Novel environment-friendly garbage can device

A trash can and environmental protection technology, applied in the direction of grinding drive device, grinding/polishing safety device, device for coating liquid on the surface, etc. It can reduce the problem of waste bin processing and production efficiency, and achieve the effect of simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

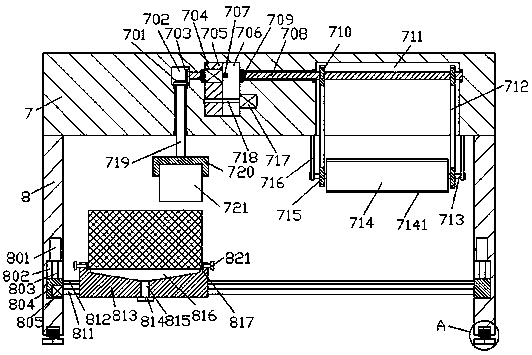

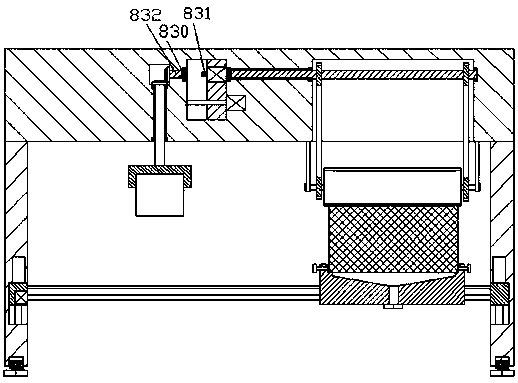

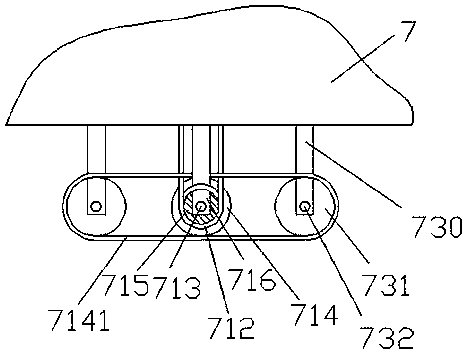

[0016] Such as Figure 1-5As shown, a kind of novel environment-friendly dustbin device of the present invention comprises the frame 8 that is installed on the bottom end face of the placement plate 7 mutually symmetrically. 881 is provided with a screw angle 882, through which the screw angle 882 can be adjusted when the ground is uneven, thereby increasing the stability of the frame 8 when it is supported, and the inner wall of the placement plate 7 A left conduction groove 702, a middle end groove 706, and a right conduction groove 711 are respectively provided, and a sliding block 705 is installed in the middle end groove 706, and a first screw rod is installed in the sliding block 705. 718, the left extension tail of the first screw rod 718 is connected to the inner wall on the left side of the middle end groove 706 in rotational fit, the right extension tail of the first screw rod 718 is connected with the first motor 717, and the first screw rod 718 The outer side of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com