Patents

Literature

305 results about "Ethylene Dibromide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

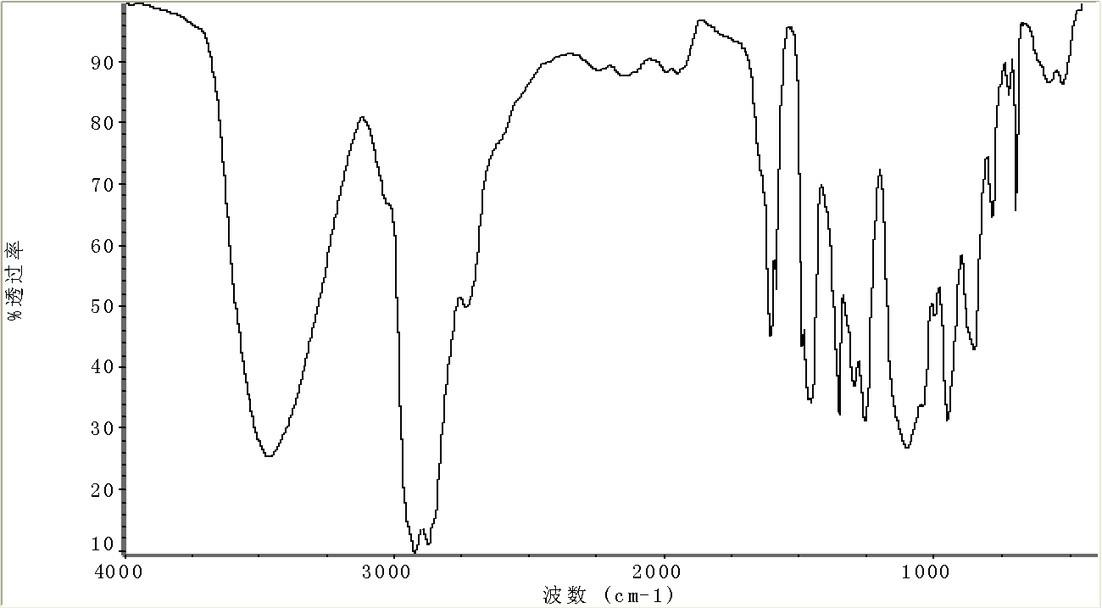

A clear, colorless, volatile liquid brominated hydrocarbon with a mild, sweet, chloroform-like odor that emits corrosive and toxic fumes when heated to decomposition. Ethylene dibromide is used as a chemical intermediate in the synthesis of resins, waxes, gums, dyes and pharmaceuticals and is used to produce vinyl bromide. Exposure to ethylene dibromide severely irritates the skin and causes depression and collapse. Ethylene dibromide affects DNA integrity by alkylation and is reasonably anticipated to be a human carcinogen.

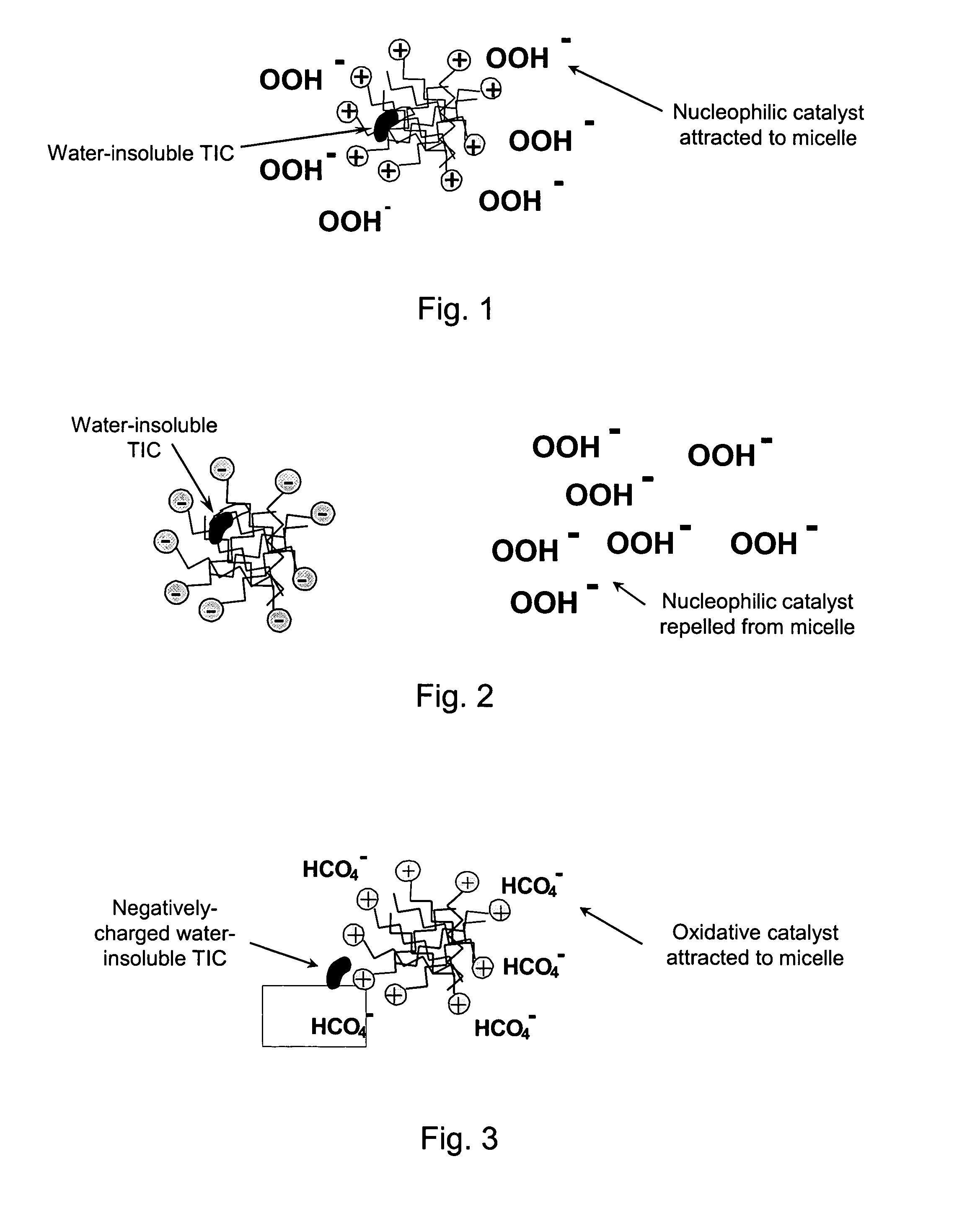

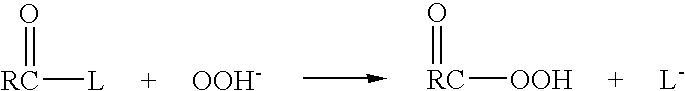

Reactive formulations for a neutralization of toxic industrial chemicals

InactiveUS7125497B1Efficiently neutralizedHydrogen peroxideLiquid degasificationBoron trichlorideMalathion

Decontamination formulations for neutralization of toxic industrial chemicals, and methods of making and using same. The formulations are effective for neutralizing malathion, hydrogen cyanide, sodium cyanide, butyl isocyanate, carbon disulfide, phosgene gas, capsaicin in commercial pepper spray, chlorine gas, anhydrous ammonia gas; and may be effective at neutralizing hydrogen sulfide, sulfur dioxide, formaldehyde, ethylene oxide, methyl bromide, boron trichloride, fluorine, tetraethyl pyrophosphate, phosphorous trichloride, arsine, and tungsten hexafluoride.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

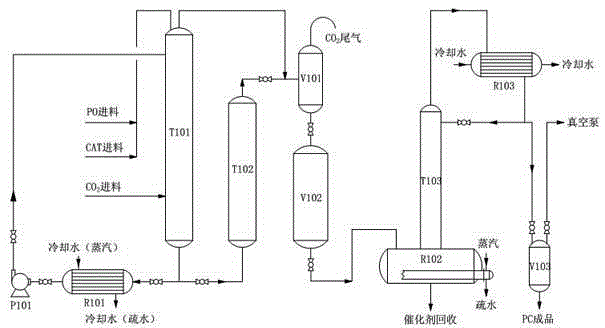

Method for preparing ethylene carbonate through continuous heterogeneous catalysis and catalyst

ActiveCN102513158AInnovativeEconomicalOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsDistillationReaction temperature

The invention relates to a continuous heterogeneous catalyst and a process for synthesizing ethylene carbonate through continuous heterogeneous catalysis. The ethylene carbonate is prepared through carrying out a catalytic addition reaction on a packed bed reactor device by taking ethylene oxide and carbon dioxide as raw materials and taking a novel functional ionic liquid polymer adsorbed on an inorganic particle as a solid catalyst. The catalyst is prepared by stirring and coating a functional imidazolium ionic liquid polymer on an inorganic carrier. The ethylene carbonate is prepared by mixing ethylene oxide and the carbon dioxide by using nitrogen gas as carrier gas in the packed bed reactor device and carrying out a cyclic addition reaction under the action of the catalyst, wherein the reaction pressure is 1.0-6.0MPa, the reaction temperature is 80-150 DEG C, and the reaction time is 1-6h. The continuous heterogeneous catalyst and the process for synthesizing ethylene carbonate through continuous heterogeneous catalysis have the advantages that the method with a continuous process is simple in operation, low in cost, free of separation and distillation and suitable for large-scale industrial production; and the catalyst has high activity, low loss, high ethylene oxide conversion ratio up to 97% and high electivity up to 98%.

Owner:SHANGHAI NORMAL UNIVERSITY

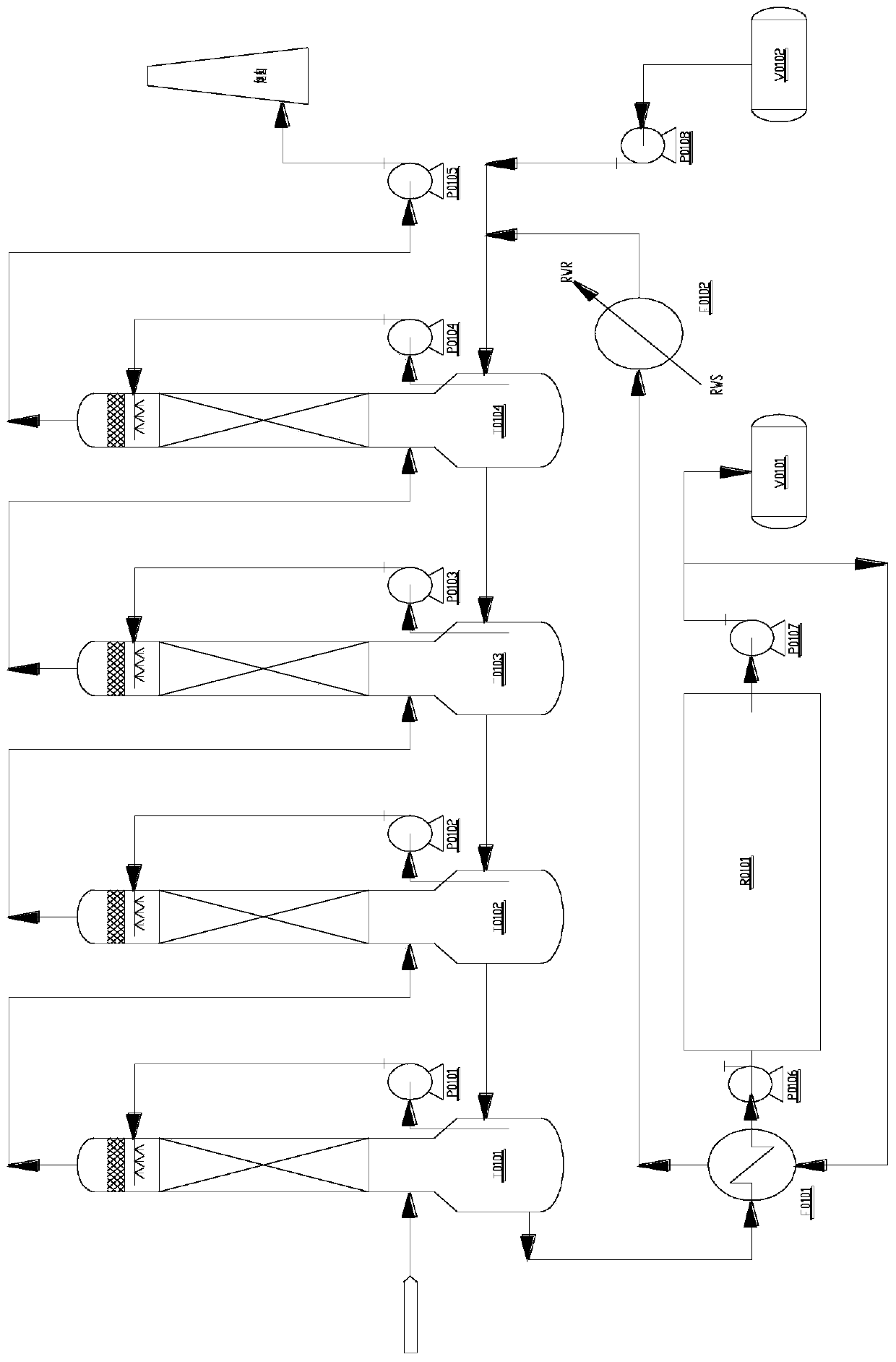

Ethylene oxide waste gas recycling treating system

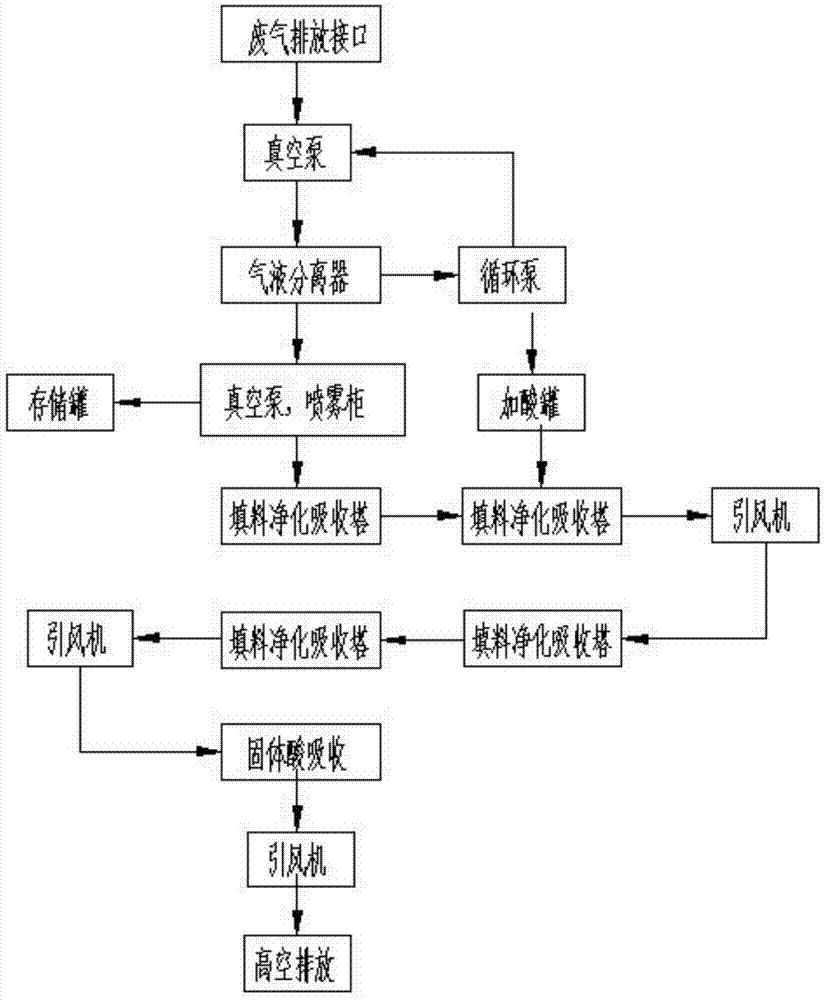

ActiveCN104275085AGood technical effectEmission reductionDispersed particle separationVapor–liquid separatorEthylene oxide

