Cutting and trepanning method for concrete chimney

A technology of concrete and concrete blocks, which is applied in the direction of portable lifting devices, load hanging components, hoisting devices, etc., can solve problems such as inappropriateness, and achieve simple production, clear method thinking, strong versatility and operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

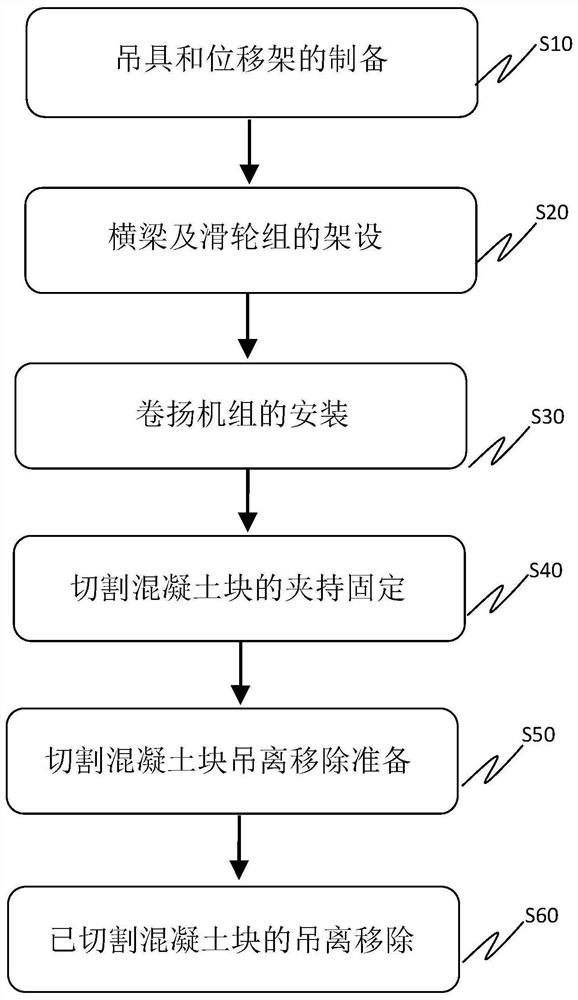

[0069] like figure 1 The schematic block diagram of the process of a cutting and opening method for a concrete chimney provided by an embodiment of the present invention:

[0070] A method for cutting and opening holes in a concrete chimney, comprising:

[0071] S10) preparation steps of spreader and displacement frame;

[0072] S20) erection steps of beam and pulley block;

[0073] S30) installation steps of the hoisting unit;

[0074] S40) a clamping and fixing step for cutting concrete blocks;

[0075] S50) a preparatory step for cutting the concrete block and lifting it away for removal;

[0076] S60) Lifting and removing step of the cut concrete block.

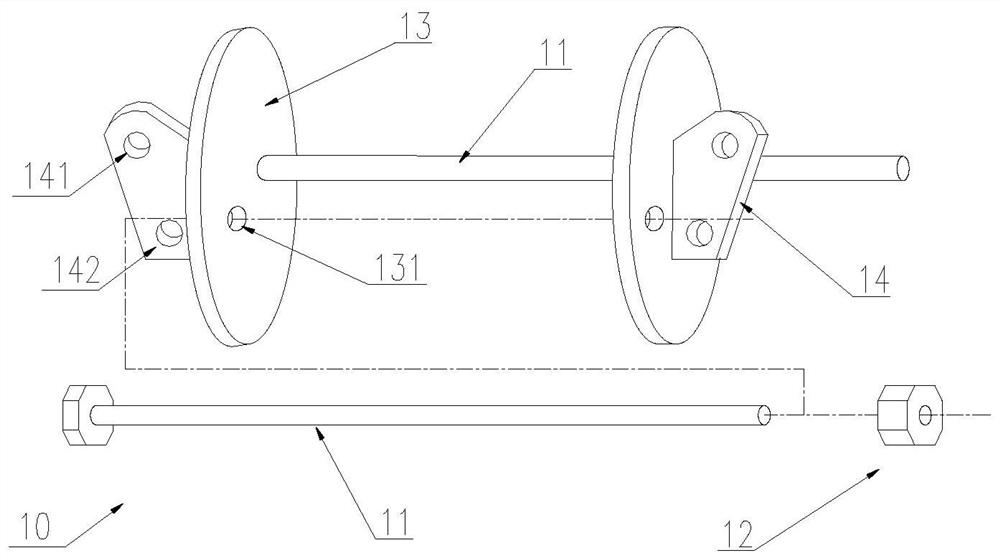

[0077] like figure 2 The schematic diagram of the three-dimensional structure of the spreader in the cutting and opening method of a concrete chimney provided by the embodiment of the present invention is as follows:

[0078] The spreader 10 includes an inner splint, an outer splint, bolts 11 and nuts 12. Both the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com