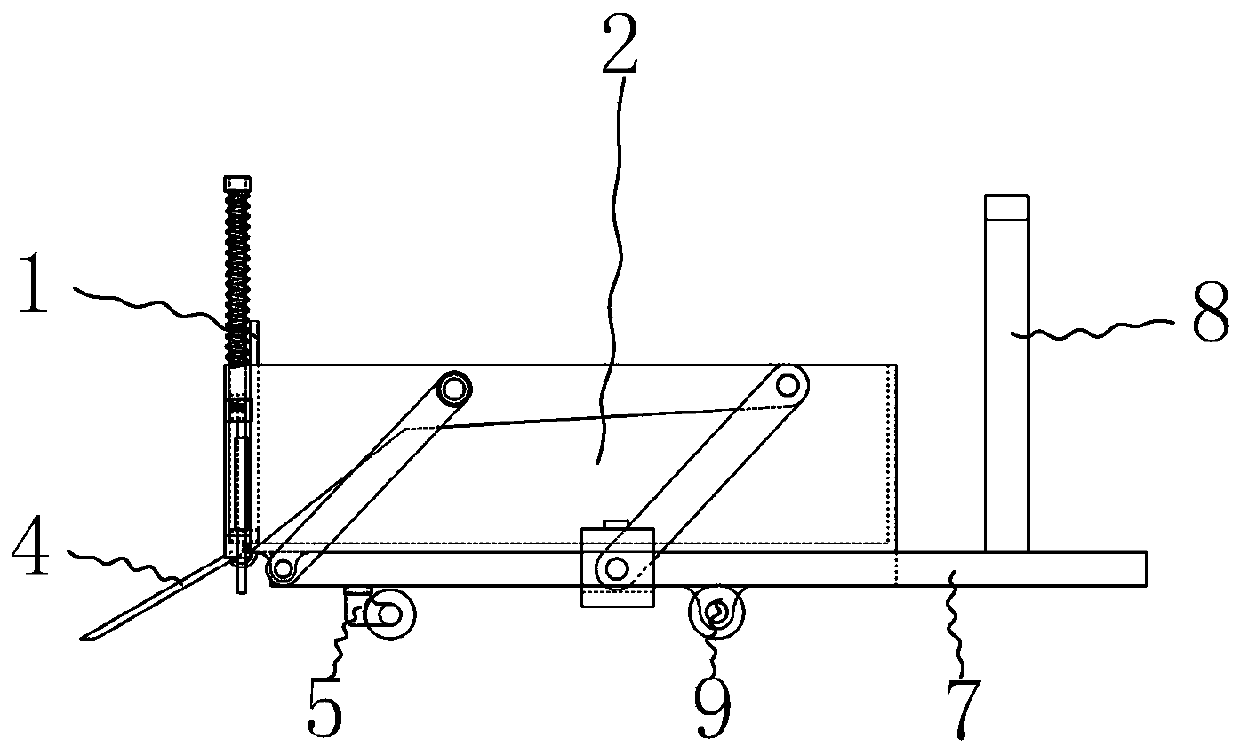

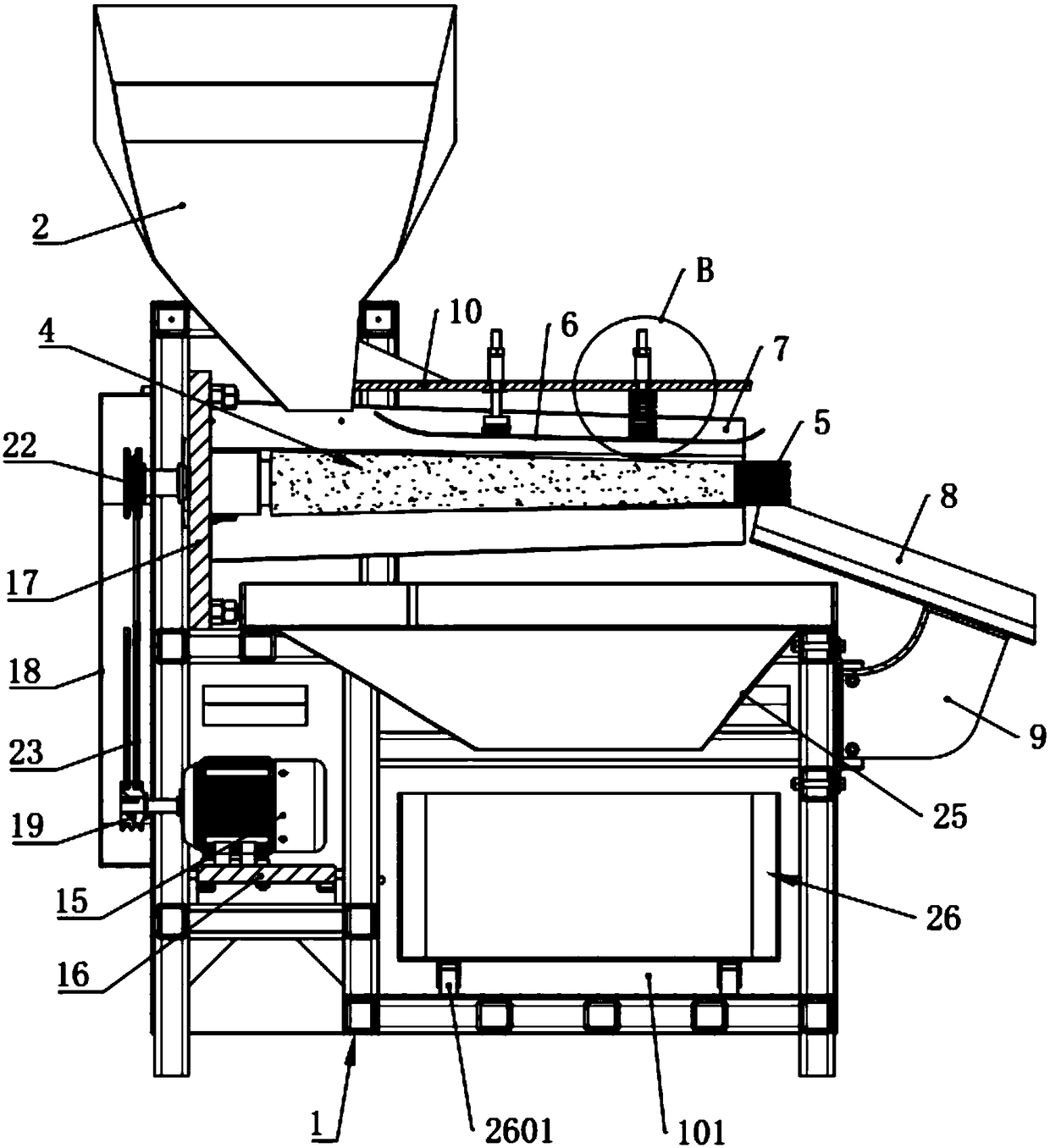

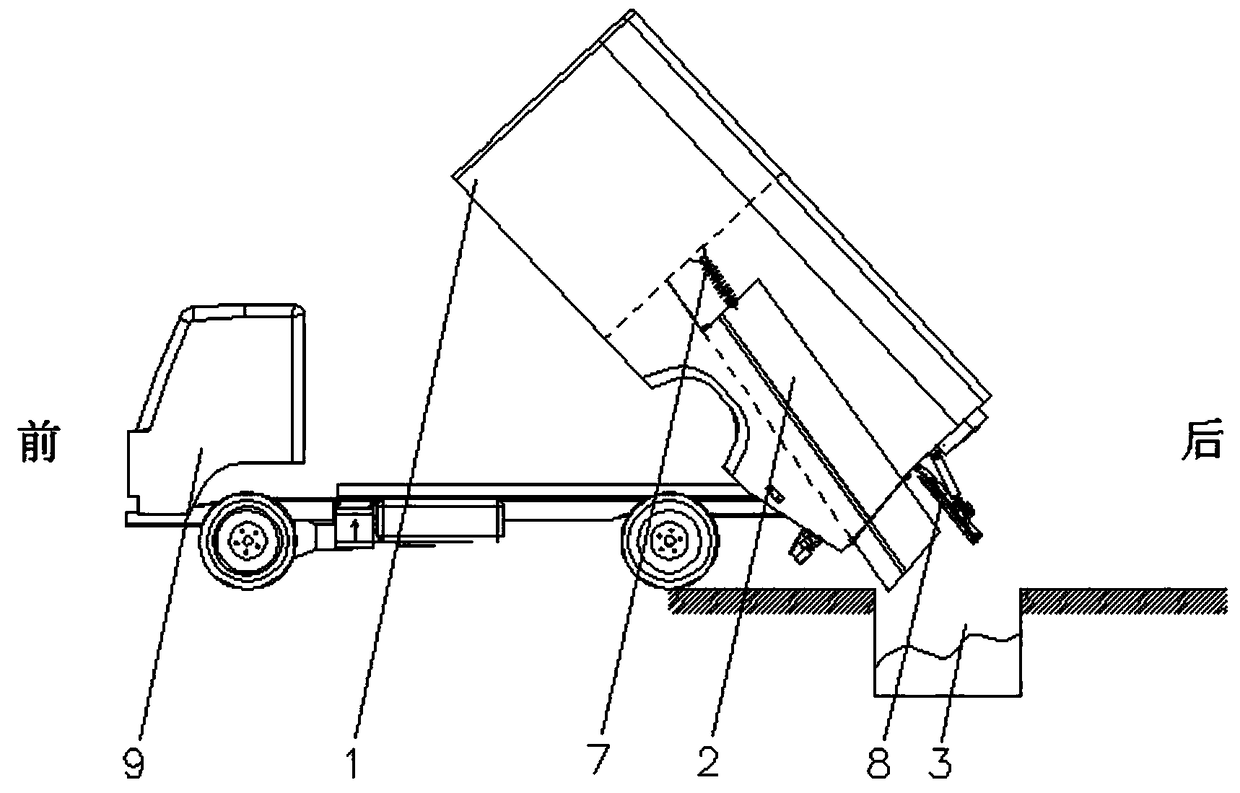

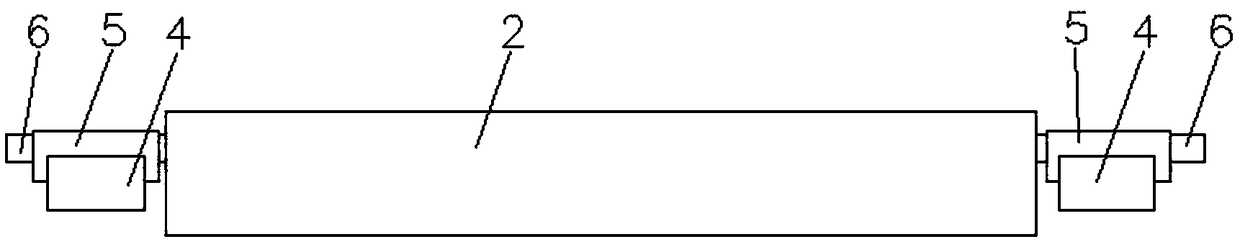

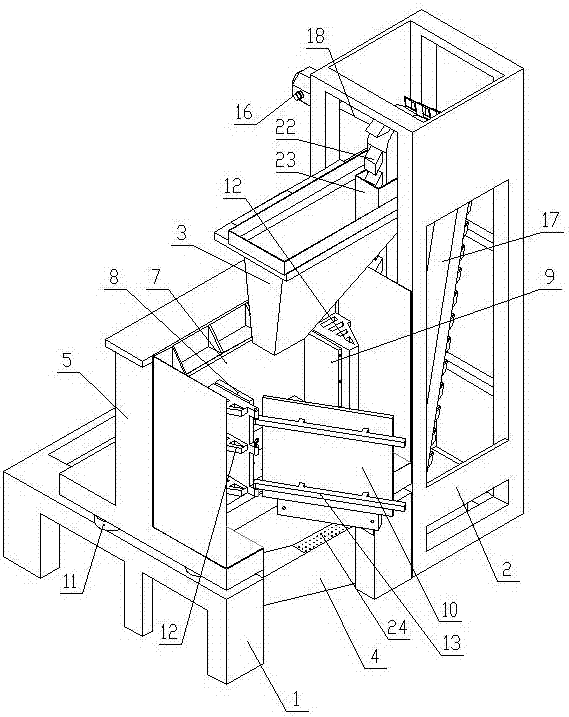

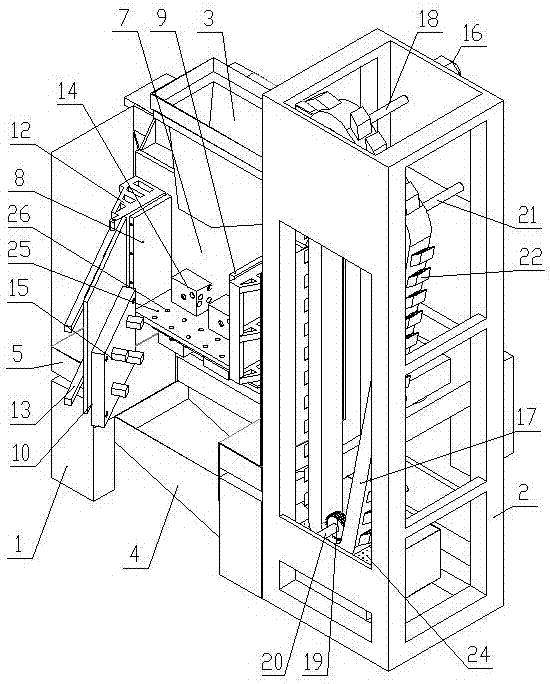

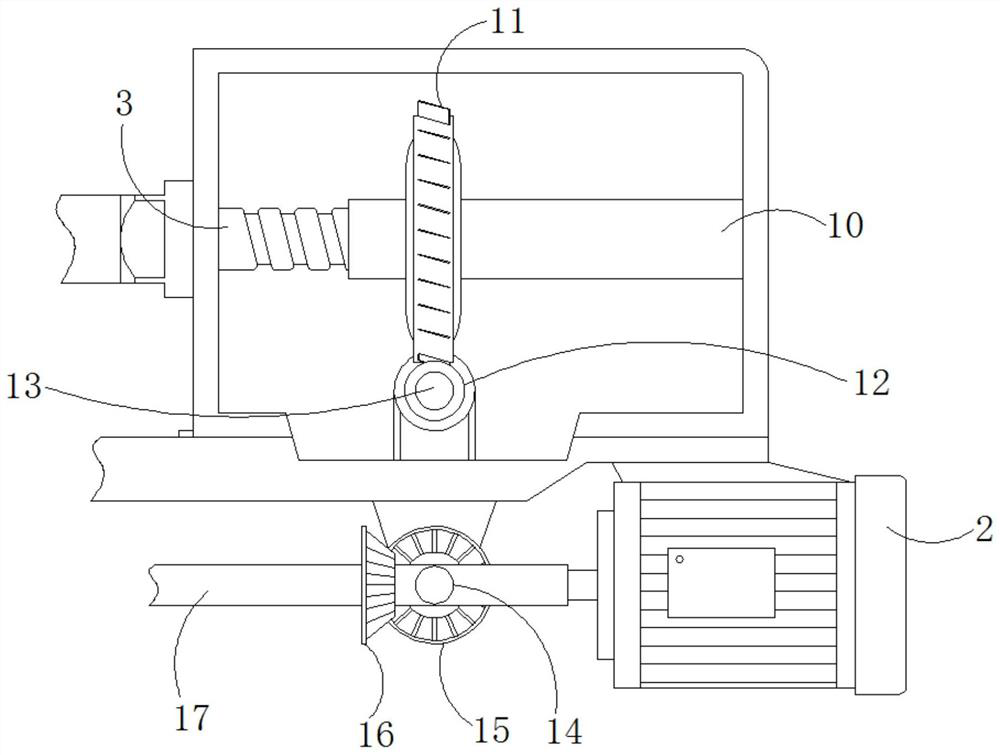

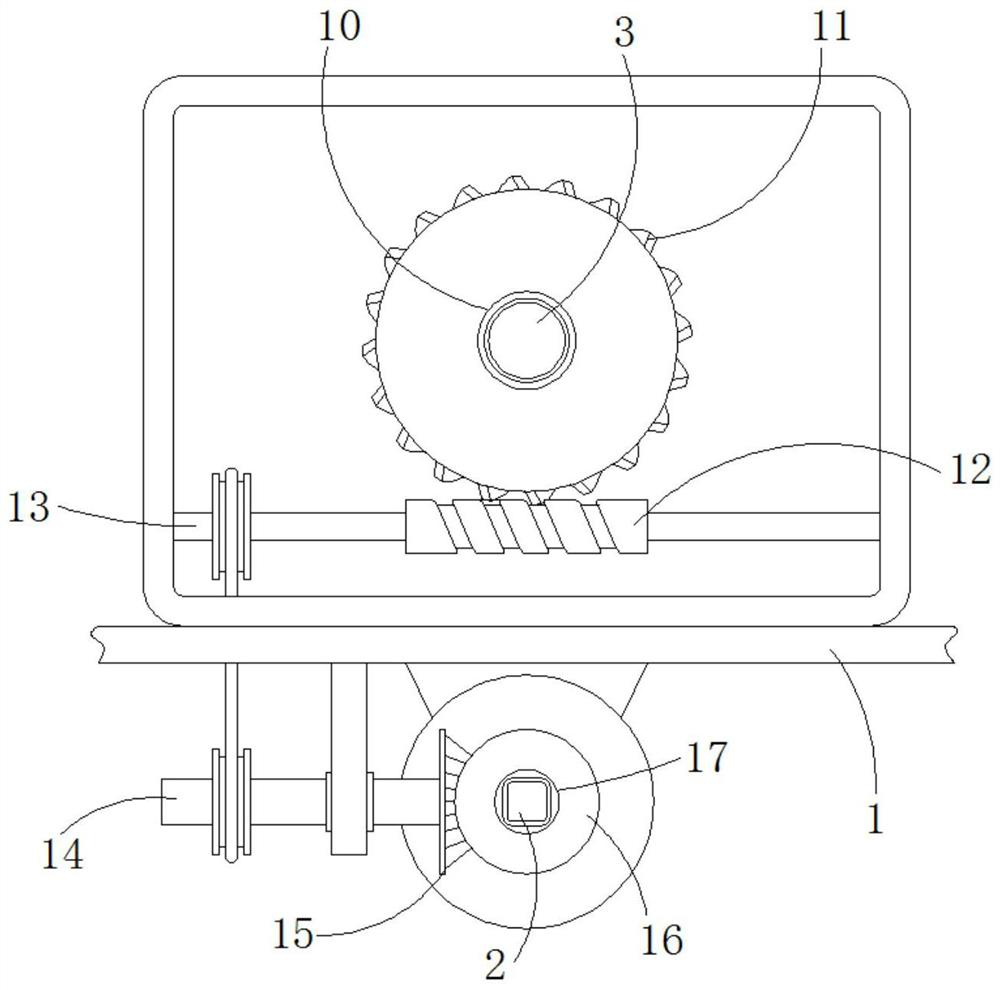

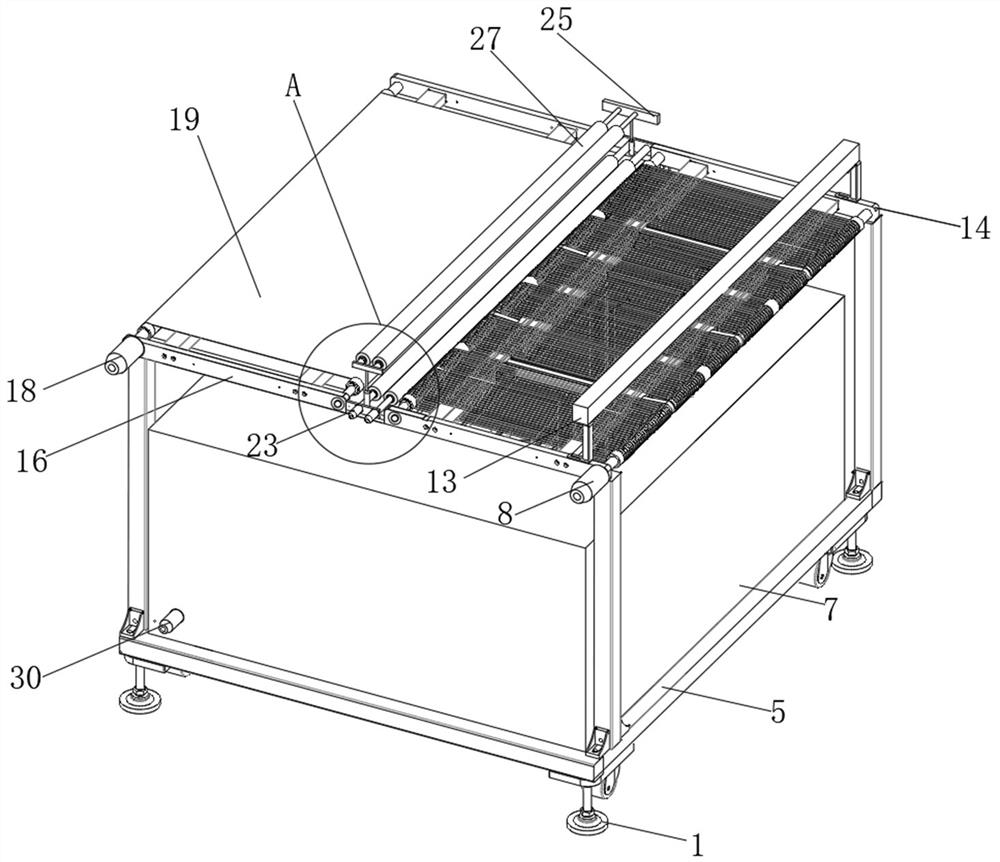

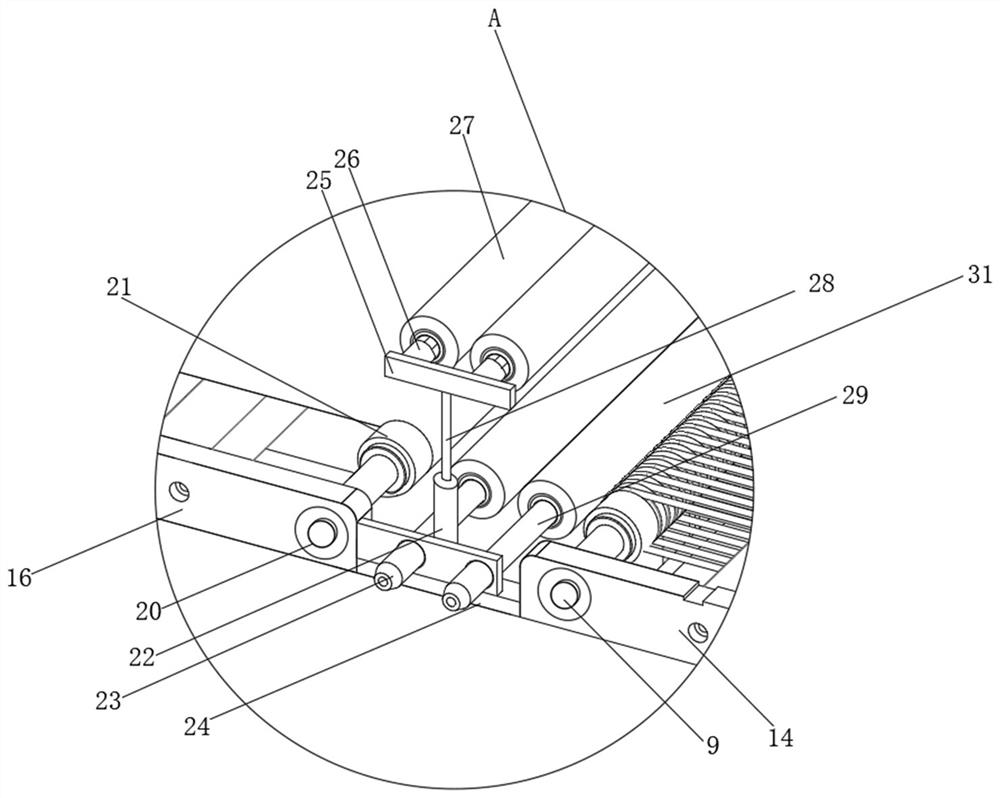

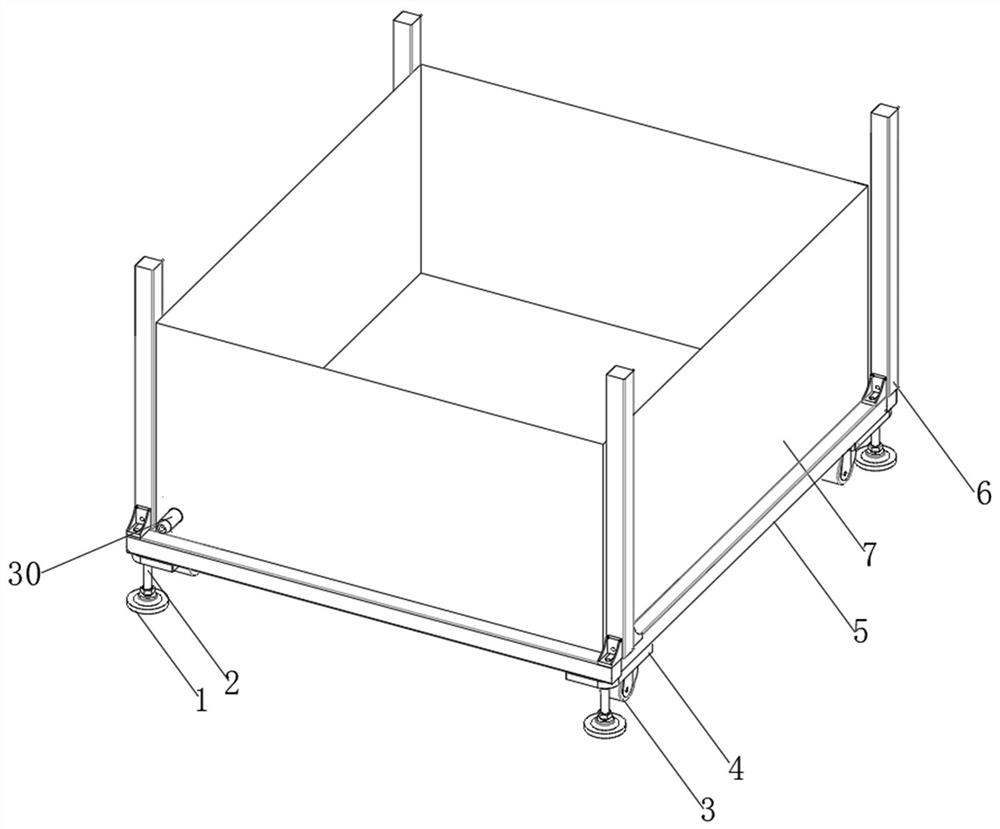

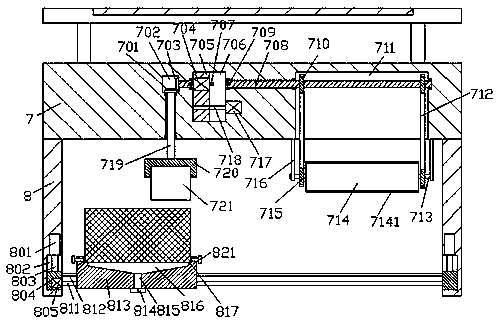

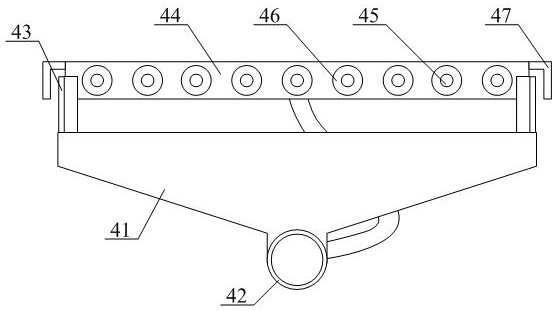

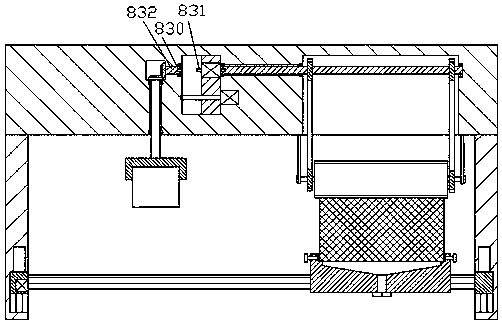

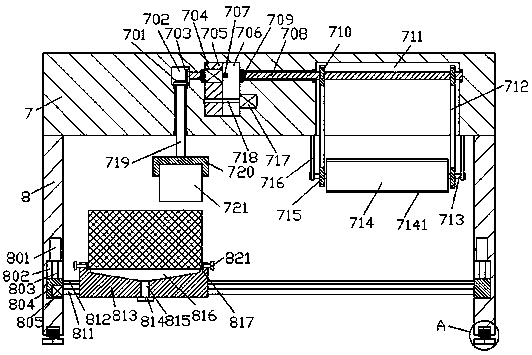

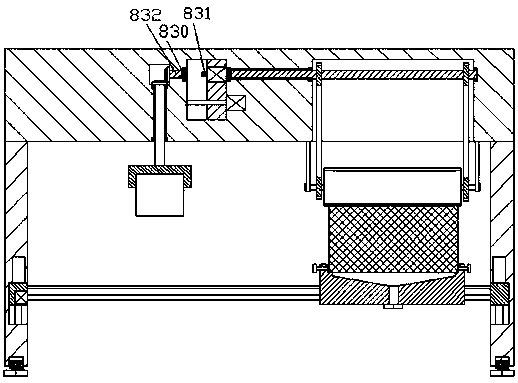

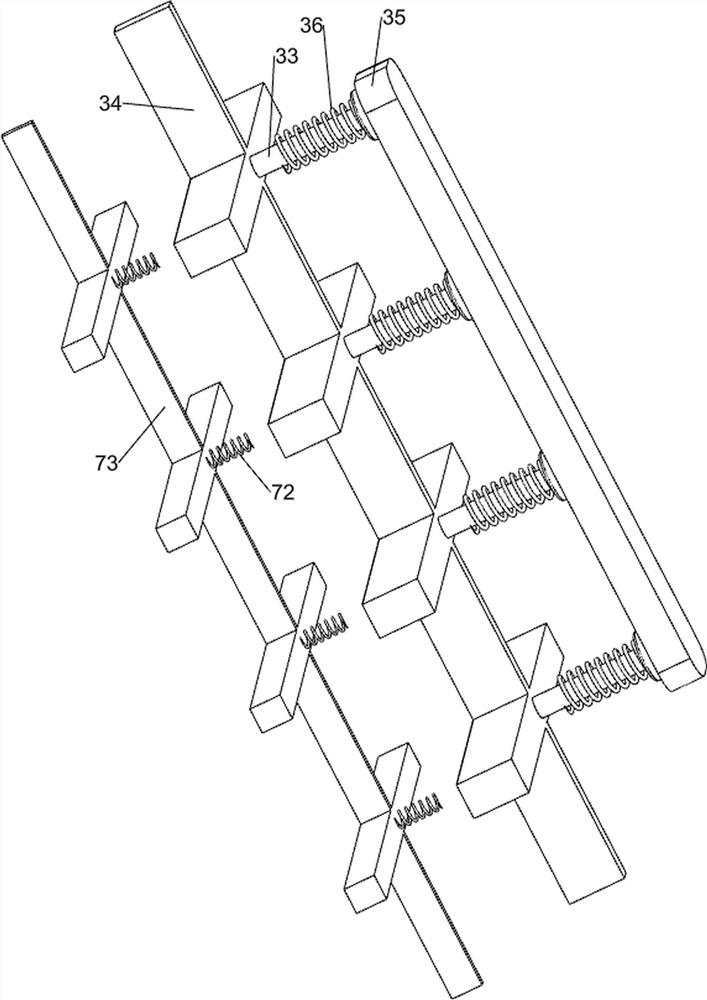

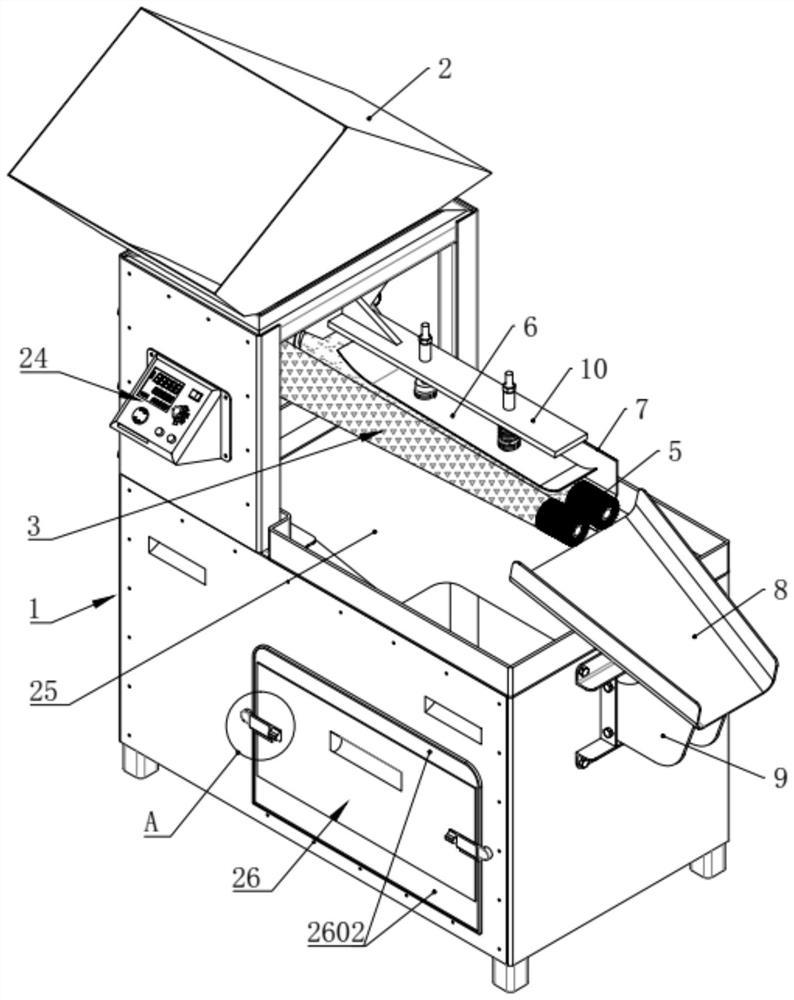

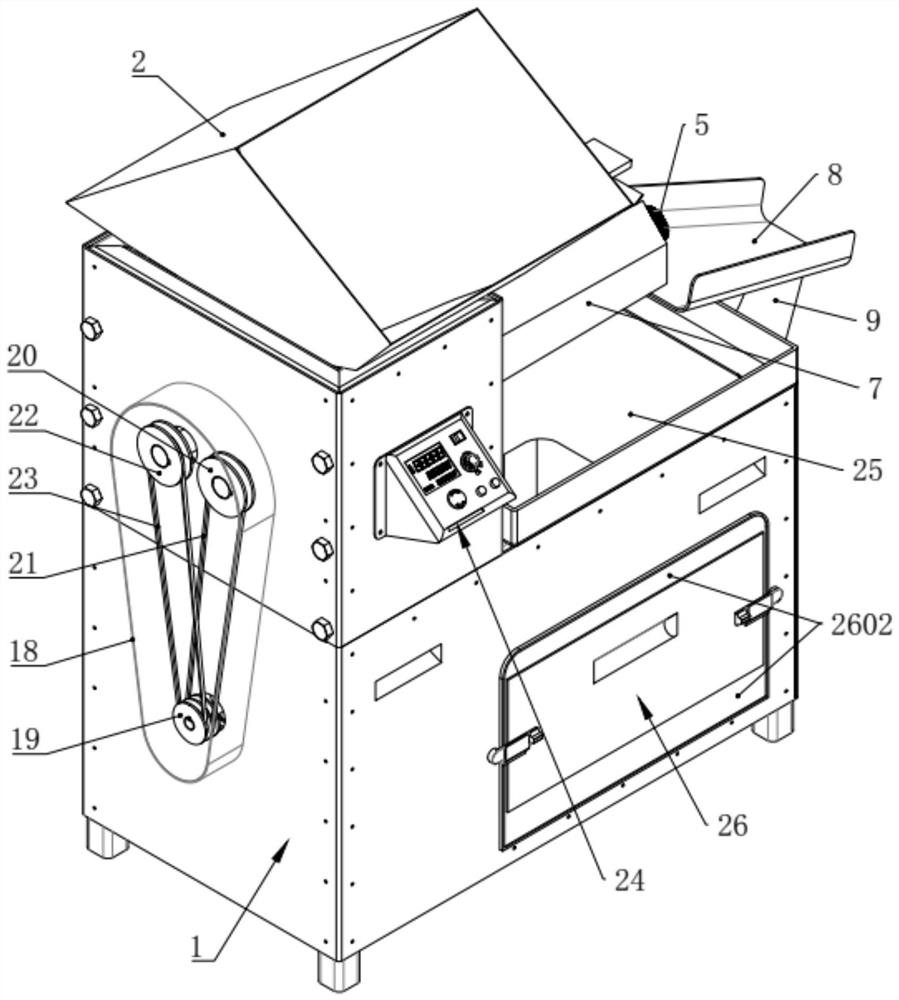

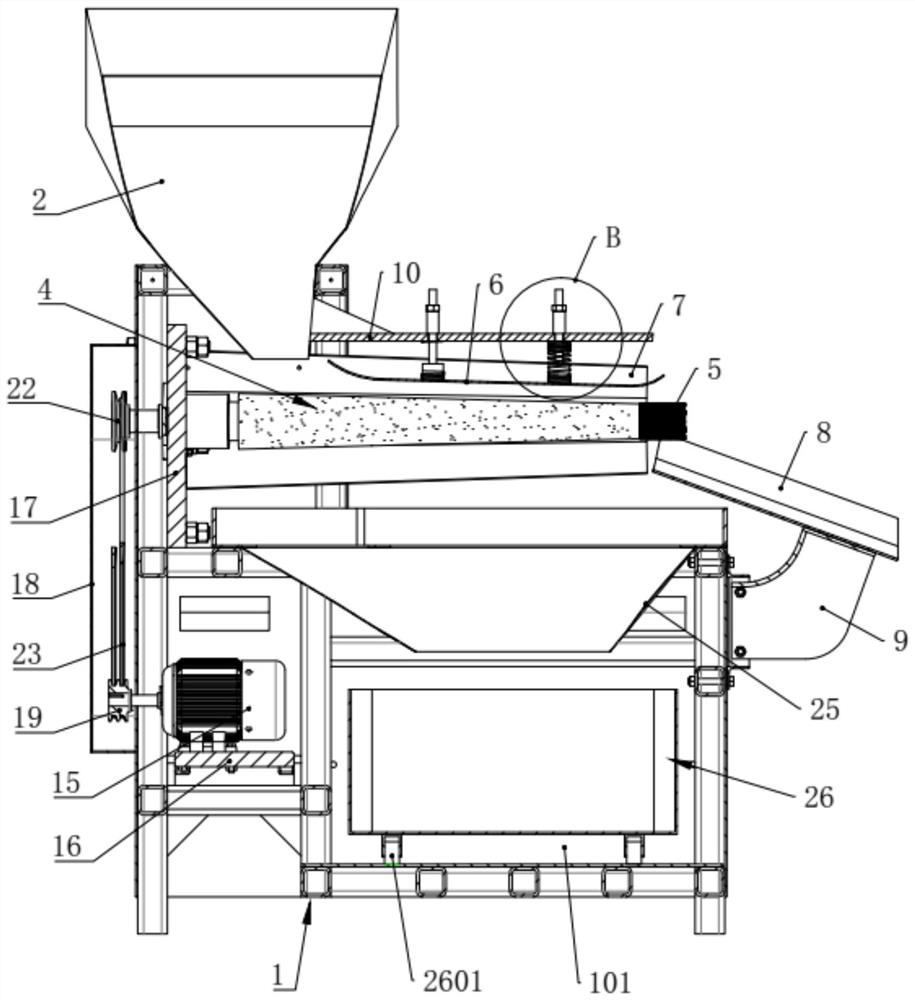

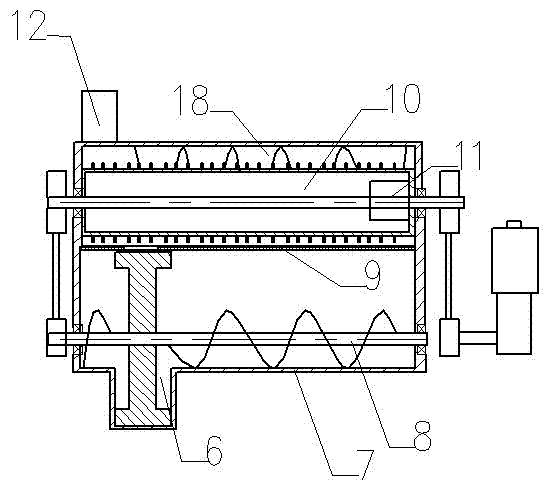

