Method and device for reducing metal microwire and/or nanowire network electrode resistance

A technology of metal nanowires and electrode resistance, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the pollution of metal microwires and nanowires, the chemical method is difficult to control the processing intensity, and consumes a lot of energy Chemical and other problems, to achieve the effect of simple and efficient processing, low cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

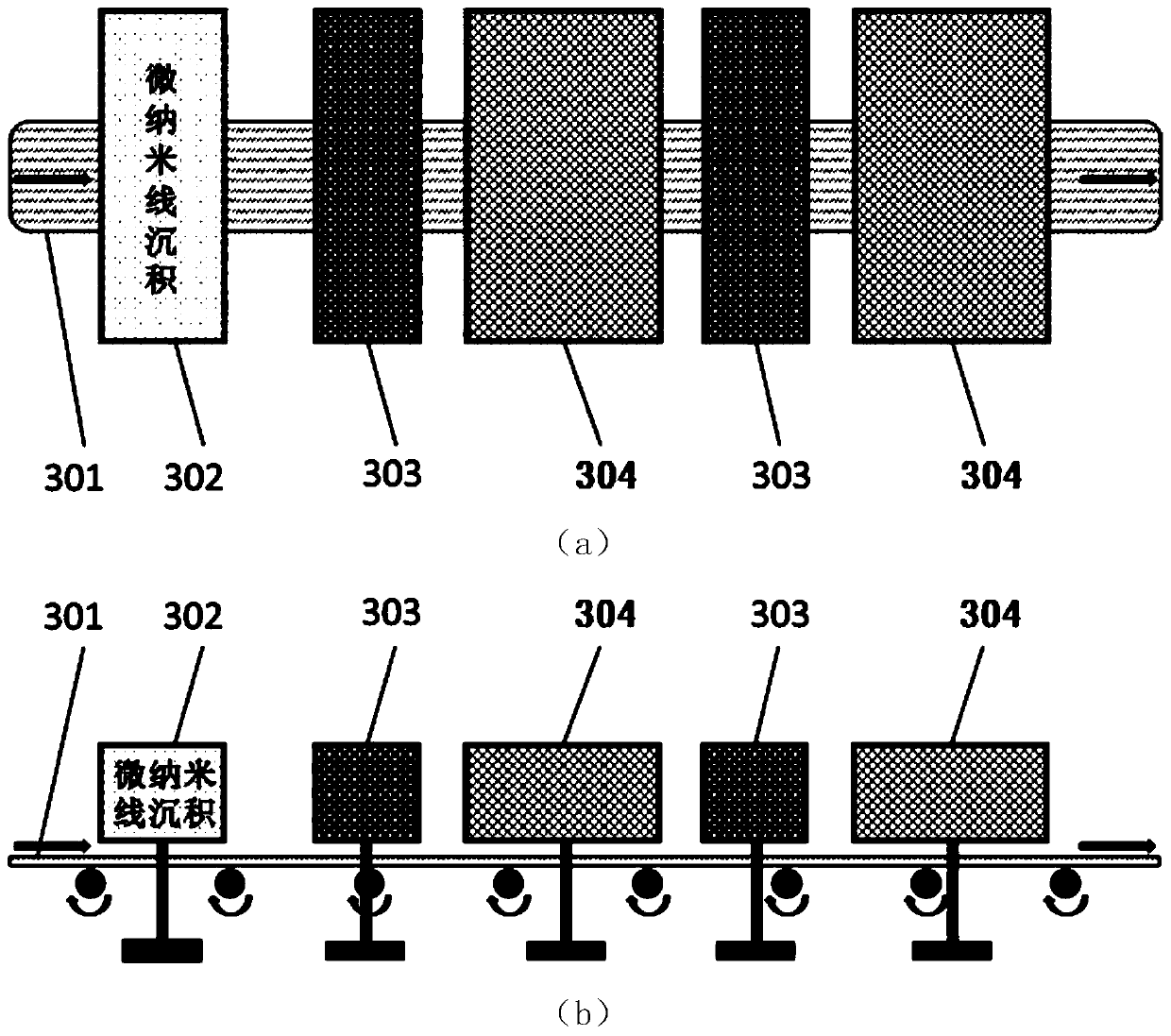

[0051] This embodiment provides a device for quickly reducing the resistance of metal microwires and / or nanowire network electrodes, and its structural schematic diagram is as follows image 3 As shown, the device includes a transfer unit 301 , a deposition unit 302 , two wetting units 303 and two drying units 304 .

[0052] The transfer unit 301 communicates with other units in the device, and sends the substrate from the starting position to the metal microwire and / or nanowire deposition unit 302 for deposition, by means of contact or non-contact printing, spray coating or spin coating, Deposit the conductive nanowires on the surface of the substrate to form a network, and then continue to send the substrate with the metal microwires and / or nanowire network electrodes deposited on the surface into the wetting unit 303 to conduct the metal microwires and / or nanowire network electrodes. Wetting, and finally the solvent is dried by the drying unit 304; after a round of "wetting...

Embodiment 2

[0054] This embodiment provides another device for quickly reducing the resistance of metal microwires and / or nanowire network electrodes, and its structural schematic diagram is as follows Figure 4 As shown, the device includes a conveying unit 401 , a deposition unit 402 , two wetting units 403 , two drying units 404 and two direction-controllable conveying subunits 405 .

[0055] The transfer unit 401 communicates with all other units in the device, and sends the substrate from the initial position to the metal microwire and / or nanowire deposition unit 402 for deposition, by means of contact or non-contact printing, spray coating or spin coating , deposit conductive nanowires on the surface of the substrate to form a network, and then continue to send the substrate with metal microwires and / or nanowire network electrodes deposited on the surface into the wetting unit 403 for metal microwires and / or nanowire network electrodes Wetting, and then drying the solvent through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com