Steel ball flow polishing machine

A polishing machine and steel ball technology, applied in the field of mechanical processing, can solve problems such as unsatisfactory equipment, and achieve the effects of improving surface finish, low energy consumption, and optimizing production lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

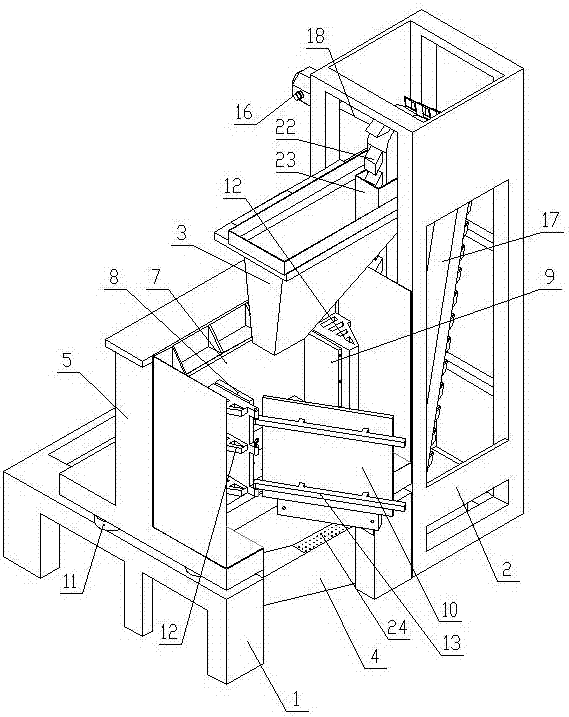

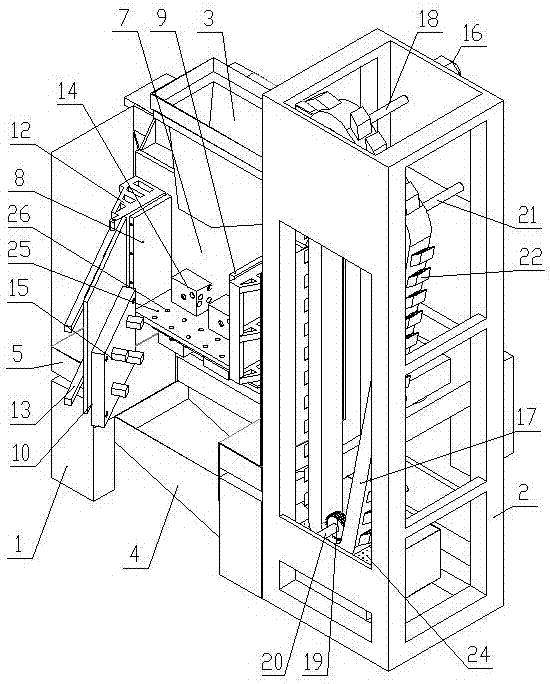

[0023] Such as figure 1 and figure 2 As shown, the steel ball flow polishing machine of the present invention includes a frame 1, which is provided with a workpiece mounting vibration container assembly, and the top and bottom of the workpiece mounting vibration container assembly are respectively provided with a steel ball inlet and a steel ball outlet, and the right side of the frame 1 The frame 2 in the shape of a cuboid is fixedly installed, and the upper left side of the upper part of the frame 2 is fixedly installed with an upper funnel 3 located above the steel ball inlet. , the frame 1 is provided with a lower funnel 4 located below the outlet of the steel balls, the lower funnel 4 is arranged with a high left and a right low slope, the lowest point inside the lower funnel 4 is located at the lower part of the frame 2, and a steel ball hanging and lifting mechanism is arranged in the frame 2 The left side of the upper part of the steel ball hanging and lifting mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com