Chemical structure modification-based water-soluble curcumin dye, and preparation method and application thereof

A technology of chemical structure and curcumin, applied in the direction of chemical instruments and methods, dyeing methods, azo dyes, etc., can solve the problems of difficult industrial production, high preparation cost, poor color fastness, etc., to achieve improved color fastness, no Effect of heavy metal residue and high dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Synthesis of Curcumin Bis(2-Bromoethyl) Ether Intermediate 1

[0051] Curcumin powder (1 g, 2.72 mmol), potassium carbonate (0.94 g, 6.8 mmol) and tetrabutylammonium bromide (0.043 g, 0.126 mmol) were placed in a chamber containing 1,2-dibromoethane (12 mL). In a round-bottomed flask, the mixture was heated at 90 °C for 24 h and cooled to room temperature. The unreacted 1,2-dibromoethane was collected by distillation under reduced pressure, the residue was washed several times with an appropriate amount of n-hexane, and the obtained orange-yellow solid powder (1.38g) was naturally dried, which is curcumin bis(2-bromoethane) ethyl) ether intermediate in 87% yield.

[0052] m.p.137.5-139.3℃;

[0053] FT-IR(KBr)ν2923,1626,1587,1508,1257,1136,1021,971cm-1; as Figure 9 shown.

[0054] 1 H NMR (400MHz, CDCl 3 )δ3.68(t,J=7.8Hz,4H),3.92(s,6H),4.37(t,J=7.8Hz,4H),5.82(s,1H),6.50(d,J=16Hz,2H ), 6.89 (d, J=8Hz, 2H), 7.11 (m, 4H), 7.59 (d, J=16Hz, 2H), 15.94 (br, ...

Embodiment 2

[0057] Example 2: Synthesis of water-soluble curcumin dye 2

[0058] Curcumin bis(2-bromoethyl) ether (1 g, 1.72 mmol) was placed in a round-bottomed flask containing triethylamine (12 mL), wrapped with thick tin foil to protect from light and passed through a stream of nitrogen, and the mixture was heated at 90°C After 48 hours of reaction, it was cooled to room temperature. The unreacted triethylamine was collected by distillation under reduced pressure, and the residue was washed several times with an appropriate amount of acetone. The obtained orange-red solid powder (1.23 g) was dried in a vacuum drying oven at 60°C and stored in a desiccator. The obtained product is water-soluble curcumin dye with a yield of 91%.

[0059] m.p.>360℃;

[0060] FT-IR (KBr) ν3388 (water peak due to moisture absorption), 2938, 2675, 1624, 1592, 1511, 1262, 1139, 1030, 808cm -1 ;like Figure 13 shown.

[0061] 1 H NMR (400MHz, CDCl 3 )δ1.43(t,J=7.2Hz,18H),3.11(q,J=7.2Hz,12H),3.69(t,J=6....

