Reworking liquid for CF Rework color film process and preparation method thereof

A kind of process and technology of color film, which is applied in the direction of photoplate making process, photomechanical equipment, photosensitive material processing and other directions on the pattern surface, to achieve the effect of short peeling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A rework liquid used in the CF Rework color film process, including the following percentage raw materials: sodium hydroxide 5%, surfactant 3%, N-methylpyrrolidone 30%, γ-butyrolactone 10%, acetic acid 5% , the balance is water;

[0036] The rework fluid is made by the following steps:

[0037] The above raw materials are weighed and mixed until they are completely dissolved to obtain a rework solution.

[0038] Described tensio-active agent is made by following steps:

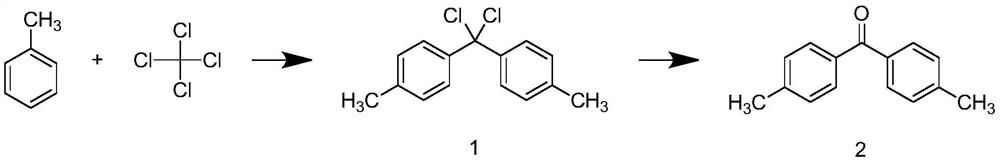

[0039] Step A1: Mix aluminum trichloride and carbon tetrachloride evenly, stir at 150r / min and 10°C, add toluene, and react for 1 hour at 40°C to prepare To obtain intermediate 1, intermediate 1 was mixed with deionized water, and refluxed for 10 minutes at a temperature of 110°C to obtain intermediate 2;

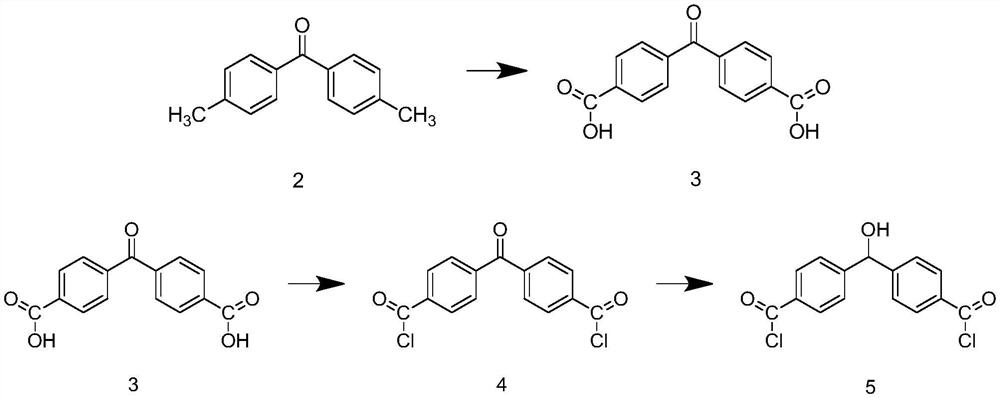

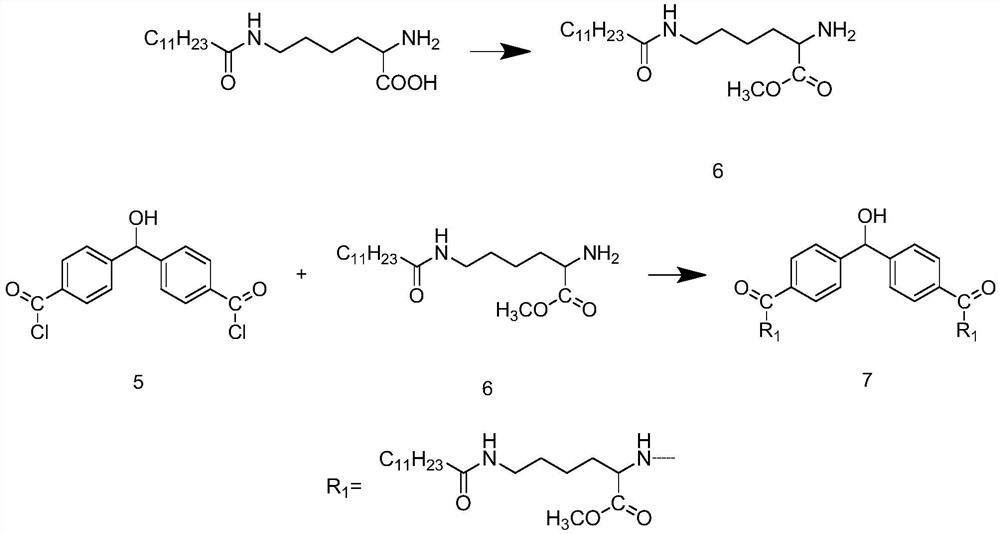

[0040] Step A2: Mix intermediate 2, deionized water, and potassium permanganate evenly, and react for 2 hours at a speed of 150r / min and a temperature of 110°C to obtain intermediate 3, and dissol...

Embodiment 2

[0044] A rework liquid used in the CF Rework color film process, including the following percentage raw materials: 10% potassium hydroxide, 4% surfactant, 40% ethylene glycol butyl ether, 13% propylene glycol carbonate, 6% lactic acid, and amount of water;

[0045] The rework fluid is made by the following steps:

[0046] The above raw materials are weighed and mixed until they are completely dissolved to obtain a rework liquid.

[0047] Described tensio-active agent is made by following steps:

[0048] Step A1: Mix aluminum trichloride and carbon tetrachloride evenly, stir at 180r / min, 13°C, add toluene, and react for 1.3h at 43°C. To prepare intermediate 1, mix intermediate 1 with deionized water, and reflux at a temperature of 115°C for 13 minutes to obtain intermediate 2;

[0049] Step A2: Mix intermediate 2, deionized water, and potassium permanganate evenly, and react for 2.5 hours under the conditions of a rotating speed of 180r / min and a temperature of 115°C to obta...

Embodiment 3

[0053] A rework liquid used in the CF Rework color film process, including the following percentage raw materials: sodium bicarbonate 15%, surfactant 5%, dimethyl succinate 50%, benzyl alcohol 15%, hydrogen peroxide 8% , the balance is water;

[0054] The rework fluid is made by the following steps:

[0055] The above raw materials are weighed and mixed until they are completely dissolved to obtain a rework liquid.

[0056] Described tensio-active agent is made by following steps:

[0057] Step A1: Mix aluminum trichloride and carbon tetrachloride evenly, stir at 200r / min, and add toluene at a temperature of 15°C, and react for 1.5h at a temperature of 45°C. To prepare intermediate 1, mix intermediate 1 with deionized water, and reflux at a temperature of 120°C for 15 minutes to obtain intermediate 2;

[0058] Step A2: Mix intermediate 2, deionized water, and potassium permanganate evenly, and react for 3 hours at a rotation speed of 200r / min and a temperature of 120°C to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com