Optical cable

An optical cable and cable core technology, applied in the field of optical fiber and cable communication and manufacturing, can solve problems such as affecting optical characteristics and transmission effects of optical fibers, unsatisfactory, damaged optical fibers, etc., to achieve the effect of small appearance and performance, easy repair, and protection of the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

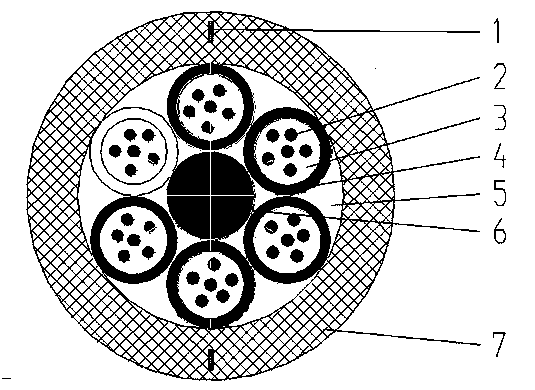

[0022] A preferred structure of the present invention is as figure 1 and figure 2 As shown, the optical cable includes a cable core and an outer sheath 7 arranged outside the cable core, the cable core includes an optical fiber 2, a loose tube 4 and a central strength member 6, the optical fiber 2 is arranged in the loose tube 4, and the loose tube 4 surrounds the The central reinforcements 6 are arranged, and two adjacent loose tubes 4 are hinged, and the outer sheath 7 is embedded with two axially extending strip-shaped separation strips. The two separation strips 1 are evenly distributed along the circumference of the outer sheath 7 .

[0023] A metal armor layer may be provided between the cable core and the outer sheath.

[0024] The thickness of the outer sheath 7 is 1.8 mm, the outer diameter of the outer sheath 7 is 13 mm, and the inner diameter is 9.4 mm.

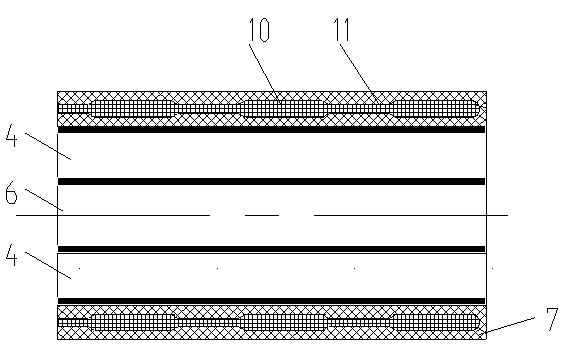

[0025] The separation zone 1 is formed by connecting a wide unit 10 and a narrow unit 11 with a rectangular ...

Embodiment 2

[0035] In Example 2, the number of separation strips is three, which are evenly distributed in the outer sheath in the circumferential direction. The thickness of the outer sheath 7 is 1.8mm, the length of the wide unit cross-section is 1 / 2 of the thickness of the outer sheath, and the length of the narrow unit cross-section is 1 / 4 of the thickness of the outer sheath; The axial lengths of the sleeves are 1 cm and 0.8 cm respectively; the widths of the cross-sections of the wide unit and the narrow unit are both 0.1 mm. Other structures are with embodiment 1.

Embodiment 3

[0037]In Example 3, the number of separation strips is 4, which are evenly distributed in the outer sheath in the circumferential direction. The thickness of the outer sheath 7 is 1.8mm, the length of the wide unit cross-section is 2 / 3 of the thickness of the outer sheath, and the length of the narrow unit cross-section is 1 / 3 of the thickness of the outer sheath; The lengths of the units along the axial direction of the outer sheath are 1 cm and 1.5 cm respectively; the widths of the cross-sections of the wide unit and the narrow unit are both 0.15 mm. Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com