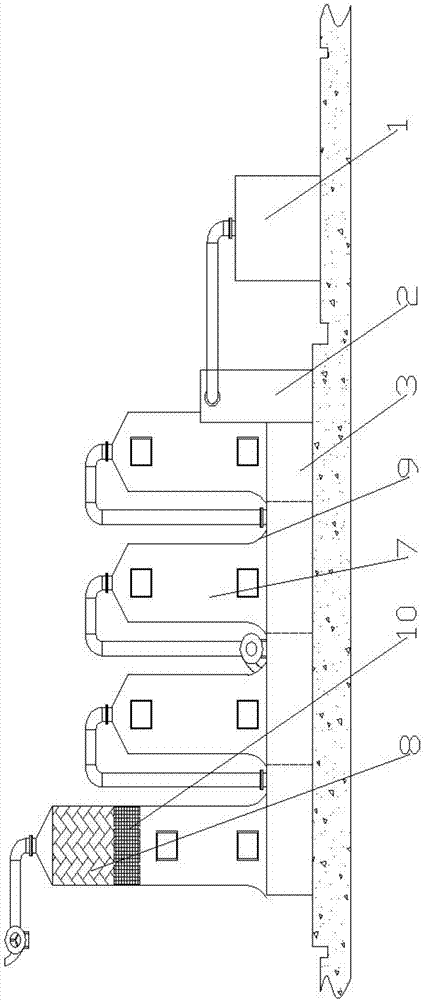

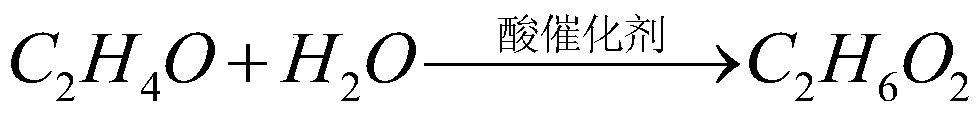

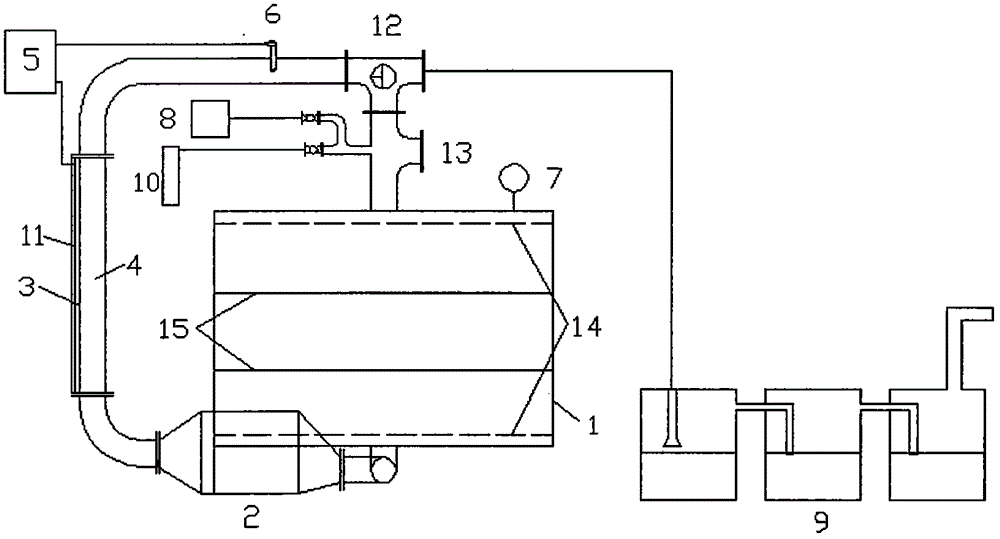

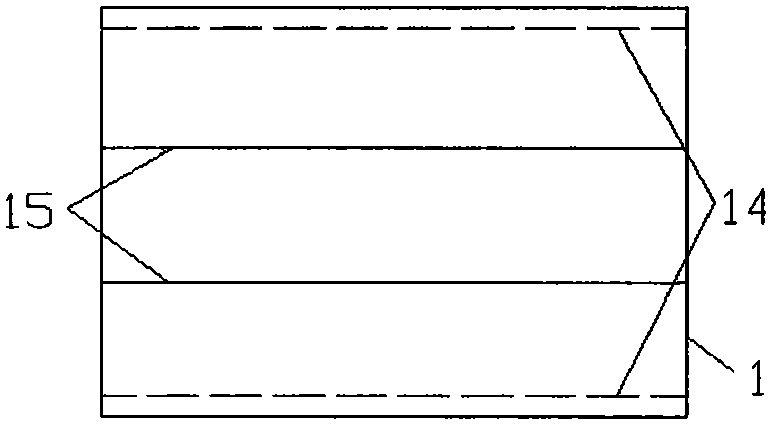

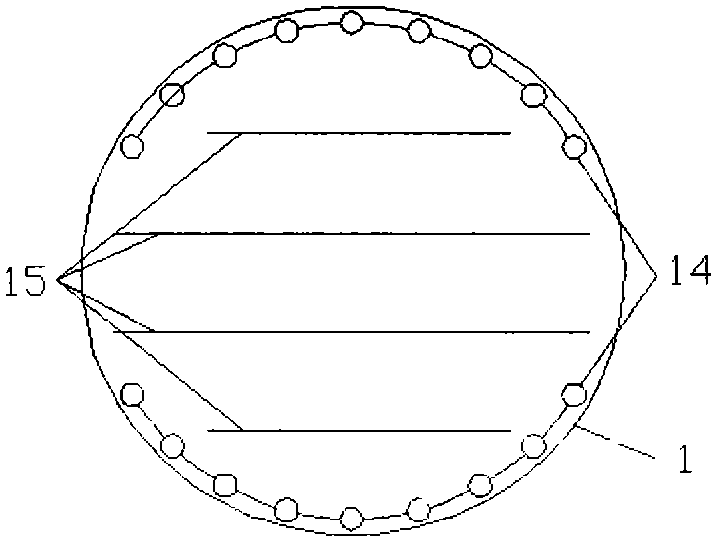

The invention relates to a waste gas treatment system and in particular relates to an ethylene oxide waste gas recycling treating system. The ethylene oxide waste gas recycling treating system comprises a gas-liquid separator (1), an atomizing cabinet (2) and a water collection tank (3) which are sequentially connected with one another by virtue of a pipeline, wherein N filler purifying absorbing towers (7) used for absorbing ethylene oxide are sequentially arranged inside the water collection tank (3); filler layers are arranged inside the filler purifying absorbing towers (7); pipelines connected with the water collection tank are arranged at the top ends of former N-1 filler purifying absorbing towers (7); an active carbon solid acid layer (8) is arranged at the upper part of the filter layer of the Nth filler purifying absorbing tower (7). According to the ethylene oxide waste gas recycling treating system, the ethylene oxide is cooled firstly and is in relatively well contact with water vapor, then ethylene glycol within a wide application range is generated by the ethylene oxide in a multistage absorbing tower, finally the ethylene oxide is adsorbed and converted again by active carbon solid acid, so that the emission amount of the ethylene oxide is minimized.

Owner:杭州竹影科技有限公司

Recycling method of ethylene oxide-containing organic waste gas

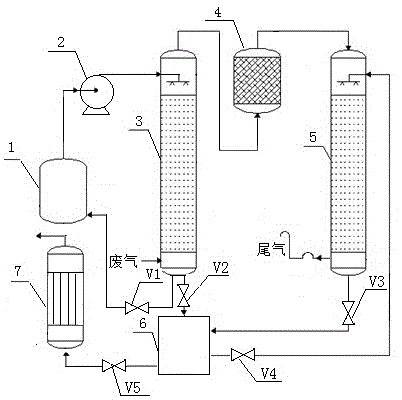

InactiveCN104815535AReduce contentReduce environmental disposal costsDispersed particle separationHydration reactionResource utilization

The present invention discloses a recycling method of ethylene oxide-containing organic waste gas. The specific technical scheme comprises that: ethylene oxide in ethylene oxide-containing organic waste gas is subjected to circulation absorbing in a hydrolysis tower by using dilute sulfuric acid with a certain concentration as an absorbent so as to produce a hydration reaction to generate ethylene glycol, the ethylene glycol is conveyed into an ethylene glycol solution storage tank after the ethylene glycol in the solution achieves a certain concentration, a sodium hydroxide solution is added to neutralize, one part of the neutralized ethylene glycol solution is used for the acid gas washing process, the other part is conveyed to the product separation and recovery, the tail gas discharged from the hydrolysis tower enters a reactor to carry out deep oxidation, an acid gas washing treatment is performed, the treated standard tail gas is discharged into the atmosphere, and the absorbing liquid is recycled to the ethylene glycol solution storage tank. According to the present invention, the method has characteristics of short process and simple operation, and with the treatment of the present invention, the ethylene oxide content in the organic waste gas tail gas does not exceed 1 ppm, and a certain amount of the ethylene glycol solution is recovered so as to achieve the resource utilization of the waste gas.

Owner:SHANXI DATONG UNIV

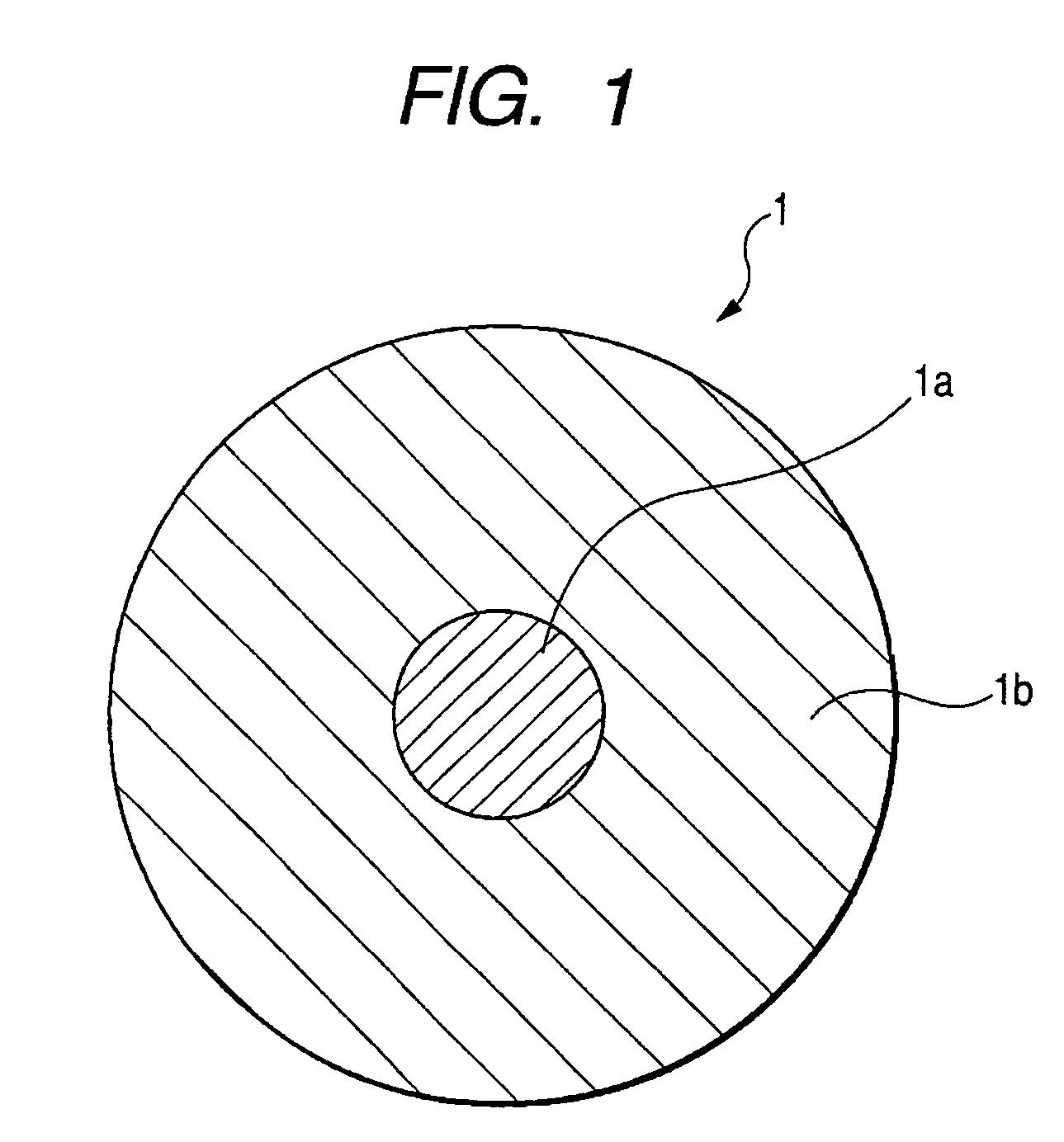

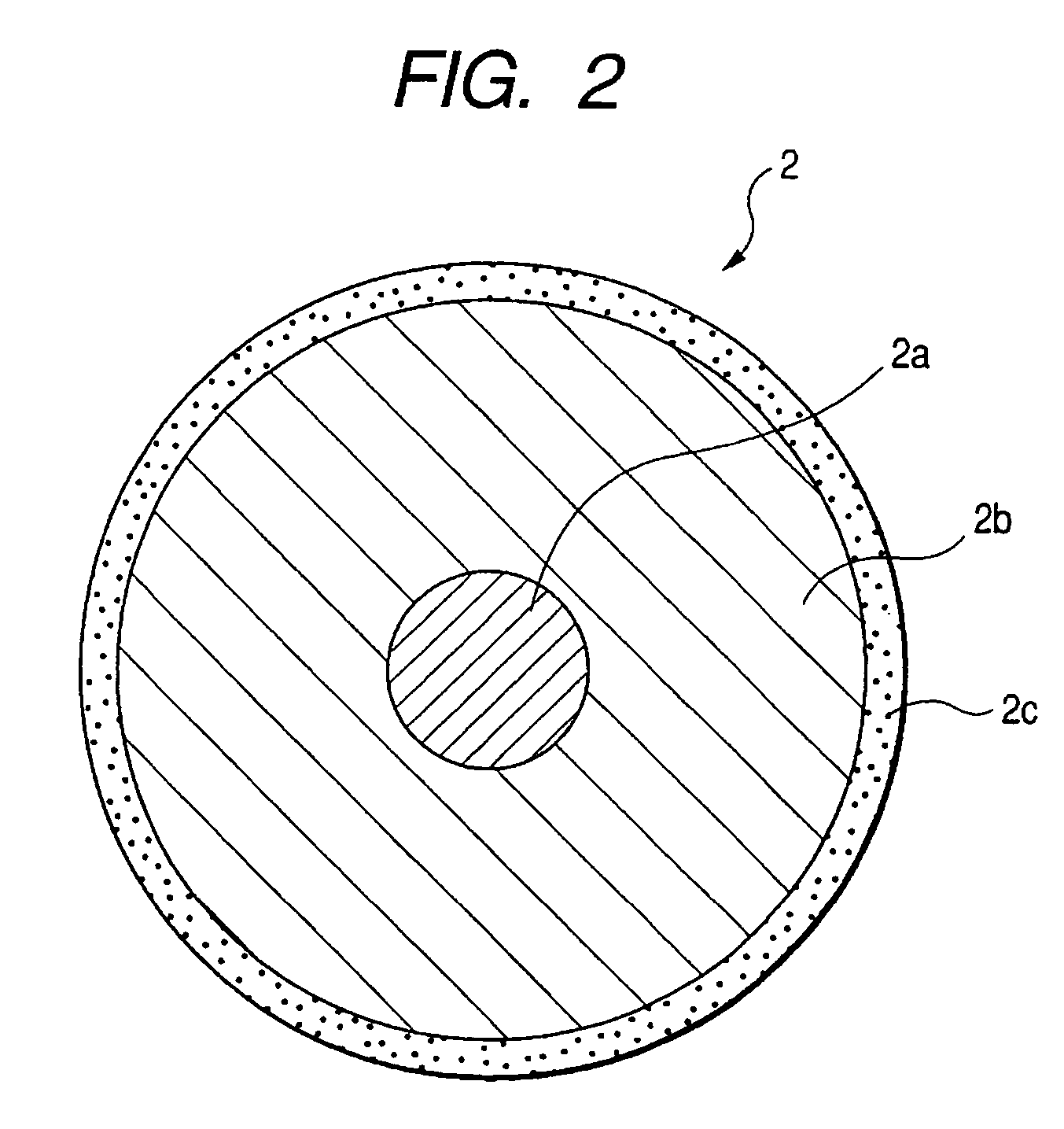

Electroconductive rubber roller

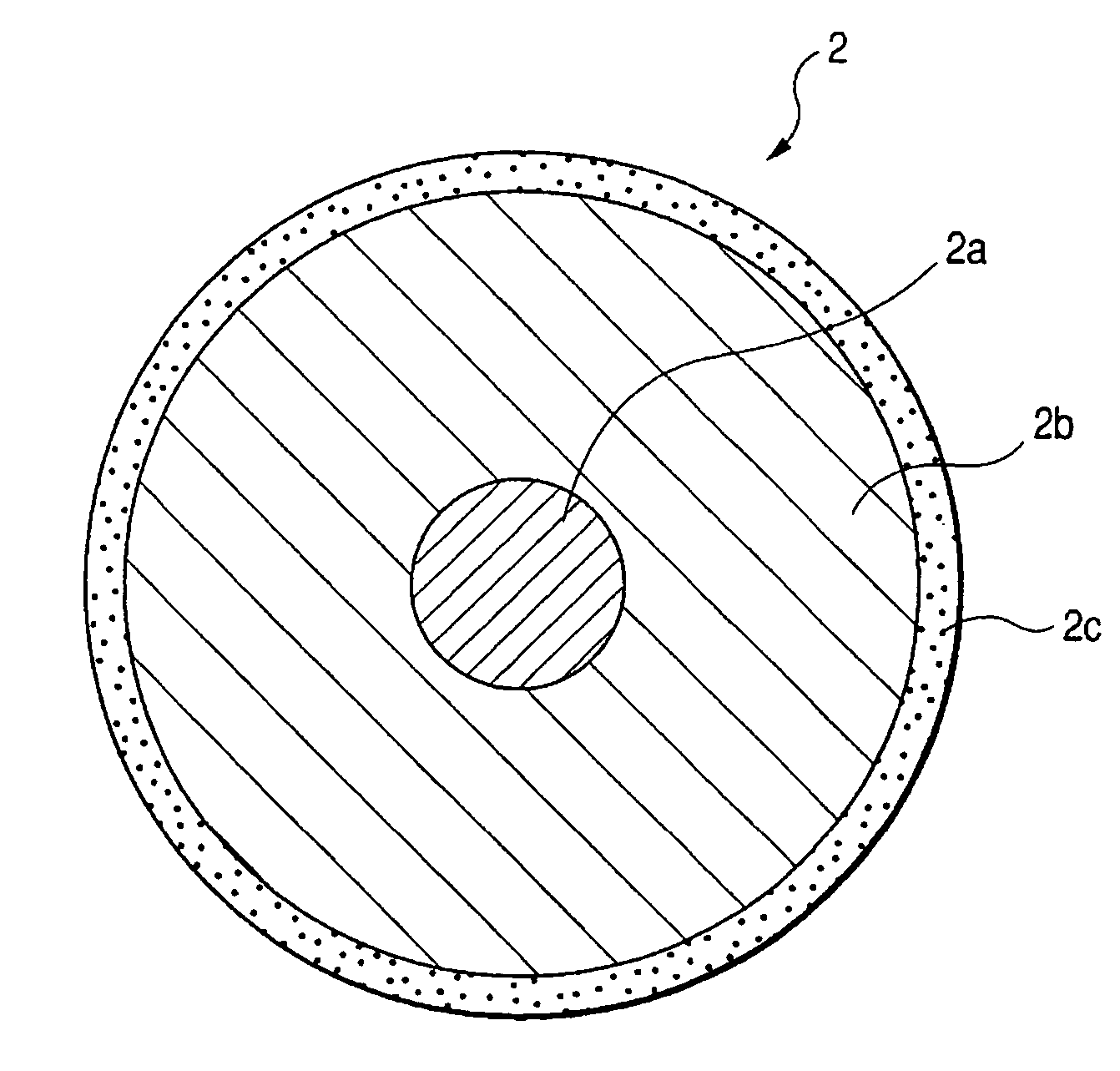

ActiveUS7544158B2Desirable electrical characteristicExcellent permanent compression strain resistanceShaft and bearingsPortable power-driven toolsPolymer scienceEthylene oxide

An electroconductive rubber roller constituted of an electroconductive metal core and an electroconductive crosslinked rubber layer including an epichlorohydrin-based rubber, wherein the epichlorohydrin-based rubber is at least one copolymer selected from the group consisting of an epichlorohydrin-ethylene oxide copolymer and an epichlorohydrin-ethylene oxide-allyl glycidyl ether ternary copolymer. The ethylene oxide unit in the epichlorohydrin-based rubber is in a content of 40 to 90 mol %, and, the electroconductive crosslinked rubber layer has a heat quantity (enthalpy: ΔH) 5 mJ / mg or less as measured by a differential scanning calorimetry (DSC) and indicated by a peak appearing within a range of −20 to 150° C.

