Intelligent laser washing system for wheel sets and bogies

A technology of laser cleaning and bogies, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as adhesion to the surface of the cleaned object, mechanical force damage, environmental pollution, etc., to reduce operation and maintenance costs , reduce the intensity of work, and solve the effect of environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

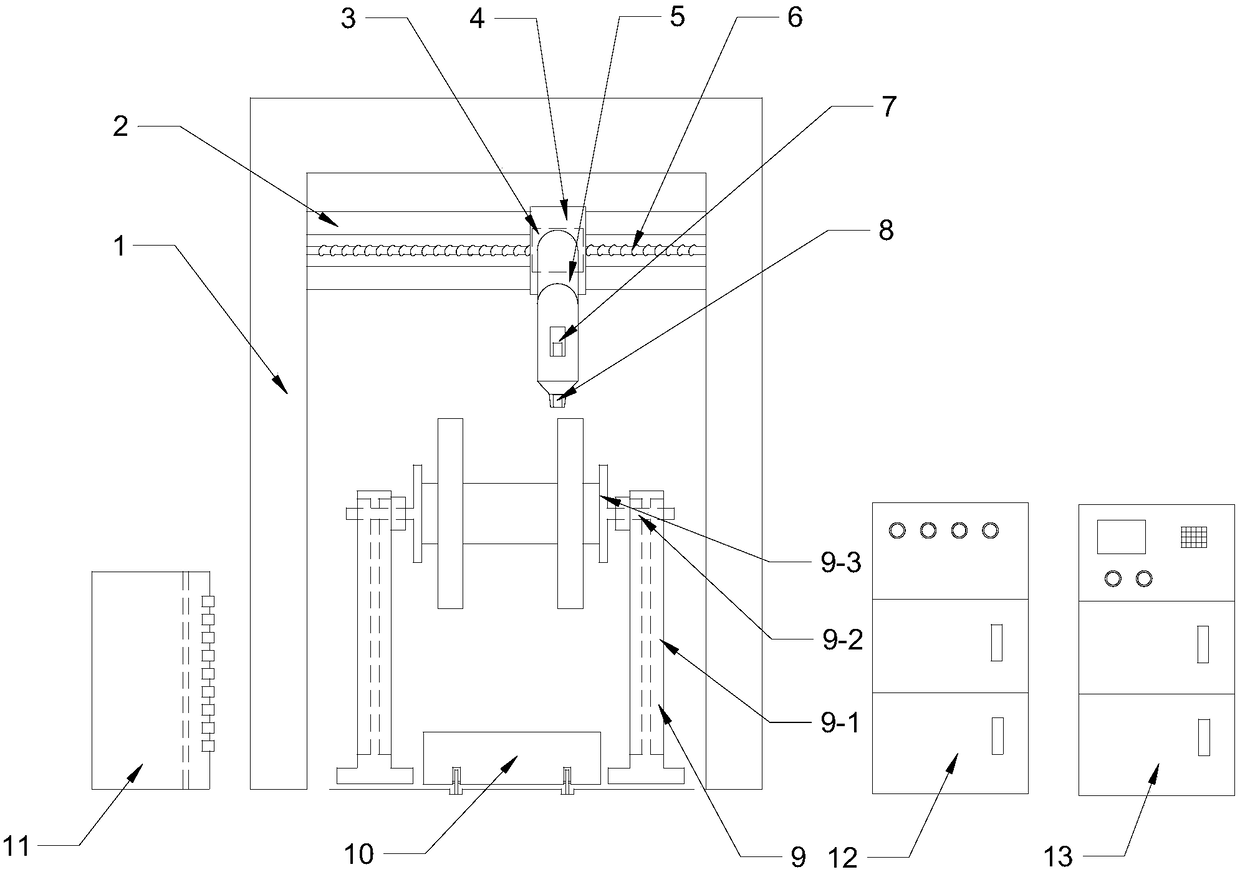

[0028] see figure 1 , an intelligent laser cleaning system for wheel sets and bogies, including a gantry 1, a horizontal linear rolling guide rail pair 2 and a horizontal ball screw pair 6, the moving parts of the rolling guide rail pair 2 are installed on the gantry frame 1 A fixed box 4 is fixed on the top, and a matching ball screw 3 is installed on the ball screw pair 6. The ball screw 3 is connected and fixed with the backboard of the robot 5 through the fixed box 4, and the machine between the elbow joint and the wrist joint of the robot 5 A machine vision system 7 is installed on the arm, and a laser head 8 is installed on the part below the robot 5 wrist joint.

[0029] In this example, the workpiece to be cleaned is transported to the recognizable range of the machine vision system 7, recognized by the machine vision system 7, the image signal is processed and displayed, and according to the display result, the ball screw on the ball screw pair 6 is rotated The mothe...

Embodiment 2

[0031] see figure 1 , an intelligent laser cleaning system for wheel sets and bogies, including a gantry 1, a horizontal linear rolling guide rail pair 2 and a horizontal ball screw pair 6, the moving parts of the rolling guide rail pair 2 are installed on the gantry frame 1 A fixed box 4 is fixed on the top, and a matching ball screw 3 is installed on the ball screw pair 6. The ball screw 3 is connected and fixed with the backboard of the robot 5 through the fixed box 4, and the machine between the elbow joint and the wrist joint of the robot 5 A machine vision system 7 is installed on the arm, and a laser head 8 is installed on the part below the robot 5 wrist joint.

[0032]A workpiece fixing device 9 is arranged under the gantry 1, and the workpiece fixing device 9 is composed of two opposite pillars 9-1. A vertical lifting mechanism 9-2 is arranged inside the pillars 9-1, and a turning mechanism 9-2 is arranged on the vertical lifting mechanism 9-2. Mechanism 9-3, turnin...

Embodiment 3

[0035] see figure 1 , an intelligent laser cleaning system for wheel sets and bogies, including a gantry 1, a horizontal linear rolling guide rail pair 2 and a horizontal ball screw pair 6, the moving parts of the rolling guide rail pair 2 are installed on the gantry frame 1 A fixed box 4 is fixed on the top, and a matching ball screw 3 is installed on the ball screw pair 6. The ball screw 3 is connected and fixed with the backboard of the robot 5 through the fixed box 4, and the machine between the elbow joint and the wrist joint of the robot 5 A machine vision system 7 is installed on the arm, and a laser head 8 is installed on the part below the robot 5 wrist joint.

[0036] A section of rail groove is arranged on the ground below the gantry 1, and a workpiece transport vehicle 10 is installed on the rail groove. The bottom of the workpiece transport vehicle 10 is provided with rollers. The workpiece moves freely on the rail groove below the gantry 1 through the rollers on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com