Combine of various crops

A technology for combine harvesters and crops, which is applied in the fields of harvesters, agricultural machinery and implements, agriculture, etc., can solve the problem of unsatisfactory effects of grain separation mechanism and suction and slag discharge mechanism, difficulty in transferring to another field, and affecting the harvester. Popularize use and other issues to achieve the effect of low cost, large market value and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in combination with a preferred embodiment and accompanying drawings, so as to help understanding of the content of the present invention.

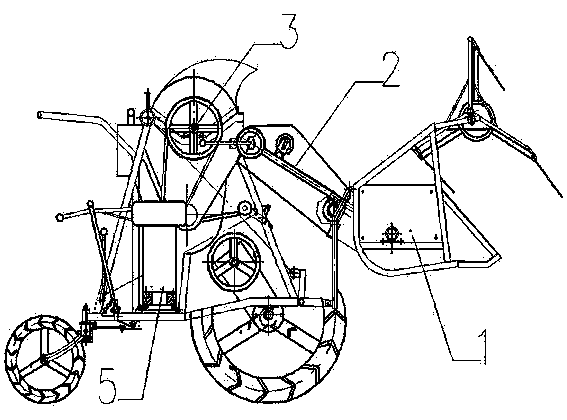

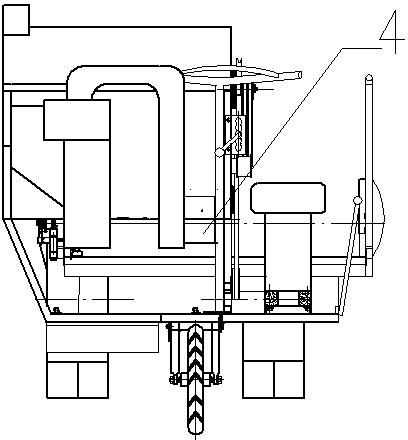

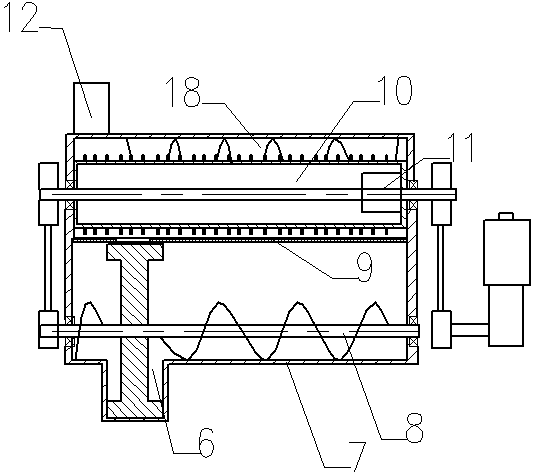

[0021] Such as Figure 1-5 As shown, the assembly relationship of the present invention is: the equipment is mainly composed of the following parts: seedling ear harvesting mechanism (1), seedling ear transport mechanism (2), grain separation mechanism (3), suction and slag discharge mechanism (4 ), the power transmission mechanism (5) and the grain lifting mechanism (6); the seedling harvesting mechanism (1) is connected with the seedling transportation mechanism (2), and the seedling transportation mechanism (2) is connected with the grain separation mechanism (3) , the bottom of the grain detachment mechanism (3) is connected with a grain lifting mechanism (6), and the end of the grain lifting mechanism (6) is connected with a suction and slag discharge mechanism (4);

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com