Owner:CANON KK

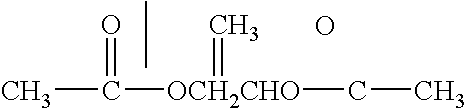

Saturated cardanol polyoxyethylene ether and preparation method thereof

The invention relates to saturated cardanol polyoxyethylene ether and a preparation method thereof, which belongs to the technical field of organic synthesis, and the structural formula of the saturated cardanol polyoxyethylene ether is as follows, wherein n=2-30. The preparation method comprises the following steps: performing a hydrogenation reaction of cardanol; performing filtration and distillation, and performing an addition reaction with ethylene oxide; adjusting the pH value, filtering, and performing reduced-pressure distillation; or performing an addition reaction of cardanol and ethylene oxide; adjusting the pH value, filtering, performing a hydrogenation reaction, filtering, and performing reduced-pressure distillation. The preparation method of the invention uses cardanol as a raw material, and prepares cardanol polyoxyethylene ether with different ethylene oxide adduct numbers and saturated side chains; the product does not contain mixed unsaturated double bond structures, has surface activity, and has stable using performance.

Owner:NORTHEASTERN UNIV

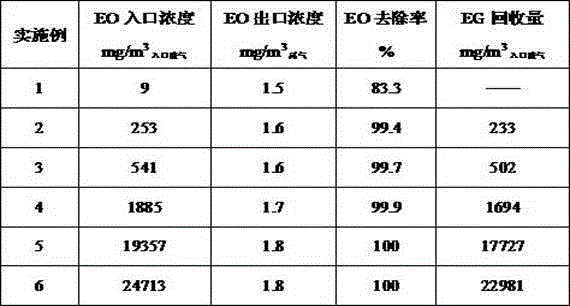

Ethylene oxide waste gas absorption coupling catalytic reaction purification device and process

InactiveCN110302634ANo emissionsSmall footprintGas treatmentOrganic compound preparationHigh concentrationResource utilization

The invention discloses an ethylene oxide waste gas absorption coupling catalytic reaction purification device and process. High-concentration ethylene oxide waste gas is absorbed by several-level absorption spray tower water, remaining waste gas is emitted on standard, ethylene oxide water solution collected by an absorption spray tower kettle enters a hydration reactor to perform ethylene oxidehydration reaction to generate high-concentration ethylene glycol, part of ethylene glycol water solution reflows into the tower kettle after reaction, clear water is added, the ethylene glycol watersolution continues to serve as ethylene oxide waste gas absorption solution to be used, and parts of reaction products returns to an ethylene glycol water solution storage tank to be recycled. According to the process, absorption and reaction are divided into two portions of an independent unit, the absorption efficiency of a whole process is high, operation processes are simple, energy consumption is low, resource utilization of the absorption solution is achieved, occupied area is small, operation is simple, integrated operating cost is low, safety is high, emission of waste liquid is omitted, and the process is applicable to control of ethylene oxide waste gas of various large and small sterilization enterprises.

Owner:ZHEJIANG UNIV OF TECH

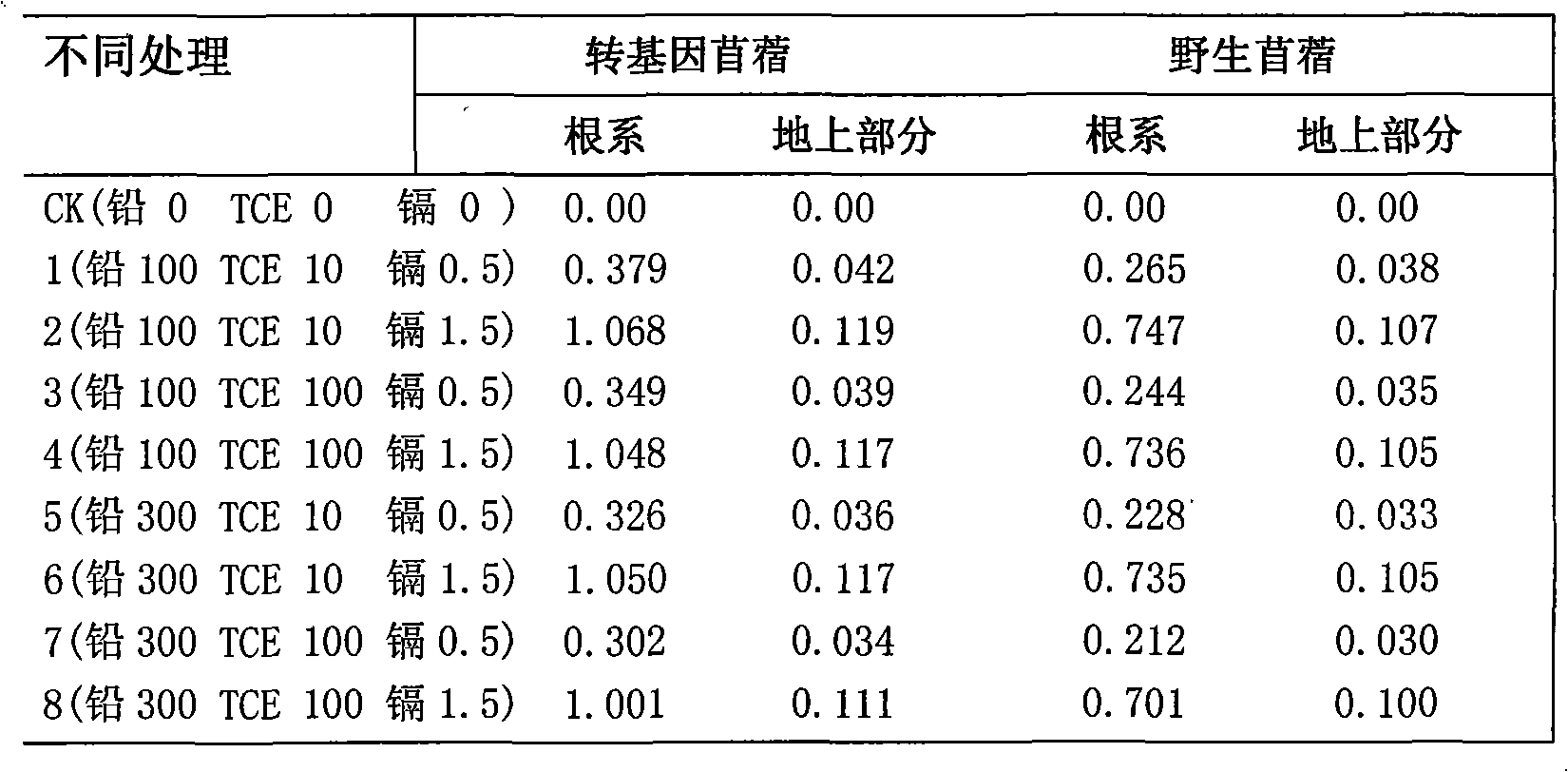

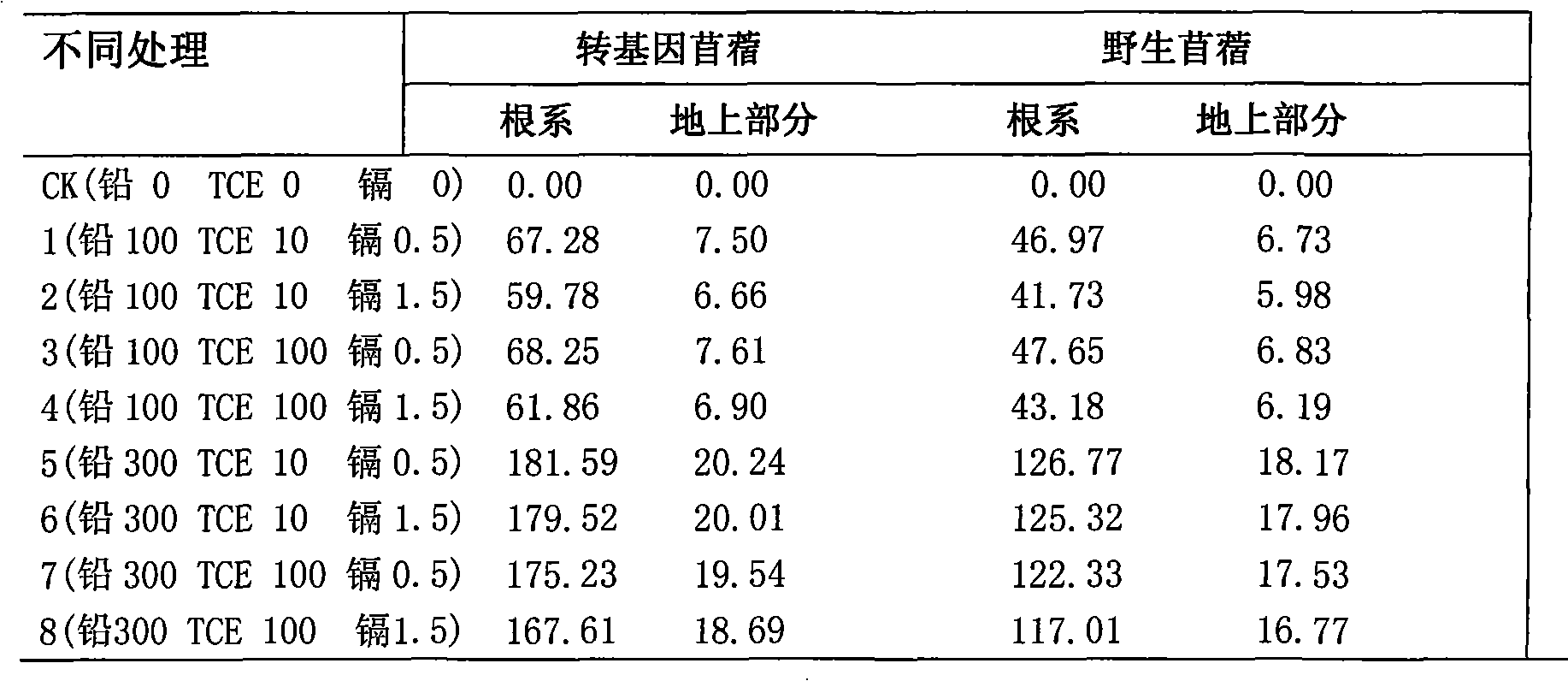

Method for repairing heavy metal and organic compound contaminated soil using transgenic plant

InactiveCN101310882AImprove toleranceImprove accumulation abilityContaminated soil reclamationFermentationHalohydrocarbonGenetically engineered

The invention discloses a method for restoring soil compositely polluted by heavy metals and organics by using a transgenic plant and is technically characterized in that foreign genes which can strengthen the efficiency for restoring the organic pollution of the plant and foreign genes which can improve the tolerance and the accumulation to a plurality of metals of the plant are introduced to the plant so as to establish a transgenic plant which has a better restoring effect on the pollution by the heavy metals and the organics. The method of the invention has a better restoring effect on the polluted soil of the three types as follows: (1) the soil polluted by organic pollutants of halohydrocarbon compounds such as trichloroethylene, dibromethane, and the like; (2) the soil polluted by various heavy metals such as Cd, Cr, Cu, Mn, Zn and Pb; (3) the soil compositely polluted by the heavy metals and the organics. In addition, the method of the invention comprises the procedures of establishing the transgenic plant, the screening and cultivation of light-demanding plants and the restoring of polluted soil by the transgenic plant. The method of the invention has broad application prospect in the restoring of the soil compositely polluted by the heavy metals and the organics.

Owner:QINGDAO UNIV OF SCI & TECH

Paraffin emulsifier and its making method

InactiveCN1570038AGood water solubilityImprove stabilityWax physical treatmentTransportation and packagingParaffin waxEthylene oxide

Owner:杨建军

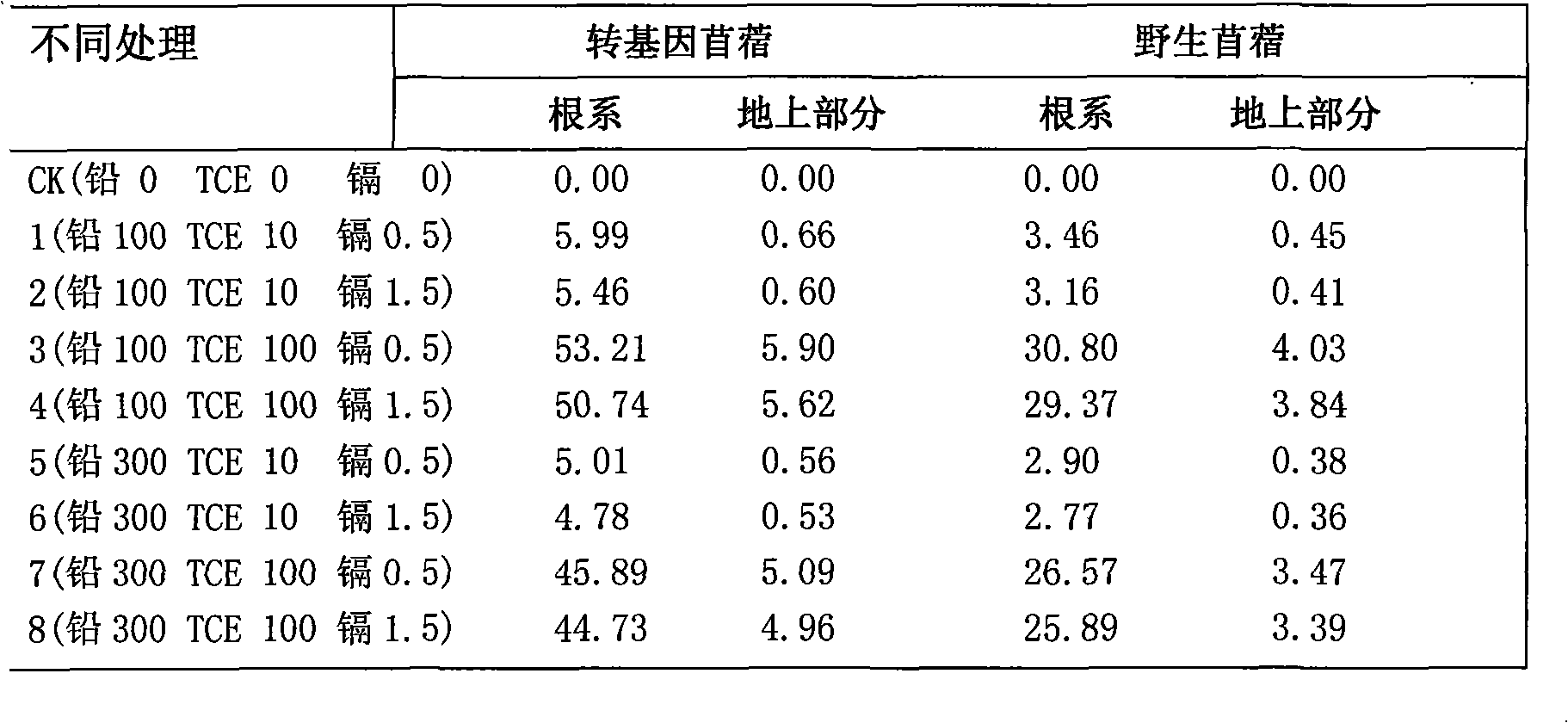

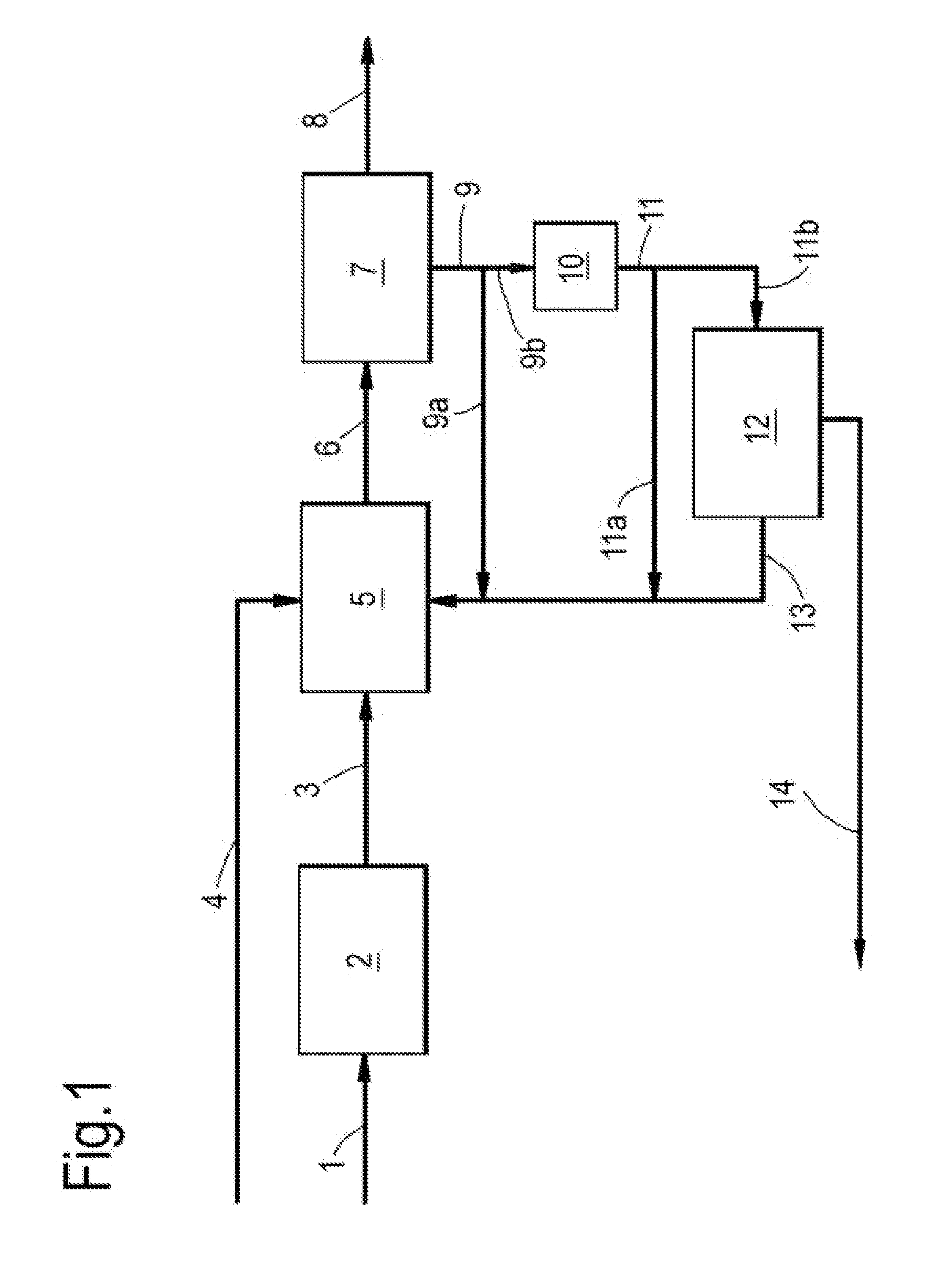

Production method for preparing propylene (ethylene) carbonate from carbon dioxide and propylene oxide (ethylene oxide) through tubular reaction

