Wax-sealed water blasting bead and preparation method and device thereof

A preparation device and popping bead technology, which is applied in the field of tobacco and cigarettes, can solve the problems of safety risks, excessive auxiliary materials, and difficulty in washing, so as to improve the convenience and comfort of use, easy to pinch, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

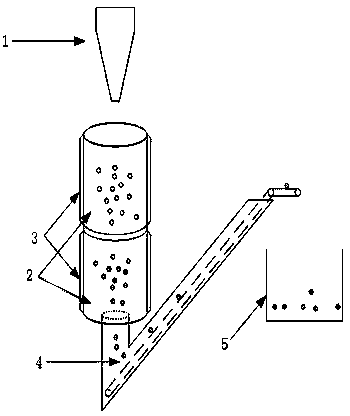

Embodiment 1

[0031] Configure ethanol / water solution at a volume ratio of 1:2, and pour it into cylinder 2 to fill the lower section. Adjust the condensing temperature to 0°C to maintain the low temperature and constant temperature of the lower section. Heat and melt the paraffin and pour it into the cylinder to fill the upper section. Adjust the heating temperature to 50°C to maintain the high temperature and constant temperature of the upper section. Use a dropper to drop the core material with 100% water content into the melted wall material liquid. Since the density of water is higher than that of paraffin, based on the action of gravity and surface tension, a wax layer is formed on the surface of the water droplets during the settlement process. Based on the thickness of the wall material formed by the viscosity of the wax layer at 50°C, a wall core material consisting of 60% wall material and 40% core material by mass was obtained. The wall core material is cooled after entering th...

Embodiment 2

[0033] Configure ethanol / water solution at a volume ratio of 1:5, and pour it into the cylinder to fill the lower section. Adjust the condensation temperature to 10°C to maintain the low temperature and constant temperature of the lower stage. Heat and melt the beeswax, and pour it into the cylinder to fill the upper section. Adjust the heating temperature to 75°C to maintain the high temperature and constant temperature of the upper section. Use a dropper to drop the core material with 100% water content into the melted wall material liquid. Since the density of water is higher than that of beeswax, based on the action of gravity and surface tension, a wax layer is formed on the surface of the water droplets during the settlement process. Based on the thickness of the wall material formed by the viscosity of the wax layer at 75°C, a wall core material consisting of 39% wall material and 61% core material by mass was obtained. The formed wall core material enters the lower p...

Embodiment 3

[0035] Configure ethanol / water solution at a volume ratio of 1:10, and pour it into the cylinder to fill the lower section. Regulate condensing temperature to 20 DEG C, to keep lower stage low temperature constant temperature. Heat and melt the paraffin and pour it into the cylinder to fill the upper section. Adjust the heating temperature to 85°C to maintain the high temperature and constant temperature of the upper section. Use a dropper to drop the water / green mandarin essence core material with a mass ratio of 95:5 into the melted wall material liquid. Since the density of the essence solution is higher than that of paraffin, based on gravity and surface tension, the essence droplet will During the settling process, a wax layer forms on the surface. Based on the thickness of the wall material formed by the viscosity of the wax layer at 85°C, a wall core material consisting of 27% of the wall material and 73% of the core material was obtained. The formed wall core materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com