Falling rock transportation equipment for construction

InactiveCN110576783ASave spaceNo need for secondary cleaningVehicle with pusher plateTransportation itemsElectric machineryDrive motor

Owner:陆未沫

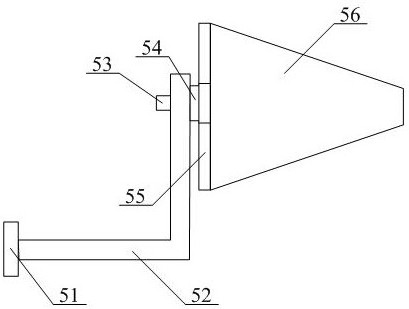

Conical roller grinding type green walnut peeling machine

The invention, which belongs to the technical field of walnut peeling, provides a conical roller grinding type green walnut peeling machine comprising a frame provided with a feeding hopper. A first conical roller and a second conical roller that are driven by a driving device are installed on the frame in a rotating manner; and the first conical roller and the second conical roller are arranged side by side and a mounting gap is arranged between the rollers. Cutting teeth for peeling off the green coat of the walnut are arranged on the wall of the first conical roller; and a rubber sleeve fordriving the walnut to make rotation sleeves the outside of the second conical roller. A discharge hole of the feeding hopper is arranged above the first conical roller and the second conical roller and is close to the thick ends of the first conical roller and the second conical roller. Under the effect of the driving device, the first conical roller and the second conical roller make rotation ina same direction. Compared with the traditional green walnut peeling equipment, the conical roller grinding type green walnut peeling machine has the following beneficial effects: the peeling efficiency and the peeling quality are greatly improved; the peeling is done completely; no manual secondary cleaning is needed; the damages on the walnut are reduced substantially; and the quality of the walnut after peeling processing is ensured effectively.

