Ethylene oxide waste gas absorption coupling catalytic reaction purification device and process

A technology of ethylene oxide and purification equipment, which is applied in organic chemistry, gas treatment, chemical instruments and methods, etc., can solve the problems of ineffective recycling, high cost of rectification and purification, secondary pollution, etc., and achieve comprehensive The effect of low operating cost, small footprint and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

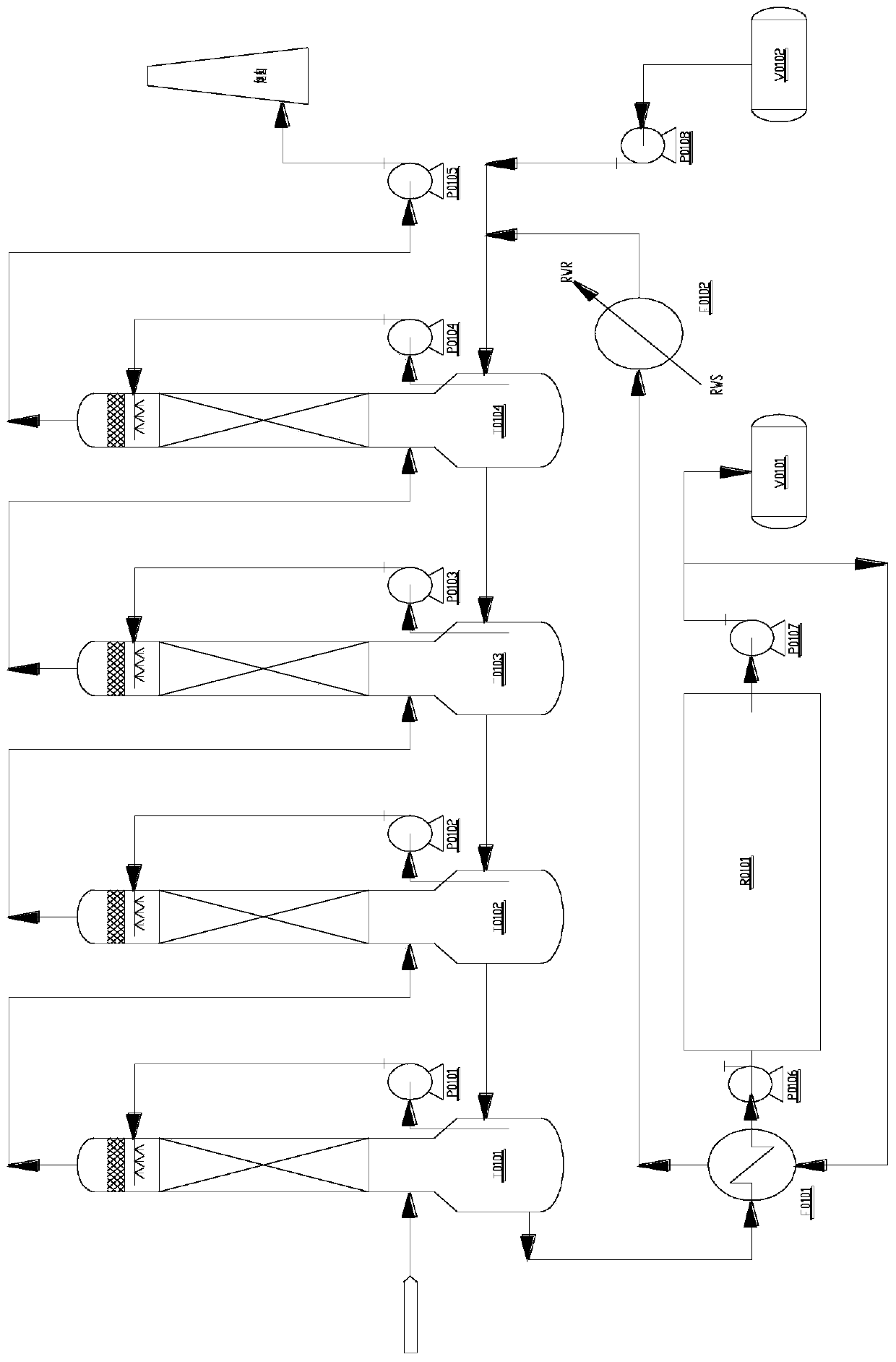

[0034] See figure 1 , using a four-stage absorption process specifically, the devices used include 4 absorption spray towers, 4 circulation pumps, 1 vacuum pump, 1 high-pressure pump, 1 liquid separator pump, 1 ethylene glycol aqueous solution storage tank, 1 Water supply tank, 1 heat exchanger, 1 cooler. The 4 absorption spray towers have the same structure, the tower diameter is 600mm, the tower height is 3000mm, the lower part of the tower body is equipped with a gas inlet, and above the gas inlet is a 2m high plastic PP hollow ball filler. Shower head, a 200mm wire mesh defogging layer is set above the water spray head, and a gas outlet is set on the top of the tower; the bottoms of the four absorption towers are connected through connecting pipes;

[0035] One side of each absorption spray tower is provided with a circulation pump, and the inlet of the circulation pump is connected with a liquid inlet pipe, and the end of the liquid inlet pipe far away from the inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com