A method for recovering titanium by centrifugal extraction from titanium white waste sulfuric acid

A waste sulfuric acid and titanium recovery technology, which is applied in the field of titanium recovery, can solve the problems of high price of neutral phosphorus-type extractants, long extraction time, and low extraction rate of titanium, and achieve short stripping time, short extraction time, and reverse extraction The effect of high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

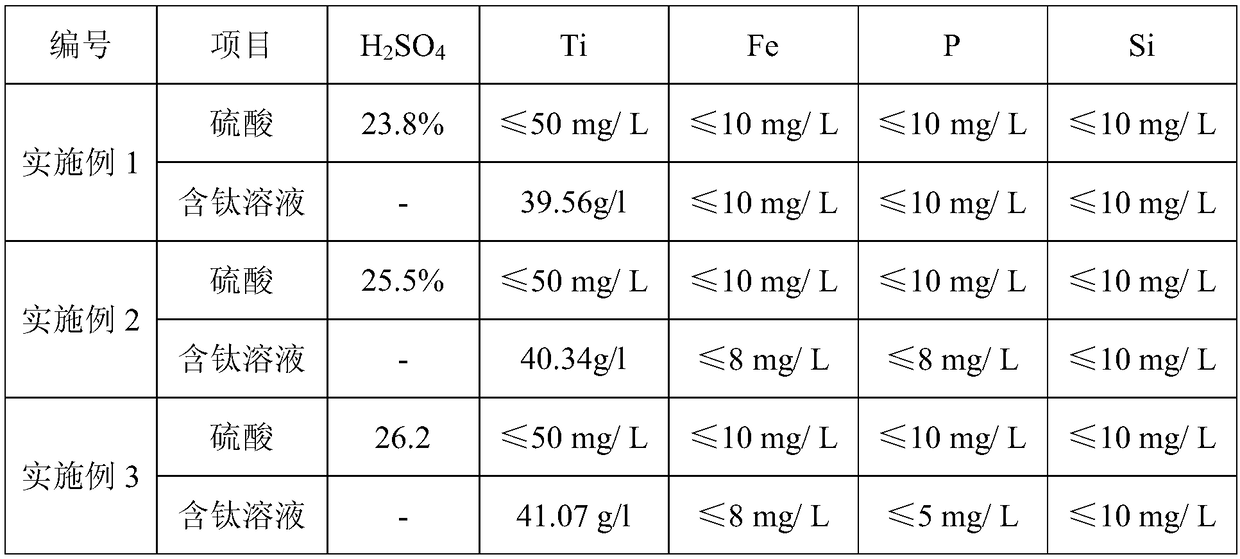

Embodiment 1

[0028] 1) Sulfuric acid production of titanium dioxide waste sulfuric acid (component H 2 SO 4 : 22.2%, Ti: 7.6g / L, Fe: 0.05g / l, P: 0.001g / l, Si: 0.023g / l, Na: 0.016g / l), extractant: 25% N116+75% sulfur Petroleum oil, three-stage countercurrent extraction and centrifugal extraction at 32°C, compared to O:A=1:5, extraction time 10s, flow rate 40m 3 / h, the titanium in the sulfuric acid is extracted into the organic phase, and after the extraction, purified sulfuric acid (containing Ti≤80mg / L) and a titanium-rich organic phase are obtained.

[0029] 2) Wash the titanium-rich organic phase in a single-stage agitated storage tank, the washing liquid is 5% sulfuric acid (prepared with raffinate acid), compared with O:A=20:1, polyethylene storage tank 30m 3 , the rotation speed of the stirring blade is 150r / min, and the stirring time of each tank is 5min, and then the phase separation is static; the washing solution is replaced when Fe≥0.5g / l.

[0030] 3) Using 0.65mol / L ammonia ...

Embodiment 2

[0032] 1) Sulfuric acid production of titanium dioxide waste sulfuric acid (component H 2 SO 4 : 24.2%, Ti: 8.2g / L, Fe: 0.08g / l, P: 0.0008g / l, Si: 0.016g / l, Na: 0.01g / l), extractant: 30% N1923+70% sulfonium Petroleum oil, three-stage countercurrent extraction and centrifugal extraction at 26°C, compared to O:A=1:4, extraction time 7s, flow rate 35m 3 / h, the titanium in the sulfuric acid is extracted into the organic phase, and after the extraction, purified sulfuric acid (containing Ti≤50mg / L) and a titanium-rich organic phase are obtained.

[0033] 2) Wash the titanium-rich organic phase in a single-stage agitated storage tank, the washing solution is 7% sulfuric acid (prepared with raffinate acid), compared to O:A=18:1, polyethylene storage tank 20m 3 , the rotation speed of the stirring blade is 150r / min, and the stirring time of each tank is 7min, and then the phase separation is static; the washing solution is replaced when Fe≥0.5g / l.

[0034] 3) Using 0.65mol / L sodiu...

Embodiment 3

[0036] 1) Sulfuric acid production of titanium dioxide waste sulfuric acid (component H 2 SO 4 : 20.2%, Ti: 8.3g / L, Fe: 0.01g / l, P: 0.001g / l, Si: 0.02g / l, Na: 0.02g / l), with extractant: 35%Primene81R+65% Sulfonated kerosene, three-stage countercurrent extraction and centrifugal extraction at 28°C, compared to O:A=1:4, extraction time 9s, flow rate 40m 3 / h, the titanium in the sulfuric acid is extracted into the organic phase, and after the extraction, purified sulfuric acid (containing Ti≤50mg / L) and a titanium-rich organic phase are obtained.

[0037] 2) The titanium-rich organic phase is washed in a single stage with a stirring storage tank, and the washing liquid is 5% sulfuric acid (prepared with raffinate acid), compared with O:A=20:1, and the polyethylene storage tank is 30 m 3 , the speed of stirring paddle is 150r / min, and the stirring time of each tank is 8min after static phase separation; when the washing liquid Fe ≥ 0.5g / l, replace it.

[0038] 3) Using 0.7mol / L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com