Owner:WEIFANG VOCATIONAL COLLEGE

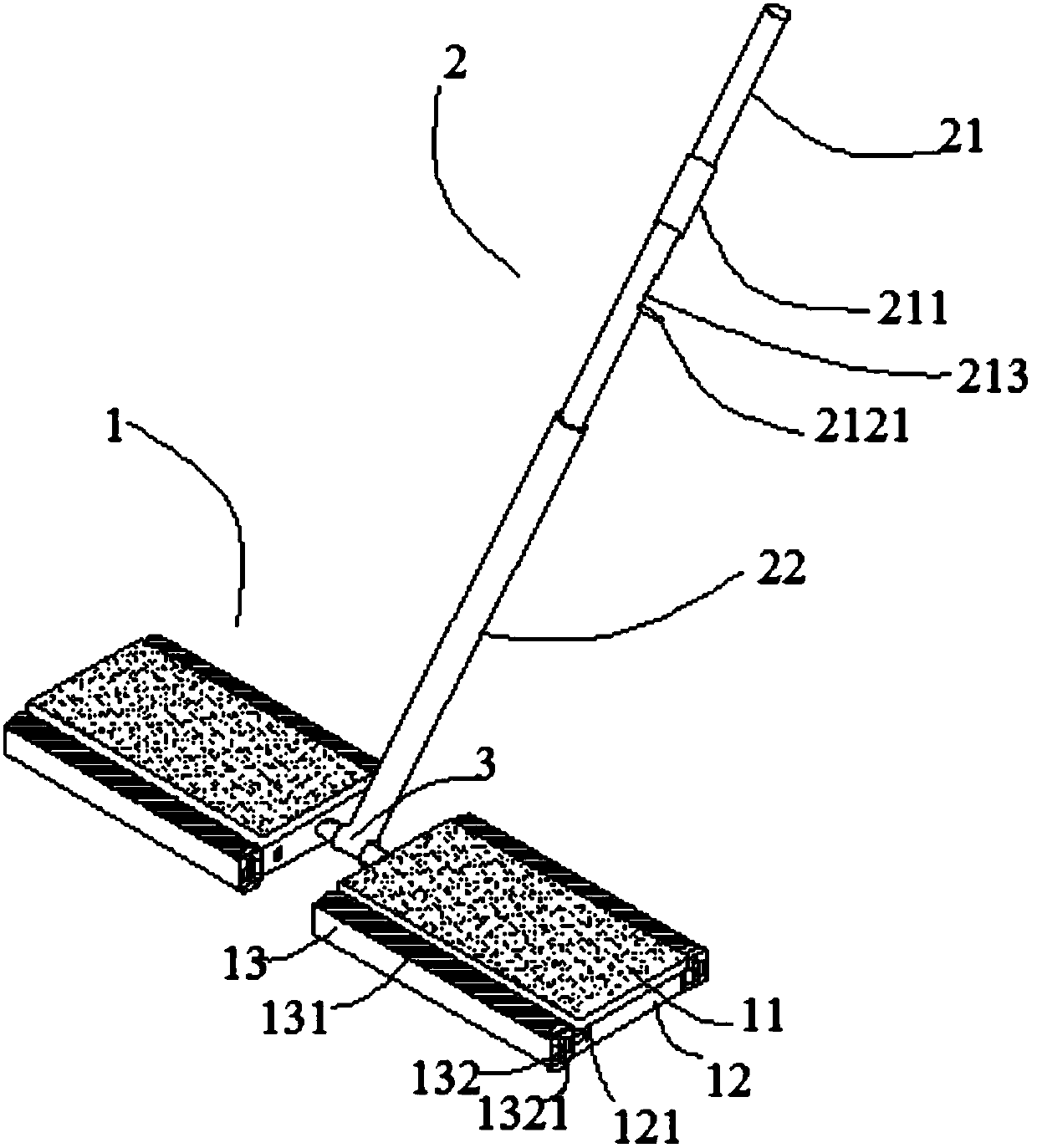

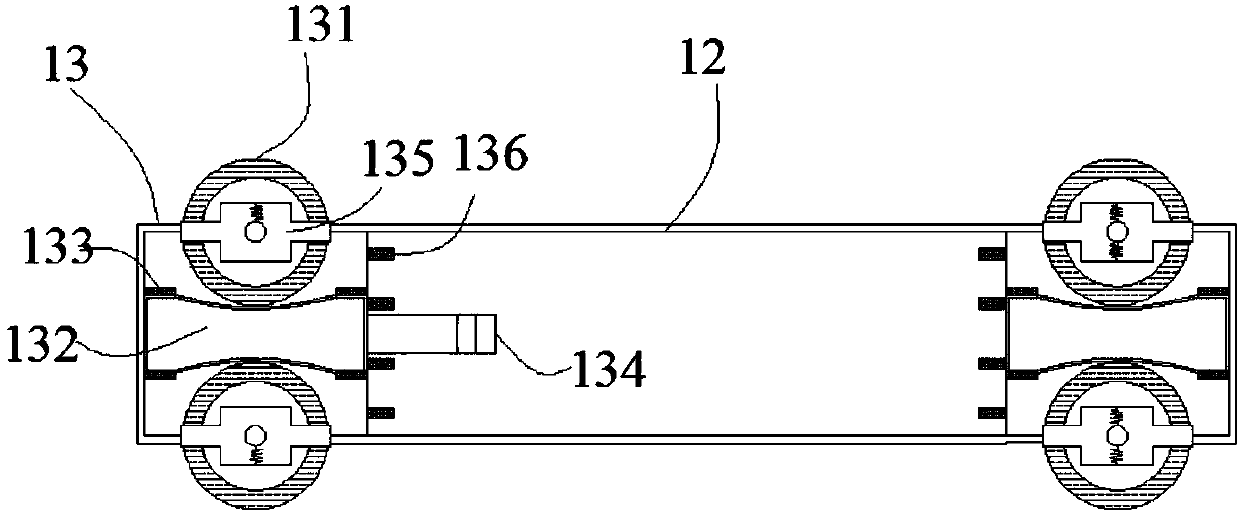

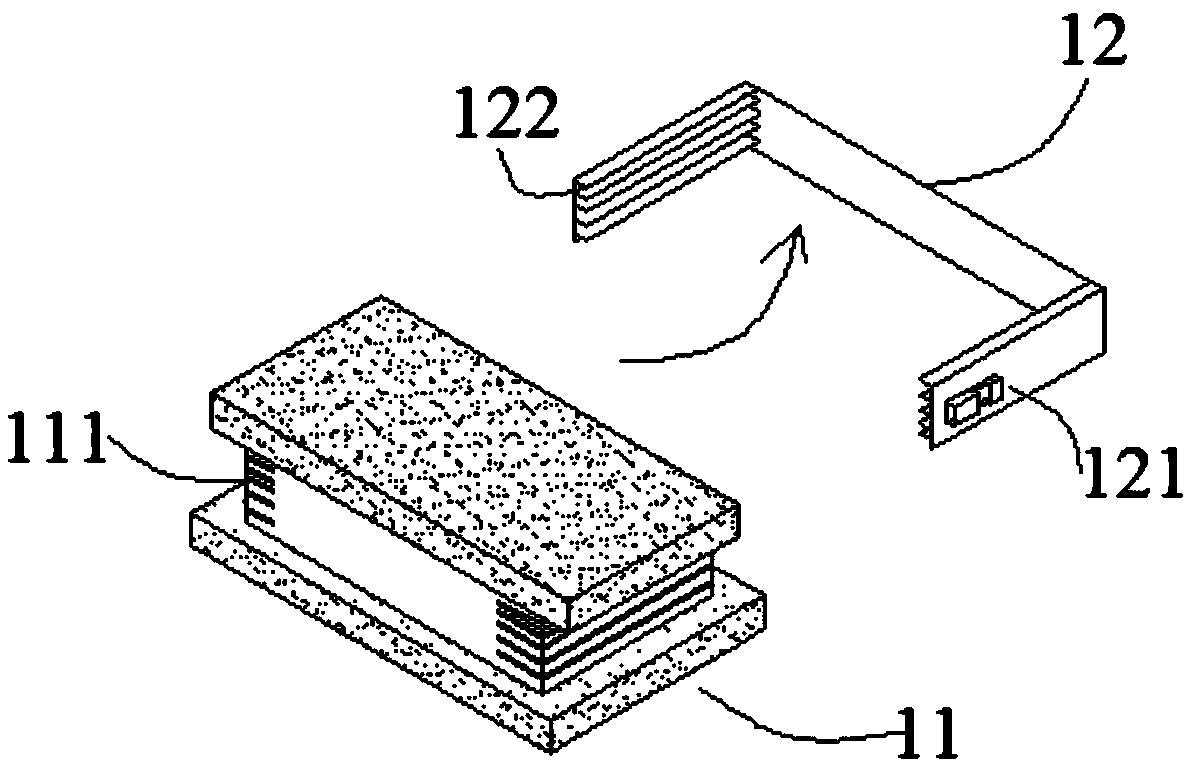

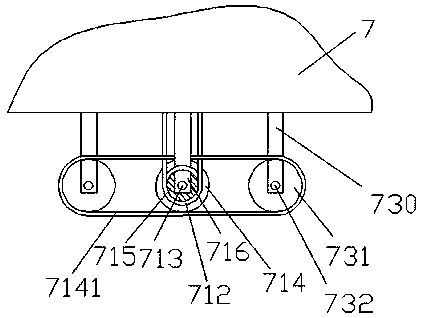

Double-surface mop

PendingCN107788923ASwitch freelyEasy to replaceCarpet cleanersFloor cleanersStructural engineeringMechanical engineering

The invention relates to the technical field of cleaning equipment, in particular to a double-surface mop. The mop comprises two mop heads and a holding rod. The mop heads are rotatably connected withthe holding rod through a hinge part. The mop heads comprise cleaning sponges, sponge fixing devices and dust cleaning devices. The cleaning sponges are arranged in the sponge fixing devices. Two sides of each cleaning sponge are exposed out of the sponge fixing devices. The dust cleaning devices are respectively arranged on two sides of each sponge fixing device. One end of each dust cleaning device is connected with each sponge fixing device through a snap joint. The other end of each dust cleaning device is fixedly connected with each sponge fixing device. Each dust cleaning device comprises a housing, a dust sticking roller, a dust storage net box and an elastic device. The holding rod has a telescopic function. The double-surface mop can freely switch two surfaces of cleaning sponges. The function of cleaning dust remaining on the ground is fulfilled. Additionally, the cleaning sponges can be detached for replacement.

Owner:南丹县青少年学生校外活动中心

Method for preparing environmental-friendly non-tonic livestock depilatory

InactiveCN106667891AGood hair removal effectNo need for secondary cleaningCosmetic preparationsHair removalPetalPolyethylene glycol

The invention relates to a method for preparing an environmental-friendly non-tonic livestock depilatory, and belongs to the technical field of livestock depilatory preparation. The method comprises the following steps: firstly, cutting chicken feather, burying into soil to load microorganisms in the soil, performing constant-temperature culture enrichment so as to obtain a hypha suspension, putting into a fermentation tank to ferment in an alkalescence environment, performing centrifugal separation on a fermentation product, concentrating so as to obtain a concentrated solution I, extracting effective components in petals of straw flowers and calendula officinalis through ultrasonic waves with an ethanol solution as an extraction agent, performing rotary evaporation concentration so as to obtain a concentrated solution II, and mixing the concentrated solution II with polyethylene glycol and menthol, thereby obtaining the environmental-friendly non-tonic livestock depilatory. The environmental-friendly non-tonic livestock depilatory prepared by using the method is good in depilation effect, depilated livestock can be clean and feather-free on surfaces and needs no secondary treatment, and in addition, as the depilatory is free of toxic substance, meat of the livestock is not contaminated, and thus human body health can be ensured.

Owner:孙祎

Drawer type vacuum sweeper dust bin

PendingCN109457648ASimple structureNo need for secondary cleaningRoad cleaningWaste collectionEngineering

The invention relates to a drawer type vacuum sweeper dust bin which comprises a big compartment and a small compartment. The upper end and the rear end of the big compartment are open; the upper endand the rear end of the small compartment are open, the small compartment is slidably arranged in the big compartment, and the small compartment slips out of the big compartment so as to make garbagepoured into a garbage collection pit. The drawer type vacuum sweeper dust bin has the advantages that the structure is simple, when the garbage is poured, the garbage can be fully poured into the garbage collection bin, manual secondary cleaning is not needed, and time and labor are saved.