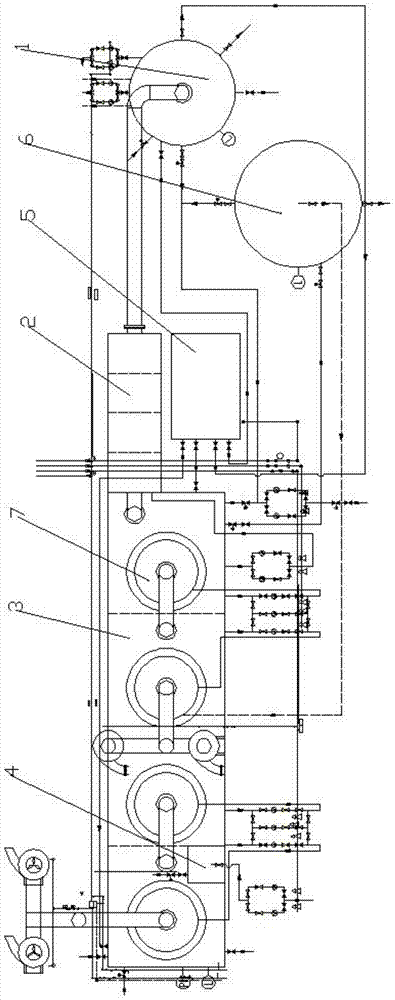

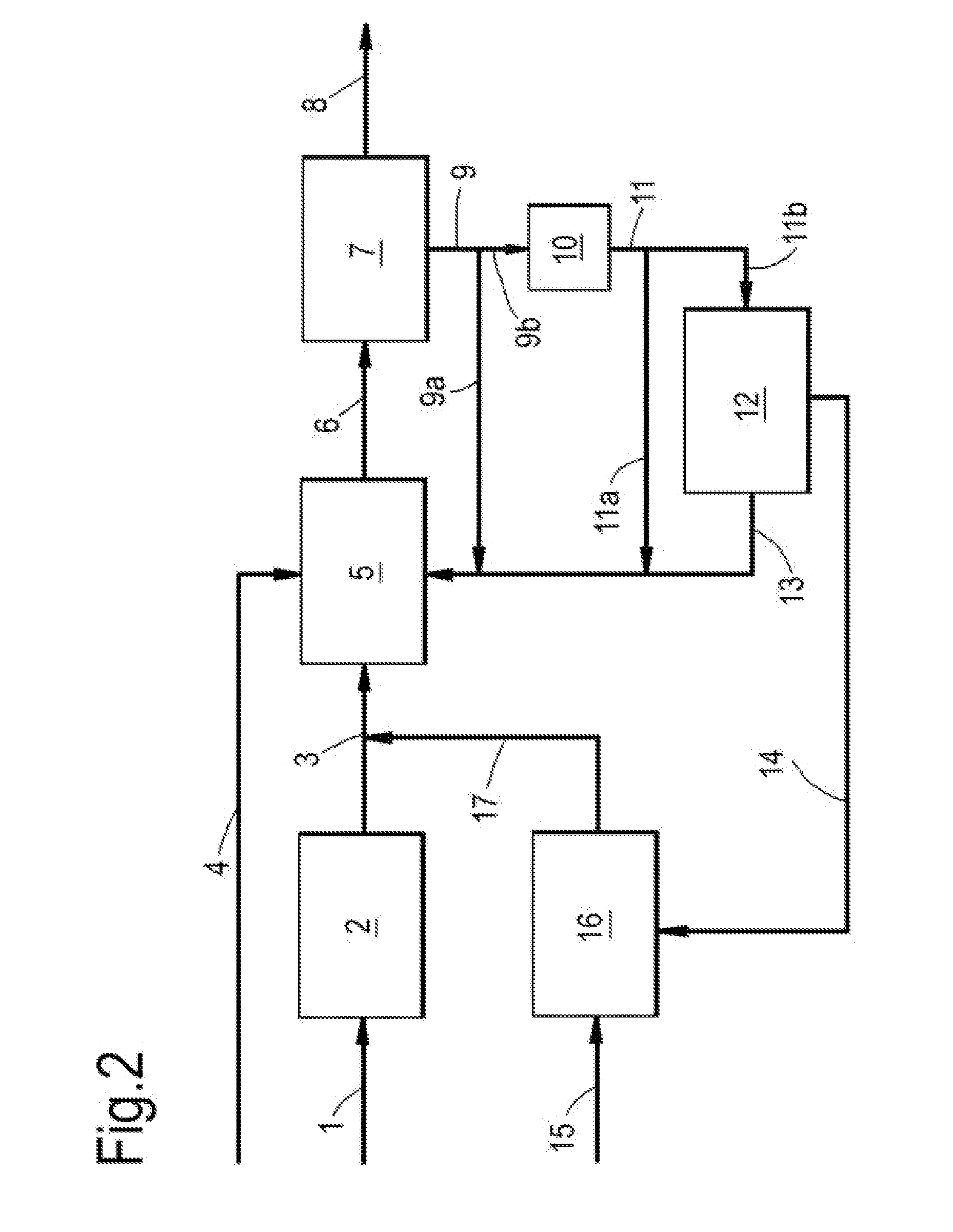

ActiveCN103980246ASimple processLess investmentProductsOrganic chemistryVapor–liquid separatorEthylene Dibromide

The invention discloses a production method for preparing propylene (ethylene) carbonate from carbon dioxide and propylene oxide (ethylene oxide) through tubular reaction. The production method comprises the following steps: feeding a catalyst and propylene oxide (ethylene oxide) mixture liquid and carbon dioxide dispersed in circulating propylene (ethylene) carbonate into a tubular propylene (ethylene) carbonate synthesis reactor (3) in parallel, and mixing to react when flowing; taking out the reaction heat by using an outer jacket of the tubular propylene (ethylene) carbonate synthesis reactor (3); adjusting the amount of a cooling medium inside different tube sections of the tubular propylene (ethylene) carbonate synthesis reactor (3) to obtain appropriate reactor axial temperature distribution; feeding crude propylene (ethylene) carbonate discharged from the tubular propylene (ethylene) carbonate synthesis reactor (3) into a gas-liquid separator (4), releasing excessive carbon dioxide, and subsequently feeding into a propylene (ethylene) carbonate separation and refining device (5), thereby obtaining a product, that is, propylene (ethylene) carbonate. The production method is excellent in mass transfer and heat conduction effect, the reaction heat can be removed in time, and the production process is stable, easy to control and convenient to operate.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

Process for the removal of ethylene oxide from air

A process for removal of ethylene oxide (EO) from ambient air laden with EO is passed through a zeolite-based removal media, which preferrably consists of the acid form of zeolite ZSM-5, herein referred to as “H-ZSM-5.” The process described herein may be applied to many forms, configurations and uses, such as, for example, gas masks, fume hood ventilation filters, cartridge filters, etc. Preferably, the H-ZSM-5 is configured within an apparatus in such a manner that the stream containing EO is brought into sufficient contact with the zeolite to remove the EO from the airstream.

Owner:GUILD ASSOCS

Method and device for quickly desorbing ethylene oxide

InactiveCN106139199ASecurity analysisParsing fastLavatory sanitoryChemicalsTemperature controlEthylene oxide

The invention discloses a method and device for quickly desorbing ethylene oxide. An indirect heating method is adopted, the temperature is controlled to be 15 DEG C to 80 DEG C, and cylic heating and vacuumizing on inert gas in the device are alternately conducted. The device is mainly formed by connecting a desorbing cabinet, a heater, a heat conduction pipe, a circulating fan, a temperature measuring controller, a three-way valve and an exhaust gas treatment device through pipelines; work of the heater is controlled by the temperature controller and linked with work of the circulating fan, a gas distributor is installed in the desorbing cabinet, desorbed gas is treated by the exhaust gas treatment device and then exhausted, and therefore the purpose of quickly and safely desorbing ethylene oxide is achieved.

Owner:NATONG HORCO N MEDICAL TECH CO LTD

Medicinal collagen material and its making process

InactiveCN1463984AStable molecular structureGood anti-leakage performanceConnective tissue peptidesPeptide/protein ingredientsEthylene Oxide SterilizationSpinal dura mater

The medical collagen material is made through the processes of chondroitin sulfate crosslinking, high temperature vacuum drying and ethylene oxide. Is has stable molecule structure and better anti-seepage and anti-stick performance, and is used in repairing cerebral dura mater, spinal dura mater and peripheral nerve.

Owner:于海鹰 +1

Process for the production of ethylene oxide

InactiveUS9260366B2Simple processLess equipmentOrganic compound preparationHydrocarbon from oxygen organic compoundsPolymer scienceEthylene oxide

The invention relates to a process for the production of ethylene oxide, comprising the steps of: producing ethylene by converting a stream comprising an oxygenate into a stream comprising ethylene and ethane; producing ethylene oxide by subjecting ethylene and ethane from the stream comprising ethylene and ethane to oxidation conditions resulting in a stream comprising ethylene oxide, unconverted ethylene and ethane; and recovering ethylene oxide from the stream comprising ethylene oxide, unconverted ethylene and ethane.

