Polyurethane composition for glass fiber reinforced honeycomb sandwich panels and application method of polyurethane composition

A technology of polyurethane and composition, applied in the field of polyurethane, can solve the problems that the flame retardancy is difficult to meet the requirements of flame retardant properties of automobile interior materials, and the dimensional stability is poor, and achieves good dimensional stability, high impact strength, and good flame retardancy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

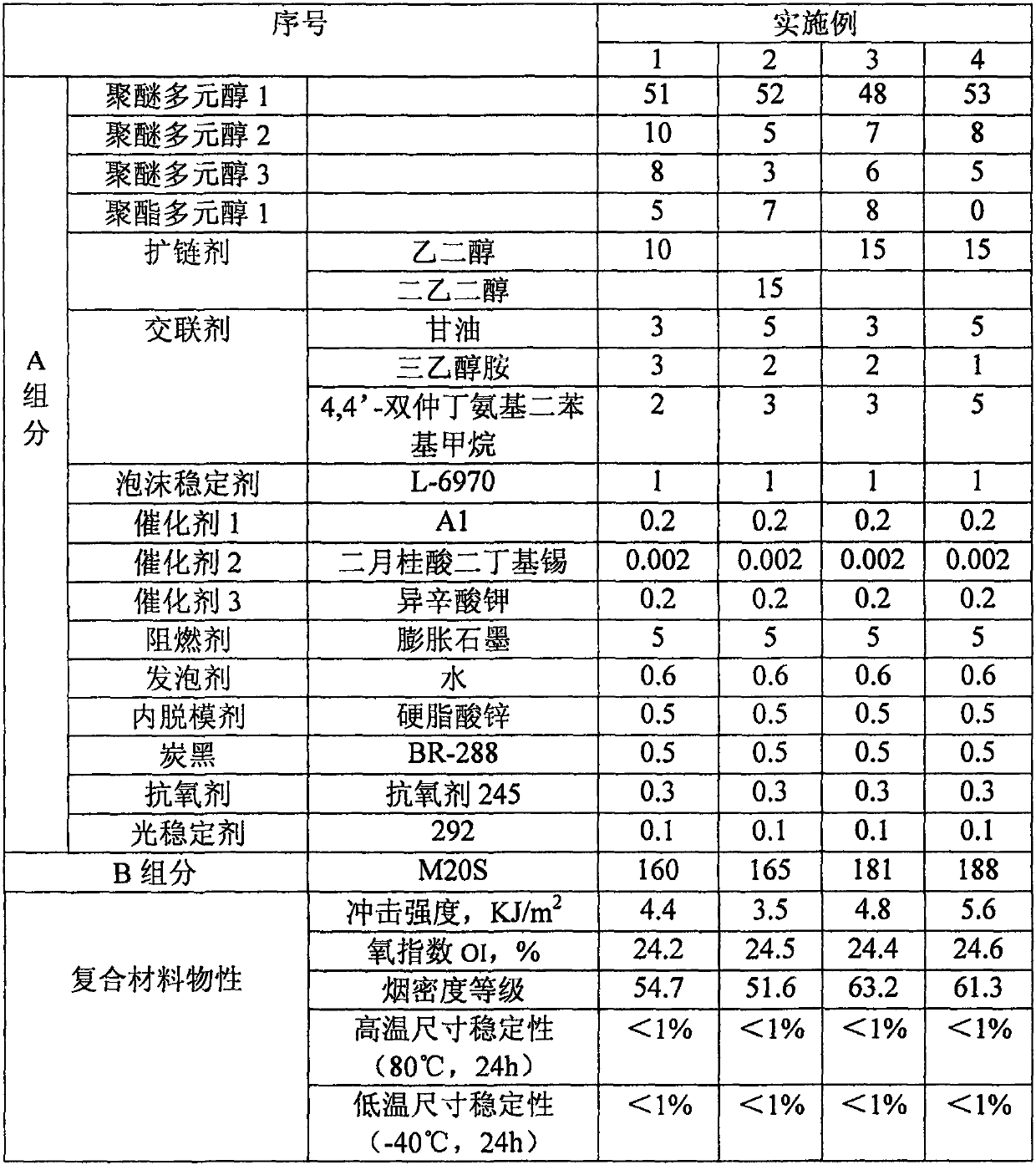

[0039]Preparation of composite materials: prepare a core layer and at least one fiber-reinforced layer, apply the fiber-reinforced layer to one or both sides of the core layer, fix the fiber and the core layer with a manipulator, and keep a polyurethane A and B components separately At 25°C, apply the reaction mixture evenly to the fiber reinforced layer, put it into a mold at 130°C, close the mold, open the mold after 10 seconds to deflate, close the mold again, open the mold after 10 seconds to deflate, and close the mold again, The finished product can be obtained after mold opening in 60s. The weight parts of raw materials and the material properties of glass fiber reinforced honeycomb sandwich panels are shown in Table 1.

[0040] Table 1 Example 1-4 raw material weight parts and glass fiber reinforced honeycomb sandwich panel material properties

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com