Drawer type vacuum sweeper dust bin

A vacuum cleaner and drawer-type technology, which is applied in cleaning methods, road surface cleaning, construction, etc., can solve the problems of time-consuming and labor-intensive, garbage and dust can not fall normally, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

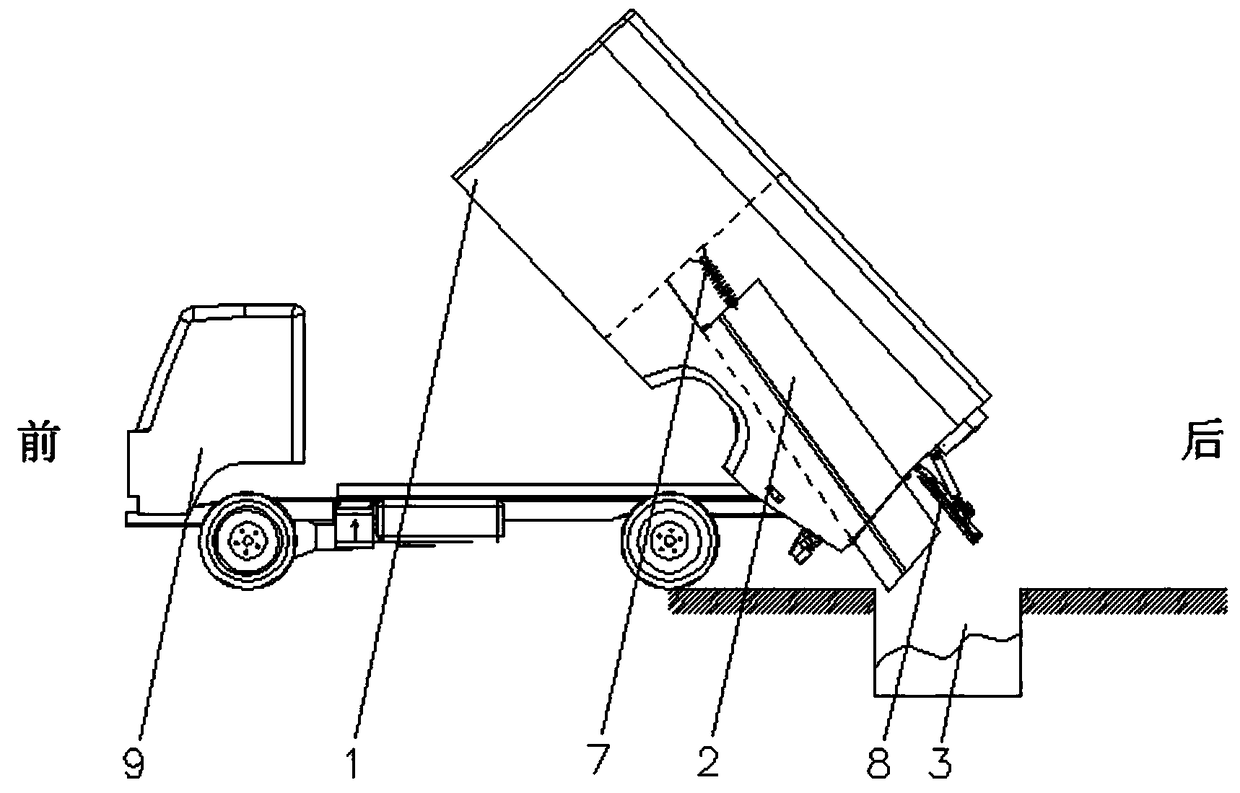

[0031] In this embodiment, the rear end of the large compartment 1 is provided with an openable and closable door panel 8, and the rear end of the large compartment 1 is sealed by the door panel 8 to prevent the dust from being scattered from the small compartment 2 during the transportation of the vacuum truck 9. The upper side of the door panel 8 near the two ends is hinged with the two sides of the rear end of the main compartment 1 through hinges. The two ends of the upper side of the door panel 8 are respectively provided with an extension part, and the extension part is provided with a card slot. A hook matched with the card slot is respectively provided, and the door panel 8 is manually closed manually.

Embodiment 2

[0033] The difference between this embodiment and the first embodiment is that: the rear end of the large compartment 1 is provided with an air cylinder, and the telescopic end of the air cylinder is fixedly connected with the door panel 8. The door panel 8 can be closed by the air cylinder expansion and contraction. .

[0034] It should be noted that the hydraulic cylinder (model MOB63) and air cylinder (model SC63) involved in the present invention all adopt existing technology, and the above-mentioned components are electrically connected to the controller (model TC-SCR), and the controller is connected to each component The control circuit between is the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com