Owner:SHELL OIL CO

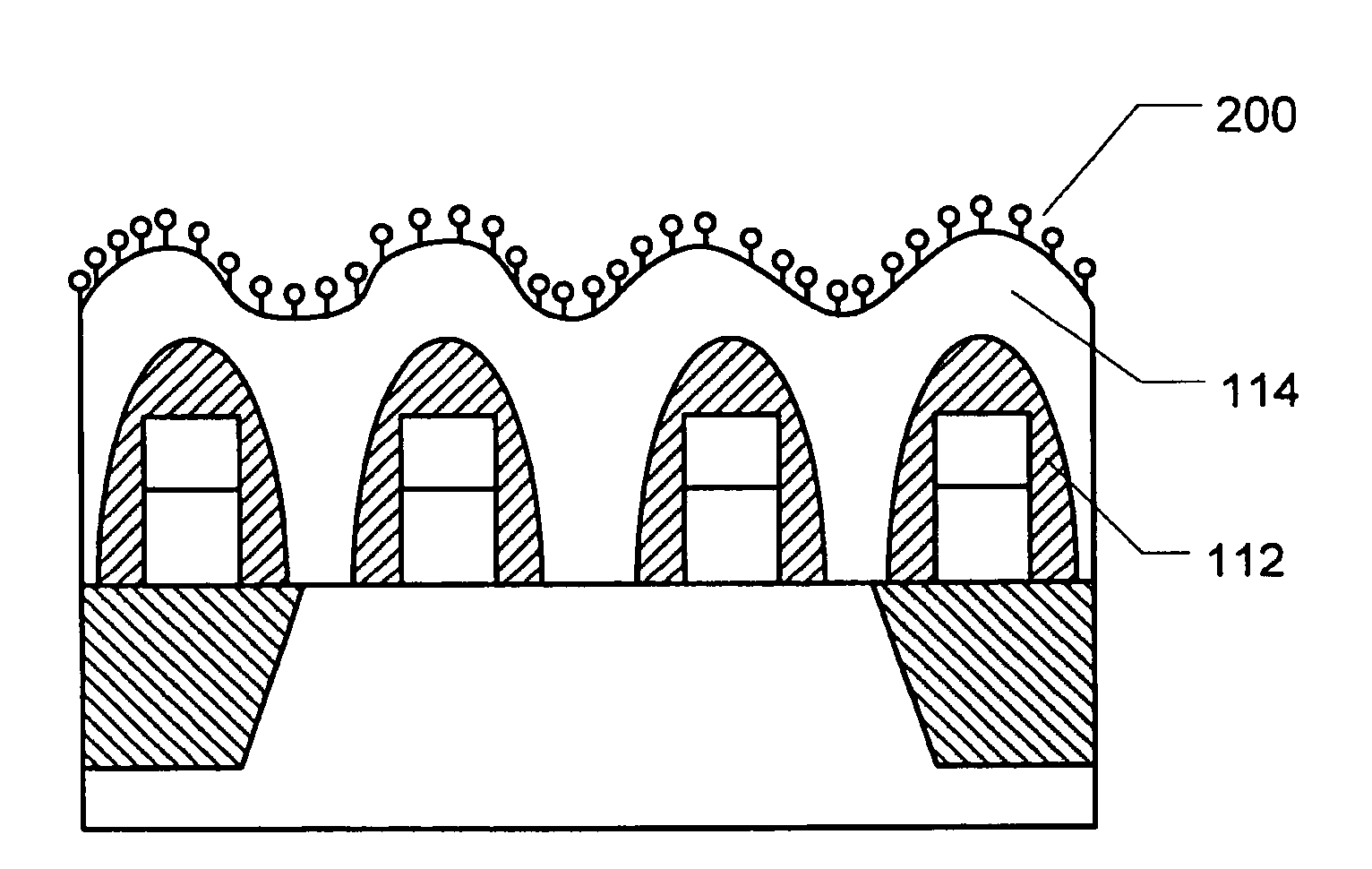

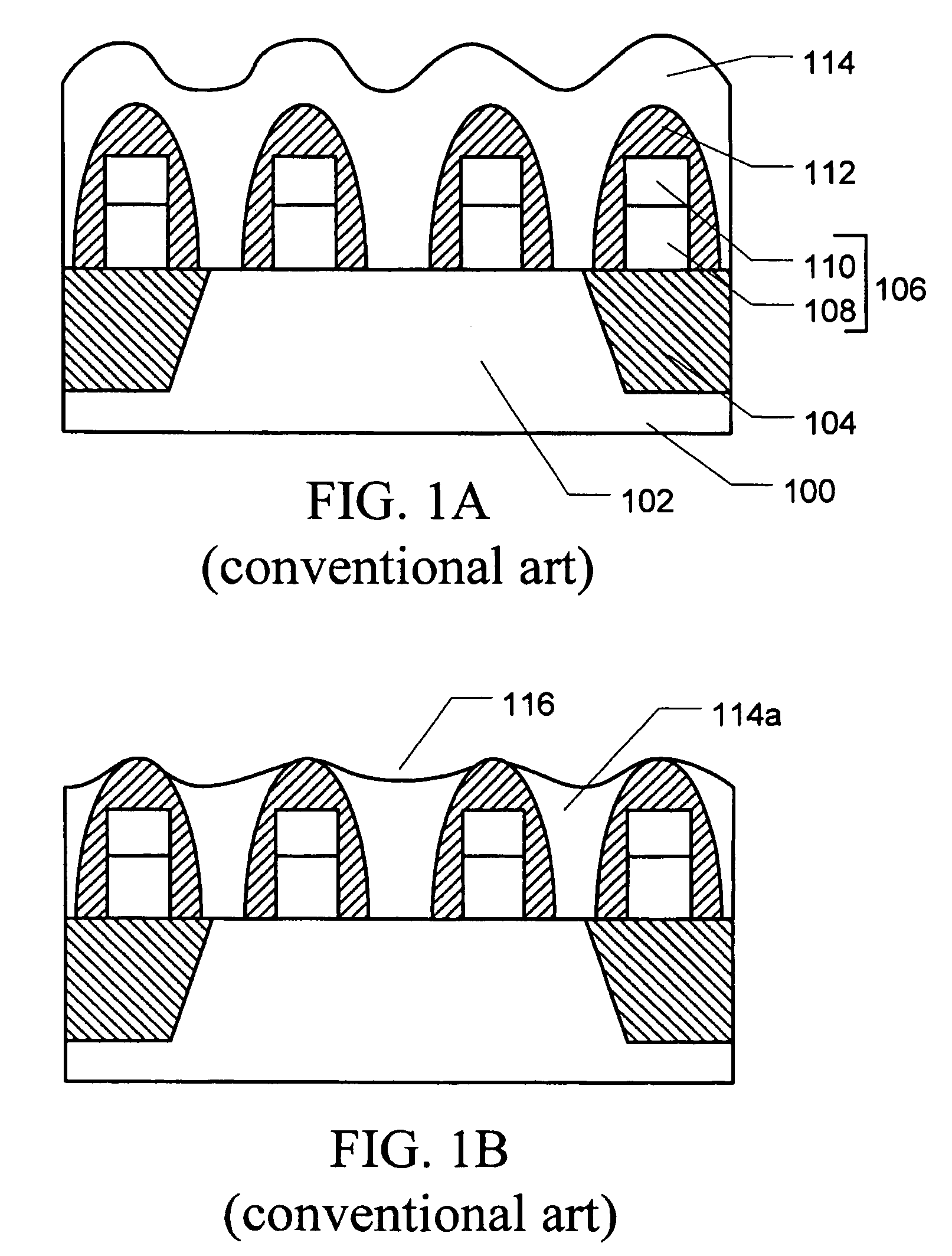

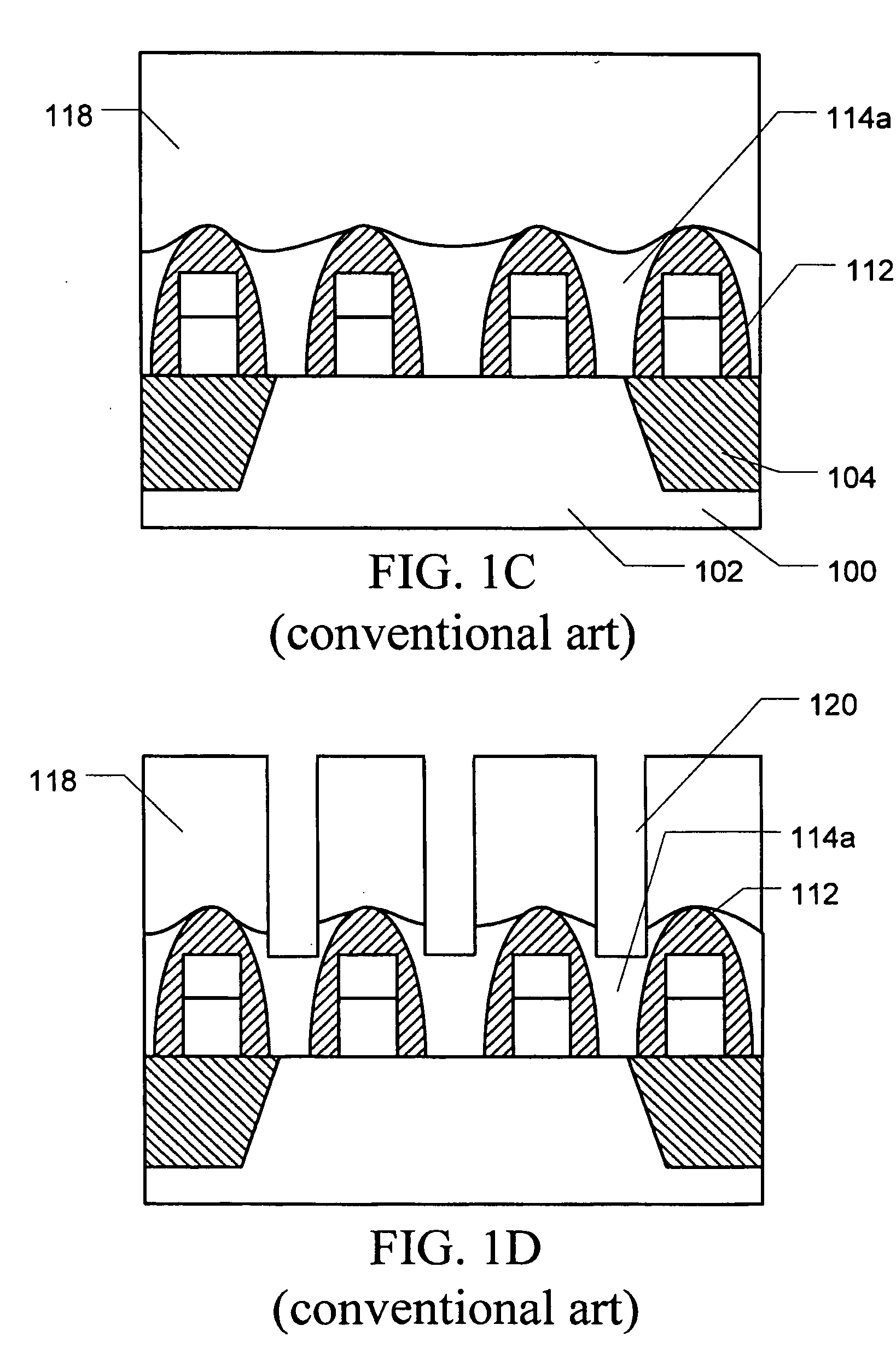

Slurry compositions and CMP methods using the same

InactiveUS7314578B2Reduce and eliminate excessive removalOther chemical processesSemiconductor/solid-state device manufacturingSilicon oxideSlurry

The exemplary embodiments of the present invention providing new slurry compositions suitable for use in processes involving the chemical mechanical polishing (CMP) of a polysilicon layer. The slurry compositions include one or more non-ionic polymeric surfactants that will selectively form a passivation layer on an exposed polysilicon surface in order to suppress the polysilicon removal rate relative to silicon oxide and silicon nitride and improve the planarity of the polished substrate. Exemplary surfactants include alkyl and aryl alcohols of ethylene oxide (EO) and propylene oxide (PO) block copolymers and may be present in the slurry compositions in an amount of up to about 5 wt %, although much smaller concentrations may be effective. Other slurry additives may include viscosity modifiers, pH modifiers, dispersion agents, chelating agents, and amine or imine surfactants suitable for modifying the relative removal rates of silicon nitride and silicon oxide.

Owner:SAMSUNG ELECTRONICS CO LTD

Ethylene oxide waste gas treatment and energy recovery system

ActiveCN106861388AFully dispersedIncrease contact areaGas treatmentDispersed particle separationLiquid wasteAutomatic control

The invention relates to an ethylene oxide waste gas treatment and energy recovery system. The system comprises an EO tail gas generating device, a tail gas absorbing device and an energy recycling device, wherein the tail gas absorbing device comprises a water ring type vacuum pump, a steam-water separator, a water storage tank, a plurality of combined type ethylene glycol reaction tanks and a combined type spraying tower; the energy recycling device comprises a waste liquid combustion spiral tube heat exchanger, a plurality of gas-water heat exchangers, a plurality of combined type air energy heat pumps, an activated carbon adsorption box and an induced draft fan, the waste liquid combustion spiral tube heat exchanger comprises a combustion tank, a waste liquid spraying device, a combustion-supporting gas jetting device and a compressed air jetting device. According to the invention, the waste liquid of ethylene glycol treated by the tail gas absorbing device and the ethylene oxide gas which is not absorbed by water are combusted, through automatic control, full combustion is guaranteed, and the ethylene oxide, ethylene glycol and other organic matters are completely converted into water and carbon dioxide to realize the zero emission of ethylene oxide, at the same time, a plurality of groups of heat exchangers are arranged, and the combusted energy is subjected to heat exchange application.

Owner:杭州博控机电设备有限公司

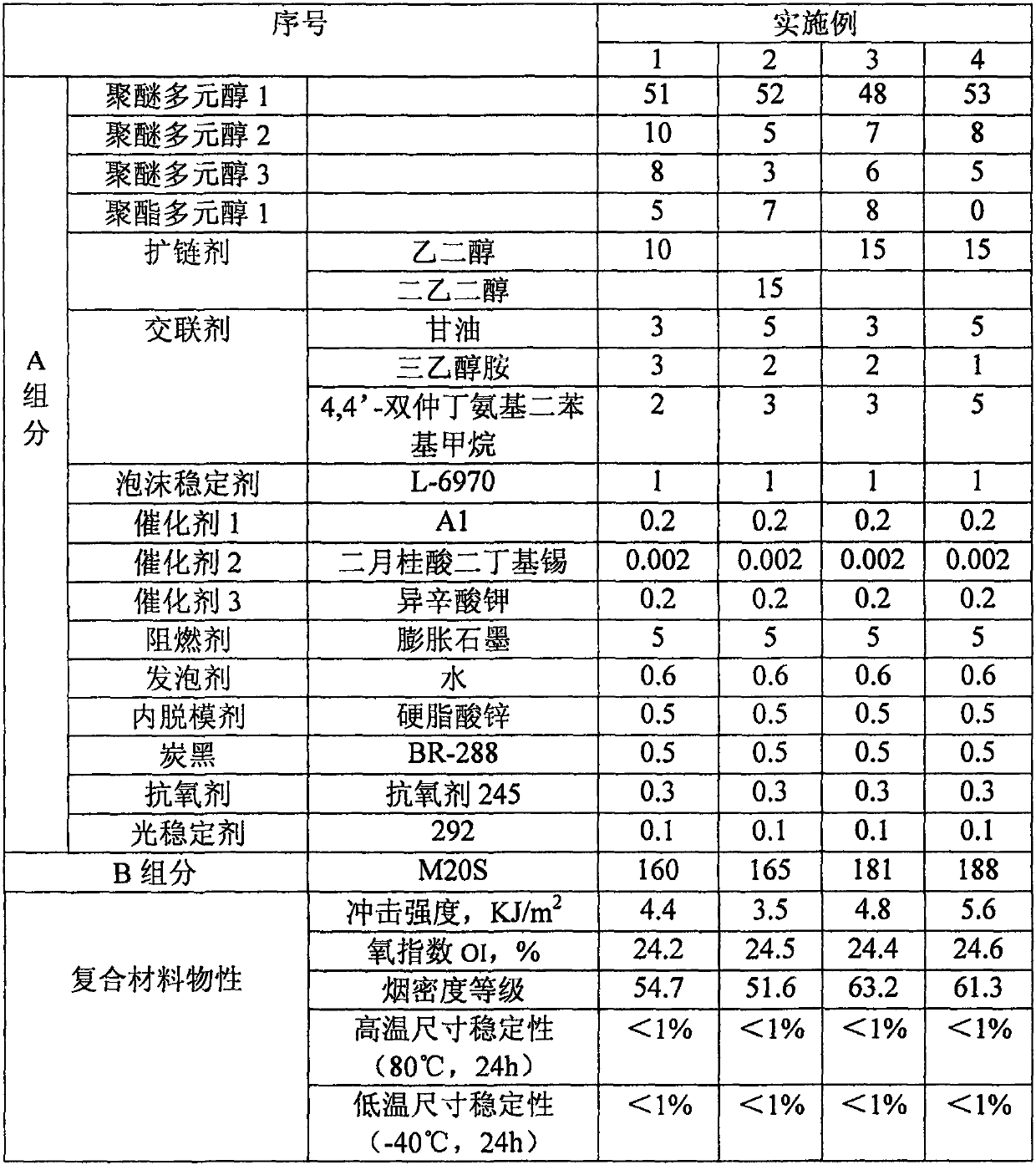

Polyurethane composition for glass fiber reinforced honeycomb sandwich panels and application method of polyurethane composition

The invention discloses a polyurethane composition for glass fiber reinforced honeycomb sandwich panels and an application method of the polyurethane composition. The polyurethane composition comprises a component A and a component B; the component A comprises 40-70% of polyether polyol 1, 5-10% of polyether polyol 2, 5-10% of polyether polyol 3, 0-10% of polyester polyol 1, 4-10% of crosslinkingagents, 5-15% of chain extenders, 0.2-2% of foam stabilizers, 0.2-1.5% of catalysts, 5-10% of flame retardants, 0.2-1% of water, 0.2-2% of internal releasing agents and 0.2-1% of other additive; the component B comprises polyaryl polymethylene isocyanate; the polyether polyol 1 is prepared by taking D-glucitol as an initiator and alkali metal hydroxide as a catalyst, performing anionic polymerization on 1,2-propylene oxide and adding ethylene oxide for terminating; the polyether polyol 2 is propylene oxide polyether polyol with the functionality being 2, and is prepared by taking bisphenol A as an initiator; the polyether polyol 3 is prepared by taking glycerol as an initiator and is terminated by ethylene oxide; the polyester polyol 1 is obtained by polycondensation reaction between terephthalic acid and ethylene glycol.

Owner:LIMING RES INST OF CHEM IND

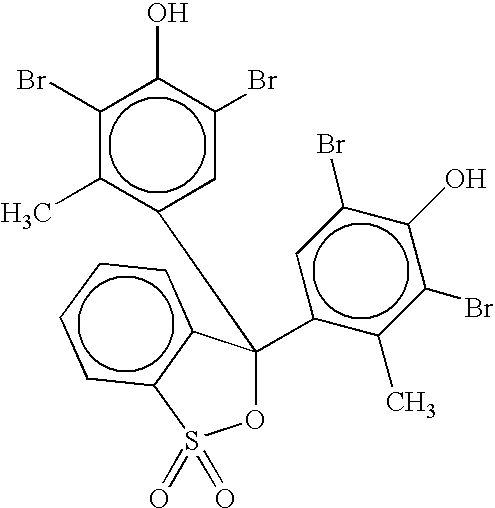

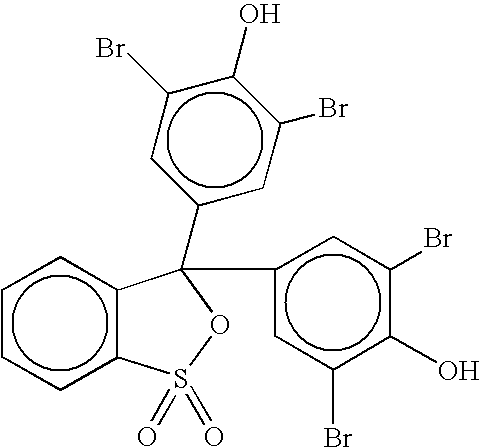

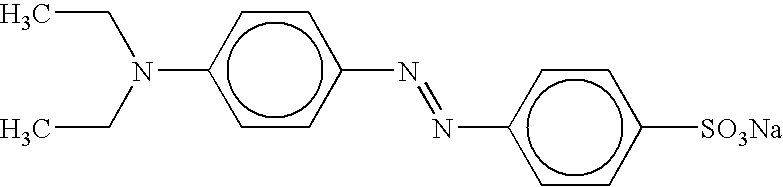

Ethylene oxide sterilization process indicator inks

Water-based chemical indicator inks for ethylene oxide sterilization processes and methods for its use. The chemical indicator ink contains at least one pH indicator dye selected from the group consisting of Bromocresol green, Bromophenol blue, Methyl red, Ethyl orange, and combinations thereof. The pH indicator dye undergoes an irreversible color change when exposed to ethylene oxide vapor in the presence of low-temperature steam, but when exposed to other sterilization processes either does not undergo a color change or undergoes a color change that is different than is obtained when exposed to ethylene oxide.

