LFP lithium ion cell capacity grading and screening method

A screening method and lithium-ion technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problem of low cell consistency, improve cycle performance and safety performance, and ensure consistency and consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

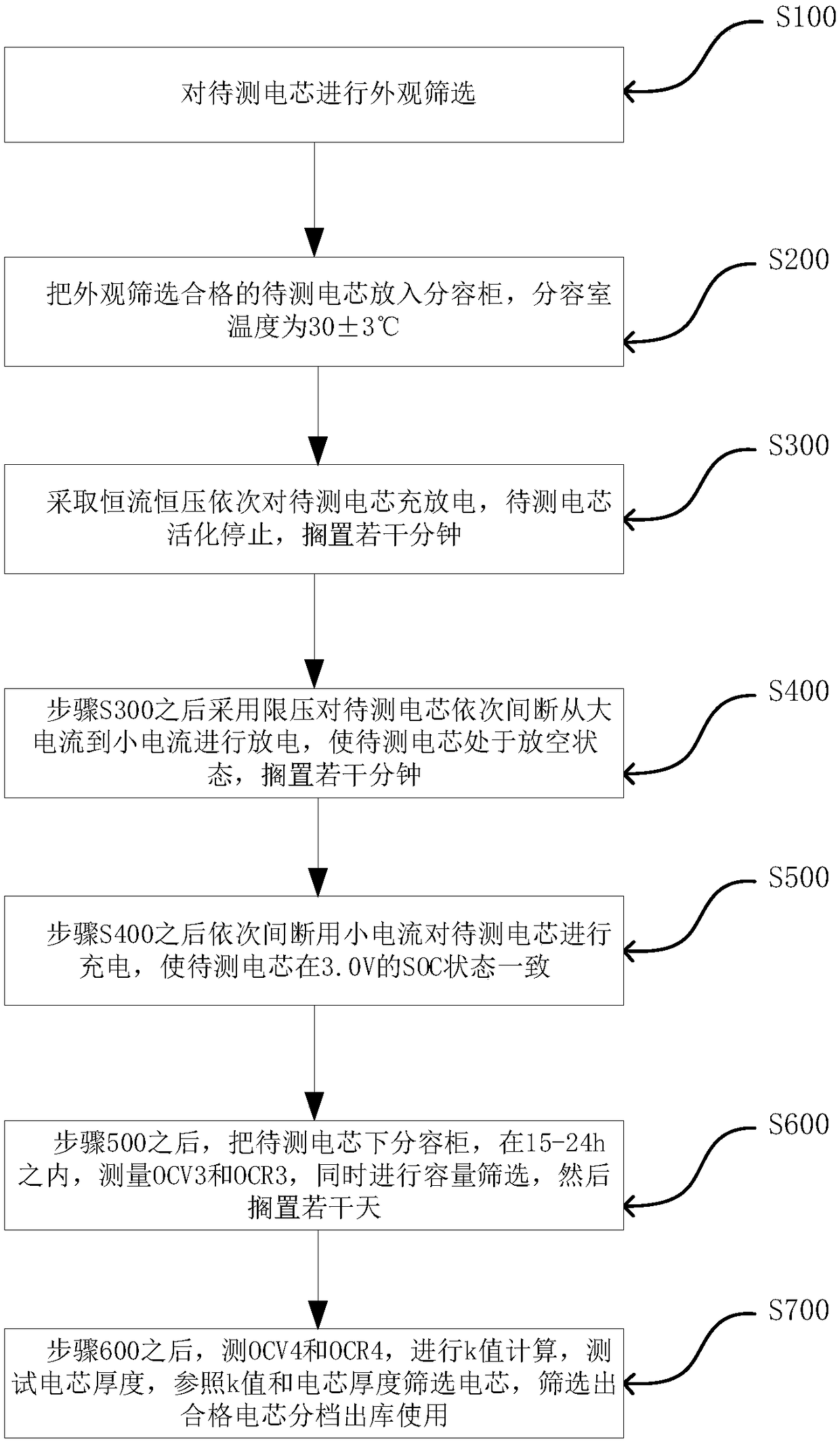

[0050] A sorting and screening method for 30Ah cells with a square aluminum shell, including the steps of sorting and binning:

[0051] The specific steps are as follows:

[0052] (1) Clean the battery cells on the production line, and conduct visual inspection and screening;

[0053] (2) Put the batteries that pass the appearance screening into the capacity separation tray, scan the tray code and the battery barcode, and put it into the capacity separation cabinet. The temperature of the capacity separation room is controlled at 30±3°C;

[0054] (3) Set aside for 5 minutes;

[0055] (4) Charge with constant current and constant voltage at a certain current, the current is 9000mA, the voltage limit is 3.65V, the current limit is 500 mA, and the time limit is 180min;

[0056] (5) Set aside for 5 minutes;

[0057] (6) Discharge with a certain current, the current is 18500mA, the cut-off voltage is 2.0V, and the time limit is 120min;

[0058] (7) Set aside for 5 minutes;

[...

example 2

[0078] A method for sorting and screening 27Ah batteries with square aluminum shells, including the steps of sorting and binning:

[0079] The specific steps are as follows:

[0080] (1) Clean the battery cells on the production line, and conduct visual inspection and screening;

[0081] (2) Put the batteries that pass the appearance screening into the capacity separation tray, scan the tray code and the battery barcode, and put it into the capacity separation cabinet. The temperature of the capacity separation room is controlled at 30±3°C;

[0082] (3) Set aside for 5 minutes;

[0083] (4) Charge with constant current and constant voltage at a certain current, the current is 6000mA, the voltage limit is 3.65V, the current limit is 500 mA, and the time limit is 180min;

[0084] (5) Set aside for 5 minutes;

[0085] (6) Discharge with a certain current, the current is 18500mA, the cut-off voltage is 2.0V, and the time limit is 70min;

[0086] (7) Set aside for 5 minutes;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com