Breaking device of cast-in-place concrete pile head and construction method thereof

A construction method and concrete technology, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of large dust, high labor intensity, and large demolition workload during the demolition process, and achieve fast and efficient truncation and hoisting, and reduce The investment of manpower and material resources and the effect of eliminating hidden dangers of engineering safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

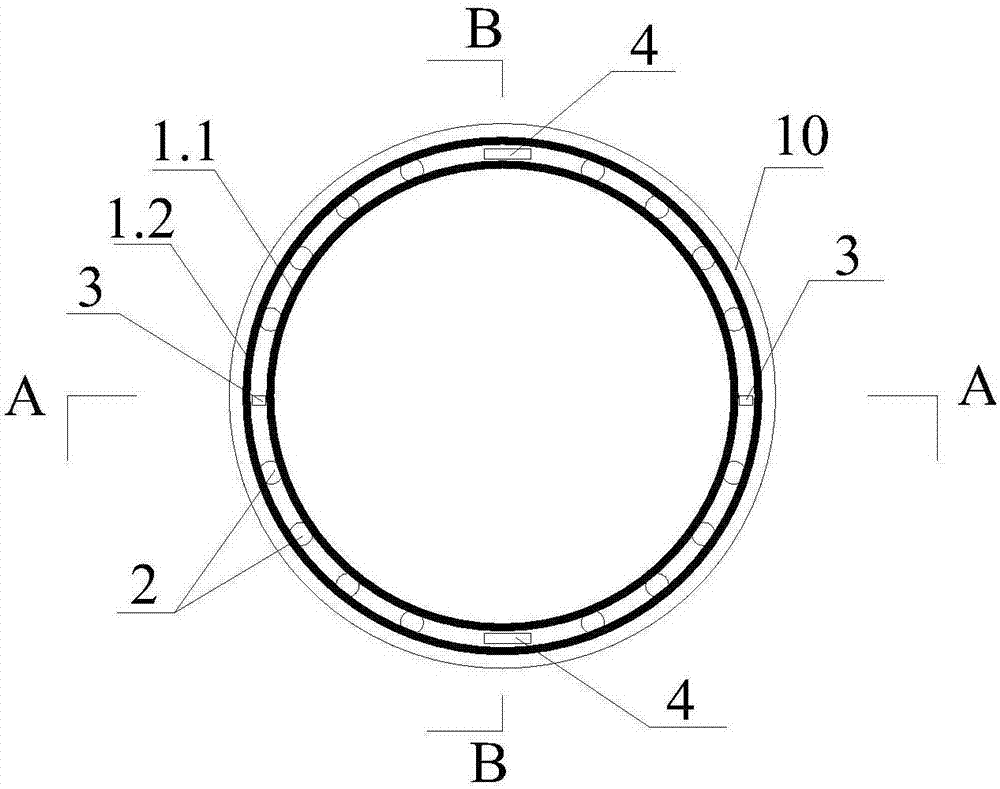

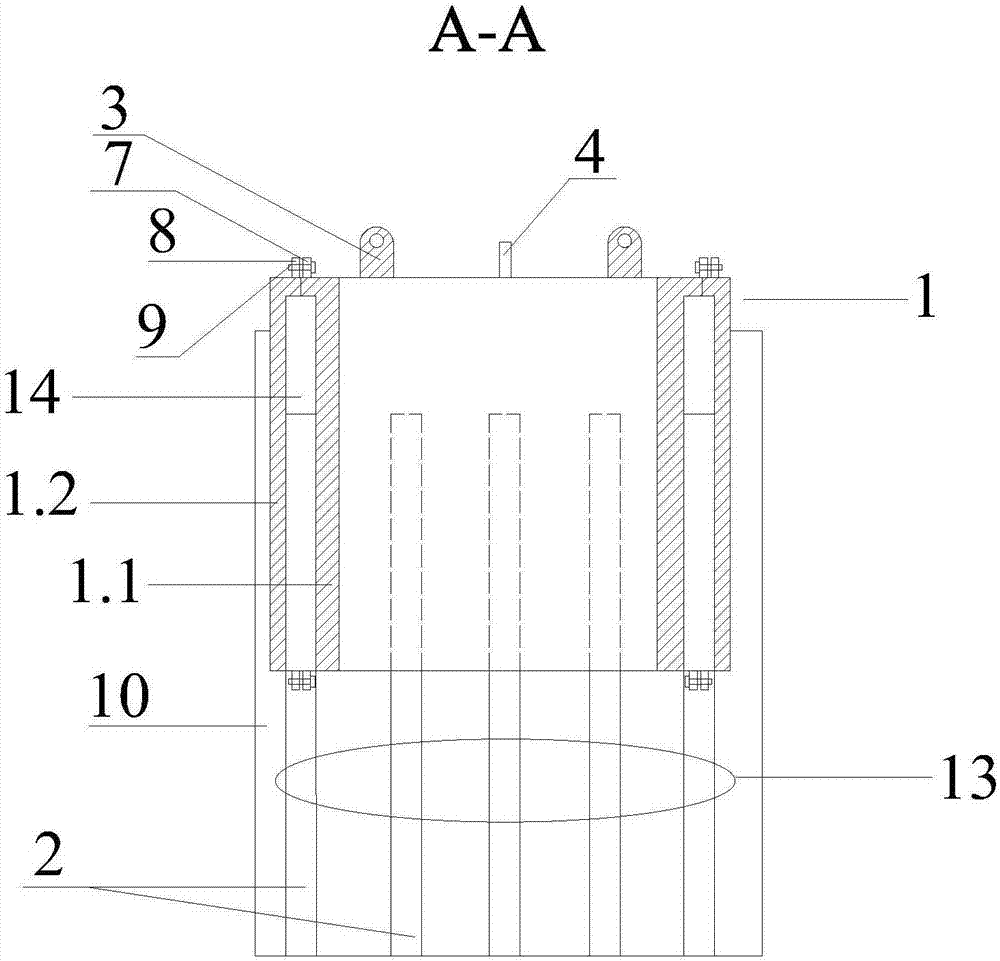

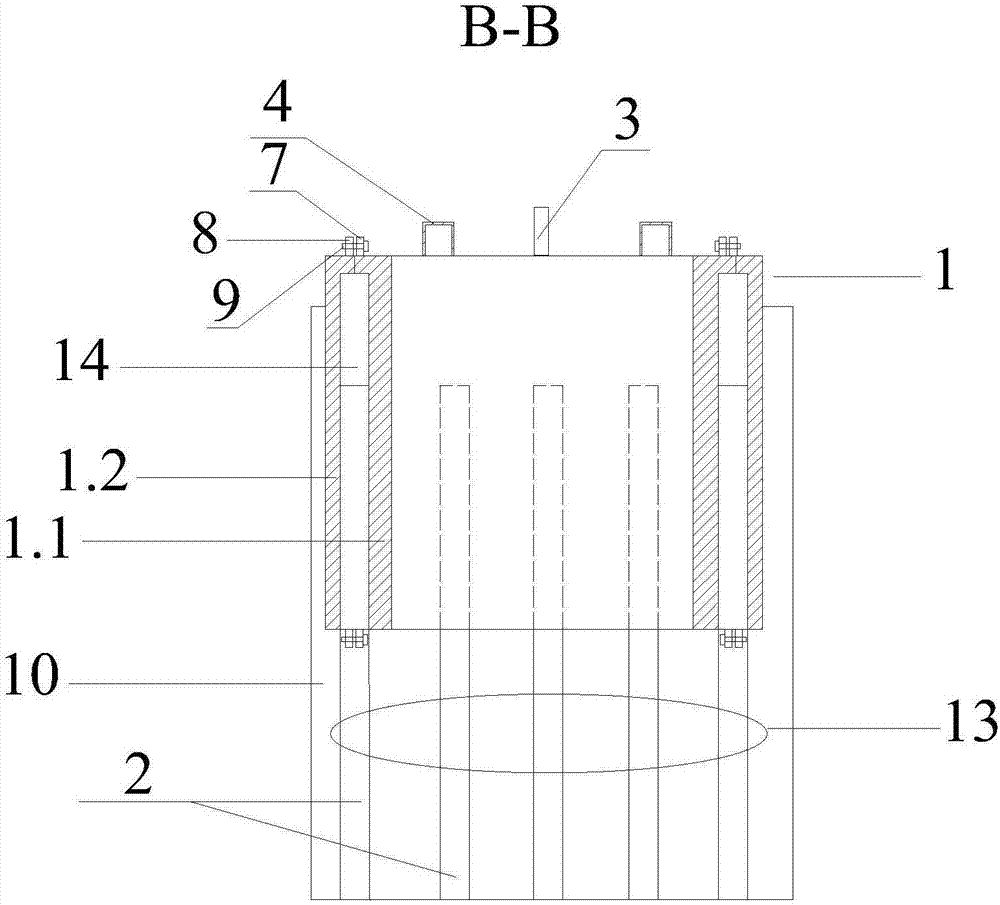

[0026] Such as figure 1 The demolition device for the pile head of the concrete pouring pile shown in —5 includes an annular main reinforcement positioning casing 1, and the main reinforcement positioning casing 1 includes two coaxial annular inner casings 1.1 and annular outer casing 1.2, and the annular inner casing The outer wall of 1.1 fits and fixes with the inner wall of the annular outer casing 1.2, and the main rib positioning groove 14 includes the first main rib positioning half-groove 5 opened on the outer wall of the annular inner casing 1.1 and corresponding to the first main rib positioning half-groove 5, opened in The second main rib on the inner wall of the annular outer casing 1.2 positions the half groove 6 . Two lifting lugs 3 that are symmetrical to the axis of the main reinforcement positioning casing 1 are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com