Owner:LA CO IND INC

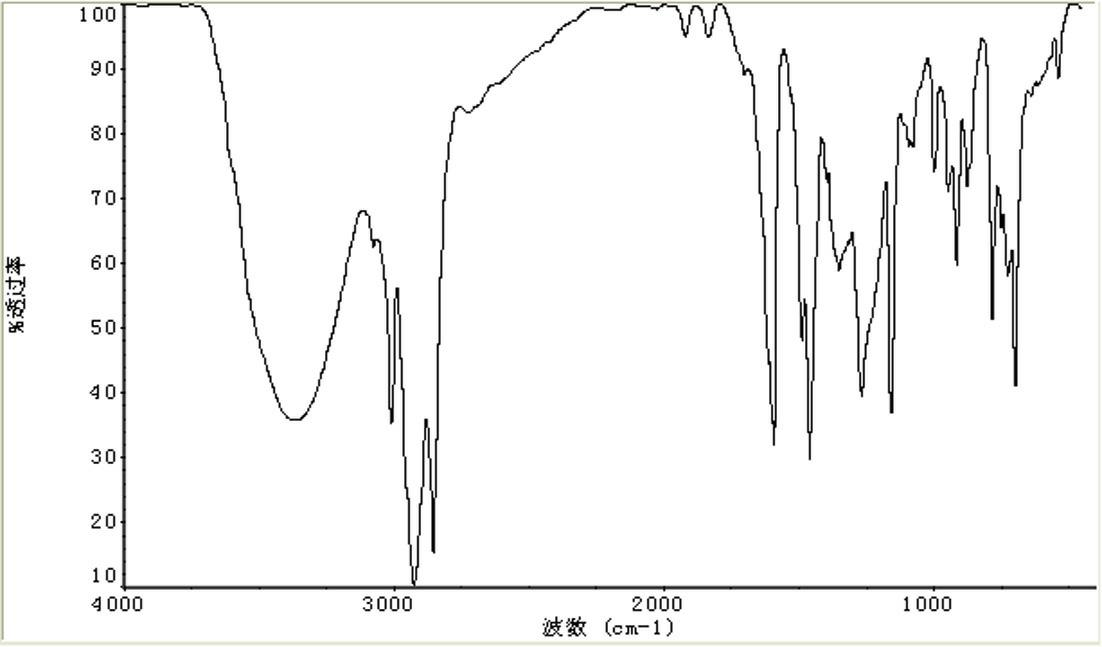

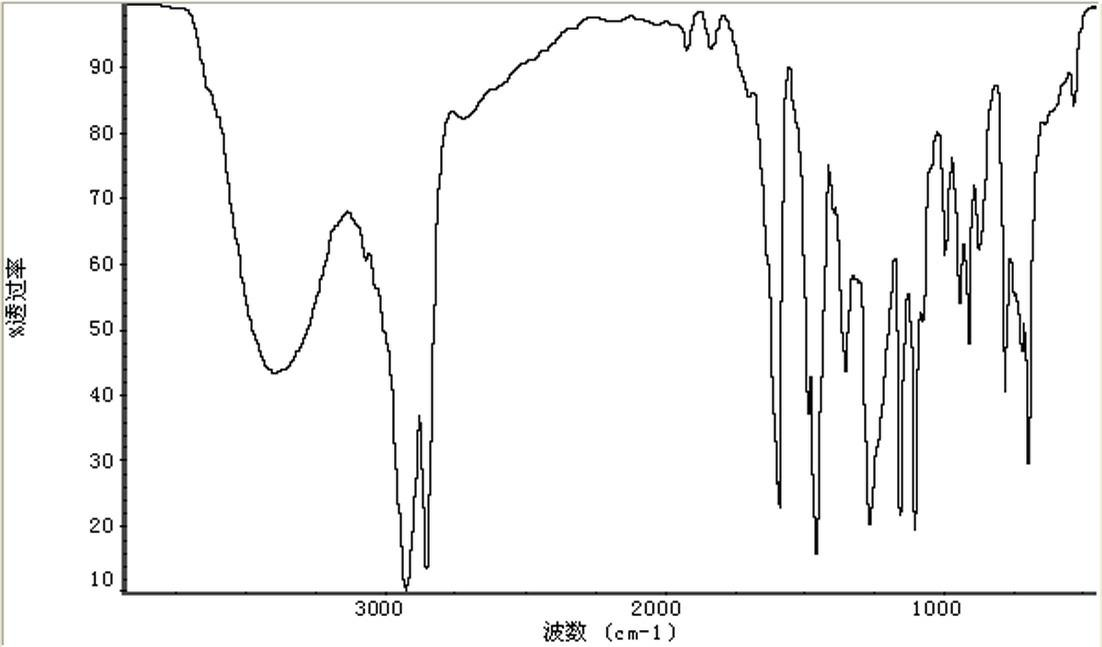

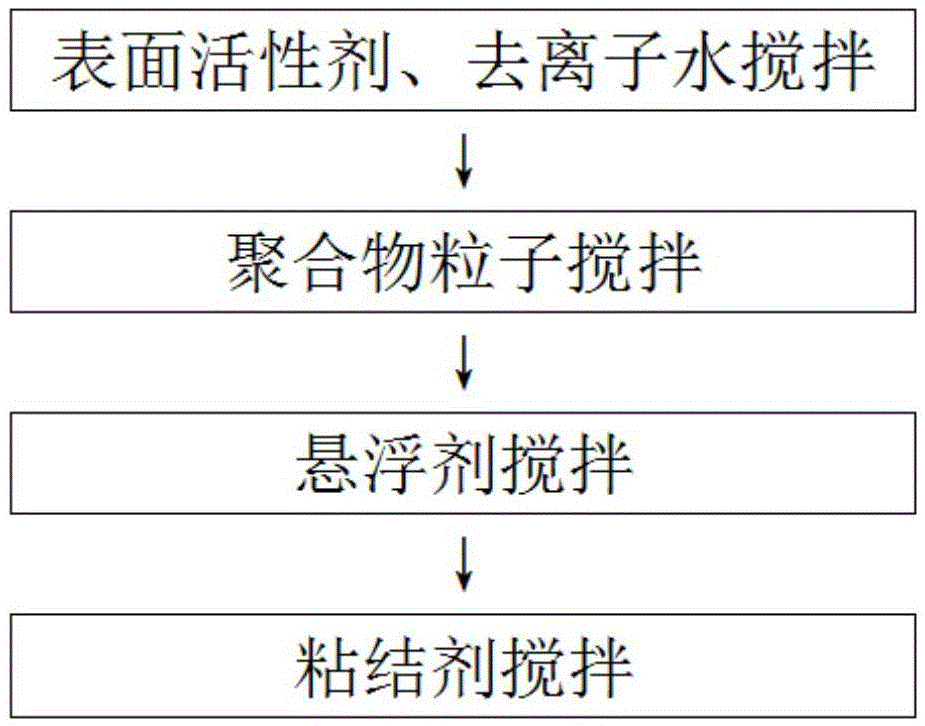

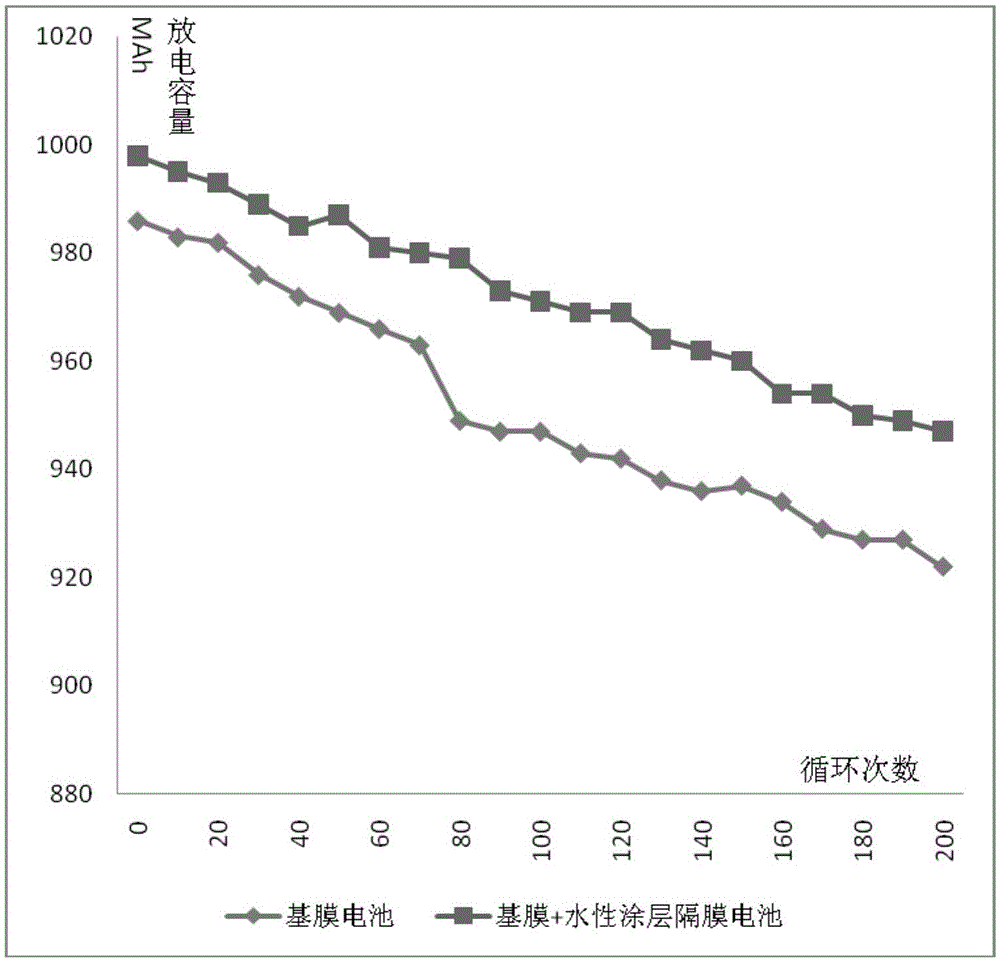

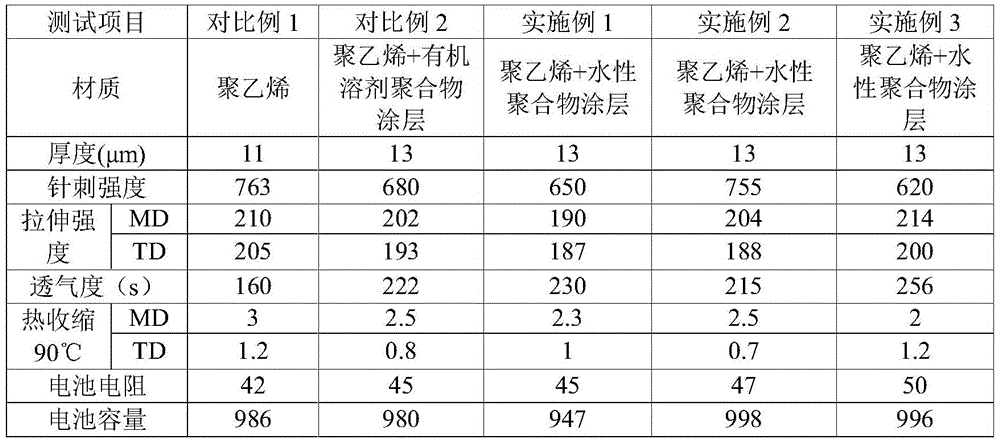

Composite membrane with polymer coating and preparation method of composite membrane

ActiveCN105576175AHigh densityImprove product qualityCell seperators/membranes/diaphragms/spacersWater basedSlurry

The invention discloses a composite membrane with a polymer coating and a preparation method of the composite membrane. According to the preparation method, water-based slurry coats one or two surfaces of a base membrane to form the polymer coating; with deionized water as a solvent, polymer particles, a surfactant and an aqueous adhesive are dispersed into the deionized water to form the water-based slurry; the water-based slurry also contains a suspending agent; the amount of the suspending agent is 3%-25% of total weight of the water-based slurry; and the suspending agent is at least one of potassium chloride, sodium chloride, dichloroacetic acid, ethylene dibromide, 3-bromopyridine, 4,5-dichloro 1,3-dioxolame-2-ketone, dichloroethane, dichloroethylene and 1,3-butanediol sulfite. According to the preparation method, the suspending agent is added to the water-based slurry; the solvent density is improved; and the polymer particles can be evenly dispersed into the deionized water to form the stable water-based slurry, so that the production quality of the composite membrane with the polymer coating is improved; and a basis is laid for preparation of a high-quality lithium-ion battery.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

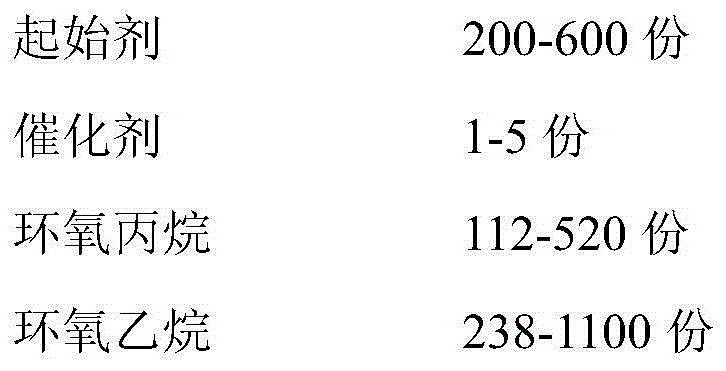

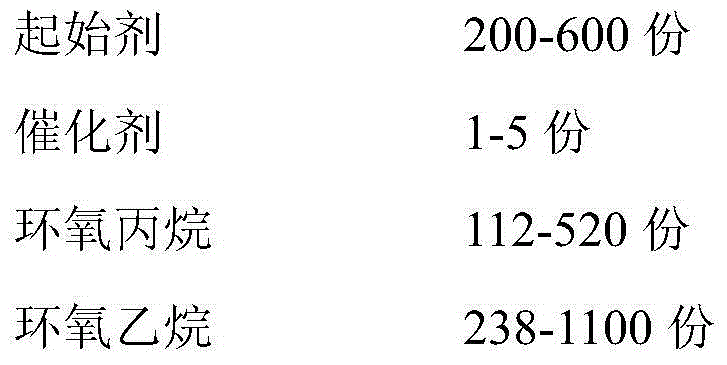

Antioxidant polyether polyol and preparation method thereof

The invention belongs to the technical field of synthesis of polyether and particularly relates to antioxidant polyether polyol and a preparation method thereof. The antioxidant polyether polyol is prepared from the following raw materials in parts by weight: 200-600 parts of an initiator, 1-5 parts of a catalyst, 112-520 parts of propylene oxide and 238-1100 parts of ethylene oxide, wherein the initiator is o-phenylenediamine and sorbitol. The preparation method comprises the following steps: dissolving the initiator and the catalyst until a homogeneous phase is formed, displacing, heating, dropwise adding propylene oxide and ethylene oxide and reacting to obtain crude polyether polyol; washing crude polyether with water, neutralizing, adsorbing, drying and filtering to obtain the finished product, namely, polyether polyol. The polyether polyol prepared by the preparation method disclosed by the invention has good antioxidant effect, the amount of the antioxidant is reduced, the production steps are simplified, the benefits are increased and the range of source of raw materials is wide; the preparation method is scientific, reasonable, simple and feasible.

Owner:ZIBO DEXIN LIANBANG CHEM IND

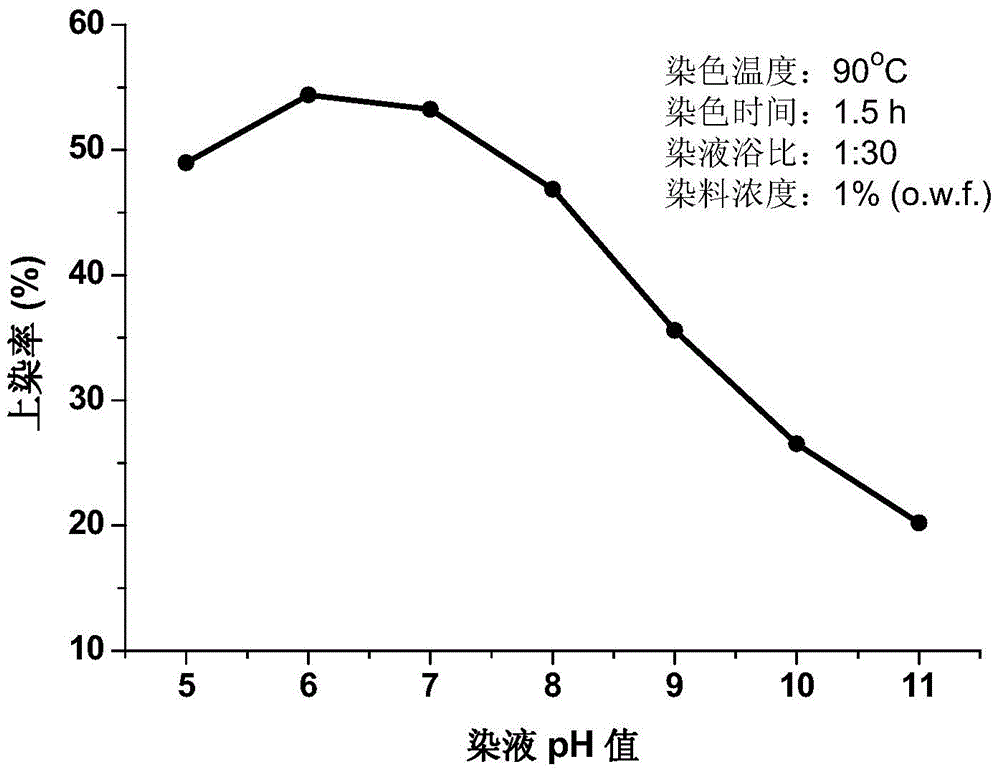

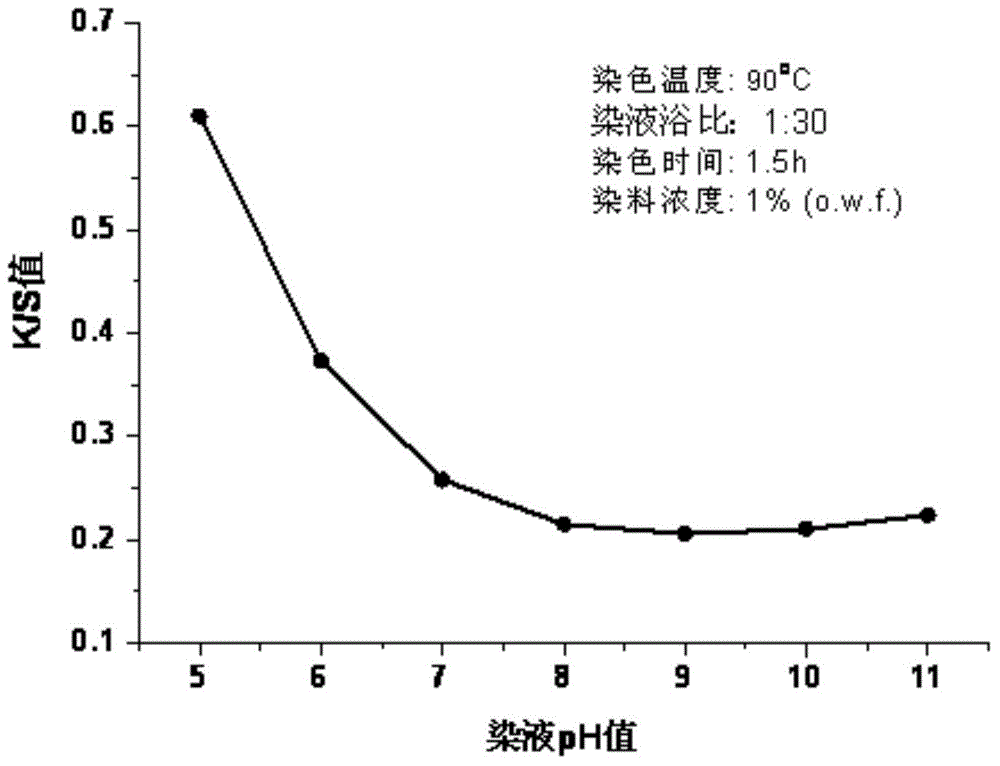

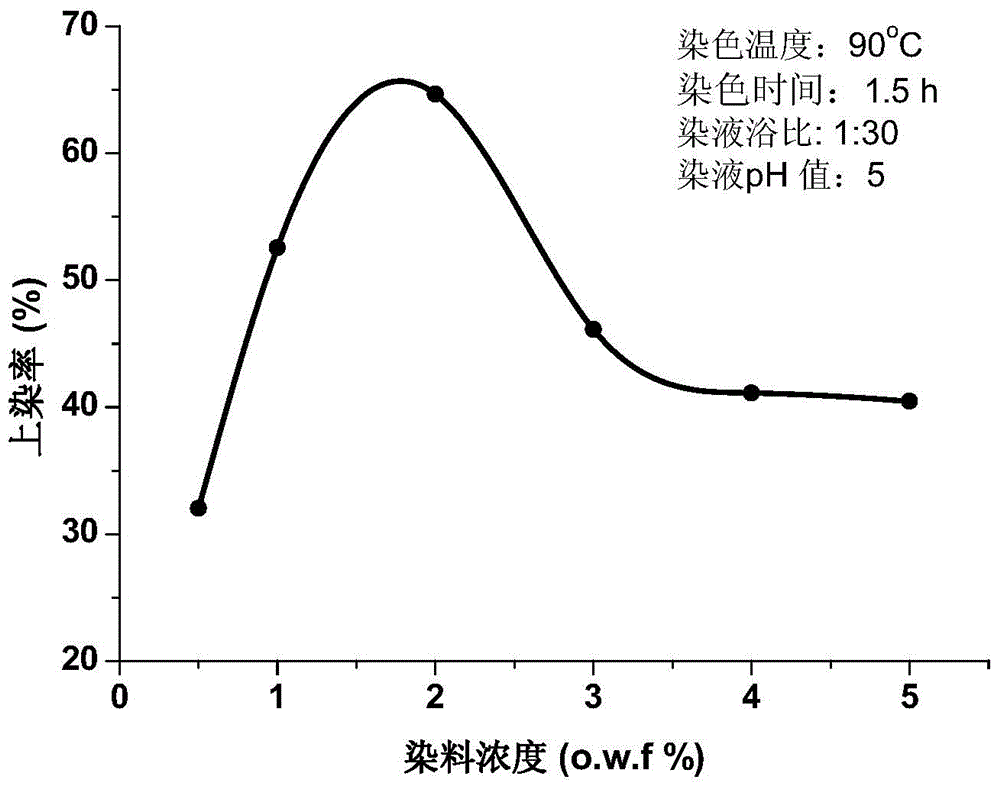

Chemical structure modification-based water-soluble curcumin dye, and preparation method and application thereof

The invention discloses a chemical structure modification-based water-soluble curcumin dye. The invention also discloses a preparation method of the chemical structure modification-based water-soluble curcumin dye. The preparation method comprises the following steps: reacting curcumin with 1,2-dibromoethane, and reacting the above obtained product with triethylamine to obtain the chemical structure modification-based water-soluble curcumin dye. The invention also discloses an application method of the chemical structure modification-based water-soluble curcumin dye. The dye can be directly used for dyeing unmodified cotton fabrics without a dyeing accelerant, a dye leveler or a dye mordant, so the environmental protection property of a dyeing process and the safety of the fabric are improved. All dyeing indexes, especially the indexes comprising the washing color fastness and the like of the water-soluble dye are obviously better than that of natural curcumin for direct dyeing, wherein the washing color fastness reaches 3 level, the staining fastness reaches 5 level, and each of the dry crock fastness and the wet crock fastness reaches 5 level.