Owner:HUBEI JULI AUTOMOTIVE TECH CO LTD

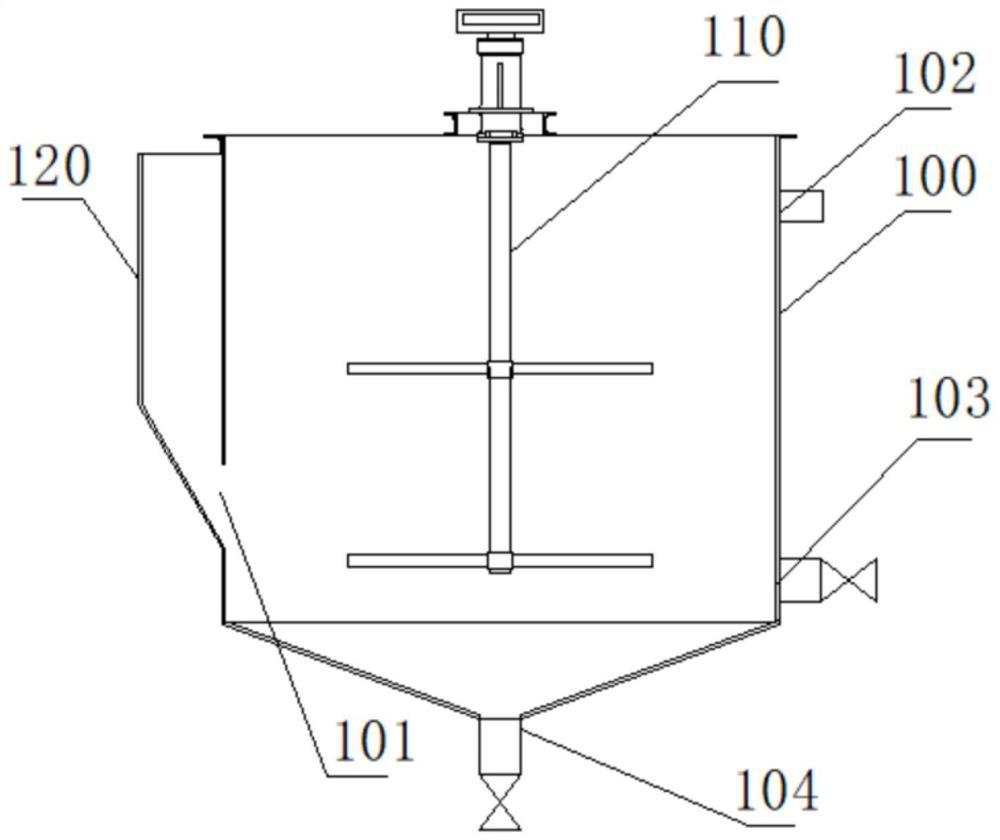

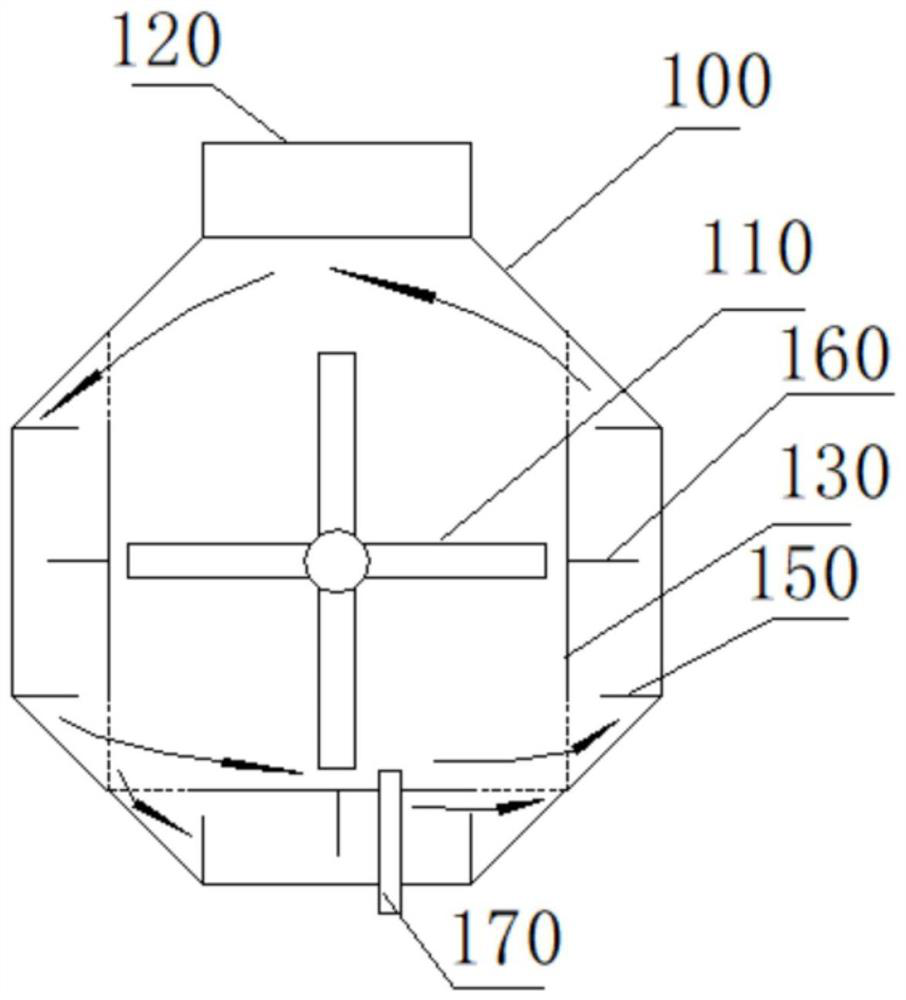

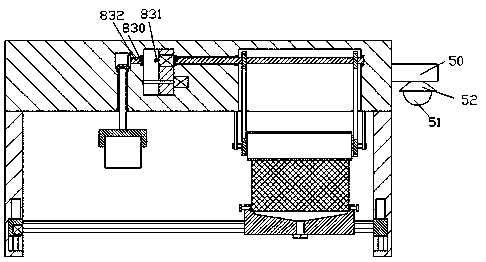

Carbon washing tank and production method of low ash water purification activated carbon

ActiveCN108940201BIncrease separation speedEasy and quick to cleanOther chemical processesCombustible gas purificationActivated carbonWater vapor

The invention discloses a carbon washing tank and a production method of low-ash water-purifying activated carbon. The carbon washing tank includes: a tank body, on which a material inlet, a water inlet, a slurry outlet and a sand outlet are arranged, and the sand outlet is located at the side of the slurry outlet. Below; a stirring device, which is arranged in the tank body. The production method of activated carbon for water purification with low ash content comprises: preheating the crushed carbonized material, activating with water vapor, cooling, crushing, and then elutriating through a charcoal washing tank; desanding and After desliming, add it to the modified container, add water to submerge the material, then add acid or alkaline modifier, stir to make the pH of the water 6.5-7.5; rinse and dehydrate the modified material in turn and dry. The charcoal washing tank provided by the invention can quickly clean the activated carbon and reduce the impurity and ash content of the activated carbon. The activated carbon produced by the method of the invention has low ash content, well-developed micropores, high iodine adsorption value, and improves the adsorption capacity of the activated carbon.

Owner:BEIHAI HERONG ACTIVE CARBON TECH +1

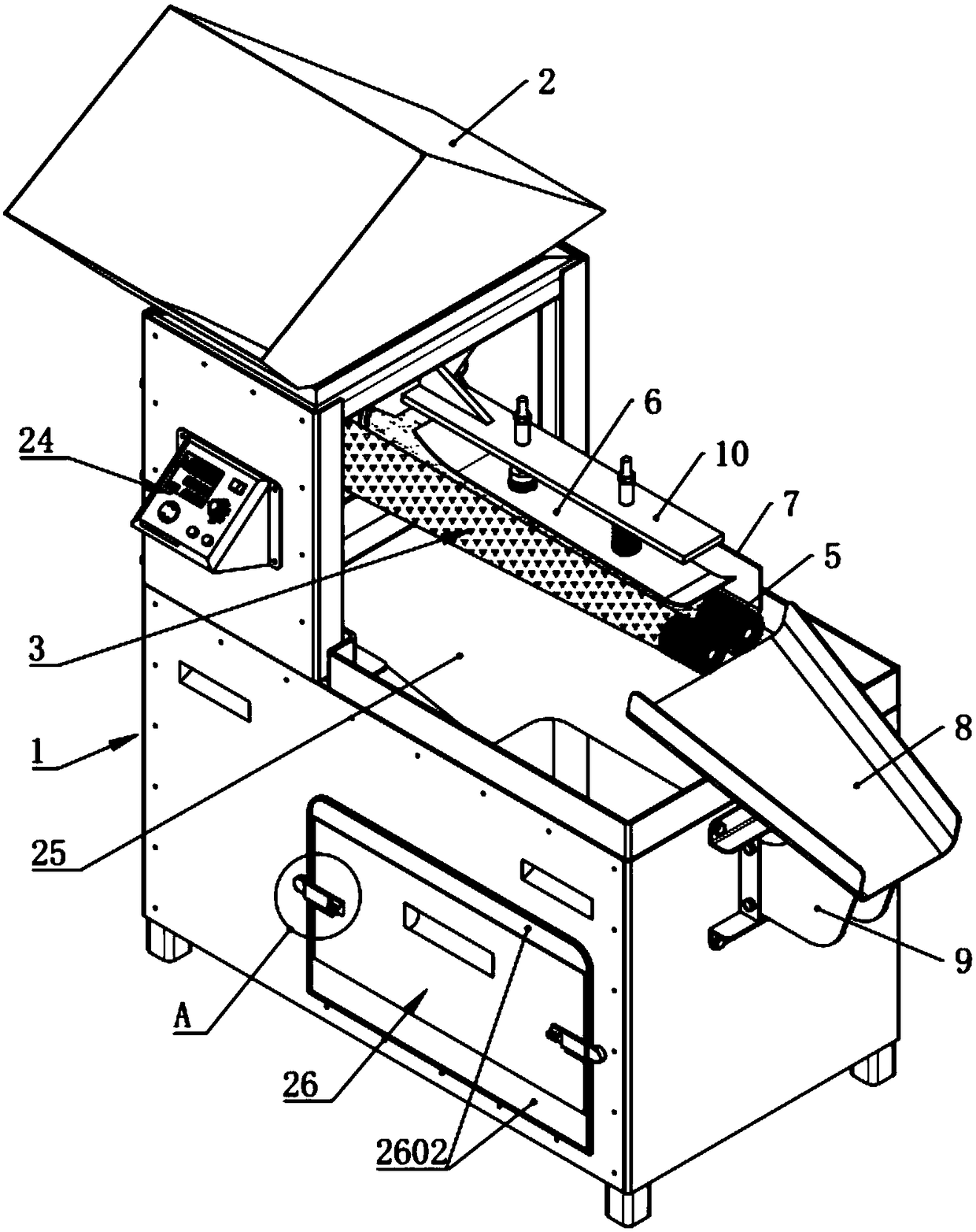

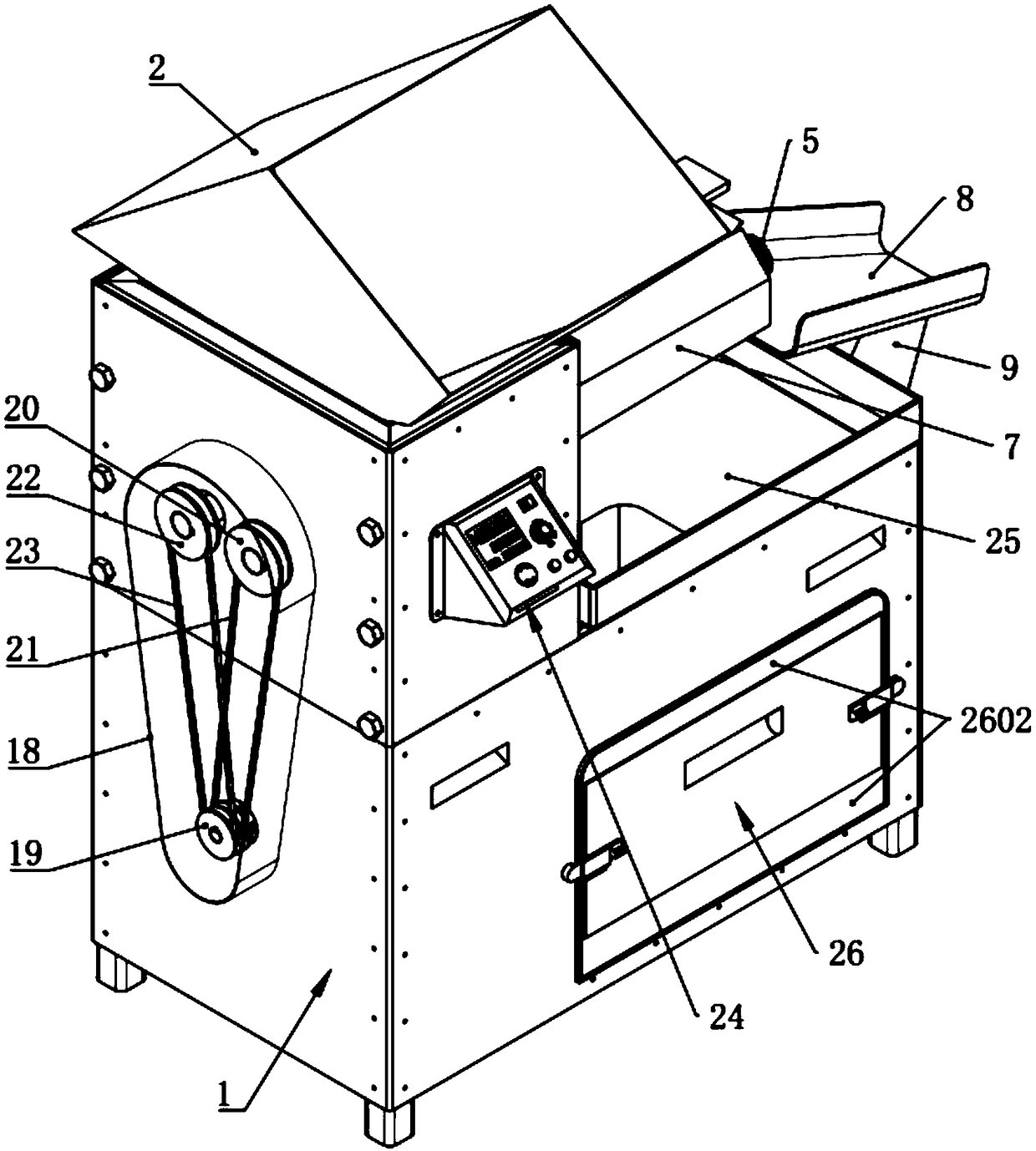

Steel ball flow polishing machine

PendingCN107350956AGuaranteed working environmentReliable processingEdge grinding machinesGrinding carriagesProduction lineSurface finish

Provided is a steel ball flow polishing machine. The machine comprises a rack, a workpiece mounting vibration container component is arranged on the rack, a steel ball inlet and a steel ball outlet are formed in the top and the bottom of the workpiece mounting vibration container component respectively, and a cuboid-shaped frame is fixedly arranged on the right side of the rack; an upper hopper located above the steel ball inlet is fixedly arranged on the left side of the upper portion of the frame, the bottom of the upper hopper is slantly arranged with the left lower than the right, and the right side of the top of the upper hopper is located on the upper portion in the frame; a lower hopper located below the steel ball outlet is arranged on the rack, the lower hopper is slantly arranged with the left higher than the right, the lowest portion in the lower hopper is located on the lower portion in the frame, and a steel ball hanging and lifting mechanism is arranged in the frame. The steel ball flow polishing machine can be used for removing chips of the workpiece of a complicated structure, can conduct chip removing, cleaning and rust removal at the same time and can improve the surface finish degree of the shiny side of the workpiece; no workpiece deforms after being machined, and second cleaning is not needed; multiple products can be machined at the same time, and the steel ball flow polishing machine can be matched with mechanical arms to achieve production line optimization, and is low in energy consumption, environmentally friendly and pollution free.

Owner:苏州斯曼克磨粒流设备有限公司

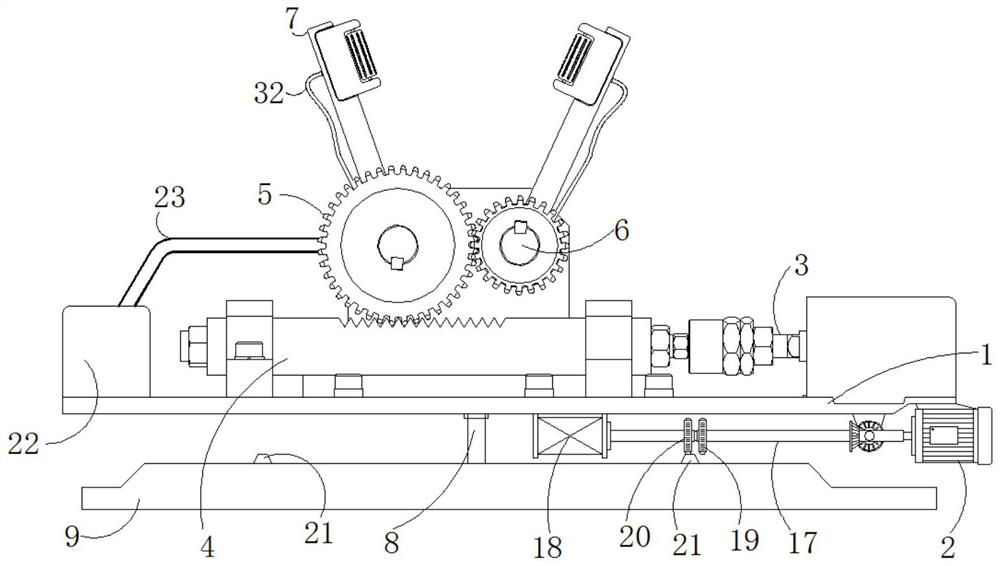

Clamp for transferring metal part

The invention discloses a clamp for transferring a metal part. The clamp comprises a base, an electromotor, a tooth groove plate, transmission gears and driving shafts, the electromotor is installed below the base and used for driving a transverse rod to move horizontally, the transverse rod is horizontally installed on the upper end face of the base in a sliding mode, the two transmission gears are installed on the left driving shaft and the right driving shaft respectively, the driving shafts are horizontally and rotationally installed above the base, and the driving shafts are fixedly connected with the tail end of a clamp plate. According to the clamp for transferring the metal part, a clamp mechanism is redesigned, operation of the same motor is utilized, on the basis that the basic function that the clamp clamps a workpiece is complete, convenient adjustment can be carried out on the angle of the clamped workpiece, the two functions do not influence each other, meanwhile, the structure of the clamp plate in the clamp is redesigned, and air flow is used as power to synchronously achieve adjustment on the height of the workpiece and removal of chippings and dust after surface machining.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

