Modified alumina carrier, its preparation method, silver catalyst prepared from it, and its application in production of ethylene oxide

An alumina carrier, ethylene oxide technology, applied in physical/chemical process catalysts, catalyst carriers, bulk chemical production, etc., can solve the problems of carrier performance and limited improvement of catalyst activity and selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

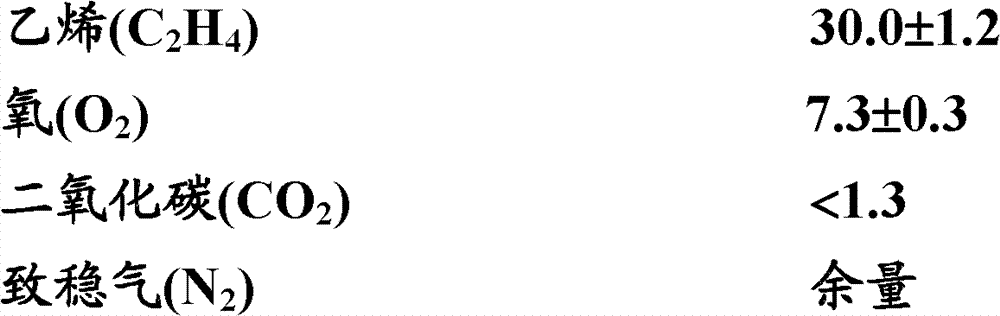

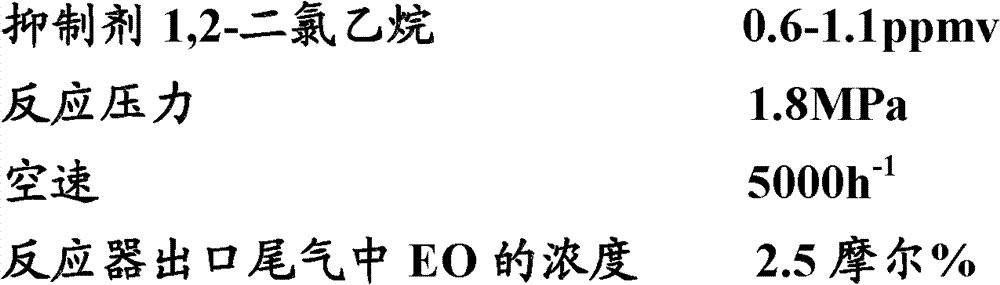

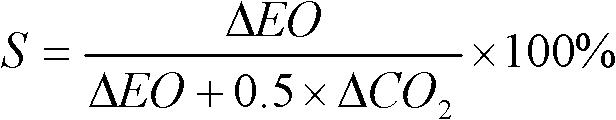

Image

Examples

preparation example Construction

[0027] In the preparation method of the α-alumina carrier of the present invention, in step (i), the semi-finished α-alumina carrier is impregnated with a solution of a soluble salt of metal lanthanum in water or an organic solvent. For this impregnation, the concentration of the impregnation solution is advantageously 0.05-2 wt%, and the amount of the impregnation solution is preferably 1-3 times the mass of the semi-finished α-alumina support. The impregnation time is generally advantageously from 5 to 60 minutes.

[0028] To prepare the inventive porous alumina support, a soluble salt of the metal lanthanum is used in step (i). The soluble salts refer to all lanthanum salts that are soluble in water or organic solvents. Preferably, the lanthanum salt is selected from acetates and / or nitrates of metallic lanthanum, particularly preferably lanthanum nitrate. Examples of the organic solvent include organic compounds such as methanol and ethanol, or mixtures thereof with wate...

Embodiment

[0084] The present invention adopts following examples to illustrate further, but the scope of the present invention is not limited to the situation of following examples.

[0085] Preparation of vector

[0086] Comparing carrier A

[0087] Put 372.0g of industrial α-alumina trihydrate, 110.0g of pseudo-alumina monohydrate, 8.0g of ammonium fluoride, 1.0g of barium sulfate and 10.0g of petrolatum in a mixer and mix evenly, then add 17% by weight of dilute nitric acid aqueous solution 132.0g, fully kneaded into a paste that can be extruded, and then extruded into a briquette-shaped seven-hole cylinder with an outer diameter of 8.3mm and a height of 8.0mm (the cylinder has seven parallel channels along the axial direction, and the diameter of the central hole is 1.7mm, there are six small holes with a diameter of 1.5mm evenly distributed around the central hole). The formed carrier blank was dried at 80-100°C for 10 hours, then heated to 1300-1350°C within 40 hours in a hi...

Embodiment 1-4

[0107]Using the same impregnating solution in Comparative Example 1 above, take 10g each of the carriers B, C, D and E of the example, place them in vacuumable containers respectively, evacuate until the degree of vacuum is higher than 700mmHg, and put them into the above silver-containing Immerse the carrier with the impregnating solution, keep it for 30 minutes, remove the excess solution by leaching, then heat it in the air stream of 280°C for 5 minutes, and cool it down to prepare the inventive silver catalysts 1-4. The respective silver contents of these four catalysts were measured respectively 17.4%, 17.5%, 17.2% and 17.5% by weight, based on the total weight of the catalyst.

[0108] Under the standard conditions given above in the "Measurement of Catalyst Performance" section, the comparative silver catalysts 1-2 and the inventive silver catalysts 1-4 were compared and evaluated at the same time, and the results obtained are shown in Table 1 below.

[0109] Table 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com