Owner:嘉兴君宏光学有限公司

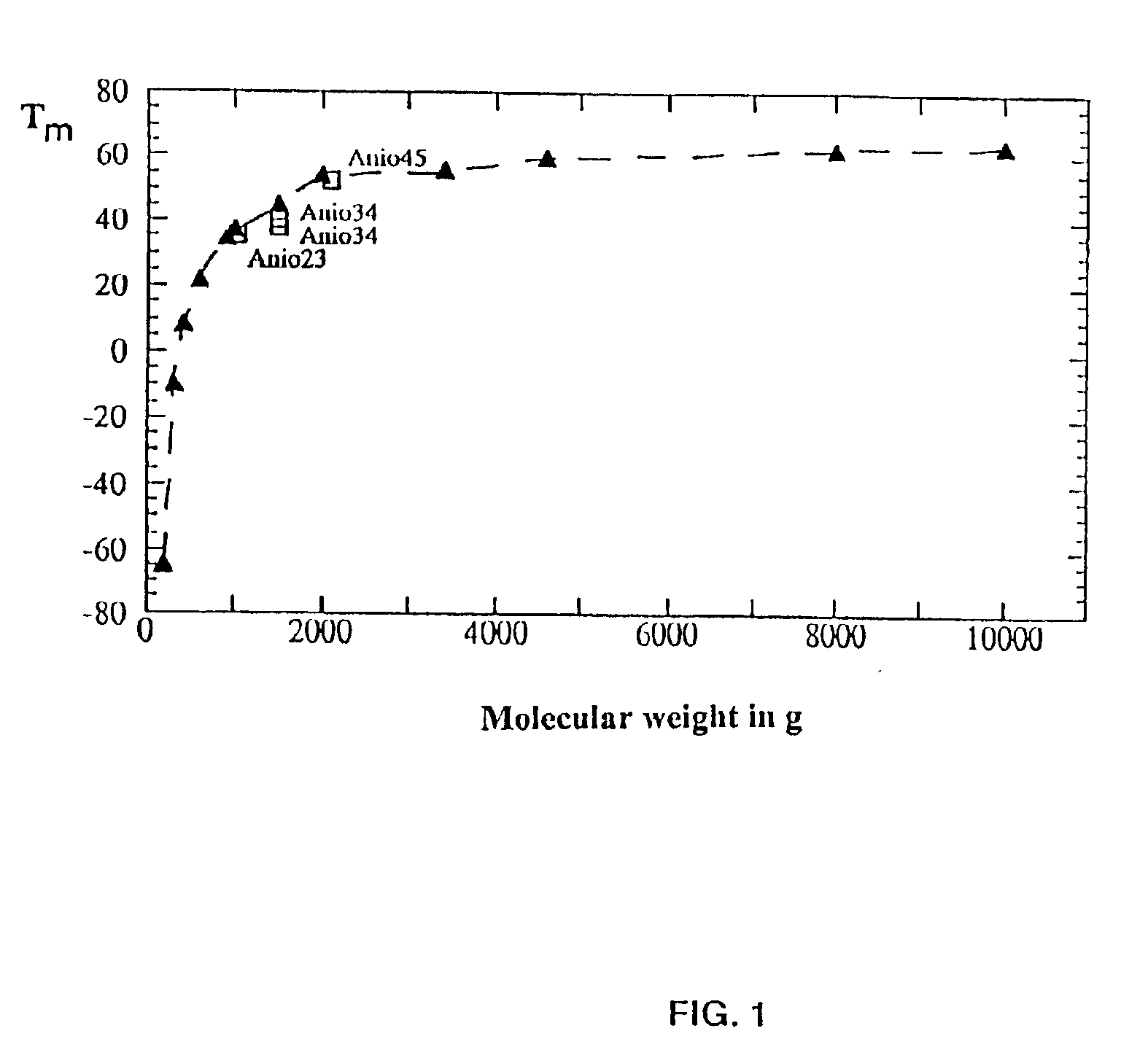

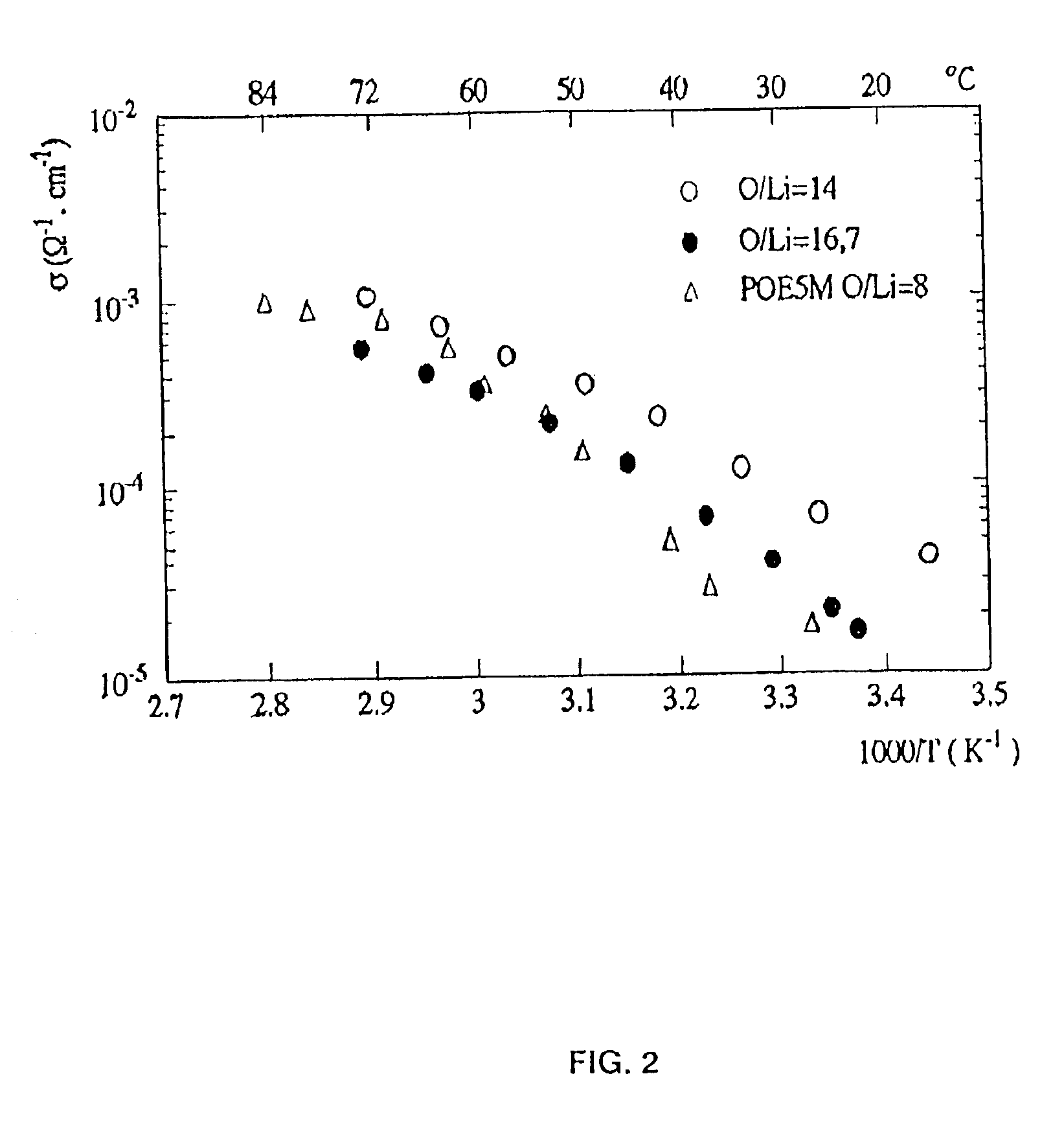

Copolymer of ethylene oxide and at least one substituted oxirane carrying a cross-linkable function, process for preparation thereof, and use thereof for producing ionically conductive materials

InactiveUS6855788B2High reaction yieldLess impuritiesCell electrodesConductive materialChemical compatibilityConductive materials

Owner:BATHIUM CANADA

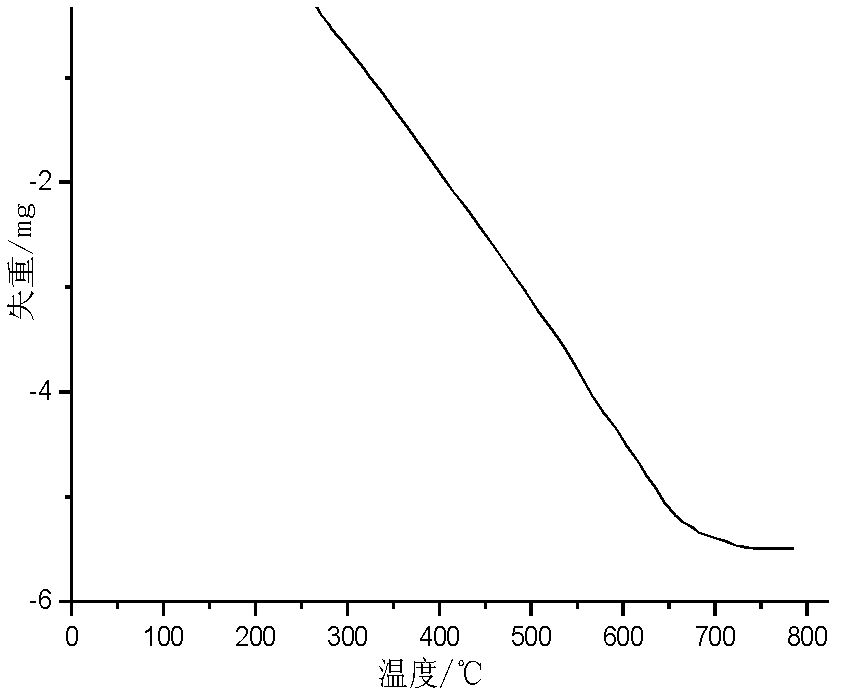

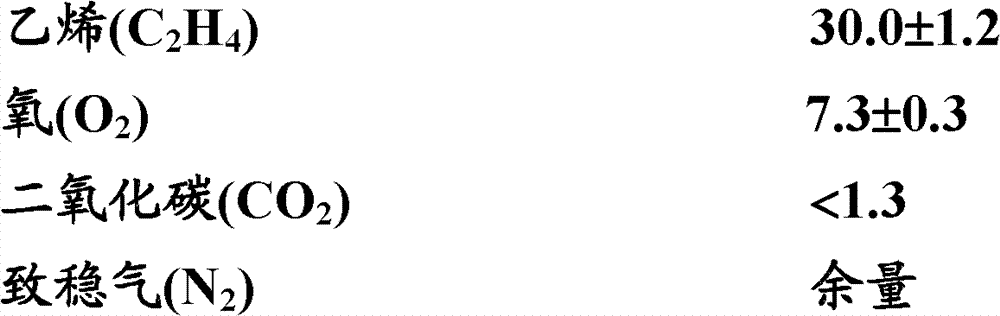

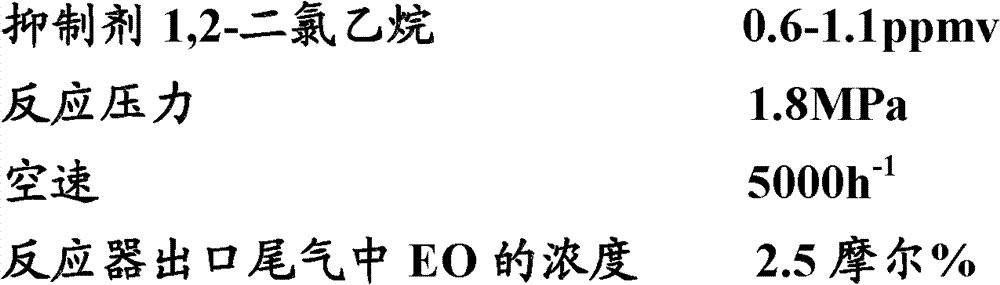

Modified alumina carrier, its preparation method, silver catalyst prepared from it, and its application in production of ethylene oxide

ActiveCN102950029AHigh activityImprove stabilityCatalyst carriersOrganic chemistryLanthanum fluorideEthylene Dibromide

The invention relates to a porous alumina carrier for a silver catalyst used in the production of ethylene oxide through ethylene epoxidation. The porous alumina carrier comprises 90wt% or more of alpha-alumina, and 0.01-1.0wt%, preferably 0.05-0.6wt% and most preferably 0.15-0.4wt% of a metallic lanthanum fluoride (by lanthanum) deposited on the surface of the carrier and the tunnel surfaces of the carrier. A supported silver catalyst prepared from the porous alpha-alumina carrier has a high catalytic activity and a high stability when the supported silver catalyst is used in the production of ethylene oxide through ethylene epoxidation. The invention also relates to a preparation method of the porous alumina carrier, the silver catalyst prepared from the porous alumina carrier, and an application of the porous alumina carrier in the production of ethylene oxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

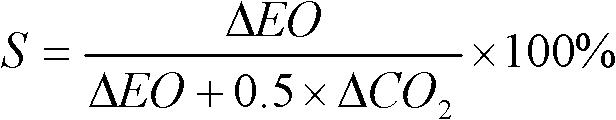

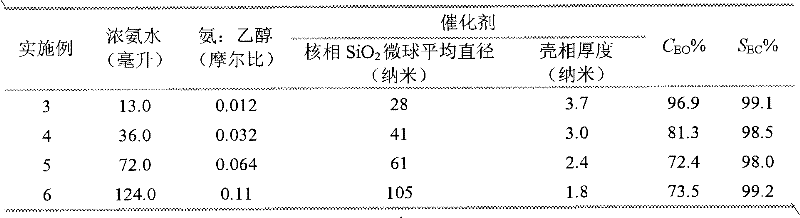

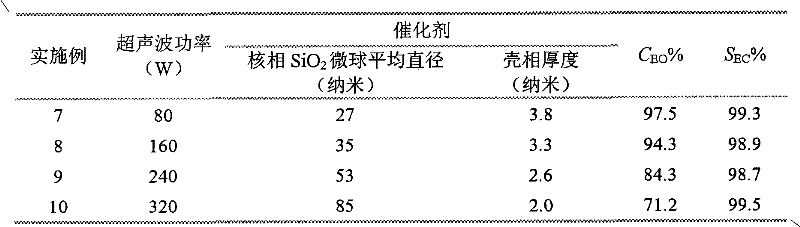

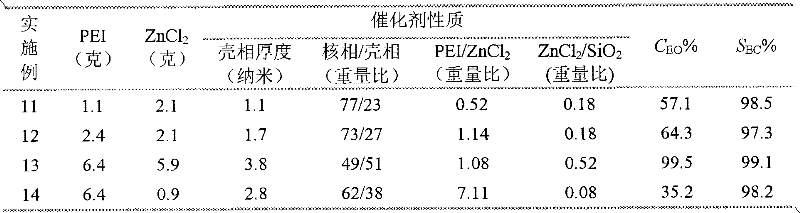

Core-shell catalyst for preparing ethylene carbonate from ethylene oxide and carbon dioxide and preparation method thereof

ActiveCN102294264AHigh N contentHigh activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyMicrosphere

The invention relates to a nuclear-shell catalyst applied to preparation of ethylene carbonate from epoxy ethane and carbon dioxide and a preparation method thereof, which are mainly used for solving the problems of low catalyst activity and easy loss of active ingredients existing in the prior art. In the preparation method, SiO2 microspheres of which the average diameter is 15-500 nanometers are taken as a nuclear phase, and metal salt MYn compounded with polyethylene imine is taken as a shell phase, wherein M is Ni, Zn, Cu, Fe or Co; Y is Cl, Br or I; n is 2 or 3; the periphery of the nuclear phase SiO2 microspheres is coated with a metal salt shell phase compounded with polyethylene imine; the thickness of the shell phase is 0.5-8 nanometers; the weight ratio of polyethylene imine to the metal salt in the shell phase is 0.3-10; and the weight ratio of the nuclear phase to the shell phase is 45:55-99.5:0.5. By adopting the technical scheme, the problems are well solved; and the nuclear-shell catalyst can be applied to industrial production of ethylene carbonate prepared from epoxy ethane and carbon dioxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

