Thermal insulation foam layer cutting machine with scrap collecting function for anti-corrosion thermal insulation pipeline

A technology for insulating pipes and foam layers, applied in metal processing and other directions, can solve problems such as inability to quickly move the tool to the cutting position, inability to locate and detect the level of the pipe, and inconvenient cleaning of foam chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

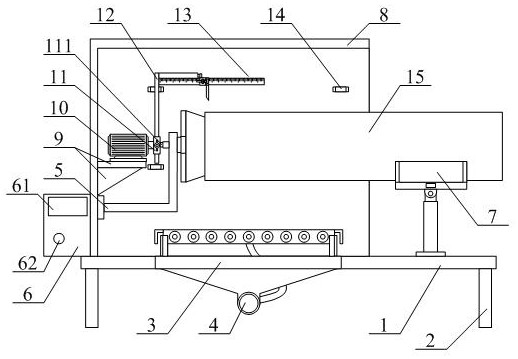

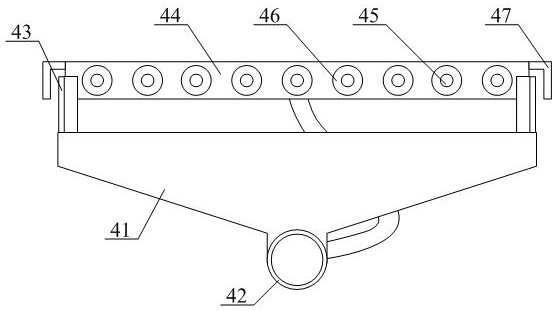

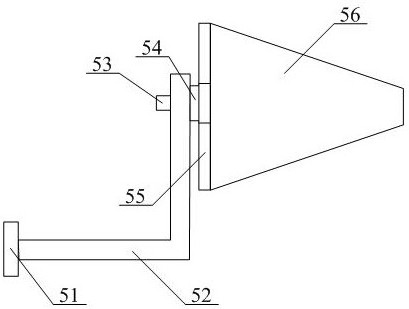

[0040] as attached figure 1 And attached figure 2 As shown, a cutting machine for anti-corrosion and thermal insulation pipe insulation foam layer with the function of collecting waste, including a workbench 1, support legs 2, installation groove 3, foam chip collection frame structure 4, pipe positioning frame structure 5, control box 6, Horizontal support frame structure 7, protective cover 8, mounting frame 9, angle motor 10, fixed pipe 11, vertical rod 12, knife rest fine-tuning mobile frame structure 13, hanging ring 14 and anti-corrosion insulation pipe 15, described support legs 2 respectively Welded at the four corners of the lower part of the workbench 1; the installation groove 3 is set on the inner side of the workbench 1; the foam chip collection frame structure 4 is arranged on the inner lower part of the workbench 1; the pipe positioning frame structure 5 Installed on the inner left side of the protective cover 8; the control box 6 is bolted to the lower left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com