Method for preparing antimicrobial polymer separation membrane

A technology of polymer and separation membrane, applied in the field of separation membrane, can solve the problems of low utilization rate of antibacterial substances, single antibacterial effect, etc., and achieve the effect of excellent antibacterial effect, good long-term stability, and prevention of loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

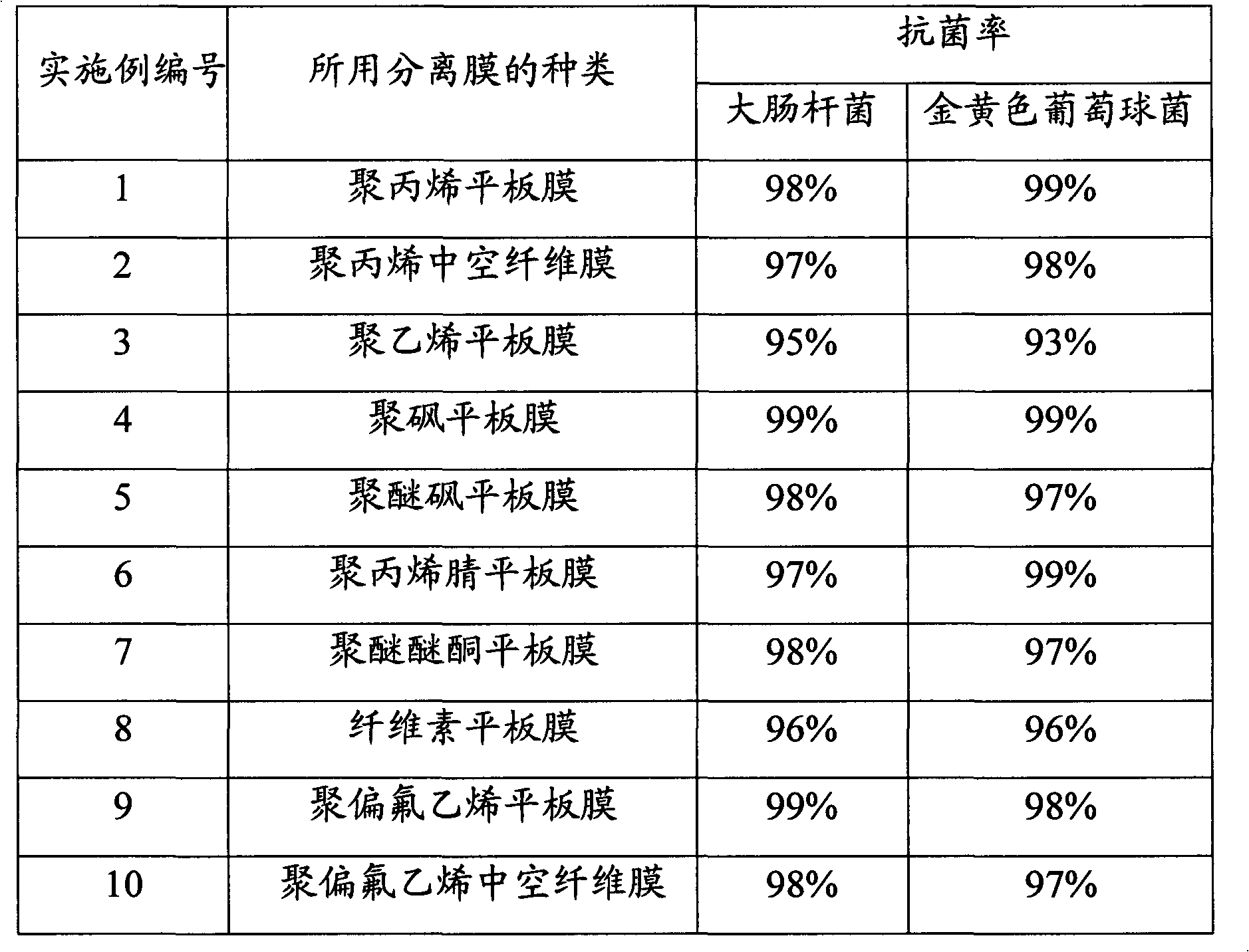

Examples

Embodiment 1

[0023] PDMAEMA is introduced into the surface of the polypropylene flat film by graft polymerization to prepare a base film containing a PDMAEMA surface modification layer, wherein the weight of the PDMAEMA is 10% of the total weight of the base film. The graft polymerization is carried out as follows: immerse the polypropylene flat film in the n-heptane solution of the photoinitiator benzophenone with a concentration of 0.001mol / L, let it dry naturally after 1 hour, and then immerse the film in the monomer volume concentration In a 10% dimethylaminoethyl methacrylate (DMAEMA) solution, take it out after 20 minutes of ultraviolet light irradiation, dry after cleaning, and obtain a substrate containing a polydimethylaminoethyl methacrylate modification layer. membrane.

[0024] Soak the base film in a silver nitrate aqueous solution with a concentration of 0.01mol / L for 30 minutes, take it out and immerse it in a sodium borohydride aqueous solution with a concentration of 0.2mo...

Embodiment 2

[0026] PDMAEMA is introduced into the surface of the polypropylene hollow fiber membrane by plasma treatment to prepare a base membrane containing a PDMAEMA surface modification layer, wherein the weight of the PDMAEMA is 10% of the total weight of the base membrane. The method of introducing PDMAEMA by plasma treatment is as follows: the polymer PDMAEMA is dissolved in acetone to make a polymer solution with a concentration of about 5g / L, then the polypropylene hollow fiber membrane is immersed in the solution, shaken at room temperature for 3 hours and then taken out to air dry, and then treated in an atmospheric pressure plasma apparatus for 30 seconds, washed and dried to obtain a base film containing a polydimethylaminoethyl methacrylate modification layer.

[0027] Soak the basement film in an aqueous silver nitrate solution with a concentration of 0.01mol / L for 30 minutes, take it out and immerse it in an aqueous solution of sodium ascorbate with a concentration of 0.2mo...

Embodiment 3

[0029] PDMAEMA is introduced into the surface of the polyethylene flat film by plasma treatment to prepare a base film containing a PDMAEMA surface modification layer, wherein the weight of the PDMAEMA is 1% of the total weight of the base film. The method of introducing PDMAEMA by plasma treatment is as follows: the polymer PDMAEMA is dissolved in acetone to make a polymer solution with a concentration of about 5g / L, and then the polyethylene flat film is immersed in the solution, shaken at room temperature for 10 minutes, and then taken out to dry , and then treated in an atmospheric pressure plasma apparatus for 10 seconds, washed and dried to obtain a base film containing a polydimethylaminoethyl methacrylate modification layer.

[0030] Soak the base film in a silver nitrate aqueous solution with a concentration of 1mol / L for 1 minute; take it out and immerse it in a sodium borohydride aqueous solution with a concentration of 1mol / L for 1 minute; then immerse it in a cross...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com