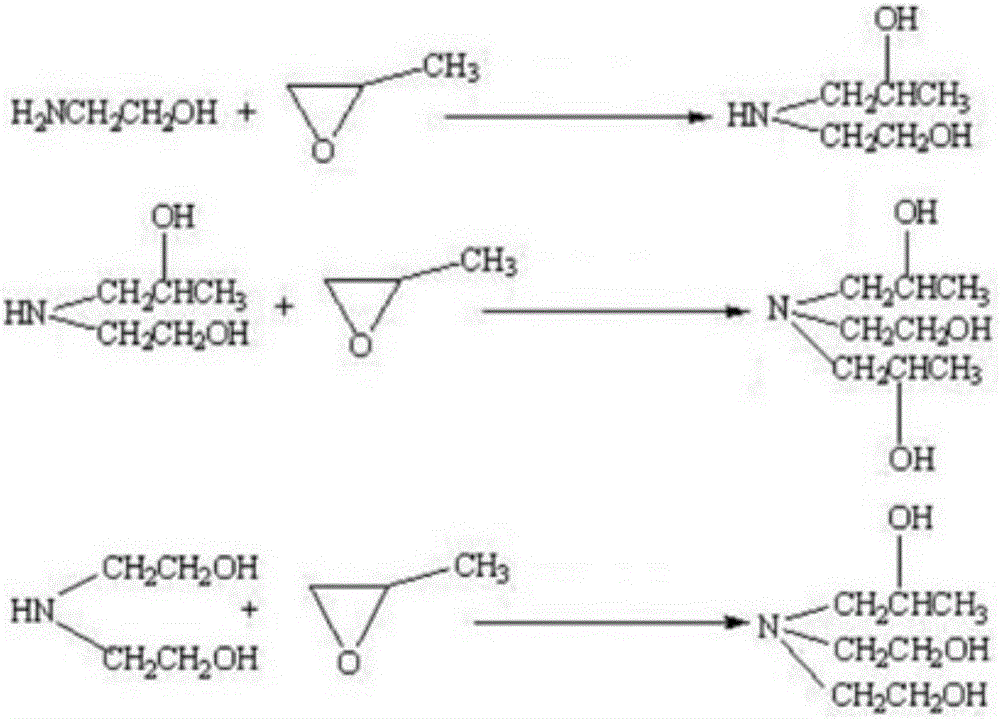

Preparation method of novel isopropanolamine

InactiveCN106631836AIncrease the molar ratioHigh yieldOrganic compound preparationAmino-hyroxy compound preparationMolecular sieveAlcohol

The invention provides a preparation method of novel isopropanolamine. The preparation method comprises the following steps: (1) preparing a catalyst; (2) preparing diethanol amine; (3) synthesizing diethanolisopropanolamine. In the method, liquid ammonia, ethylene oxide and propylene oxide are taken as raw materials, and the diethanolisopropanolamine is synthesized in two steps; when the liquid ammonia and the ethylene oxide are used for synthesizing the diethanol amine, a molecular sieve catalyst is adopted, so that the generation of triethanolamine is inhibited effectively, the production of monoethanolamine is reduced by increasing the molar ratio of ethylene oxide to the liquid ammonia, the yield of the diethanol amine is increased, and the yield of the diethanolisopropanolamine is increased. Since byproducts in a final product are all alcohol amine substances which can be used directly in the production of a cement grinding aid, thereby simplifying the production process and lowering the production cost.

Owner:北京德博莱化工产品销售有限公司

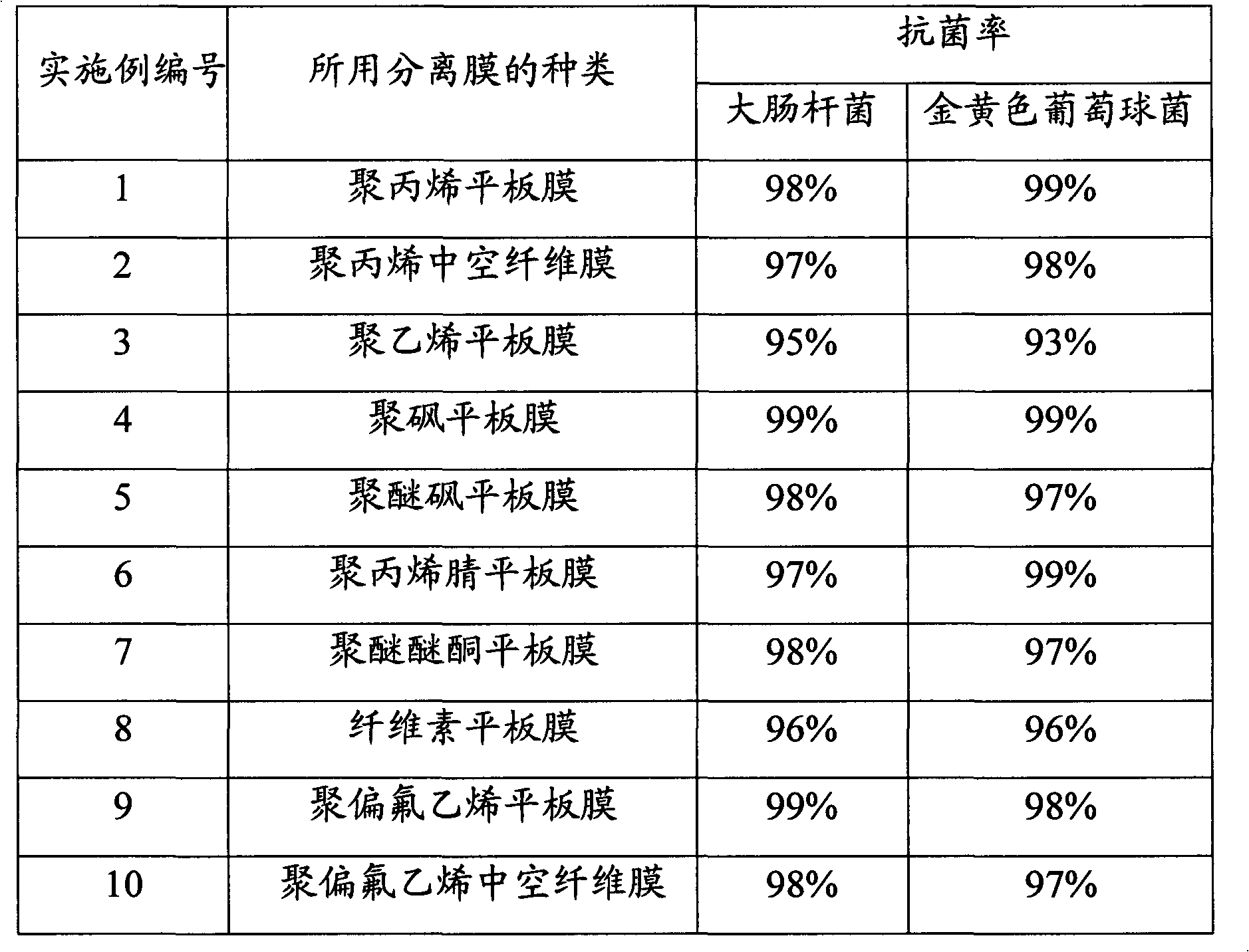

Method for preparing antimicrobial polymer separation membrane

InactiveCN101934202AAvoid churnImprove antibacterial propertiesSemi-permeable membranesCross-linkSodium ascorbate

The invention discloses a method for preparing an antimicrobial polymer separation membrane, which comprises the following steps of: (1) selecting a polymer separation membrane containing a dimethylaminoethyl methacrylate surface modification layer as a basement membrane; and (2) soaking the basement membrane in aqueous solution of silver nitrate and aqueous solution of sodium borohydride in turn, taking out, soaking in cross-linking agent solution for quaternization and in-situ cross-linking reaction, taking out, cleaning, and drying to obtain the antimicrobial polymer separation membrane, wherein a reducing agent is sodium borohydride or sodium ascorbate; and a cross-linking agent is on ore more of alpha,alpha'-dichloro-p-xylen, 1,2-dibromoethane, 1,3-dibromopropane, and 1,4-dibromobutane. The polymer separation membrane prepared by the method fully utilizes the antibacterial performance of silver nanoparticles and quaternized dimethylaminoethyl methacrylate, and has excellent antimicrobial effect.

Owner:ZHEJIANG UNIV

Conductive rubber composition, conductive polymer composition, conductive vulcanized rubber, conductive rubber roller and conductive rubber band

InactiveCN1366002ANo side effectsRelieves compression setConductive materialPolymer scienceConductive polymer

The invention provides a rubber product with a low volume intrinsic resistance value, a small compression permanent deformation, no toxic gas generated during product burn-off after use, and no adverse effects on the environment. The conductive rubber composition of the present invention comprises a copolymerization ratio of ethylene oxide / propylene oxide / allyl glycidyl ether of 50-95 mole % / 1-49 mole % / 1-10 mole %, number average molecular weight Ethylene oxide-propylene oxide-allyl glycidyl ether terpolymer (A) and nitrile rubber (B) with Mn above 10000, according to (A):(B)=70:30~5: The conductive polymer mixed in a weight ratio of 95 is mixed with 0.1 to 7.0 parts by weight of a non-halogenated quaternary ammonium salt corresponding to 100 parts by weight of the conductive polymer. Also provided is a non-halogen composition comprising a non-halogen polymer and a non-halogen quaternary ammonium salt of sulfonic acid or the like. The composition can be used to prepare rubber products such as conductive rubber rollers.

Owner:SUMITOMO RUBBER IND LTD

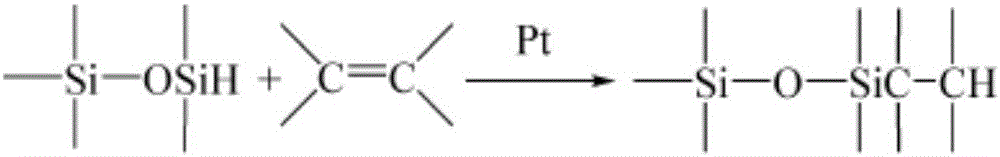

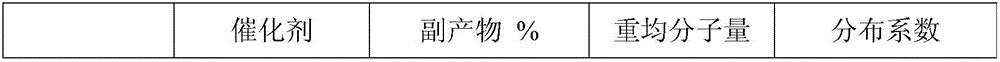

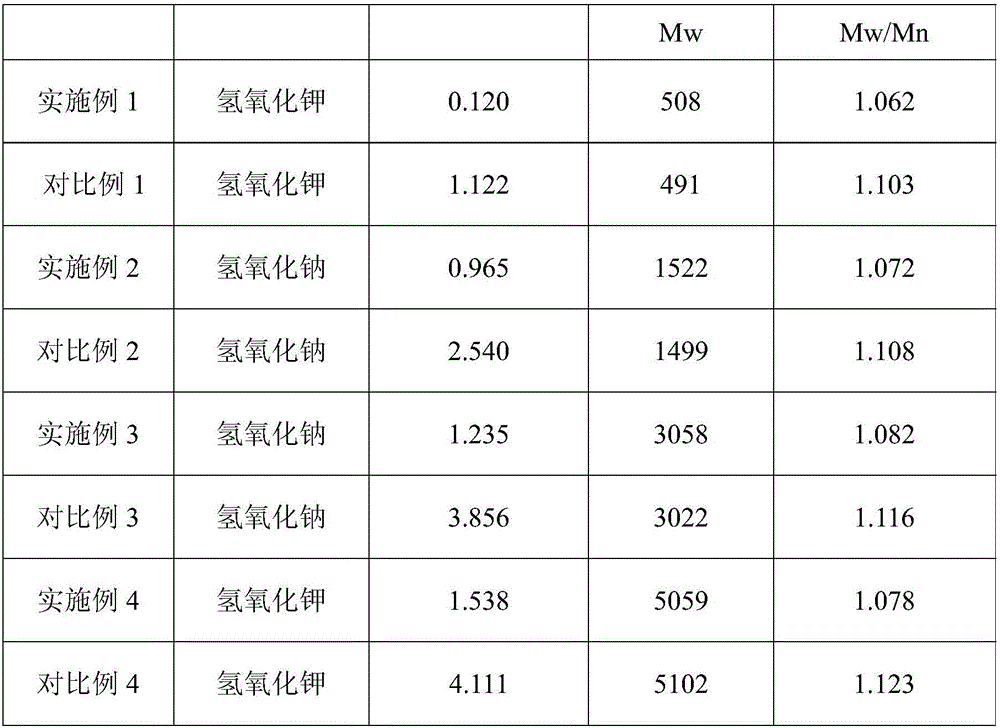

Preparation method of unsaturated polyether

ActiveCN106589344AEffective control of water contentReduce and eliminate generationAlcoholEthylene Dibromide

The invention relates to a preparation method of unsaturated polyether and belongs to the technical field of polymer synthesis. The preparation method comprises: using an unsaturated alcohol as an initiator, adding first catalyst, subjecting the unsaturated alcohol to azeotropic dewatering with water generated by reaction, and adding ethylene oxide, propylene oxide or their mixture to carry out ring-opening copolymerization to obtain unsaturated polyether intermediate oligomer having molecular weight of 300-500; adding second catalyst, subjecting the intermediate oligomer to polycondensation with ethylene oxide and propylene oxide to form the finished unsaturated polyether having molecular weight of 300-500. The application is applied to the synthesis of unsaturated polyether, and the preparation method has the advantages of high purity, low byproduct content and the like.

Owner:ZHEJIANG HUANGMA TECH

Crude oil demulsifier and preparation method thereof

ActiveCN106336892AGood demulsification effectImprove adaptabilityDewatering/demulsification with chemical meansHydrocarbon oils treatmentDemulsifierEthylene oxide

The invention relates to a crude oil demulsifier and a preparation method thereof. The crude oil demulsifier comprises macromolecular resin, bicyclo-oxide, sulfonic acids and solvent oil at a weight ratio of 100:(15-30):(2-5):(30-50), wherein the macromolecular resin is formed by polymerization of alkyl phenolic resin, ethylene oxide and propylene epoxide. The crude oil demulsifier is good in demulsification effect, wide in application range and good in adaptability and can be suitable for dewatering and desalting of a vast majority of crude oils.

Owner:广东粤首新科技有限公司

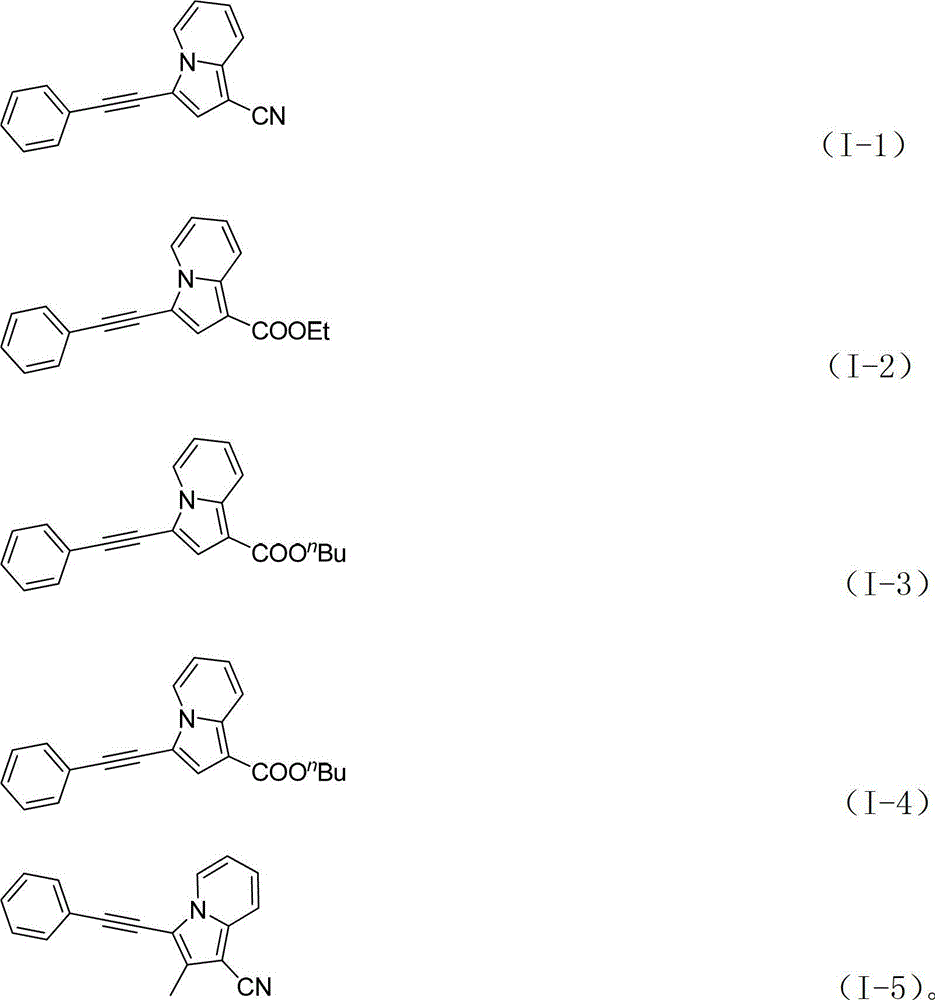

Aryne-based substituted indolizine derivative and preparation method and applications thereof

InactiveCN102977097AGood reaction selectivityMild reaction conditionsOrganic chemistryAntineoplastic agentsNitrogenPalladium catalyst

The invention discloses an aryne-based substituted indolizine derivative and a preparation method and applications thereof. The preparation method is characterized by comprising the following steps: under the condition of stirring, adding indolizine compounds, 2, 2-ethylene dibromide aromatic compounds, inorganic alkali and a metallic palladium catalyst into N, N-dimethyl formamide; and under the protection of nitrogen, carrying out complete reaction on the obtained mixture at a temperature of 80-100 DEG C, and carrying out post-treatment on the obtained product so as to obtain the aryne-based substituted indolizine derivative. According to the aryne-based substituted indolizine derivative and the preparation method, the aryne-based substituted indolizine derivative is prepared by using easily-available raw materials, the reaction selectivity is good, the reaction conditions are mild, the preparation process is simple, and the production cost is low.

Owner:SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com