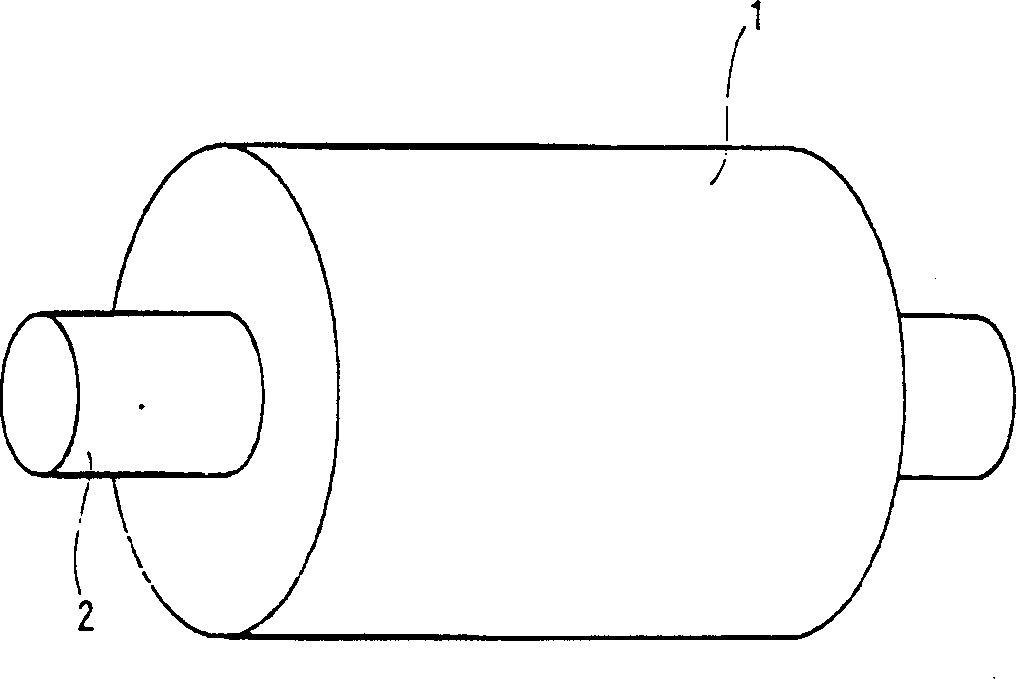

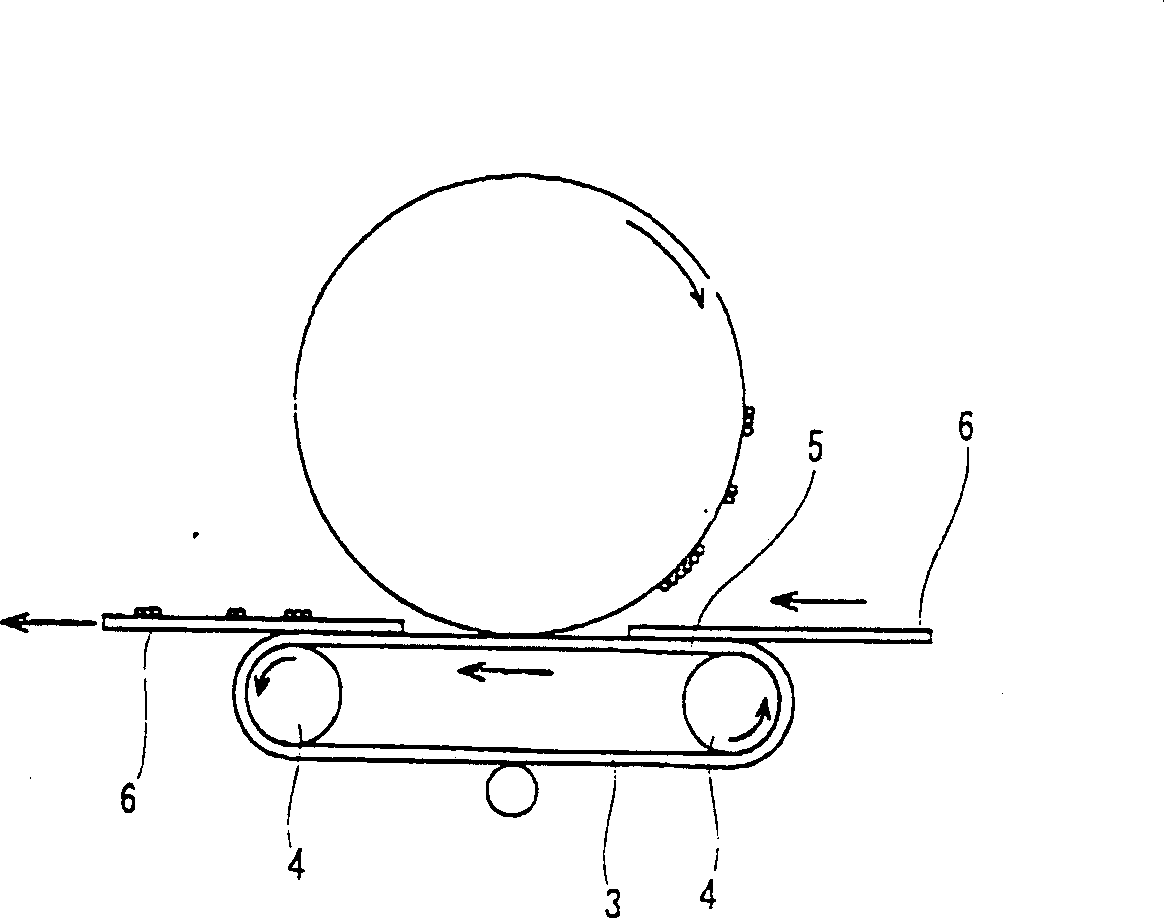

Conductive rubber composition, conductive polymer composition, conductive vulcanized rubber, conductive rubber roller and conductive rubber band

A technology of conductive polymer and rubber composition, applied in conductive materials, conductive materials, conductors, etc., can solve problems such as side reactions, compression set deterioration, etc., achieve good ozone resistance, relieve compression set, and compress permanent small deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 5

[0122] Mix the above-mentioned non-halogen quaternary ammonium salt in the EO-PO-AGE terpolymer and nitrile rubber shown in Table 1 according to the ratio shown in Table 1, and prepare the conductive rubber composition according to the above method. test piece.

Embodiment 11

[0136] Embodiment 11, comparative example 12 and 13 are based on the proportioning described in table 5 and table 6, add quaternary ammonium salt, 1,4-butanediol and silicon series surfactant in polyether polyol, with general After stirring by the mixer, the raw materials are uniformly dispersed. After dispersion, defoaming treatment was performed under reduced pressure, and the isocyanate and reaction catalyst were added thereto, and then poured into a mold for producing a test piece for physical property evaluation. Finally, curing was carried out at 80° C. for 12 hours to prepare the same test piece for evaluation of physical properties.

[0137] Complex reagent

[0138] Complex reagent

Embodiment 6~ Embodiment 11

[0140] As a non-halogen polymer, only nitrile rubber (Example 8) or styrene-butadiene rubber and nitrile rubber were used, or EO-PO-AGE terpolymer and butadiene-butadiene rubber were used according to the ratio shown in Table 1. Nitrile rubber (Examples 6-7, Examples 9-10). The non-halogenated quaternary ammonium salt was mixed therein according to the proportion shown in Table 3, and the test piece was prepared from the conductive polymeric composition by the above method.

[0141] In addition, as the polyether polyol, the polyether polyol described in Table 5 having branches was used, and as the short-chain polyol, 1,4-butanediol was used. The above-mentioned non-halogenated quaternary ammonium salt was mixed according to the proportion shown in Table 5, and a test piece (Example 11) was prepared from the conductive polyurethane composition by the above method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Volume intrinsic resistance value | aaaaa | aaaaa |

| Volume intrinsic resistance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com