Embodiment 3

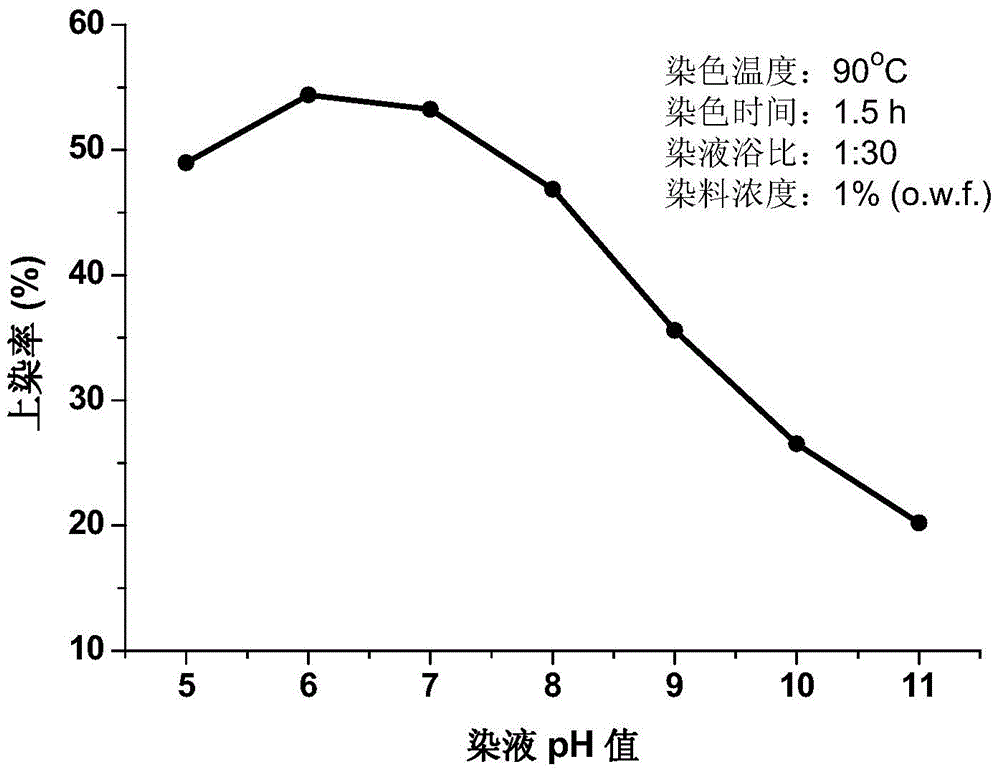

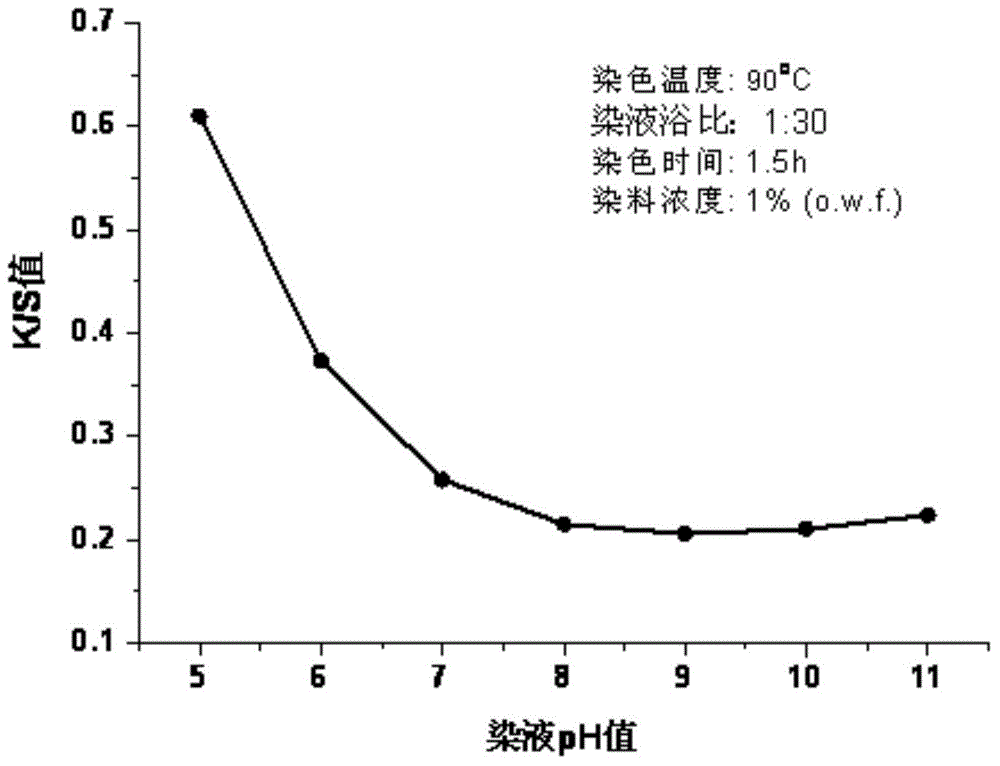

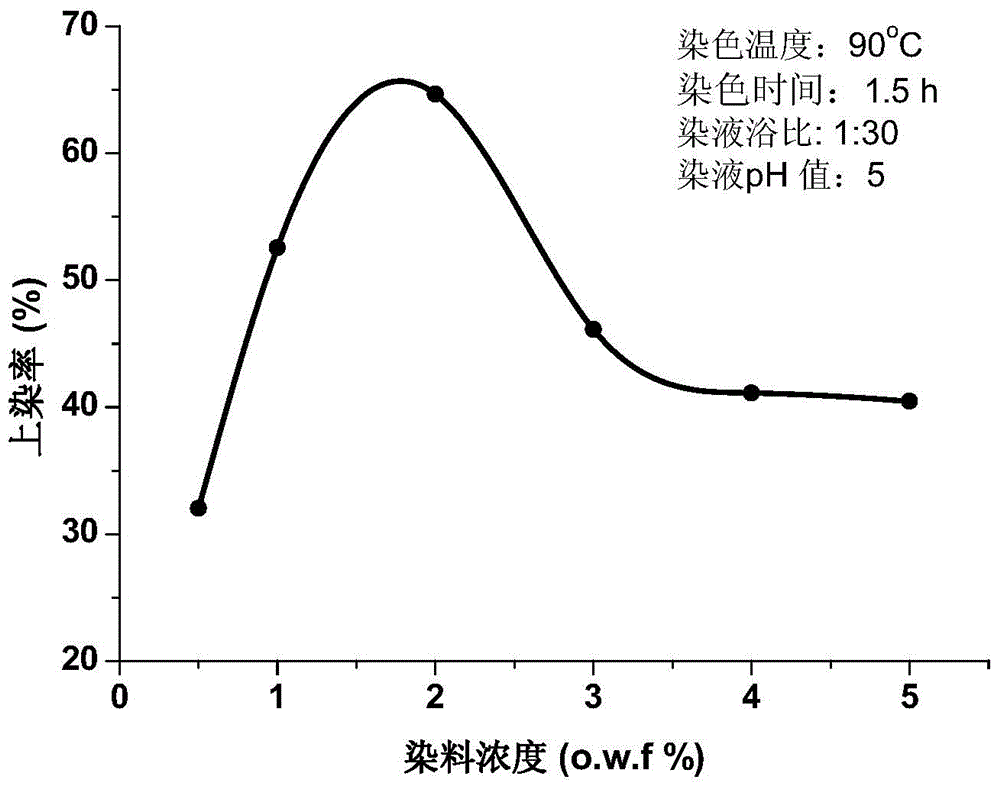

[0077] Example 3: Dyeing of cotton fabric with water-soluble curcumin dyes

[0078]The water-soluble curcumin dye was dissolved in an aqueous solution of acetic acid with a pH value of 5 to a concentration of 2% (o.w.f.). Take a piece of boiled and bleached cotton grey cloth (about 5×10cm 2 ), put it in the conical flask containing the above dye solution, and the liquor ratio is 1:30. The conical flask was placed in a constant temperature water bath shaker at 70°C and kept for 1.5h. Take out the cotton cloth, squeeze the dye liquid, rinse it with water, and hang it to dry naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com