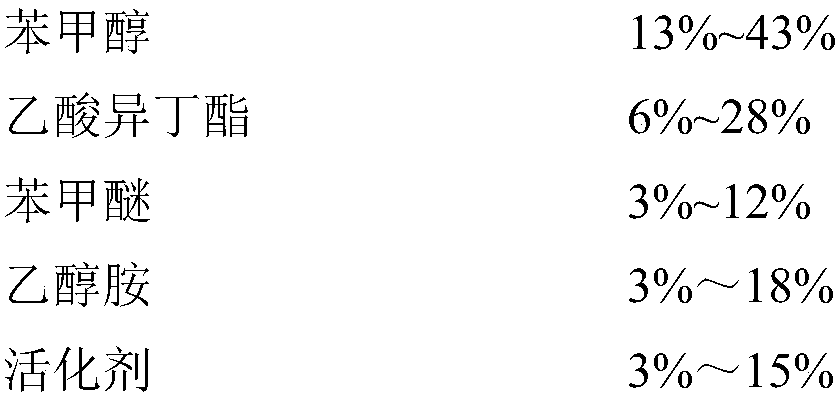

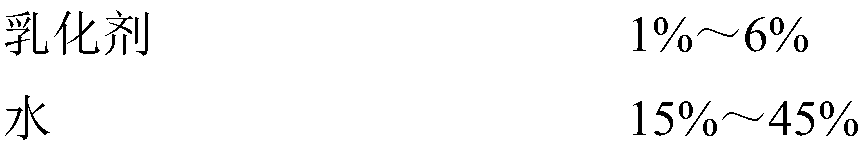

Room-temperature aqueous paint remover and preparation and use methods thereof

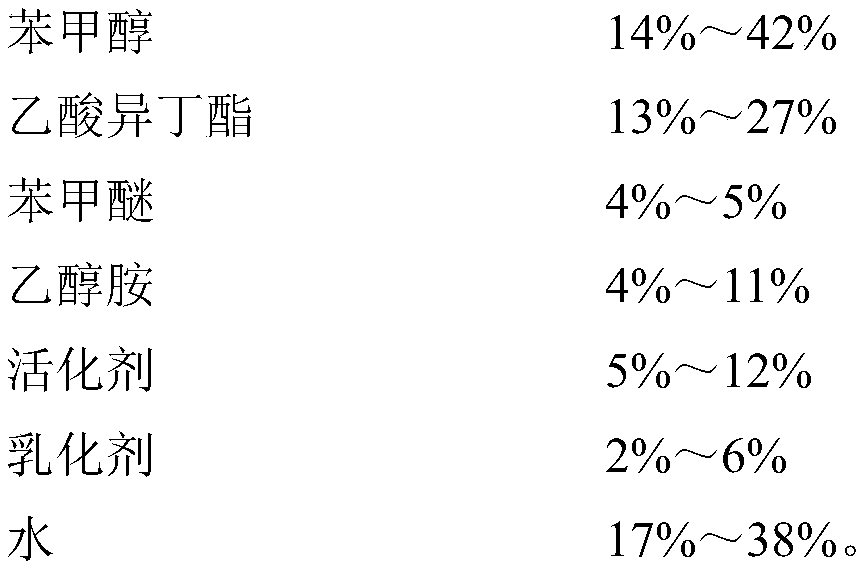

InactiveCN109135407AEnvironmentally friendlyNo need for secondary cleaningChemical paints/ink removersRoom temperatureIsobutyl acetate

The invention discloses a room-temperature aqueous paint remover and preparation and use methods thereof. The paint remover comprises, by mass, the following components: 13-43% of benzyl alcohol, 6-28% of isobutyl acetate, 3-12% of anisole, 3-18% of ethanolamine, 3-15% of activator, 1-6% of emulsifier and 15-45% of water, wherein the mass ratio of benzyl alcohol to isobutyl acetate is 3:1-3:2, themass ratio of anisole to ethanolamine is 1:1-1:3. The aqueous paint remover has the advantages of environmental protection, quick paint removal, low energy consumption and room-temperature operation.

Owner:SICHUAN UNIV

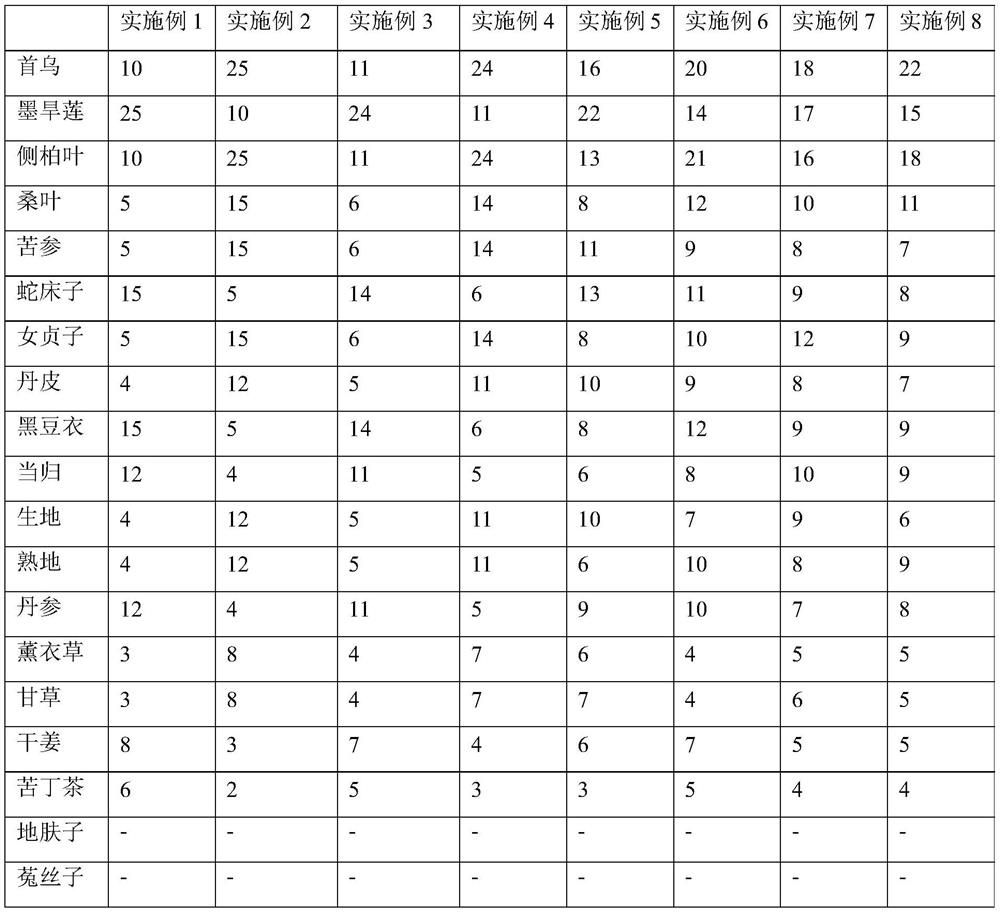

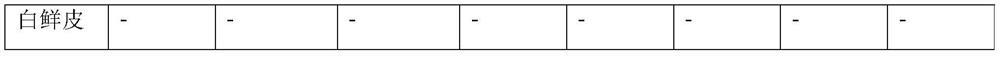

A plant essence formula capable of effectively promoting hair growth and preparation method thereof

ActiveCN111419769BPromote growthSuitable for long-term useCosmetic preparationsHair cosmeticsBiotechnologyAngelica Sinensis Root

The invention discloses a plant essence formula capable of effectively promoting hair growth and a preparation method thereof. The plant essence formula comprises: fleece-flower roots, herba ecliptae,cacumen biotae, folium mori, radix sophorae flavescentis, fructus cnidii, glossy privet fruit, cortex moutan, black bean coat, angelica sinensis, radix rehmanniae, radix rehmanniae preparata, radix salviae miltiorrhizae, lavender, liquorice, rhizoma zingiberis and folium llicis latifoliae. The preparation method comprises the following steps: (1) crushing and uniformly mixing plant raw materialsto obtain plant powder; (2) adding white spirit into the plant powder, and performing soaking and filtering to obtain a plant essence leaching solution; (3) heating and extracting the plant essence leaching solution to obtain a plant essence concentrated solution; and (4) stirring and filtering the plant essence concentrated solution to obtain the plant essence. The plant essence formula takes pure traditional Chinese medicine plants as raw materials, is safe, non-toxic and free of side effects, has the effects of nourishing scalp, repairing hair follicles, eliminating dandruff and effectivelypromoting hair growth, can be directly smeared on scalp, does not need secondary cleaning, and is convenient to use.

Owner:广州市白云区莱媚美容美发日用化妆品厂

Automatic cleaning and wiping device for aluminum plate strip foils

InactiveCN112620218AComprehensive cleaningReduce wasteDrying machines with progressive movementsCleaning using liquidsHydraulic cylinderMechanical engineering

The invention relates to the technical field of aluminum plate strip foils, in particular to an automatic cleaning and wiping device for aluminum plate strip foils. A third roller and a fourth roller are adjusted to a proper distance by utilizing a hydraulic cylinder and a hydraulic rod, when the aluminum plate strip foils enter the position between the third roller and the fourth roller, friction between the outer surface of the aluminum plate strip foils and the third roller and friction between the outer surface of the aluminum plate strip foils and the fourth roller are kept, short fluff is arranged on the outer side walls of the aluminum plate strip foils, the third roller and the fourth roller, the short fluff is softer in texture through friction between the aluminum plate strip foils and the rotating fourth roller, the aluminum plate strip foils can be better wiped, the outer surfaces of the aluminum plate strip foils are not abraded in the wiping process, the aluminum plate strip foils slide forwards to drive the third roller to rotate, water spots on the aluminum plate strip foils are wiped off by rotating the third roller and the fourth roller, and short fluff on the outer side wall of a second conveying belt can continuously keep the aluminum plate strip foils dry when the second conveying belt makes contact with the aluminum plate strip foils.

Owner:安徽力幕新材料科技有限公司

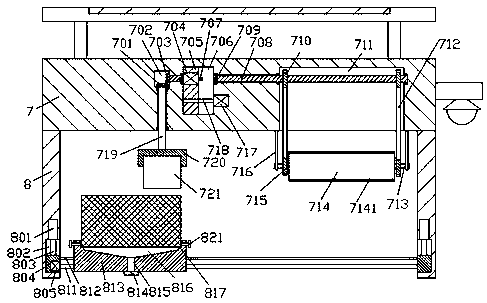

Novel communication machine case device

InactiveCN108015644ASimple structureEasy to operateLiquid surface applicatorsGrinding carriagesEngineeringComputer engineering

The invention discloses a novel communication machine case device. The novel communication machine case device comprises bearing supports installed on the end faces of the bottom of an installing plate in an eudipleural manner, a left rotating groove, a middle groove and a right rotating groove are formed in the inner wall body of the installing plate, a sliding block is installed in the middle groove in a sliding fit manner, a first spiral rod is installed in the sliding block in a matched manner, the left side extending tail end of the first spiral rod is connected with the left side inner wall of the middle groove in a rotary fit manner, the right side extending tail end of the first spiral rod is connected with a first driver, the outer surface of the first driver is fixedly installedon the inner wall of the right side of the middle groove, a second driver is fixedly installed in the position, on the upper side of the first spiral rod, of the sliding block, the left side extendingtail end of the second driver is connected with a first spline shaft, and a right side extending section is connected with a second spline shaft. The novel communication machine case device is simplein structure and convenient to operate, and the labor amount of workers can be reduced.

