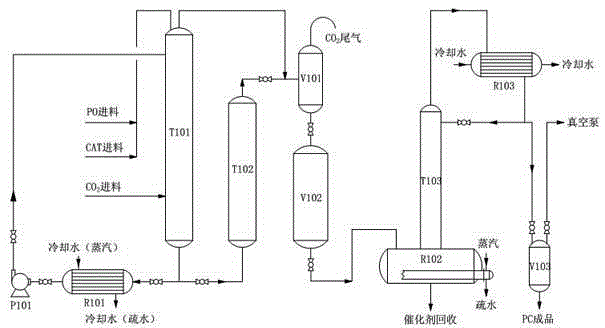

Production method for preparing propylene (ethylene) carbonate from carbon dioxide and propylene oxide (ethylene oxide) through tubular reaction

A carbon dioxide and production method technology, applied in the direction of products, organic chemistry, reagents, etc., can solve the problems of insufficient gas-liquid contact in the reactor, untimely removal of reaction heat, low production efficiency, etc., and achieve easy control, low energy consumption and low production efficiency. The effect of low material consumption and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

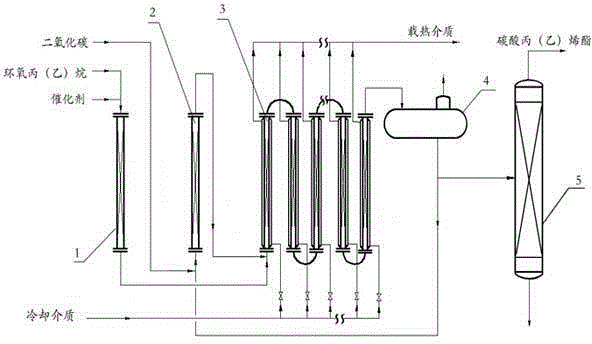

Embodiment 1

[0019] The production method of producing propylene carbonate by tubular reaction, the raw materials used in the production process are propylene oxide, carbon dioxide and propylene carbonate synthesis catalyst. The production equipment used includes 10 sets (segments) of tubular propylene carbonate synthesis reactors (3), 1 set (segment) of tubular catalyst mixers (1), and 1 set (segment) of tubular carbon dioxide predispersers used in series (2), gas-liquid separator (4), propylene carbonate separation and refining device (5), connecting pipelines and various accessories. The production method of producing propylene carbonate by tubular reaction includes: the catalyst and propylene oxide enter the tubular catalyst mixer (1) to form a mixed solution of catalyst and propylene oxide; carbon dioxide and circulating propylene carbonate enter the tubular carbon dioxide predisperser (2 ) to form a carbon dioxide dispersion; the mixed solution of catalyst and propylene oxide, and th...

Embodiment 2

[0021] Example 2 is basically the same as Example 1, except that the tubular catalyst mixer (1), the tubular carbon dioxide predisperser (2), and the tubular propylene carbonate synthesis reactor (3) are commercially available static mixers .

Embodiment 3

[0023] Embodiment 3 is substantially the same as Embodiment 1, except that the raw materials used in the production process are ethylene oxide, carbon dioxide and ethylene carbonate catalyst, and the product is ethylene carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com