Preparation method of unsaturated polyether

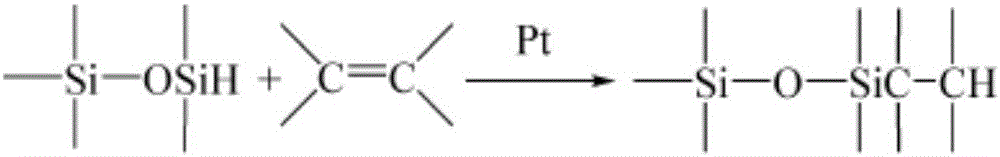

A technology of unsaturated polyether, applied in the field of preparation of unsaturated polyether, can solve the problem of high by-products of unsaturated polyether, achieve the effect of low by-products, high purity, and eliminate the formation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

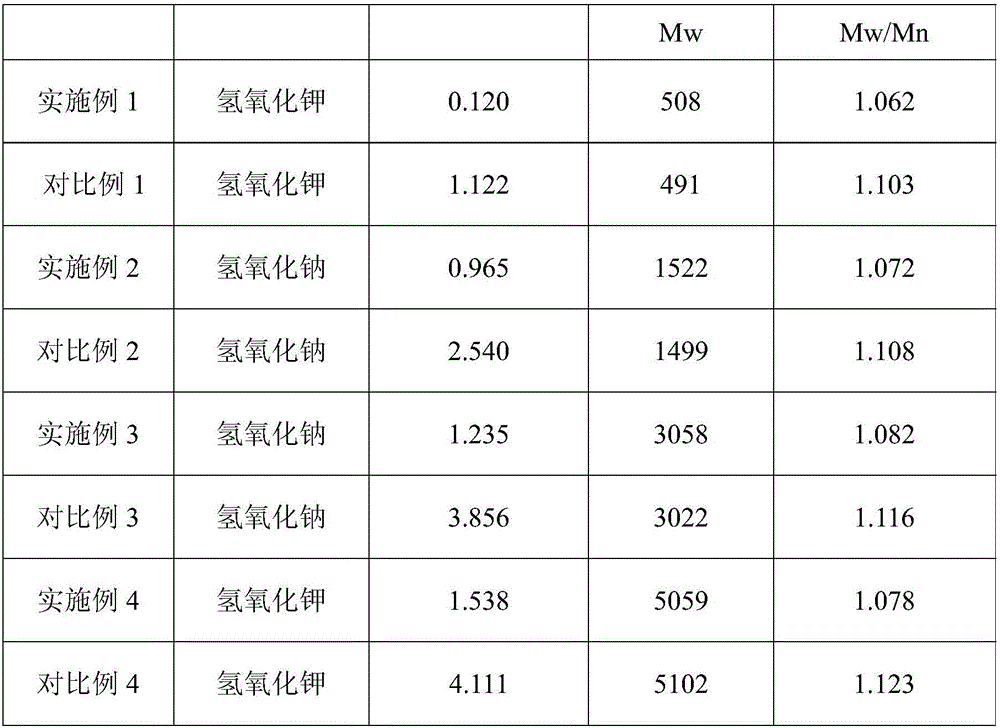

Examples

Embodiment 1

[0036] Embodiment 1: the synthesis of allyl alcohol polyoxyethylene ether 500

[0037] Add 168 parts of allyl alcohol and 0.45 parts of potassium hydroxide into the reaction kettle, raise the temperature to 88°C for azeotropic distillation and dehydration until the water content reaches 120ppm and stop dehydration. Start stirring and heat up to the reaction temperature of 95-100°C, add 1332 parts of ethylene oxide dropwise, control the reaction pressure at 0.05-0.20Mpa, after the dropwise addition of ethylene oxide is complete, continue the reaction for 1 hour, cool down to 70°C and inject for post-treatment kettle, add phosphoric acid to neutralize, polyether adsorbent treatment, and filter to obtain the product.

Embodiment 2

[0041] (1) Synthesis of allyl alcohol polyoxyethylene polyoxypropylene ether oligomer 400:

[0042] Add 200 parts of allyl alcohol and 0.72 parts of sodium hydroxide into the reaction kettle, raise the temperature to 88°C for azeotropic distillation and dehydration until the water content reaches 110ppm and stop dehydration. Start stirring and heat up to the reaction temperature of 100-105°C, add 662 parts of ethylene oxide and 444 parts of propylene oxide dropwise, control the reaction pressure at 0.20-0.30Mpa, complete the dropwise addition of ethylene oxide and propylene oxide, and continue the reaction for 2 Hours, the temperature was lowered to 70°C.

[0043] (2) Synthesis of allyl alcohol polyoxyethylene polyoxypropylene ether 1500:

[0044] Add 3.00 parts of sodium hydroxide and 400 parts of allyl alcohol polyoxyethylene polyoxypropylene oligomer 400 synthesized in step (1) in the reactor, seal the reactor, first use nitrogen to blow and replace, then vacuumize, repeat...

Embodiment 3

[0048] (1) Synthesis of methallyl alcohol polyoxyethylene polyoxypropylene ether oligomer 400: add 200 parts of methallyl alcohol and 0.72 part of sodium hydroxide in the reaction kettle, heat up to 91°C for azeotropic rectification dehydration, Stop dehydration until the moisture reaches 110ppm. Start stirring and heat up to the reaction temperature of 100-105°C, add 860 parts of ethylene oxide and 369 parts of propylene oxide dropwise, control the reaction pressure at 0.20-0.30Mpa, complete the dropwise addition of ethylene oxide and propylene oxide, and continue the reaction for 2 Hours, the temperature was lowered to 70°C.

[0049] (2) Synthesis of methallyl alcohol polyoxyethylene polyoxypropylene ether 3000: add 3.80 parts of sodium hydroxide and 200 parts of methallyl alcohol polyoxyethylene polyoxypropylene low in the reaction kettle synthesized in step (1) Polymer 400, seal the reactor, first use nitrogen to blow and replace, then vacuumize, repeat the replacement tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| azeotropic temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com