Owner:朱国新

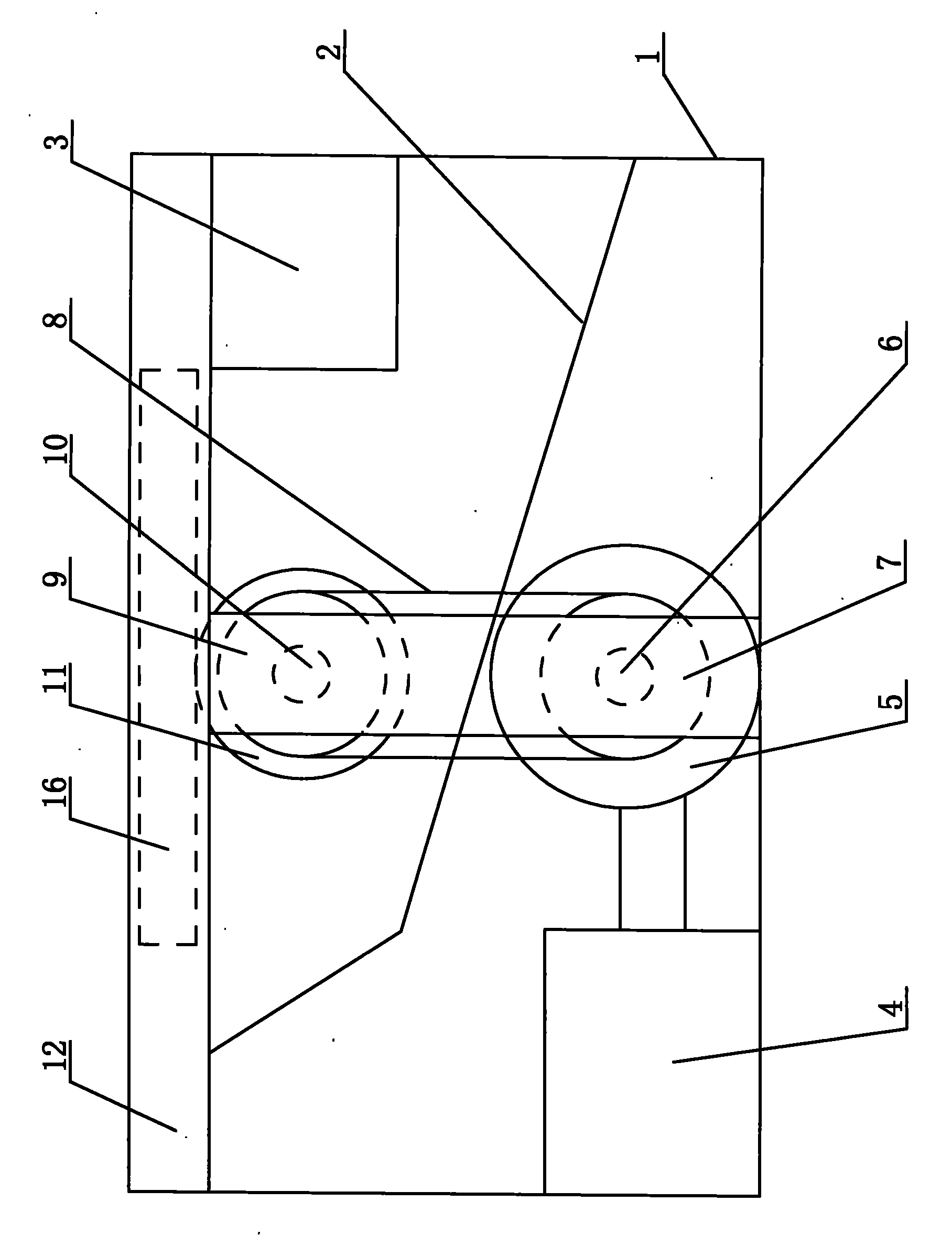

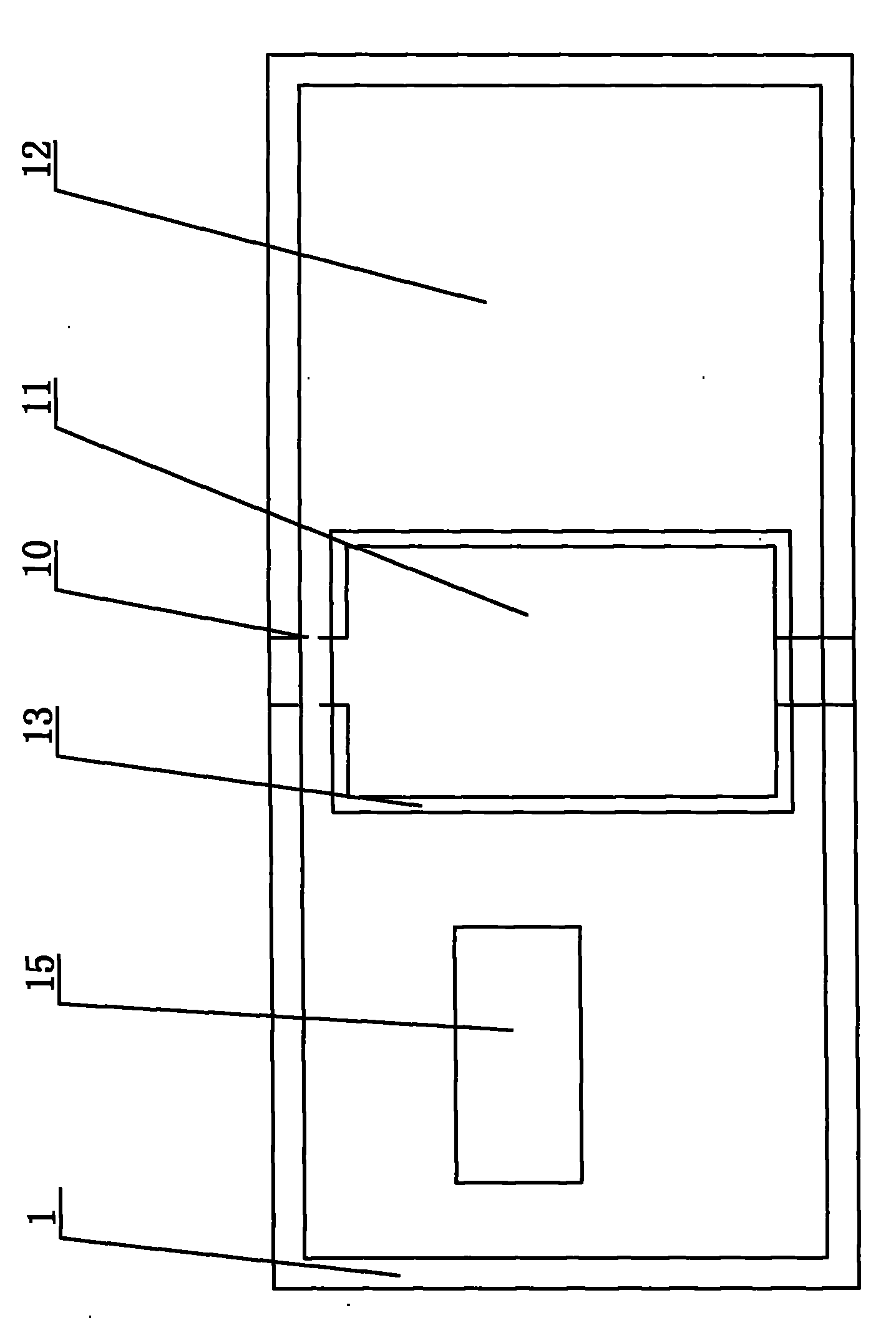

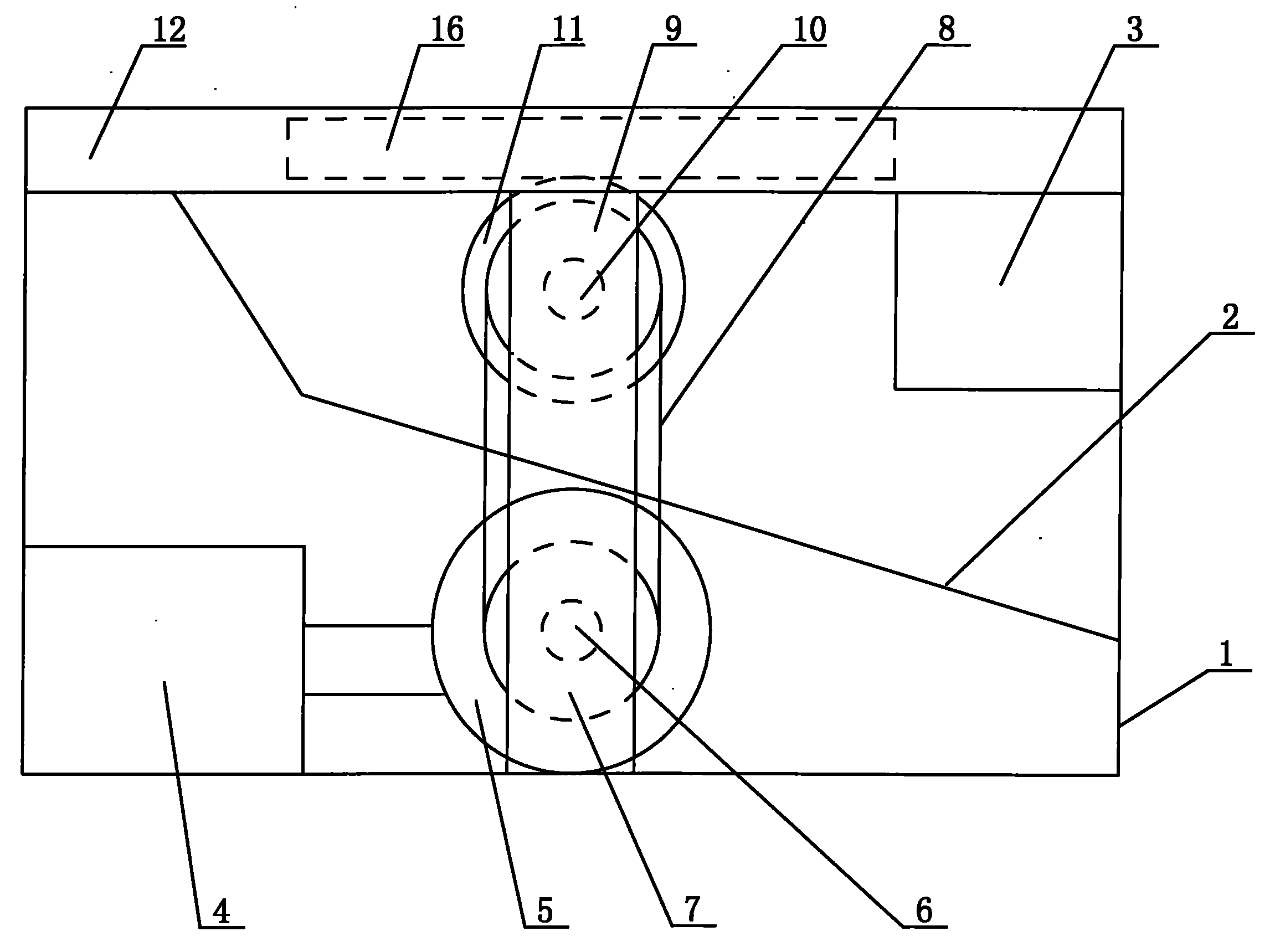

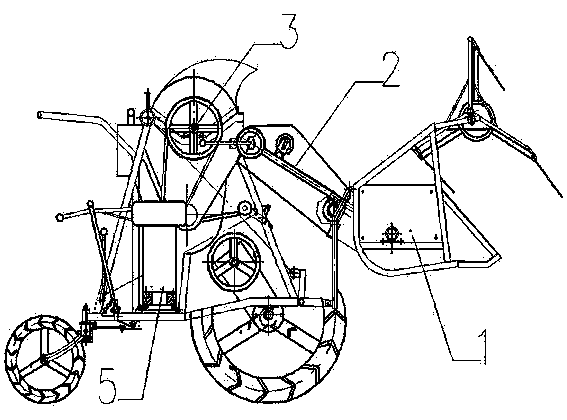

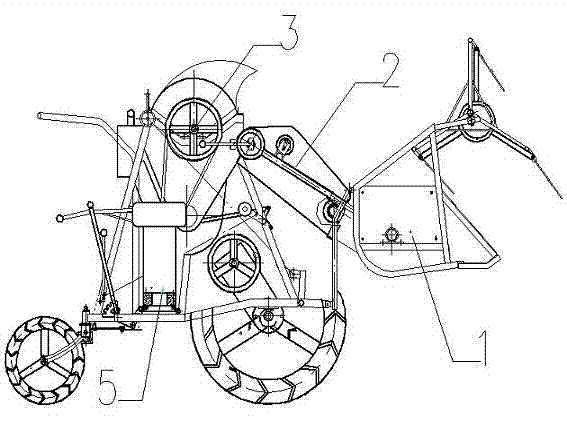

Combine of various crops

The invention discloses a combine of various crops. The combine is characterized by being mainly composed of a grain cutting mechanism (1), a grain conveying mechanism (2), a seed separating mechanism (3), an induced draft slagging mechanism (4), a power transmission mechanism (5) and a seed lifting mechanism (6). The grain cutting mechanism (1) is connected with the grain conveying mechanism (2) which is connected with the seed separating mechanism (3), the bottom of the seed separating mechanism (3) is connected with the seed lifting mechanism (6), and the tail end of the seed lifting mechanism (6) is connected with the induced draft slagging mechanism (4). The combine modifies the seed separating mechanism and the induced draft slagging mechanism, and enables clean grains to be obtained finally.

