Ultrasonic peeling device for preparing graphene

An ultrasonic peeling and graphene technology, applied in the field of graphene, can solve the problems of uneven cavitation effect, limited tank size, limited tank power density, etc., achieves good ultrasonic radiation effect and stability, improves power density, The effect of improving the peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

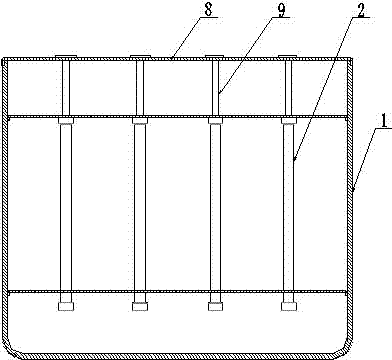

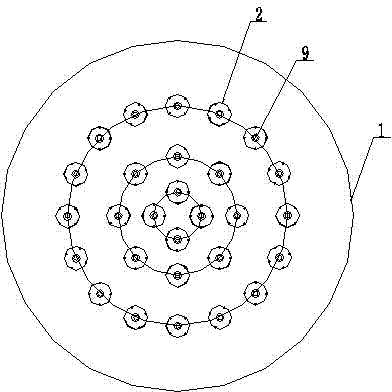

[0038] An ultrasonic stripping device for preparing graphene, comprising a tank body 1 and a plurality of ultrasonic vibrating rods 2, the plurality of ultrasonic vibrating rods 2 are vertically fixed in the tank body 1, and the plurality of ultrasonic vibrating rods 2 are placed on the same The distribution in the orthographic projection plane is circular.

[0039] In this embodiment, the multiple ultrasonic vibrating rods 2 in the tank body 1 are distributed in multiple rings in the same orthographic projection plane, and the ultrasonic vibrating rods 2 on each ring are evenly distributed. Further, all the ultrasonic vibrating rods 2 have the same height in the tank body 1, such a structure is equivalent to all the ultrasonic vibrating rods 2 being multi-ringed and uniformly arranged in the tank body 1 with a large inner diameter and a low height, that is, to increase The large tank body 1 occupies an area to achieve the purpose of large-scale stripping of materials.

[004...

Embodiment 2

[0045] An ultrasonic stripping device for preparing graphene, comprising a tank body 1 and a plurality of ultrasonic vibrating rods 2, the tank body 1 is cylindrical, and its upper part is provided with a feed port 4 and an overflow port 5, and the middle part is provided with Manhole 6, the bottom is set as a slanted bottom 7, and the lower end of the slanted bottom 7 is provided with a discharge port 10; the multiple ultrasonic vibrating rods 2 are vertically fixed in the tank body 1, and the multiple ultrasonic vibrating rods 2 are distributed in multiple rings in the same orthographic projection plane.

[0046] In this embodiment, the distance between two adjacent ultrasonic vibrating rods 2 on the same ring is 40 cm, so that the ultrasonic vibrating rods 2 maintain a better radiation effect.

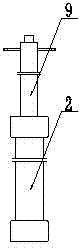

[0047] In this embodiment, a plurality of ultrasonic vibrating rods 2 are vertically arranged in layers in the tank body 1, and the number of ultrasonic vibrating rods 2 in each lay...

Embodiment 3

[0055] An ultrasonic stripping device for preparing graphene, comprising a tank body 1 and a plurality of ultrasonic vibrating rods 2, the plurality of ultrasonic vibrating rods 2 are vertically fixed in the tank body 1, and the plurality of ultrasonic vibrating rods 2 are There are multiple rings in the same orthographic projection plane.

[0056] In this embodiment, the distance between two adjacent ultrasonic vibrating rods 2 on the same ring is 35 cm, so that the ultrasonic vibrating rods 2 maintain a better radiation effect.

[0057] In this embodiment, the side wall and the bottom of the tank body 1 are provided with compressed air nozzles 3, and the nozzles 3 are evenly arranged in the tank body 1. When the material is stripped, the nozzles 3 spray compressed air to make the material tumble in the tank body 1. In order to improve the stripping efficiency.

[0058] Further, an air pipe connected with compressed air is welded and fixed on the inner wall of the tank body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com