Owner:CHANGSHA SHUNTIAN MACHINERY

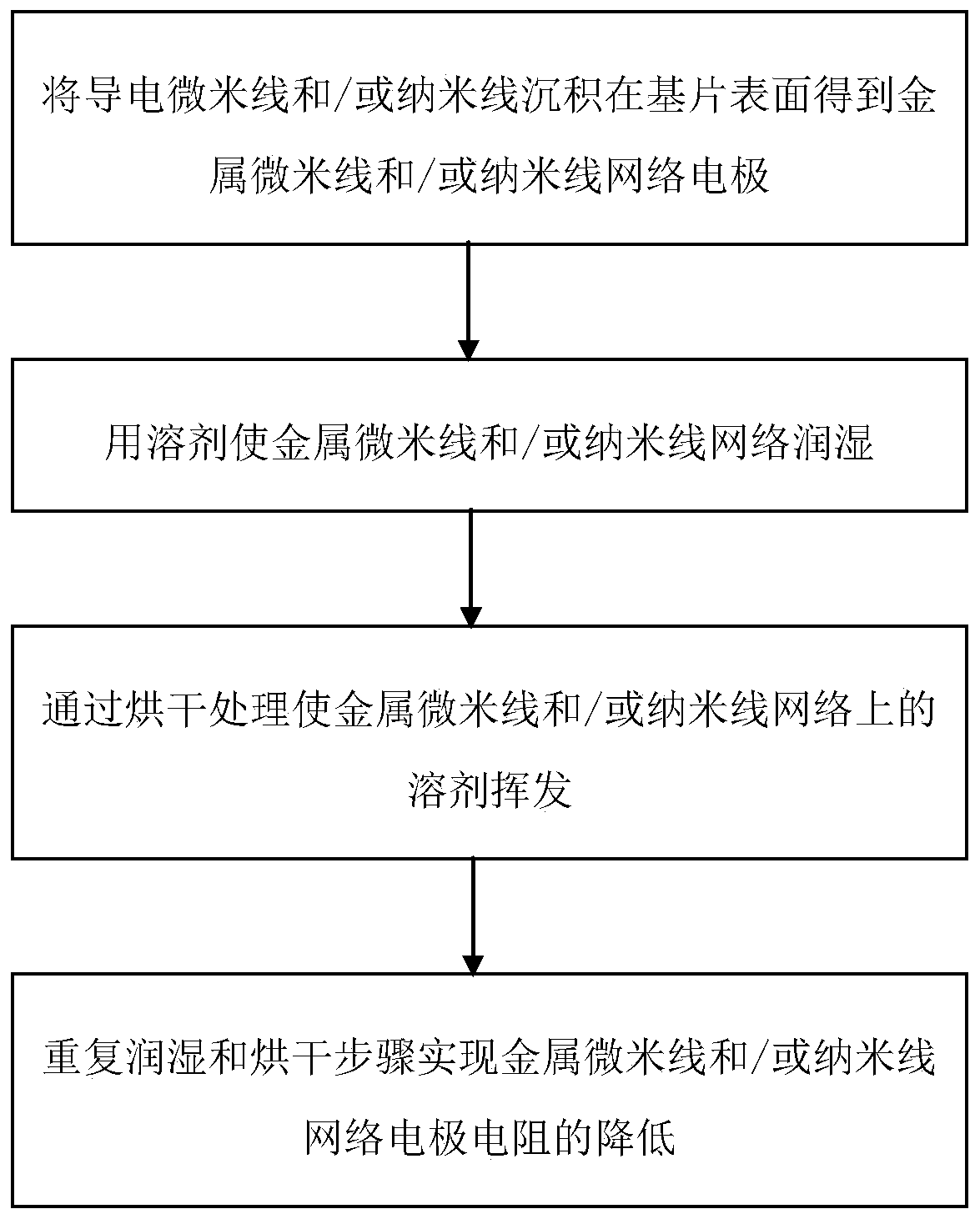

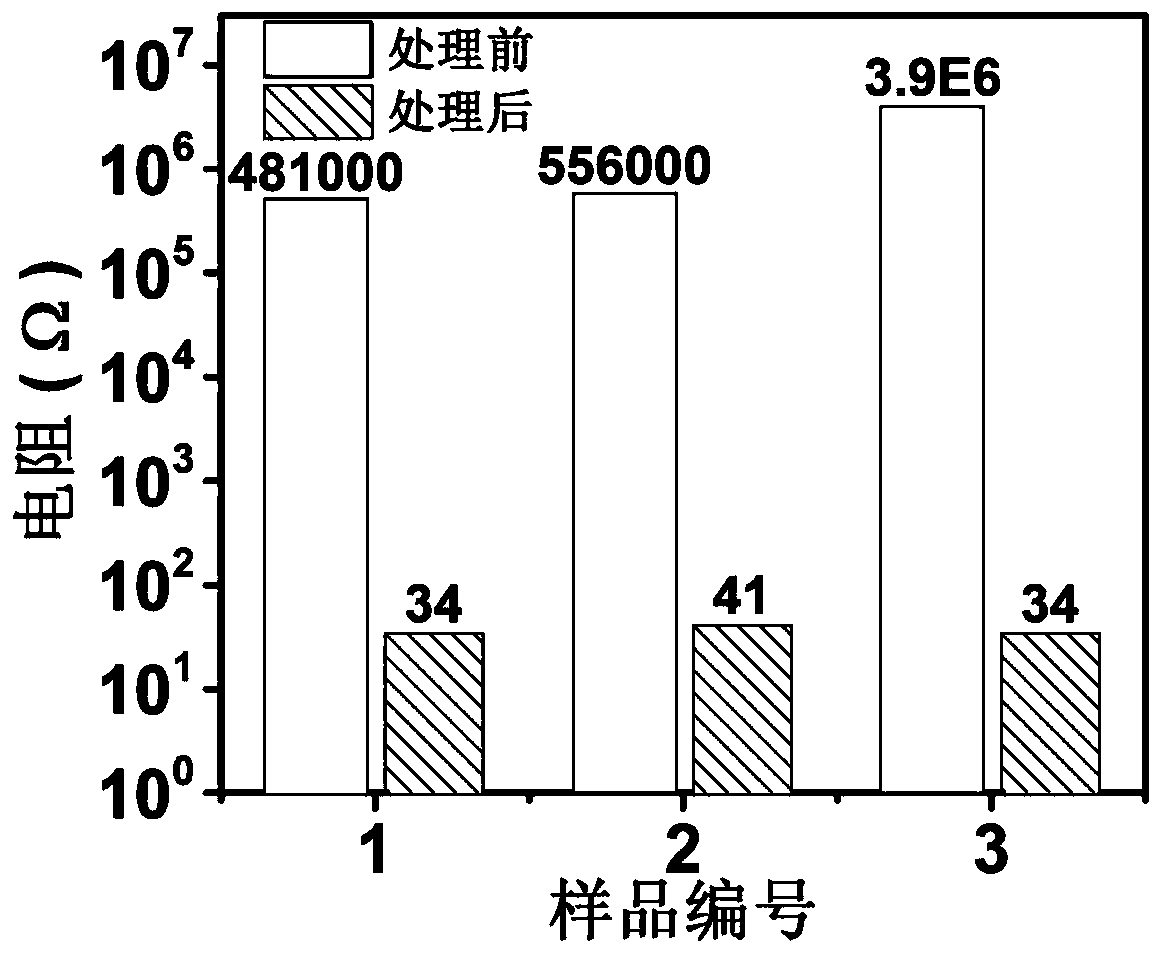

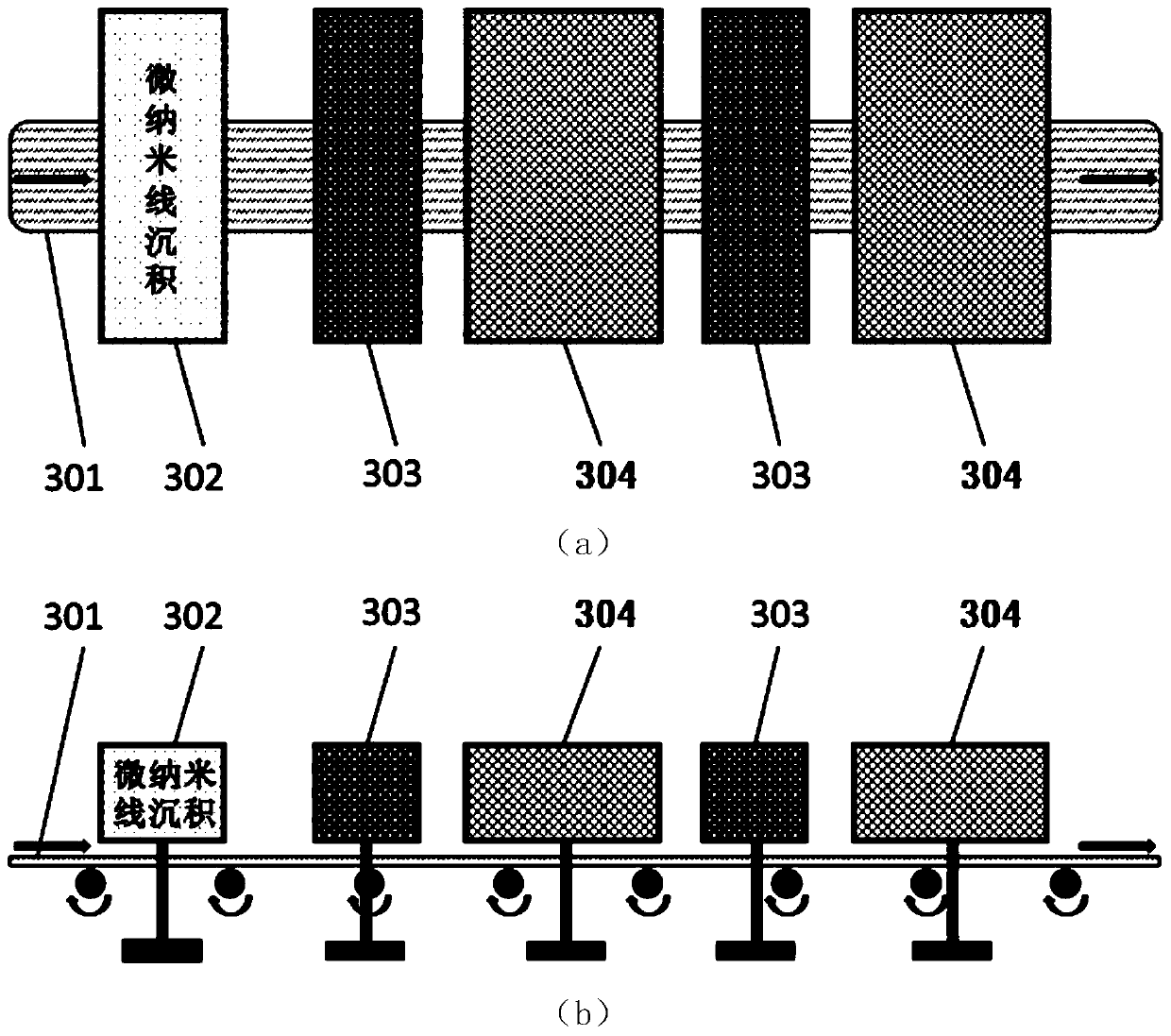

Method and device for reducing metal microwire and/or nanowire network electrode resistance

ActiveCN106449390BLower resistanceLow costMaterial nanotechnologySemiconductor/solid-state device manufacturingElectrical resistance and conductanceNanowire

The invention discloses a method and apparatus reducing the resistance of metal micrometer wire and / or nanowire network electrodes. The method comprises the step of firstly depositing metal micrometer wires and / or nanowires on the surface of a substrate, and then wetting a metal micrometer wire and / or nanowire network with a solvent, subjecting the network to drying to volatilize the solvent, and finally repeating wetting and drying to realize the lowering of the resistance of the metal micrometer wire and / or nanowire network electrodes. The apparatus comprises a deposition unit for depositing the metal micrometer wires and / or nanowires on the surface of the substrate, a wetting unit for wetting the metal micrometer wire and / or the nanowire network electrodes, a drying unit for volatilizing the surface solvent of the micrometer wire and / or the nanowire network electrodes and a transfer unit for transporting substrates and the metal micrometer wire and / or the nanowire network electrodes between the wetting unit and the drying unit. The method and apparatus of the invention can greatly reduce the resistance of the metal micrometer wire and / or the nanowire network electrodes, and has advantages such as rapidness, high efficiency, low cost, no pollution, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

Thermal insulation foam layer cutting machine with scrap collecting function for anti-corrosion thermal insulation pipeline

ActiveCN111844198AEasy to collectPrevent fallingMetal working apparatusThermal insulationIndustrial engineering

The invention provides a thermal insulation foam layer cutting machine with a scrap collecting function for an anti-corrosion thermal insulation pipeline. The cutting machine comprises a workbench, supporting legs, a mounting groove, a foam scrap collecting frame structure, a pipeline positioning frame structure, a control box, a horizontal supporting frame structure, a protective cover, a mounting frame, an angle motor, a fixing pipe, a vertical rod, a knife rest fine adjustment movable frame structure, a hanging ring and the anti-corrosion thermal insulation pipeline. The supporting legs arewelded at the four corners of the lower portion of the workbench respectively; the mounting groove is formed in the inner side of the workbench; and the foam scrap collecting frame structure is arranged on the inner side of the mounting groove. The device has the beneficial effects that through the arrangement of a collecting hopper and an external connecting pipe, an air suction pipe of an external dust collector is connected with the external connecting pipe through bolts, so that foam scraps generated during cutting of equipment can be collected, the situation that the foam scraps fall onto the ground and are inconvenient for workers to clean is prevented, and the cleaning effect of the equipment is improved.

Owner:河北君业科技股份有限公司

Improved mailbox processing device

InactiveCN108161608ASimple structureEasy to operateLiquid surface applicatorsGrinding carriagesArchitectural engineeringWorkload

The invention discloses an improved mailbox processing device which comprises supporting plates, wherein the supporting plates are mounted on the bottom end surface of a processing machine body in a left-right symmetric manner; a left transmission groove, a driving groove and a right transmission groove are separately formed in the inner wall body of the processing machine body; an embedding blockis mounted in the driving groove in a sliding fit manner; a first threaded rod is mounted in the embedding block in a screw-thread fit manner; the left extending tail end of the first threaded rod isconnected with the left inner wall of the driving groove in a rotating fit manner; the right extending tail end of the first threaded rod is connected with a first motor; the outer surface of the first motor is fixedly mounted on the right inner wall of the driving groove; a second motor is fixedly mounted in the embedding block on the upper side of the first threaded rod; the left extending tailend of the second motor is connected with a first spline shaft; and the right extending tail end of the second motor is connected with a second spline shaft. The improved mailbox processing device disclosed by the invention has the beneficial effects that the structure is simple, the operation is convenient, and the workload of workers is reduced.

Owner:程明琴

Novel environment-friendly garbage can device

InactiveCN108340217ASimple structureEasy to operateLiquid surface applicatorsGrinding carriagesEngineeringElectric motor

The invention discloses a novel environment-friendly garbage can device. The novel environment-friendly garbage can device comprises machine frames, wherein the machine frames are symmetrically arranged on the bottom end face of a placing plate in a left-right mode, screw holes are formed in the bottoms of the four corners of the machine frames simultaneously, screwing screw angles are formed in the screw holes, a left conduction groove, a middle end groove and a right conduction groove are formed in the inner wall body of the placing plate, a sliding block is arranged in the middle end groovein a sliding fit mode, a first spiral rod is arranged in the sliding block in a matched mode, the left extension tail part of the first spiral rod is rotationally matched and connected with the innerwall of the left side of the middle end groove, the extension tail part of the right side of the first spiral rod is connected with the first motor, the outer surface of the first motor is fixedly arranged on the inner wall of the right side of the middle end groove, a second motor is fixedly installed in the sliding block on the upper side of the first spiral rod, the tail end of the left side of the second motor is connected with a first spline shaft, and the right extension section of the second motor is connected with a second spline shaft. The novel environment-friendly garbage can device has the advantages of being simple in structure and convenient to operate, and reducing the labor amount of workers.

Owner:广州建德农业科技有限公司

One-inch photo pressing and cutting type separation equipment

The invention relates to separation equipment, in particular to one-inch photo pressing and cutting separation equipment. According to the one-inch photo pressing and cutting type separation equipment, one-time cutting can be achieved; photos can be automatically fixed; the photos can be evenly cut; and waste materials can be collected. the one-inch pressing and cutting type separation equipment comprises a base and a placing mechanism; the placing mechanism is arranged at the top of the base; a pressing and cutting mechanism is arranged on one side of the base and located above the placing mechanism; and the placing mechanism and the pressing and cutting mechanism work in a matched mode. The one-inch photo pressing and cutting type separation equipment achieves the effects that one-time cutting can be achieved; the photos can be automatically fixed; the photos can be evenly cut; one-inch photo pressing and cutting type separation is achieved by collecting waste materials; under the cooperation of the placing mechanism, the pressing and cutting mechanism and a downward pressing assembly, one-time pressing and cutting of the photos and automatic fixing of the photos can be achieved; and therefore repeated manual pressing and cutting operation of people is not needed.

Owner:李伟娣

A conical roller grinding type green walnut peeling machine

The invention, which belongs to the technical field of walnut peeling, provides a conical roller grinding type green walnut peeling machine comprising a frame provided with a feeding hopper. A first conical roller and a second conical roller that are driven by a driving device are installed on the frame in a rotating manner; and the first conical roller and the second conical roller are arranged side by side and a mounting gap is arranged between the rollers. Cutting teeth for peeling off the green coat of the walnut are arranged on the wall of the first conical roller; and a rubber sleeve fordriving the walnut to make rotation sleeves the outside of the second conical roller. A discharge hole of the feeding hopper is arranged above the first conical roller and the second conical roller and is close to the thick ends of the first conical roller and the second conical roller. Under the effect of the driving device, the first conical roller and the second conical roller make rotation ina same direction. Compared with the traditional green walnut peeling equipment, the conical roller grinding type green walnut peeling machine has the following beneficial effects: the peeling efficiency and the peeling quality are greatly improved; the peeling is done completely; no manual secondary cleaning is needed; the damages on the walnut are reduced substantially; and the quality of the walnut after peeling processing is ensured effectively.

Owner:WEIFANG VOCATIONAL COLLEGE

Combine of various crops

The invention discloses a combine of various crops. The combine is characterized by being mainly composed of a grain cutting mechanism (1), a grain conveying mechanism (2), a seed separating mechanism (3), an induced draft slagging mechanism (4), a power transmission mechanism (5) and a seed lifting mechanism (6). The grain cutting mechanism (1) is connected with the grain conveying mechanism (2) which is connected with the seed separating mechanism (3), the bottom of the seed separating mechanism (3) is connected with the seed lifting mechanism (6), and the tail end of the seed lifting mechanism (6) is connected with the induced draft slagging mechanism (4). The combine modifies the seed separating mechanism and the induced draft slagging mechanism, and enables clean grains to be obtained finally.

Owner:CHANGSHA SHUNTIAN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com